Understanding how a vacuum cleaner works, its structure and the main differences between different designs of similar equipment makes the choice easier for a potential buyer. After all, its quality characteristics, consumer properties and maintenance rules depend on the operating principle and design features of the device.

All these points have been studied by us and described in detail in the article. The information presented will help you understand the specifics of the functioning of various types of vacuum cleaners, as well as choose the most suitable option among the variety of designs.

Device and design features

The design of the unit has not changed much over the past hundred years, nor has its performance. Having gone from an electric broom, a manually driven machine, to a gas-powered pneumatic carpet “renewer”, the vacuum cleaner technically settled on the James Spangler model.

An Ohio janitor has created a revolution by creating an upright and portable machine out of a broom, a pillowcase and an electric motor. Spangler's invention was sold under the Hoover brand. The modern device inherits the same design of the electrical part, brush and dust collector.

Hoover vacuum cleaners are the first to use aluminum in their housings. This happened around 1923

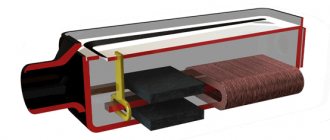

The main components of a conventional vacuum cleaner:

- Centrifugal compressor - creates a vacuum and pumps air.

- The commutator motor drives the compressor.

- Air purifier - separates dust from the air and collects it in special containers.

- A set of attachments and brushes for various purposes.

The device body itself is made of durable plastic. An engine, compressor, dust collector, filters, and control unit are built inside it.

The standard household design of a vacuum cleaner is equipped with a flexible air hose and extension tube. The exceptions are small-sized manual models and devices where the compressor is built into a tube with a nozzle or brush.

Any vacuum cleaner also has a three-level filtration system through which the sucked air is passed. It consists of a main, motor part and a fine filter (sometimes a container of water serves as a filter)

In order to expand the scope of application, manufacturers equip the devices with different attachments.

The universal one is always present in this set. It is designed for cleaning flat horizontal surfaces and carpets. The design includes switches, rollers for maneuverability, and brushes with different bristles.

The crevice nozzle is convenient for cleaning hard-to-reach places (corners, gaps, spaces between the wall and furniture). There are also collapsible 2-in-1 designs - universal plus a removable surface with pile

A separate variety is represented by turbo brushes, the structure of which allows you to collect wool and hair from carpets. Relatively recently, electric brushes, cylindrical rollers, nozzles for parquet, metal debris, cleaning siphons and others have appeared.

How do different types of devices work?

All vacuum cleaners perform one function - cleaning. Why do devices, invented and manufactured with a single purpose, differ so much from each other in shape, size, and principle of operation?

When you first get acquainted with the device, the location of the dust collector, the number of wheels, or the material from which the hoses are made do not seem important. Understanding the significance of each detail comes during operation.

Let us analyze the design features and operating principle of the devices depending on the types of dust collector and the functionality of the devices.

Vacuum cleaner with bag or container

Schematically, the operating principle of this device can be represented as follows. Through the nozzle and hose, dust-filled air enters the device, namely into the dust collector - a bag or cyclone filter.

In a vacuum cleaner with a container, the garbage first falls not into a bag, but into a special centrifuge container, where large fractions are retained

Then one part of the dirt remains in the container, the other moves through the pores and vortex flows of the storage tank towards the motor. To protect it, a coarse filter was invented.

But it is not ideal either - the dirt travels to the outlet and approaches the fine filter (HEPA).

Compact vertical units

The peculiarity of this design is the absence of a hose. It is sometimes included in the kit and can be used to perform individual manipulations. The role of the main dust absorber goes to the brush - turbo or “beater”.

Modern vertical devices can interface with smartphones, thanks to which the owner can programmatically adjust the suction power, see how many kilometers the home assistant has traveled and other information

The motor and dust collector in the device are located in a pipe - the body of the unit. The motor does not so much create suction force as it rotates the brush shaft. In this case, the garbage seems to be “swept” into the dust collector.

Vertical models also have a suction module. But it is used when the device is used as a horizontal one.

Water filtered design

Vacuum cleaners with an aqua filter provide a different method of cleaning the incoming air, hence the structural features. The device is externally similar to a conventional container-type vacuum cleaner - it includes a nozzle and a hose, from which debris falls into the dust collector-aquafilter.

But the latter is made in the shape of a flask with water. The engineers' idea is for debris and dirt to sink under the influence of vortex flows.

What creates these flows? A turbine or separator rotating inside the flask. This visible part of the engine swirls dust and creates high pressure. The latter “captures” particles regardless of size, immerses them in water and does not give them a chance to get out.

In such devices, the shape of the turbine and its rotation speed are important. Manufacturers still have to add filters to designs that are not technically well thought out. The statement applies to budget separator models.

In a device with a Krausen aquafilter, dust moves through the pipe (1) into the aquafilter (2), then the separator (3) creates water-vortex flows (4) and reaches the ideal air purification coefficient (5)

These vacuum cleaners cannot be called completely filterless either, because they contain a protective filter for the motor. Only German engineers managed to get rid of it, who “sewed up” the motor into a stainless steel capsule. In this case, the motor is securely protected from dust and wet dirt.

Complex built-in modifications

These devices are not portable and are mostly mounted inside the walls. Their nozzles and hoses are not connected to the body of the vacuum cleaner, but are inserted into pneumatic sockets located throughout the intended operation area of the device.

Built-in vacuum cleaners are not very common in everyday life due to the need to use long hoses, which makes it difficult to perform comprehensive cleaning of premises.

A complex chain of air ducts is installed in the walls, through which the collected waste is directed to a common dust collector. The latter is located in utility rooms or in the basement, if available.

The unit itself includes both the engine and filters. The power plant is also often located in utility rooms.

Problem areas of the structure

Most often, malfunctions can occur in:

- bearings:

- brush commutator unit;

- layer of insulation of windings and wires.

Bearings

Their location is carried out at the edges of the rotor in such a way as to transmit the axial torque load as much as possible.

In ordinary household tools, they can be damaged for two main reasons:

- from incorrect load application:

- as a result of pollution.

Directions of effort

Bearings in household power tools are generally not designed to support lateral loads. From their frequent use, for example, when, when working with a drill, they do not load the end of the drill, but cut slot holes on its side, shaft beating is transmitted to the bearing mechanism, creating additional play of the balls in the cages.

Working in a polluted environment

The commutator motor has an air cooling system. The impeller, mounted on the rotor, takes air through special slots in the motor casing and drives it throughout the entire housing to remove excess heat from the heating windings. Warm currents are ejected through special holes.

If a dusty environment is created in the room, it will be sucked into the housing and penetrate the bearings and commutator-brush mechanism. There will be an abrasive effect on the parts that come into contact during rotation, their premature wear, as well as a violation of the electrical conductivity at the brush contacts.

Using a commutator motor for purposes other than its intended purpose, for example, collecting a flow of construction dust with a household vacuum cleaner instead of a construction one, is the most common cause of its breakdown.

Why do brushes spark?

Design features

When the engine is running, there is constant friction of the brushes against the contact plates of the commutator, which requires periodic inspection.

A slight layer of coal dust appears on the working surfaces of copper pads, as shown in the photograph. This is due to material consumption and brush wear.

This process always occurs when a commutator engine is running. Even with normal sliding of the brush, a slight break in the electrical current circuit is created. And this is always associated with sparking due to the occurrence of transient processes and the appearance of microscopic arcs. In addition, the windings have high inductive reactance.

Therefore, a fully operational brush mechanism sparks during normal operation, which is not noticeable to the naked eye, but is felt by sensitive electronic devices: televisions, computers and other equipment. Noise suppression filters are always installed in their power supply circuit. An example is the electrical diagram of a microwave oven shown on the website with a highlighted green fragment.

Wear of brush material

The current-carrying part pressed against the collector plate is made of coal. Its volume wears out and its length decreases. This weakens the pressure force created by the expanding spring.

This process may or may not be taken into account in different brushed motor designs.

Rare samples

On the old 1960 engine shown as an example, the spring is compressed by screwing the dielectric cap.

The brush installation process is shown below.

Vacuum cleaner motor

The design of the brush mechanism described in the article about making a homemade trimmer has a screw for fixing the brush body.

Its installation is shown in the next photo. Please note that the brush itself was repeatedly ground down during long-term work and was replaced with a battery machined from a carbon electrode in the shape of the previous one.

When making brushes yourself, pay attention to the tightness of its entry into the socket and its perpendicular position to the shaft axis. If it is smaller, distortion will occur during operation. It will lead to excessive sparking and reduced engine life.

Therefore, it is advisable to use factory brushes from the manufacturer. There are other technical solutions to this issue.

How to check brush wear

The main method involves visual inspection. On the Internet you can find advice that recommends pressing the brush with a screwdriver while the engine is running and assessing the change in rotor speed.

This is a dangerous operation and should only be performed by trained and experienced personnel because:

- it is necessary to use protective equipment: work is performed under voltage;

- there is a possibility of creating a short circuit, because you will have to check both brushes in turn or simultaneously and use screwdrivers with insulated rods and tips.

If an external inspection shows that the length of the brush is greatly reduced or the working surface is chipped, then it simply needs to be replaced.

Contaminated collector

The formation of an excessive layer of coal dust with good conductive properties on the plates can cause them to short-circuit. It is necessary to remove it not only from the outer surface, but also from the spaces between them.

Graphite dust can be wiped off with a soft rag slightly moistened with alcohol or gasoline or removed with a thin wooden stick.

When the collector plates have lost their original shape and become grooved, they are restored using sandpaper with the finest grain on lathes. This is a complex operation that requires special equipment, but it can extend the life of the commutator motor.

Interturn short circuits in windings

Their formation on the stator or rotor sharply reduces the inductive reactance and leads to the appearance of additional sparks between different sections of the commutator and brushes. Additional overheating occurs.

Rotor winding

In some cases, the damaged section can be observed visually by a change in color. To perform electrical measurements, you will need an accurate ohmmeter. The testing technology is demonstrated in a video by the owner of altevaa TV “Checking the armature of a commutator motor.”

Repairing a damaged rotor winding is a complex operation. Sometimes it's easier to buy a new one.

Stator winding

The malfunction can be detected by measuring the active component of the electrical resistance using a bridge circuit for each half-winding. But this is also quite difficult.

Breakdown of the dielectric insulation layer

Let us briefly touch on the reasons for the formation of defects and the protective devices that must be used.

How malfunctions occur

The copper wires of the cores of all windings are covered with a layer of varnish, which can be damaged by:

- carelessly applied mechanical loads;

- at elevated temperatures.

These same factors cause insulation defects in PVC-coated supply wires.

As a result of these influences, the following electrical circuit malfunctions appear:

- interturn short circuit, which creates an additional path for leakage current to flow, which significantly reduces engine performance;

- short circuit that can burn out wires.

Protective devices

Thermal relay

The overheat protection function built into many commutator motors works automatically. When equipment is switched off from frequent operation, it is necessary to look for the cause of the temperature increase. Unfortunately, some users try to block the thermal relay. This leads to a breakdown that is difficult to repair.

Circuit breaker

Elimination of short circuits and overloads within the electrical circuit of the motor is assigned to the household circuit breaker that supplies the power outlet. It is installed in the housing panel and, according to its technical characteristics, must correspond to the operating and emergency modes of the commutator motor.

Without the protection of an established circuit breaker, using a tool with a commutator motor is life-threatening.

RCD

The residual current device is designed to protect operating personnel from the effects of leakage currents penetrating exposed metal or accidentally contacting conductive parts of the housing.

The RCD prevents the phase potential from flowing through the human body to the ground. It is also installed in the apartment panel.

To consolidate the material, we recommend watching the video by the owner of slavnatik “Why does an angle grinder sparkle.”

We remind you that now it is convenient for you to ask questions in the comments and share the article with friends on social networks.

Features of washing machine models

The main design difference between washing machines and models with a bag and container is the presence of a reservoir for clean and dirty water. Small and large fractions of dirt sink in such a container.

The main advantage of such a tank is that the owner does not have to breathe dust while emptying the tank.

The design of the washing vacuum cleaner has an additional reservoir for water and detergent, a pump, liquid supply channels integrated into hoses and tubes

But the design of washing vacuum cleaners also includes protection of the motor from moisture, which significantly increases the cost of the vacuum cleaner. And wet dirt accumulates on the HEPA filter, which creates a breeding ground for many bacteria.

There are washing vacuum cleaners with a steam generator. This device allows you to clean surfaces with steam without the use of chemicals.

Vacuum cleaners by dust collector type

Regardless of the layout, all vacuum cleaners are equipped with special compartments for storing debris and dust - a dust collector. So, all collected garbage is collected in:

- a special bag;

- separate container;

- water filter.

Special bags for collecting and storing dust were used in the very first designs of vacuum cleaners. Modern devices can be equipped with bags made of fabric, synthetic materials, paper or cellulose. Synthetic and natural fabric bags are suitable for reusable use; for disposable use, cellulose and woven bags are chosen.

Dust bag placement

Debris and dust particles settle in the bag when they pass through its internal cavity under the influence of air flow. Those small particles that can pass through the small pores of the bag settle thanks to special filtration parts that are installed in the air path. There are also special filters: which clean the air flow entering the vacuum cleaner from bacteria, dust mites and microorganisms.

Special containers for collecting dust and debris consist of transparent plastic and are used throughout the period of use and operation of the vacuum cleaner, unless there is any significant damage. That is, this type of dust collector is quite wear-resistant, and component failures are extremely rare.

Using clear plastic dust containers helps you monitor how clogged the dust container is and clean it out promptly.

Dust gets into the container thanks to a special vortex, or in other words, a cyclone dust collector, the movement of a stream of air, which is sucked up by a vacuum cleaner. If the suction speed is high, then dust and dirt particles in the air flow settle on the inner walls of the dust container due to the kinetic energy of the air flow. Currently, many devices use the principle of 2-3 vortex cleaning cycles for the most effective cleaning and dust removal. However, the use of such cyclones does not guarantee perfect cleaning, so it is still necessary to use a system of additional filtration of outgoing air jets.

Water filter for better cleaning

Effective and high-quality air purification from microscopic, subtle particles of dust, debris and various microbes is carried out by a water type filter. This aquafilter works on the principle of removing dirt and dust using water. This design of a vacuum cleaner equipped with a water filter is similar to a vacuum cleaner with a cyclone cleaning type, but the difference is that dust is collected in a water vortex flow rather than an air one.

High-quality purification through a water filter

High-tech robotic vacuum cleaners

Robot vacuum cleaners only appeared about 10 years ago. Their designs are constantly updated and improved. The devices are created according to a block design. This ensures ease of maintenance and ease of replacement of parts during repairs.

Common elements of a robot vacuum cleaner that are found in all models:

- side brush;

- block module;

- charging base;

- sensors for detecting obstacles, pollution, height differences.

The operation of such a device is based on a cleaning unit, navigation, drive mechanisms and a battery device.

Gadget navigation systems

The state-of-the-art navigation system consists of a laser, camera, internal and external sensors. The camera reads a map of the room. Rangefinder lasers transmit information to her about the presence of objects in the room and the distances between them.

The device moves in straight lines both during cleaning and during the process of returning to the base.

Robot vacuum cleaners do not yet know how to go down stairs or overcome high thresholds. Developers are trying to eliminate this defect in gadgets by inventing new models.

There are still models on sale whose operating principle is based only on sensors. They are located on the outer body of the device and inside it.

With their help, the robot navigates in space and adjusts its work, and also notices the most contaminated areas and is more careful in cleaning them.

Magnetic tape can also be used to navigate the robot. It creates a virtual barrier beyond which the device does not move. If the cleaner is equipped with a camera, it takes readings from the ceiling and walls.

Cleaning process

Here, the models differ in types of cleaning - dry cleaning and washing robotic vacuum cleaners. In the first, the side brush picks up all the dirt and directs it to the central brush. The central one has a fleecy surface and is capable of collecting hair and wool.

The design of the front brush of the robot is installed with an inclination into the device, and the side one has flexible wires, which ensures thorough collection of debris

Then these two parts send the garbage to the dust collector, where it is compressed by air currents. And the air passes through the filters to the outside.

Depending on the manufacturer, robot designs differ in the following nuances:

- Basic brushes . Most models have two of them - fleece and rubber. They work in pairs. Some devices are equipped only with rubber.

- Side brushes . There are devices that have an additional side brush built into them.

- Filters . The robots are equipped with both standard “napkins” and multilayer HEPA.

- Container + engine power . The waste collection container can have a volume from 0.4 to 1 liter. The power of such devices is 40-65 watts. If the first numbers are important during operation, then the second ones are unimportant due to the small range.

The main consumer part of robotic vacuum cleaners is the main brush. The quality of cleaning depends on it, and not on the engine, as with conventional units.

A wet vacuum cleaner has in its design a system of a water tank and a sprinkler. It can collect debris, spray liquid, polish the floor and collect dirty water back into the reservoir.

There are robot models designed for mixed cleaning. The principle of their operation is to clean smooth surfaces with a rag, and carpet surfaces with basic brushes.

Return to base

The final stage of the robot’s work is its return to the mother base. The device is powered by batteries. If they are discharged, the device turns off.

There are robots with a program that leaves the device at the cleaning site, and the user forces the return to the base

The device automatically reacts to a low charge percentage. Using a special sensor, it detects an infrared beam from the base and begins to move towards it. As soon as it finds it, it docks with it and charges.

Types of vacuum cleaners

Today, users are offered different types of such equipment, classified depending on the type of cleaning for which it is intended and design.

Users need to remember that its suitability for cleaning a particular room and its ability to clean various surfaces depends on what class the vacuum cleaner belongs to. To choose the right model, you need to understand the classification of such devices.

Detergents and dry cleaning

For wet cleaning, it is best to use a washing vacuum cleaner: you can use it to wash floors or remove accidentally spilled liquid. This technique is equipped with two reservoirs of liquid. Liquid from one reservoir enters the capillaries and is then sprayed over the surface.

After this, the contaminated water flows through the dirt removal channels into another tank designed for it.

Such models will come to the rescue when you need to thoroughly tidy up a large room. Such a device is not suitable if you need to do daily cleaning, as it is larger in size.

Important! The equipment designed for dry cleaning has a simple operating principle. Since the fans actively rotate, air is sucked in along with dust. Next, the air currents are filtered and end up back in the atmosphere.

Horizontal and vertical

Among the main advantages of vertical models, it is worth highlighting the absence of the need for their constant assembly. After finishing cleaning, you can place this structure in a closet or behind the door - it needs no more space than a regular mop.

Due to the design, such models can be used even if it is necessary to clean in inaccessible places. In this case, there is no need to move the device body. This vacuum cleaner is as effective for cleaning as its conventional counterparts.

Another advantage is its maneuverability, so you can clean the room much faster than using an ordinary vacuum cleaner.

Some types of such vacuum cleaners are suitable if you need to do wet cleaning. Air purification in such devices is carried out by anti-allergenic filters that make up the design of the device.

Horizontal devices are a body with wheels. They are equipped with dust storage compartments and a motor unit. Dust suction is carried out through pipes. They also have various attachments that allow you to penetrate even hard-to-reach corners of the house. Such models operate using electricity.

Attention! The main advantages of horizontal models are low cost and the availability of a variety of attachments. Among the disadvantages of such designs, it is worth highlighting the operation from the network and the fact that they take up a lot of space when stored.

Constructive details and quality of cleaning

Some design features of the device affect the quality of cleaning and ease of use. For example, a hose. It must be of sufficient diameter (at least 5 cm) so that it does not become clogged frequently.

The length of the flexible hose is important - the longer this accessory, the more convenient it is to clean. Especially in rooms of 15 square meters. and more. A length of 2.5 m is needed for cleaning high furniture and ceilings

The strength of the material is also important, otherwise the part will crack, which will reduce the suction power.

In addition to the main components, the quality of operation of the device is also influenced by seals, bushings, and bearings. If the joints are made of fluoropolymers, this ensures their tightness.

Bushings and bearings made of fluoroplastic and polyamide extend the life of the moving parts of the device.

Additional information about different types of vacuum cleaners, as well as tips on choosing the right unit, is provided in this article.

Conclusions and useful video on the topic

Analysis of the design and operating principle of a vacuum cleaner with pressure sensors and two electric motors - in the brush and the body of the device.

The examples of several designs of vacuum cleaners clearly show that, regardless of the type, they all serve equally as “dust cleaners.” Their effectiveness depends on the filtration system, engine power, and the presence of various nozzles.

Which vacuum cleaner did you choose for your home or apartment? Please tell us why you chose a particular model, and whether you are satisfied with the performance of the purchased equipment. Add reviews, comments and ask questions - the contact form is below.