The role of the fan in the No Frost refrigerator

In the cooling chamber located behind the inner wall of the refrigerator or freezer, the process of removing heat and moisture from the cooling zones occurs. An evaporator, with a defrosting element and a fan are placed in a compact space. At the moment of rotation, the fan blades create a vacuum and draw in gas.

Warm air from the refrigerator enters the chamber, is directed by a fan through the gaps between the evaporator tubes under pressure, cools, and leaves moisture on the radiator tubes. The gas is blown back through the chamber slits. Circulation occurs.

Manufacturers choose different flow directions. Cold air can be supplied from the ceiling, from the sides, to each shelf. A special case is two independent convection cooling circuits with 2 fans, thermostats for the refrigerator and freezer compartments.

While the evaporator is cooled by freon supplied by the compressor, the wind blower rotates, and the products are cooled. The propeller stops, the automation turns on the heating element, the ice thaws and goes through the drainage hole into a special tray. If the fan stops abnormally, the evaporator will be cold, but the chambers will become warm, and the compressor will work in vain.

Fans in the refrigerator are used not only with No Frost. A refrigerator with regular freezing and manual ice removal, which has an accelerated cooling function, also has a fan. It works for a short time, pumping cold to quickly cool a new portion of food. There are fans for cooling the refrigerator, cooling compressors and condensers in large cabinets. They have one purpose - to reduce the temperature in the unit.

Operating principles of “No Frost”

Ice interferes with the normal operation of the refrigerator, as a slow and gradual increase in temperature begins. This leads to the appearance of bacteria and an unpleasant odor. If previously you had to constantly defrost the refrigerator for this reason, modern technology allows you to avoid this.

The temperature in the freezer decreases due to the circulation of freon. Droplets of moisture settle on the walls, and frost appears. The compressor turns off for a while, the ice thaws, and the liquid flows into the reservoir. After turning on the compressor, the housing heats up and the moisture evaporates.

Most refrigerators are equipped with several fans that remove remaining moisture and create continuous air circulation. This ensures the maintenance of the same temperature throughout the chamber and allows you to preserve the freshness of the products as much as possible.

Two types of refrigerators are available: with a drip and wind system. In the first, the compressor is turned off for a while, the thawed water passes into a special container in the lower part of the housing and gradually evaporates. In the windy one, behind the casing there is a coolant that looks like a car radiator. A fan built into the back wall creates continuous air circulation throughout the chamber. This design prevents contact of the contents with the evaporator.

Asian manufacturers usually equip their equipment with a dry ice system. In Europe, windy defrosting is done exclusively in the freezer, and a kind of air shower is created along the walls. This is an auxiliary air flow, the temperature of which is regulated by closing the air channels.

By moving the heater and fan down towards the freezer, the developers have perfected No Frost.

Advantages of the No Frost system:

- There is no need for constant defrosting, and the process itself requires much less time.

- The temperature regime on all shelves is the same and even with regular opening of the door it quickly returns to normal.

- The resulting condensation and ice are quickly removed.

- Products cool faster due to constant air movement.

- Fast freezing even when the freezer is fully loaded.

- Blast freezing allows you to preserve the maximum benefits of products.

- Home repairs are possible.

Flaws:

- Due to the fan and evaporator, the internal volume is reduced.

- Increased electricity consumption.

- The noise level is higher due to non-stop ventilation.

- Constant ventilation causes food to become aerated.

- The price is significantly higher.

How to check a refrigerator fan

The fan is a unit consisting of a motor and a propeller with a common shaft. The device is included in the general electrical circuit through a fuse, has electronic control, and operates on a defrost timer command.

Like any mechanism, a wind blower creates noise during operation with rotating blades and a motor. The operating volume of the device is about 40 dB. The fan works simultaneously with the compressor, transferring the cold from the evaporator to the refrigerator. If the radiator is not completely defrosted in a timely manner, ice builds up and the propeller begins to make cracking and squeaking noises. The increased noise attracts attention. You can check whether the fan is working by placing your palm under the air shower while the compressor is running. The system uses axial and radial fans.

Consider the Indesit refrigerator fan with the No Frost system. The two-compressor refrigerator has 2 convection systems operating from the lower evaporator. Problems with the fan are displayed on the display with an error code. Most often, failures occur in the control system. The repair is carried out by a specialist. In search of a fault, he rings the contacts, replaces faulty elements, and eliminates the break.

Description of No Frost technology

Compressor-type household refrigerators began to be produced in the 30s. last century. The equipment turned out to be in demand, and by 1936 more than 2 million copies were sold in the United States. 20 years later, they created an installation with forced ventilation of the chambers, which prevented the formation of ice. Serial production of such refrigerators began in 1959, and subsequently the design was improved through the use of electronics and high-quality heat-insulating materials for the case walls.

Principle of operation

The design of the equipment uses a fan that pumps air through the evaporator. The flow is cooled and dehydrated, the condensate settles in the form of ice crystals on the surface of the heat exchanger. The evaporator is periodically heated using an electrical system, the frost turns into water.

The resulting liquid is drained through a tube into a reservoir located on the compressor.

The excess heat generated during engine operation is used to evaporate water. The operating principle is standard for all equipment manufacturers with the “No Ice” system.

Differences from the drip system

Classic equipment with a drip defrosting system, or Direct Cool, is equipped with an evaporator located behind the rear wall of the working chamber. When the compressor unit operates, frost forms on the surface. After reaching the required air temperature, the pump is switched off according to the sensor signal. The ice gradually melts, the resulting water is drained through an inclined chute and a tube into a tray on the motor housing. Then the liquid evaporates; the owner must constantly monitor the cleanliness of the drain and clean the hose from contaminants.

Equipment with the No Frost system is distinguished by the presence of a box with ventilation slots located on the rear wall of the chamber. During operation, do not press food containers tightly against the grates. The flow distribution is adjusted automatically based on information from temperature sensors.

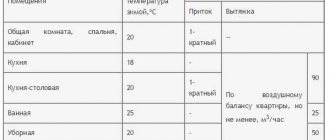

The table shows the main differences between classic refrigerators and equipment with ice protection.

| Refrigerator type | Defrosting frequency | Temperature distribution in the chamber | Presence of ice and water |

| Classical | Every 3-6 months | Uneven, the cold zone is located closer to the freezer, on the upper shelves the air is 3-5°C warmer | Condensation constantly forms on the back wall |

| Equipped with an ice-free circuit | Annually for preventive purposes | Uniform cooling of the chamber due to forced circulation of air flows | Chamber ventilation prevents moisture condensation |

Pros of the system

Equipment advantages:

- The versatility of the No Frost system, which can be installed in the freezer, refrigeration section or in all compartments.

- Easy to maintain: The owner needs to regularly wipe the inside of the refrigerator compartment. Defrosting is required no more than once every 6 months; with a small load and a high-quality seal, the interval between ice removal increases to a year.

- There is no condensation on the walls, excess moisture is removed by forced circulating air.

- Fast cooling of products and support for accelerated freezing mode with reduced air humidity.

- Temperature uniformity inside the refrigerator or freezer. Some refrigerator models are equipped with a freshness zone with separate adjustment of the degree of cooling of food.

- Quickly restore the set temperature after opening the door for a long time or loading warm food.

View » Which brand of chest freezer is better to choose for your home: rating by quality, characteristics, price

Disadvantages of technology

Equipment disadvantages:

- Installing a developed system of air channels reduces the usable volume.

- Increased energy consumption by 5-10%. The deficiency is eliminated in equipment that meets energy efficiency classes A+ or A++.

- Additional noise from the fan, which is rarely audible against the background of the monotonous hum from the compressor. Factory installation of a sound insulation layer eliminates the defect.

- Dry air negatively affects food, which must be stored in airtight containers.

- Installing additional systems negatively affects production costs. The final price for the consumer is higher than the cost of analogues with a drip defrosting system.

Refrigerator fan won't turn off

If the refrigerator fan does not turn off and runs continuously, there are few reasons. The appliance does not stop because the compressor is running. This will happen if there is no command to stop or the chamber is warm. There are several reasons:

- the thermostat or air sensor has deteriorated;

- there is a freon leak or the capillary tube is clogged;

- the connection of the door to the circuit is broken.

However, the fan can contribute to malfunctions - the blades are frozen and rotate poorly, performance and pressure are reduced.

Why is the cooler constantly buzzing?

When trying to figure out why the refrigerator fan does not work, carefully inspect the shock-absorbing units and reduce their contact with the wall. In this case, not only the blades hum, the entire unit shudders and rattles. Another reason for the increased noise level is associated with inadequate thawing and a clogged drainage hole. Ice, which regularly accumulates on the heat exchanger, gradually covers the gaps between the capillary tubes and pinches the fan blades. The growing block leads to overheating of the motor, as a result of which it burns out. To prevent this from happening, even those refrigerators that do not require defrosting must be unplugged at least sometimes.

On a note! After plugging in the appliance, check the functionality of the compressor, defrosting system and blades. If the fan does not work after defrosting, call a technician.

Refrigerator fan hums

If the fan rattles, hums, or crackles, there may be several reasons. At times, the system requires not only defrosting, but also the motor bearings need to be lubricated. When it dries out, an unpleasant grinding and humming noise is heard. It is not the fan itself that is humming, but the entire refrigerator due to vibrations. It is necessary to inspect the shock absorbers of the unit and reduce contact with the cabinet wall.

Another reason for increased noise is due to poor defrosting or a clogged drain hole. Ice accumulates on the radiator in the cooling chamber. The cracks between the tubes gradually become overgrown with frost, the block grows and pinches the blades. The motor hums before burning out under heavy load. I urgently need to defrost the refrigerator. After turning on the device, you need to make sure that the compressor is working correctly, the defrost is turned on, and the fan blades are spinning.

Fan malfunctions

There are several main faults that are often found among popular models of the brands Bosch, Ariston, Whirlpool, Daewoo:

- It happens that the refrigerator fan motor does not turn off at all. There are few reasons for this malfunction. It doesn’t stop, firstly, because the compressor is running and more precisely:

- The thermostat is faulty;

- the air sensor does not fulfill its purpose;

- freon leaks and clogs the capillary tube;

- The refrigerator door does not close tightly.

- When the fan makes a loud noise, crackling or squeaking sound, this is a sign of a malfunction. And there may be several reasons. It is worth noting that the system must not only be defrosted periodically, but also the motor bearings must be lubricated. When the lubricant dries out, unpleasant extraneous sounds are heard. More precisely, it is not the fan that is humming, but the entire refrigerator from vibrations. There is no need to change the fan; sometimes it is enough to simply reduce the contact of the equipment with the wall.

Refrigerator fan replacement

It happens that a supposedly working fan creates noise that is incompatible with further operation. Experts consider replacing the fan to be the best and not very expensive repair.

It happens that the motor is running, but the plastic wings are frayed, cracked, one blade has crumbled, disrupting the alignment. The manufacturer reduces the cost of production by using low-quality plastic.

Perhaps, as a result of increased load or due to power surges, the motor broke down. All these circumstances require repair or replacement of the refrigerator fan. A professional should diagnose and fix problems.

Consequences of breakdown

The No Frost system is significantly different from other cooling options. And if the refrigerator fan does not turn on, the interior will stop cooling completely. In this case, due to the lack of warm air flows, the evaporator will remain cold and the chambers will become warm. At the same time, the compressor continues to work properly, which makes it quite difficult to identify a breakdown.

If the fan in a refrigerator with normal freezing does not spin, the equipment will continue to work properly, since only some functions will not work:

- injection of cold air streams for rapid cooling;

- lack of cooling of the compressor or condenser.

The type of malfunction is determined by the purpose of the fan and its installation location.

Refrigerator Fan Motor

Different models of refrigerators have fan motors with a voltage of about 12 V, a propeller rotation speed of up to 2000 rpm, and a power of 1.5 W. When selecting a new fan, you need to compare the current parameters on the motor housing and in the electrical circuit of the refrigerator. A fuse is installed in the fan supply. The engine is started by an electronic control unit or a starting relay, simultaneously with the compressor. The replacement of the responsible unit is carried out by specialists.