How does a fan work?

The essence of the fan's operation is to move air using curved blades directed in a certain direction. Depending on the engine power, the blades rotate along the axis with the appropriate force, pushing away the air flow, and is intended not only for everyday use, but also for cooling various devices and equipment.

Fan device

There are many types of fans, but almost all of them have the same design. The blades are mounted on a shaft, which rotates using an electric drive. The blade and motor sizes vary according to the purpose of application. In everyday life, the diameter of the blades usually reaches 40-50 mm; in industry, the dimensions can range from 1 to 3 m. During the blowing process, the blades capture air and push it along the axis.

Does the fan cool the air?

A household fan does not cool the air, but only creates wind. Even if it works for days, the air in the room will not cool. A person purposefully directs it in his direction to feel the wind blowing. In the heat, increased sweating appears on the body, which takes away excess heat, and the fan simply speeds up this process.

How does the fan switch sensor work?

Devices with motion sensors are more often used in offices. The essence of their work is as follows: a sensor with an infrared eye is located proportionally to the axis, which reacts to movement. As soon as a disturbance is created, the drive starts immediately. As a rule, such fans differ from standard ones in price. If you buy a cheap device with a power sensor, then most likely the fan will not work correctly, will not always respond to movement and will turn off.

Industrial fans - description and application

The content of the article:

General ventilation systems (supply and exhaust) Radial fans for supply and exhaust ventilation Axial fans for supply and exhaust ventilation Roof fans for exhaust ventilation Duct fans for supply and exhaust ventilation

General ventilation systems (supply and exhaust)

To ensure proper operating conditions for industrial enterprises, general ventilation systems , which are divided into two main types.

Supply ventilation provides access to fresh air into the room, which is additionally filtered, cooled or humidified, depending on the supply fans used.

Exhaust ventilation is responsible for removing polluted air, playing the role of an industrial hood. Industrial exhaust fans are used in conjunction with supply fans, and their performance is calculated in such a way as to balance the pressure in the internal space.

Radial fans for supply and exhaust ventilation

A radial fan is used to organize supply and exhaust ventilation or for smoke removal , as a component of a fire safety system. These types of devices are also called centrifugal fans . The main purpose is the movement and circulation of a gas-air mixture without the admixture of solid particles.

Design of a radial (centrifugal) fan: 1 – casing; 2 – impeller; 3 – impeller blades; 4 – fan axis; 5 – bed; 6 – electric motor; 7 – exhaust pipe; 8 – suction pipe flange

A distinctive design feature of VR fans is the radial arrangement of the blades, which gave the category its name. The shape of the blades, the ends of which are bent forward or backward depending on the direction of flow, as well as the spiral-shaped body ensures air swirl at the inlet or outlet of the room. Due to this, the most efficient circulation is achieved, as a result of which the air is mixed and distributed throughout the entire volume of the internal space.

The bizarre shape of the body, inside of which there is an impeller equipped with spiral blades, served as the basis for the popular name of the device - the “Snail” fan . The rotation of the wheel provokes the creation of centrifugal force, due to which the air flow is sucked in and released in a certain direction. This property is associated with an alternative name for the category of equipment - VC fans , that is, centrifugal.

- Depending on the pressure created, VR fansare divided into:

- Low pressure radial fans (up to 1000Pa)

- Radial heart pressure fans (from 1000 to 3000Pa)

- High pressure radial fans (from 3000 to 12000Pa)

Low pressure centrifugal fans are units designed to move air at pressures up to 1000 Pa. They are widely used in ventilation and air conditioning systems in industrial, residential and administrative premises and buildings. Example BP 80-75

Medium pressure centrifugal fans are used in heating, air conditioning and ventilation systems for various premises. These units are designed to move gas-air mixtures with a total network resistance of no more than 3000 Pa. Example - VR 280-46

High-pressure centrifugal fans are units designed to move air at pressures up to 12,000 Pa. The powerful air pressure created by industrial high-pressure centrifugal fans allows them to be used in quite specific conditions, for example, where it is necessary to move medium volumes of air with significant equipment resistance. Example - VR 132-30

Radial centrifugal fans: 1. BP 80-75 low pressure 2. BP 280-46 medium pressure 3. BP 132-30 high pressure

All CC fans can be explosion-proof, corrosion-proof or heat-resistant.

- Radial design options VR fan:

- Version 1 – The impeller is mounted on the shaft of the drive motor. Example - VR 80-75 No. 6.3 version 1

- Version 3 – The impeller is connected to the electric motor through an intermediate bearing support.

- Execution 5 – The impeller is connected to the electric motor through an intermediate bearing support and a V-belt drive. Example - VR 80-75 No. 6.3 version 5

Design options for the Centrifugal Fan VC: 1. Design No. 1 2. Design No. 3 3. Design No. 5

Axial fans for supply and exhaust ventilation

An axial fan is a universal model of ventilation equipment, consisting of a round body with a centrally located axis on which an impeller with air intake blades rotates using an electric drive.

According to the principle of operation and purpose, industrial axial fans are divided into three types: 1. Supply and exhaust fans are reliable and compact devices that are used in the complex ventilation equipment of a building.

2. Supply fans - used to organize a constant flow of fresh air into the room

3. Exhaust fans – used to clean the internal space from combustion products. An axial exhaust fan is the most popular type of device installed for smoke removal in case of a fire hazard.

All axial models are divided into three groups depending on the discharge pressure - high (more than 3 kPa), medium (1 to 3 kPa) and low (less than 1 kPa).

Design (diagram) of an axial fan: 1. Impeller blade 2. Housing 3. Electric motor 4. Base

Roof fans for exhaust ventilation

roof fan is used as a separate element of a general ventilation system. Mounted directly into the roof structure, it is used to create exhaust ventilation for industrial premises. Another purpose of a roof fan is smoke removal, that is, the timely removal of combustion products rising upward.

Based on their design and operating principle, they are divided into two groups: 1. Roof radial fan (ROF) – a one-way suction device with free flow discharge. They are distinguished by a spiral-shaped movement of flow within the body with subsequent discharge through special openings. Example - VKR fan

2. Roof axial fan (VKO) – the design and principle of operation are similar to axial models that are used in general ventilation systems, additionally equipped with fastenings for installation in a vertical or inclined position. Example – fan VKOPv 30-160

Duct fans for supply and exhaust ventilation

A duct fan is an element of a building’s ventilation system, in which air circulation occurs by moving it through special channels. Duct ventilation devices are used to accelerate the movement of air flow through ventilation ducts. The larger the channel cross-section, the more power is required from the electric motor of the fan installed inside it.

The noise level also varies in proportion to the power. For industrial premises, powerful models of supply and exhaust duct fans with high performance are used, since constant processing of large volumes of air is required. For less polluted buildings and structures, silent duct fans are used, the level of vibration of which is reduced due to the connection to the duct body through flexible inserts.

The geometric shape of the structure is selected depending on the shape of the laid ventilation ducts. Based on this feature, two main types of products are distinguished:

- round duct fan; Example - VKK fan

- rectangular duct fan. Example - VKP fan

What types of fans are there?

Depending on preference or location, there are fans that not only differ in power and blade diameter, but they also differ in shape. Floor-standing devices are more popular because they are the most practical and powerful. Tabletop ones will supply air to a small area, and ceiling ones, although considered the most effective, have a complex design and installation.

Floor-standing

This type is the most common in everyday life. They consist of legs, a stand and a main air supply structure. Their practicality lies not only in their ease of movement, but also in their ease of assembly. Budget models are equipped with several speeds and the ability to adjust air flow. In more expensive devices you can see an LCD display with a timer, time and air temperature, as well as control using a remote control. However, in some cases this can be considered a disadvantage, since more electricity is consumed.

Tabletop

Floor-standing models are intended for individual use, as they cover a small airflow radius. More often than not, they do not have any additional features to increase comfort. Several speed modes and a power off button.

Ceiling

Efficient but not practical fans. They usually come with an installation, for installation on the ceiling or in a chandelier structure. Another disadvantage is the high cost. But this device has more advantages:

- large area coverage;

- large blades;

- rapid cooling of the room;

- does not take up space in the room.

Duct

Duct fans operate on the same principle as floor or table fans, but they are designed to extract air. In appearance, such devices resemble a pipe with blades inside. In everyday life, they are installed in the kitchen or bathroom to eliminate odors and excess moisture. In industry, they also extract air from indoor spaces, be it a factory or a store.

Household fan

The fan is designed to create air flow in the room, ensuring a comfortable stay in the summer.

Household fans are classified by size, performance, number of blades, design and functionality. There are different designs: floor-mounted, table-top and ceiling-mounted. The number of blades can be from three to six. Fans can have rotation speed control and “auto-rotate” functions.

“Auto-rotate” moves the rotor rotation axis in a horizontal plane and is designed to expand the blowing space in a horizontal plane. Fan blades are usually made of plastic, sometimes wood or metal. A plastic fan is lighter, and therefore safer, but not durable. To protect against moving blades, fans are equipped with a grille. They can also be equipped with a timer, backlight, etc.

Fan manufacturers: [www.cbifans.com/en/CBI industry.htm CBI], VENTS Elenberg, Scarlett, Vitek, Polaris, ROVEN, etc.

Types

In addition to different types of designs, fans are divided into types that differ in the process of air supply. Axial ones are used most often in everyday life, since their cost is lower than that of their analogues. Radials come in second place in popularity. Bladeless models are rare to find because they are expensive due to their complex design.

Axial

The operating process of the device consists of axial movement of the blades using an electric drive. This option is most common in everyday life due to its low cost and practicality.

Radial

The column-shaped device has a built-in special cylinder with blades that squeezes out air under pressure. This mechanism is quieter compared to the axial one, and takes up little space. Some models are equipped with a 360 degree airflow radius.

Bladeless

A bladeless fan blows air into the room using a turbine. Air is sucked in by the device and squeezed out with high pressure. Due to its complex design, it is more expensive than its analogues, but it is the safest due to the absence of blades.

Purpose, classification, and principle of operation of fans

Fans are blowing machines designed to move and supply air through ventilation ducts to consumers. They are used in ventilation, air conditioning, air heating systems, for supplying air to boiler furnaces, creating an air cushion for ships, etc.

Fans are axial and centrifugal (radial). Centrifugal fans are most widely used in ship systems.

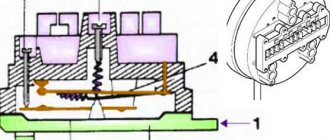

In a metal case 1

(casing) of the centrifugal electric fan (Fig. 22) there is an impeller

2

driven by an electric motor

5

.

When the wheel rotates, air is sucked in through the intake pipe 3

, passes between the blades from the axis to the periphery and then is directed through a spiral channel into the discharge pipe

4

. The fan housing is attached to the end part of the electric motor, which has feet for attaching to the ship's foundation. At the junction of the spiral chamber with the pressure pipe there is a tongue.

Radial fans can have blades that are curved forward, backward, or radial. Number of blades z

usually amounts to

20÷60

.

| Figure 22 – Centrifugal fan |

The axial electric fan (Fig. 23) consists of a cylindrical housing 2

and an impeller (propeller)

1

, driven by an electric motor

3

, which is secured in the housing with set screws

4

.

The convenience of this design lies in the fact that the fan does not change the direction of movement of the air it pumps and therefore can be installed on any straight section of the air duct, and, if necessary, secured to the foundation using paws 5

. In an axial fan, as in an axial pump, when air flows around the impeller blades, its particles are at the same distance from the wheel axis, which is why such fans are called axial.

| Figure 23 – Axial fan |

Centrifugal fans, due to the use of centrifugal forces, provide higher pressures compared to axial fans. Sometimes a guide vane is installed in front of the impeller, which serves to eliminate possible swirling of the flow before entering the impeller.

Often axial fans are equipped with a straightening device (Fig. 24) and consist of a cylindrical housing 3

, an impeller

4

and a straightening device

5

with blades

7

, which are mounted on bushings

6

.

Air enters the fan through inlet 2

, in which fairing

1

. An arrow near the shaft indicates the direction of rotation of the impeller.

| Figure 24 – Schematic diagram of an axial fan |

A straightening apparatus is used when the relative value of the twisting speed is high. This allows you to significantly increase the pressure created by the fan.

Marine fans can be classified according to various criteria. According to the principle of operation, they are divided into radial (centrifugal) and axial.

In ship practice, the classification of fans according to their purpose is widely used. There are fans for engine rooms, general ship ventilation systems, air conditioning systems, fans for boiler plants and hovercraft.

According to the value of the total pressure created in the design mode, fans are of low pressure - up to 1 kPa

, medium pressure - up to

3 kPa

and high pressure - over

3 kPa

.

Fans are also classified according to a number of other characteristics, for example, by the location of the impeller axis - horizontal and vertical, by the type of drive - electric, turbine, etc.

On inland navigation vessels, exclusively electric fans, both horizontal and vertical, are used. A comparison of the basic design diagrams of centrifugal and axial fans and the diagrams of centrifugal and axial pumps shows that they have much in common. Most ship fans create pressures of up to 4 kPa

, and for some fans it reaches

15 kPa

.

There are aerodynamic and acoustic characteristics of fans.

The aerodynamic characteristics of a fan are graphical dependences of pressure, power and efficiency on flow. The type of characteristic depends on the type of fan. The characteristics are based on the results of aerodynamic tests of the fan.

Acoustic characteristics evaluate the noise and vibration of a fan during normal operation. The noise of fans is mainly of aerodynamic origin and various means are used to reduce it, namely: the rotor is well balanced, a spiral chamber is made without a tongue, fans are installed on shock absorbers, noise mufflers are used, etc.

When preparing the fan for start-up, it is necessary to inspect the entire unit from the outside, remove foreign objects left on it, check the fasteners and connections of the pipelines; prepare the electric motor for starting. Centrifugal fans should be started with the dampers closed, and axial fans with the dampers open.

Particularly careful preparation for start-up must be carried out for fans of boiler installations of sea ships and hovercraft. If cooling of fan bearings is provided, then it is necessary to ensure that the cooling medium reaches the bearings. When preparing the fan for operation after installation or repair, it is necessary, if possible, to check that there are no cracks, dents, bending, or loose rivets on the blades.

Fans are controlled only to change the flow by throttling the air at the inlet or outlet.

When the fans are operating, do not allow impacts or jolts on the fan casing to avoid dents and distortions, which can lead to the impeller getting stuck on the casing and causing it to fail. When knocks and shocks occur, as well as when there is a noticeable increase in vibration, the fan is stopped. After an emergency stop of the fan, you should find out the reasons for its abnormal operation by checking the fan mounting, the condition of the shock absorbers and couplings, the fastening of the impeller and its balancing, and the absence of foreign objects inside the fan. The reasons for low air supply can be: incorrect position of the dampers, blockages and leaks in the air ducts, insufficient rotation speed or incorrect direction of rotation of the fan. Leaks in the connections of the fan housing are eliminated by replacing damaged gaskets and crimping the connections.

When stopping, listen to the fan mechanism to make sure there is no noise, knocking or jamming.

Which fan to choose for your home: criteria

Diameter, material and number of blades

Depending on the area of the room, you need to choose the appropriate diameter of the blades. For an ordinary apartment, standard sizes will be sufficient - 40–50 cm. The larger the blades, the larger the radius of air coverage.

The number of blades affects the speed of air flow. If you choose a model with more blades, then the air will be supplied more strongly, but such devices consume more energy and affect the longevity of the electric drive.

On budget fans, the blades are made of flexible plastic; in the case of expensive models, the design can consist of both plastic and metal. These characteristics do not affect the quality of the air supply.

Power by room area

The more powerful the fan, the more massive and further it pushes the air. This parameter is more relevant to exhaust duct devices. There is a conditional rule by which the appropriate fan power is set. We measure the area of the room horizontally and vertically, and multiply the resulting amount by 4. The final figure will indicate the power requirements of the device.

For a floor structure, square meters are calculated, since only the horizontal area where air circulation will occur will be involved in the process. The power of conventional models usually does not exceed 50 W.

Performance

Productivity is usually measured in cubic meters. You can see these characteristics in the device passport. The calculation is based on the area and the regular number of people present. For a room 8x10 m, a fan with a blowing area of 50 m will be enough.

Number of speeds

This function is found in almost all fans. In budget models, up to 3 speeds are installed, in expensive ones you can see 7 transitions. Switching speeds affects the speed of the blades. This is a convenient feature that will allow you to adjust the air flow depending on the temperature in your home.

Air strike

This term indicates the distance a fan is capable of blowing. The characteristics directly relate to the drive power and the density of the blades on the axis. The air strike parameters are also indicated in the passport. If your room is small, then 40–60 cubic meters is quite suitable for a floor fan, and 20–35 for a desktop unit.

Air exchange

Such a characteristic as air exchange refers to duct exhaust devices. Here you will also have to calculate the area of the room and compare it with the characteristics in the passport. This is determined by the multiplicity in hours. That is, how many times in an hour the air in the room will completely change. Let's take standard indicators:

- kitchen – 5–12 times per hour;

- bathroom/toilet – 5–9 times;

- bedroom – 3–7 times.

For the optimal ratio, measure the cube. area and multiply it by the standard air exchange characteristics of the corresponding room.

Airflow area

This characteristic applies to floor and tabletop models. Its value indicates the area that the fan can blow. Standard models cover an average of 40-50 m, but if you have long or large rooms, then it is better to look at a more expensive fan, otherwise the air will not reach the other end of the room. The blowing area directly depends on the engine power.

Tilt and rotation angle

Almost all modern fans are equipped with rotary axes, the only difference is in the degrees of rotation. The most common models are those with a horizontal rotation of 180 degrees, but you can also choose 45 and 360 degrees. This characteristic will largely depend on the cost of the fan. The automatic rotation function only works in the horizontal position; you will have to adjust the vertical position yourself.

Noise level

Check the noise level immediately before purchasing. Let the consultant unpack the fan and start it up, switching the blowing speeds. The standard quiet value should not exceed 40 dB. If you will turn on the fan in the bedroom, then choose a model with a noise level of no more than 30 dB.

Airflow mode

The indicator directly depends on the number of blades. Different types of fans can have from 2 to 10 blades on the axis. Accordingly, the device will blow air over the area depending on the rotation speed. There are models with automatic air flow changes, they are called climatic. According to customer reviews, this mode is not very useful.

Control block

Standard fans usually have 4 buttons: 3 speeds and stop. You can also see the backlight button, however it does not shine on the panel or fan blades, this switch indicates the exact location of the device in the dark. Expensive models are equipped with displays that show the flow rate, room temperature, clock and shutdown timer.

Remote control

Using the remote control, you can adjust the fan settings without going near it. This is not to say that this is an important function, but it is relevant for older people. There are remote controls with LCD displays, with which you can also adjust the device settings.

Timer

Models with a display have a countdown timer that allows you to set the on and off times. It is convenient to activate the function before going to bed.

Ionizer

Air ionization has a positive effect on the human body. With the help of aeroions, you will sleep better, become more active and speed up your metabolism. The ionizer also draws in harmful oxygen elements, purifying it from dust and gases.

Humidifier

The humidifier is sold as a separate device, but it can also be integrated into the fan itself. For this function, a corresponding fluid tank is located on the structure. The big advantage of using a humidifier is that the released moisture will be blown out along with the air, taking up a large area of the room. Expensive fans have an indicator indicating the water level in the tank.

Adjustable

Control of conventional fans is based on a panel with buttons. With their help you set the flow rate or timer. In the list of expensive models you can see an automatic regulator that will monitor air temperature, humidity and pressure. The built-in sensor will automatically start or turn off if the humidity or temperature levels go beyond certain limits. The high cost of such models is due to their complex design.

Protective grille

The blades of each floor axial fan must be protected with a mesh. It can be made of either metal or rough plastic. As for table fans, in some models this factor is not necessary, since due to the low power and small blades, the chance of knocking it over is insignificant. However, choose better protected models, regardless of the type, as the device can catch hair or accidentally injure you.

Sustainability

Floor fans come in different designs. Usually the rack lies “crosswise”, secured with bolts. Desktop devices have different mounting options. Designed specifically for the monitor, they are attached using a special clothespin, but there are also devices with suction cups.

Certificate

Before purchasing a fan, ask your consultant for a passport and quality certificate. Typically, the documents describe the device parameters and the level of assembly guaranteed by the manufacturer.

Fan.Classification

A fan is a unit that serves to move air flows and other gas mixtures under pressure up to 0.15*10^5 Pa.

There are two main types of fans: centrifugal and axial. Axial fans, also called duct fans, under identical conditions will create a pressure lower than centrifugal ones, which is why they are more often used.

A centrifugal fan is an impeller in a spiral casing located on a shaft. The rotor design is 2 disks, between them there are blades, of which there are from 6 to 26 pieces. The main task of the spiral casing is to collect air flows from the impeller and reduce their speed.

Centrifugal fans, in turn, are divided into:

- according to the pressure produced

- low pressure (up to 1 kPa)

- medium pressure (up to 3 kPa)

- high pressure (more than 3 kPa)

2. by purpose

- generally used (mixing air masses)

- special (for smoke removal, dust movement)

3. by the number of suction sides

- unilateral

- double sided

4. by number of steps

- single stage

- multi-stage

5. according to the design of the case

- DO - normal version

- VR - explosion-proof version

- In a sound-absorbing housing

An axial fan is a wheel with blades located in a cylindrical housing, the revolutions of which, under the action of the blades, move air masses entering the suction hole in the axial direction. The number of blades in it is from 2 to 32 pieces.

Axial fans are:

- reversible - if the shoulder blades are symmetrical

- irreversible - if the shoulder blades are asymmetrical

according to the method of manufacturing the impeller

- welded

- cast

- stamped

- plastic

Fans also differ in climate design, which is designated alphanumerically. The letters mean:

- U - temperate climate

- X - cold climate

- UHL - cold and temperate climate

- T - tropical climate

- O - general climate version

- M - marine version

- B - all-climate version

The numbers in turn indicate:

- 1 — external design (can be placed outdoors)

- 2 - can be placed outdoors but under a canopy

- 3- internal version (indoors only)

- 4- internal version for rooms with heating

- 5- for rooms with high humidity

Which fan is better, column or blade?

A blade fan operates using a simple mechanism - an electric drive rotates the blades along an axis, which creates an air flow. The column structure operates according to a more complex mechanism - air under pressure is released into the atmosphere. During operation, a column fan is quieter than a blade fan. Another advantage is increased safety, since the blades are located in the housing.

Blade fans are more common because they are inexpensive. Compared to radial ones, their design is more simplified. But it is worth noting that in brand stores even floor-standing models can be equipped with powerful, silent drives and many functions. The choice of fan will depend entirely on your preferences and budget.

Fans with built-in cooling system

Fans with air cooling function do not take up more space. The only difference that distinguishes them from conventional paddle models is the water tank. Its sizes range from 10 l to 50 l. During operation of the fan, cold fog-forming steam is released, which enters the air flow.

Before purchasing this type of device, always check its noise level, as in cheaper models, the steam production, as well as the operation of the blades, can create quite loud noises. For public institutions this indicator is not so important, but when used in everyday life, the increased noise level will cause discomfort.

Errors in selection

Many buyers do not look at the characteristics of fans at all and make a mistake because even expensive models may not only not meet the area ratio, but also be unsafe. Let's look at the main criteria you need to pay attention to when buying a fan:

- Fire safety. First of all, pay attention to the quality of the power cord. A device with a thin cord indicates poor resistance to current and is easily damaged by external objects. It is not recommended to purchase such fans, as they can begin to melt under prolonged load and cause electric shock if the outer sheath of the wire is damaged.

- Current conductivity. Fan designs are mostly made of plastic, but in expensive models you can see a solid metal casing. If you take into account the build quality and stability, then the iron one will be a level more practical, but as far as safety is concerned, the opposite is true. If the power cable is damaged, metal devices will be good conductors of current, which will lead not only to a serious short circuit leading to a fire, but also to electric shock. Never move a running fan around the room!

- Additional functions. Today there are many devices for air cooling, which differ in build quality and the presence of additional functions. If you choose a fan for your home, then you should not overpay for lighting and similar functions. The presence of an LCD display informs about the air temperature and time, but more important will be the built-in timer, which will start or turn off the fan at the time you specify. It is better to choose a device with air purification, as this function will have a positive effect on your well-being.

In addition to safety, pay attention to the noise level. Always test the fan for functionality immediately before purchasing. Carefully inspect the assembly of the structure.

How much does a fan cost?

In every home appliance store you can see many varieties of fans. They all differ in build quality, technical parameters and functionality. Many buyers often choose Chinese models, which according to advertising have high quality and a huge list of features. In reality this is not the case at all. According to statistics, cheap Chinese fans break down after just a few months, the reason for this is poor wear resistance, and this applies not only to the design, but also to the electric drive.

It is recommended to buy branded models, as they have already proven themselves in quality and performance. In case of problems or breakdowns, devices of a famous brand can be taken to a service center, which is located in almost every city.

A budget blade fan costs an average of 1,200 rubles. It consists of plastic and metal. Functionality may include backlighting and 3 air flow speeds. By purchasing a model for 3000 rub. and more, think about a radial device, since it makes virtually no noise, takes up little space, and is safe due to its design.

The cost of a duct fan will depend directly on its power. The average price of such models is 3000 rubles. For larger areas, you will need to allocate more funds to ensure the strength and shape of the structure meets the requirements.

Bladeless fans are more commonly used as desktop cooling devices. Their cost ranges from 400 rubles. up to 25,000 rubles, depending on power and brand.

Expensive or cheap, what's the difference?

Cheap models are equipped with standard features. Their design is quite simple - a mount, a leg, an electric motor and blades. If you compare them with expensive fans, the difference can be both in performance and in the number of additional functions. In addition to low noise and a powerful drive, the device can be equipped with an LCD display that will indicate the air temperature and time. These indicators are not vital, but increase comfort. The situation is similar with the remote control.

There are also useful features, such as air ionization or automatic shutdown when there is smoke or a short circuit. All these characteristics are described in the device passport and significantly affect its cost.

The choice of fan depends on your preferences. Choose the model that suits you best. Check the functionality of the device right in the store, carefully inspect the assembly to ensure that the structure is securely fastened.

Do not believe the advertisements of unknown companies that offer innovative technologies at a low cost. Use the Internet to obtain information about a particular fan model, and then you can choose a high-quality cooling device.

Radial

The basis of a radial fan (also called a centrifugal fan) is a casing shaped like a snail, inside of which is an impeller. When rotating, a centrifugal force is generated, which draws air through the suction hole in the center of the device. After this, the air mass is directed to the peripheral part of the fan, from where it is pumped through the air duct into the ventilated room. Another feature is that the air flow enters it in the axial direction, and is pushed out moving radially (its direction is tangential to the housing casing), it is always perpendicular to the incoming flow.

The main working element is a cylinder with blades fixed around the circumference at the same distance. Depending on the shape and location of the blades, different effects can be achieved:

- curved forward - create high pressure and work with large volumes of air;

- curved back - avoids dust accumulation, suitable for working in environments with high oppression;

- aerodynamic wing – very low noise figure and high performance.

The main advantages of radial fans are the ability to achieve high air pressure with fairly small dimensions, durability, low noise level and the ability to operate in continuous mode.

Therefore, they are widely used in industry, especially where powerful constant ventilation is needed - in large office buildings and shopping and entertainment complexes, supermarkets, warehouses, garages, etc. Due to the ability to quickly remove polluted air, they are actively used in hazardous industries. In everyday life, radial fans are increasingly used in kitchen hoods and duct ventilation. See also -

How a bladeless fan works