The list of equipment necessary for minor repairs includes a spray gun for painting a car. The equipment is used for spraying paints and primers (air-drop method) on certain surfaces. The trade offers a wide range of tools that can be used not only for painting cars, but also for repair work.

Equipment in use

What is a spray gun

A special device with which enamel, varnish or any other liquid solution is applied is called a spray gun. Fine spraying allows you to obtain a thin and uniform layer, practically without smudges, on the surface being treated.

Important! The device helps to work on hard-to-reach areas, corners and relief surfaces not only on the car. It can even be used to paint the inside of central heating radiators and other areas with difficult access.

Types of spray guns for painting a car

The most common are pneumatic, mechanical and electric sprayers. They differ from each other in the way pressure is pumped into the chamber.

Mechanical sprayers are also called plunger sprayers. Their design is a sealed tank with hoses. They are characterized by economical paint consumption, but the lowest productivity among all models.

Principle of operation:

- A liquid solution is poured into the container.

- Using a pump, the pressure is manually pumped to the desired level.

- The mixture enters the sleeve and is sprayed onto the object.

Using a plunger sprayer, you can paint 100 square meters in half an hour. m.

Pneumatic tools produce the best results. It is intended for professional use. The operating principle is based on the supply of compressed air from a compressor. Air particles enter the receiver and mix with the paint. Due to the pressure pumped by the compressor, the mixture is pushed out of the nozzle, breaking up into small drops. The result is a cone-shaped torch.

With this spray gun you can paint 200 square meters in 30 minutes of work. surfaces. To treat the same area with putty or varnish it will take 2-4 hours. Typically, spraying uses a high or low pressure system. There is also a mixed option from both technologies.

An electric spray gun sprays a liquid mixture using a motor or built-in pump. The quality of application of paintwork materials is worse than that of a pneumatic device. Depending on the power supply, the electric spray gun can be:

- network with connection to a 220 V network;

- rechargeable, powered by an external battery.

If the mixture enters the gun nozzle using a piston pump, then the airless spray method is used. The main advantage of this principle is the absence of fogging. But the layer of pigment material on the surface is very thick, which is not suitable for processing relief products.

When spraying by air, the paint is supplied by an electric motor. The principle of operation is the same as that of pneumatic spray guns.

Why do you need a spray gun?

In addition to painting work, the car sprayer can be used:

- for whitewashing and priming walls and ceilings;

- varnishing wooden surfaces;

- applying anti-corrosion materials to metal in the garage;

- cleaning old wallpaper from walls - uniform moistening or applying a special composition to facilitate their removal;

- spraying plants in the garden with pest control compounds.

Some pastry chefs have managed to adapt equipment for velor cakes.

Important! The equipment is used for repairing premises at all stages of work, when painting vehicles or implementing creative ideas.

Spray marking

Adjusting the spray gun

When working with a spray gun, you can adjust the air and paint supply. To do this, the gun has three adjustment screws. The first thing to do is adjust the air outlet pressure at the head. Thanks to this screw, you can calibrate the drops of paint that will come out of the nozzle.

Video: Setting up the spray gun and painting order

The second screw is responsible for the shape of the paint-air mixture emerging from the nozzle, the so-called “torch”. This screw can be used to increase or decrease the paint spray area. This adjustment allows you to paint a large surface area, or a local small spot, without applying paint to nearby surfaces.

The third screw adjusts the supply of paint and varnish material, which will be captured by the air flow. This adjustment allows you to set the amount of paint consumed.

Structurally, all spray guns are almost the same, the only difference I can make is the location of the tank and adjusting screws. But the features of the work process during which paint is applied are different. All spray guns have three main types of process - spraying paint under high pressure, low outlet pressure and medium pressure. The first two are completely different, and the third is a derivative of them.

Each of these methods has its own marking. Paint guns that apply paint under high pressure are marked with the letter “HP”. A spray gun with low pressure at the nozzle exit is designated "HVLP". Models operating with medium pressure are marked “LVLP”. There are several more models with other markings (RP, HTE, MP, LVMP), but, in fact, they are just modified versions of the first three types.

Device structure

The following components are included in car painting spray guns:

- handle - necessary for directing the sprayed composition and holding the device;

- tank - it contains the liquid composition used for spraying;

- trigger - sets the locking needle in motion, when pressed, paint begins to spray;

- nozzle - located at the front of the gun, the nozzle fits into part of the spray base.

For pneumatic models, the pressure regulator (p) is located in the rear area of the gun; it is necessary to adjust the level at which air is supplied. The second similar mechanism is a shut-off screw that regulates the intensity of supply of liquid material.

Device structure

How to choose a nozzle

This part of the atomizer plays an important role. The fact is that it has a certain size, and paint is directed through it and a needle is attached to it, which sprays the working mixture. Depending on the viscosity and physical composition of the substance used, the nozzle diameter is selected:

- Local painting and metallic color mixture -1.2.

- Water-soluble paints, as well as bases – 1.3-1.6.

- Varnish and acrylic – 1.4 -1.6.

- Primer – 1.6-2.2.

- Liquid putty – 2.5-3.0.

To begin with, you can buy a device with a nozzle with parameters 1.4. This diameter allows for different types of work. But it will also be possible to apply paint and primer, including those with the addition of solvents.

Attention! On the market you can find models with a set of replaceable nozzles and needles, and a varied range of diameters. They are universal and suitable for any event.

Replacement nozzle for spray gun

Spray gun spray systems

Pneumatic equipment is divided according to the technological features of spraying:

- with high p - HP system;

- small p with small volume - HVLP;

- small volume and p - LVLP.

Important! When purchasing equipment, you need to pay attention to the abbreviation present in the model names.

HP system

The devices are characterized by high output p values, reaching up to 1.5 atmospheres. Fast and uniform application of the solution is ensured by a wide forming torch and high air flow.

The advantages of the system include:

- short turnaround time;

- high-quality spray;

- homogeneity of the colorful torch.

The disadvantages are presented:

- high air consumption, requiring a powerful compressor;

- high p values, which require certain skills in handling the tool;

- consumption - about 60% of materials go into the “fog”.

Important! Due to severe air pollution, personal protective equipment must be used when working with garage equipment.

HP system

HVLP system

It is characterized by a lower output p, which helps to obtain a more dense application. Low rates allow you to keep the device close to the surface, reducing paint consumption and air pollution.

The advantages of the system include good coating quality and a small loss of solution of 30%. The disadvantages are high cost, the need to use a powerful compressor due to air consumption.

Important! Saving almost 20% of paint and varnish materials allows you to quickly recoup the cost of purchasing equipment.

HVLP system

LVLP system

During operation, the equipment requires minimal volumes of air at the input; it is resistant to changes in p in the compressor. The list of advantages of the system includes:

- minimal loss of solution - no more than 20%;

- resistance to unstable p;

- low air consumption.

The disadvantages of the system include its high cost and the need for skills to operate the device.

LVLP system

Spray systems

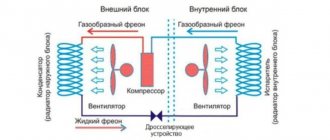

The operating principle of this equipment is the same. The device mixes the dye in a tank (or another solution). Compressed air under the compressor enters the device. The solution flows through another channel. The air splits the mixture coming out of the nozzle, forming a solution torch. Then the liquid medium is supplied in the form of a fine-grained jet to the car body part. Depending on the pressure force and the mixture supply scheme, the type of equipment is determined. There are the following spraying options by which these devices are classified:

- HP;

- HVLP;

- LVLP.

To choose the optimal specimen for painting, you need to have information about each of the systems. We will talk about three popular options.

Spray systems

HP system

Produces a working pressure of 3-4 atmospheres. Creates a wide torch and evenly applies paintwork to the surface. The speed of application of the mixture is high. The model is relatively inexpensive. The disadvantages of the unit include:

- low coefficient of transfer of liquid substance to the surface;

- significant air movement provokes the raising of dust in the workshop, which is undesirable;

- The system is quite old, but reliable.

After using this type of spray gun, the surface of the car is sanded. This is due to the high rate of air contamination with dust.

HVLP system

This type of equipment has been used since the 90s. twentieth century and has proven itself well. The device uses a significant volume of air, and the mixture is sprayed at low pressure - one atmosphere. Thanks to this technology, over 75% of the paintwork material is transferred to the working surface. The system has its advantages:

- creates a low level of fog in the air;

- does not raise dust in the workshop;

- shows good performance.

Pay attention to: How long before you can wash your car after painting, and how to do it correctly to avoid damage to the paint layer

There are several disadvantages to this system. It requires a powerful compressor to operate. The coloring solution should be applied close to the surface. This makes it difficult to process hard-to-reach, remote areas. The procedure will require special skills.

LVLP system

This type of sprayer is an innovative device, and was developed to eliminate the shortcomings of the previous two types of units. The technology used makes it possible to combine low air consumption with a significant coefficient of paint coating application. The input pressure of these devices is 1.6-2 atm, and the spraying process is 0.7-1.2 atm. The efficiency of the mixture transferred to the surface is 70%. The unit distributes any liquids. Paint guns of this brand:

- do not consume a lot of air;

- have a high percentage of efficiency;

- do not raise dust;

- create minimal “fog”;

- do not respond to power surges;

- show an excellent percentage of spray paint.

This type of equipment has few disadvantages: it creates a smaller torch than the previous two types and a low solution spraying speed. The LVLP spray gun has proven itself well during operation.

How to choose a spray gun for painting a car

Before purchasing a device, you need to familiarize yourself with the basic quality characteristics. The paint consumption and the quality of the work performed depend on the indicators.

Receiver material

The choice depends on the class of equipment:

- for HP - receiver at 4-6 atm;

- HVLP - 1.5-4 atm.;

- LVLP - 0.7-2 atm.

Important! The receiver is selected individually for each brand of spray gun.

Location and volume of the tank

The location of the tank does not affect the operation of the air gun:

- installed below - selected by craftsmen who are comfortable working with it;

- top - uses all the paint material to the last drop.

Plastic tanks are used for acrylic and water-based paints; metal tanks are used for solvent-based materials. The volume is selected at the discretion of the user - excessive weight can interfere with work.

Bottom position of the tank

Performance and Power

For domestic purposes, equipment with a power of up to 500 W is used; professional models require higher performance. The latter are capable of working with materials of any viscosity; they are always distributed evenly.

The performance of guns is the volume of air entering and exiting. Stable spraying is ensured by the high level of efficiency of the spray gun.

Nozzle diameter

The parameters differ depending on the type of paint solution used:

- local application - 1.2 mm;

- varnishes, water-soluble composition, base - 1.3 mm;

- acrylic and varnish - from 1.4 to 1.7 mm;

- primer - from 1.6 to 2.2 mm;

- liquid putty - from 2.5 to 3 mm.

If the nozzle diameter is chosen incorrectly, it may become clogged with particles that are too large.

Compressor selection

When selecting this technical unit, you should take into account what type of spray gun it is. We remind you that there are electric and pneumatic. The second model is considered preferable in terms of performance indicators. Each type of equipment (HP, HVLP, LVLP) has its own characteristics. Based on them, the compressor is selected. HP units require 4 atm for manipulation, while the spray gun incurs noticeable losses during operation (which is why they are gradually going out of use). A compressor is required that is not very productive (100-300 l/min.) with an indicator of 6 atm. AURORA BREEZE-8, KOLNER KAC 24 L are suitable. Devices designed according to the HVLP type require 2-3 atmospheres for spraying. When choosing a compressor for this type of device, we pay attention to technical products with a capacity of 360 l/min, and from 1.5 to 4 atm. The following types of equipment have proven excellent: QUATTRO ELEMENTI 248-504 KM 50-380, FUBAG VDC 400/50 CM3, GARAGE PK 50.MKV370/2.2. LVLP is a technologically advanced instrument, operating in the range from 0.7 to 1.5 atm. A compressor with a capacity of 150-300 l/min is required. The output indicators must be at least 2 atm. We recommend purchasing: QUATTRO ELEMENTI SENZA-24, ZUBR ZKP-190-24-1.5.

Compressor AURORA BREEZE-8

Compressor QUATTRO ELEMENTI KM 50-380

ZUBR compressor ZKP-190-24-1.5 Please note: Features of motorcycle painting

Which compressor is suitable for a spray gun?

The device is selected in accordance with the characteristics of the pistol:

- supply of a certain volume at the required p - the compressor capacity in cm3 should be 1.5 times greater than what is needed for the spray gun;

- insufficient performance will not give good atomization;

- the air supply parameter must be clarified - some compressors only give good pressure indicators.

Hoses with fittings are of great importance. A quarter inch cord will interfere with the stable flow of air; for normal operation, a 3/8 inch cord with fittings that do not impede air flow is required.

Compressor for spray gun

Paint spray systems

To better understand the difference in the types of spray gun, consider the simplified principle of operation when spraying. Compressed air comes from the compressor under pressure. Next, in the spray gun, the air is combined with the paint coming from the barrel. Combining in the air cap, the paint is split by air and a torch is formed at the outlet of the nozzle.

The type of spray gun determines the pressure with which the paint material is sprayed. Below are the most used spray systems by which spray guns differ.

- HP (High Pressure) - high pressure.

- HVLP (High Volume Low Pressure) - low pressure, high volume.

- LVLP (Low Volume Low Pressure) - low pressure system, low volume.

HP system spray guns

The system is long outdated. Spray guns of this type have been used in auto body repair shops for a long time. For stable operation of the device, a pressure of 4 atmospheres is required. At the moment of spraying, the pressure in the nozzle should not exceed 3 atmospheres. Such a device requires a small volume of compressed air to operate; the compressor is not very productive.

The HP system spray guns form a wide spray, and the paint and varnish material is applied evenly. The main disadvantage is the low coefficient of transfer of paints and varnishes to the surface. That is, when spraying, a mist is formed, as a result of which some of the materials do not reach the surface. Thus, only 45-50% of the sprayed material covers the surface, the remaining 50-55% does not settle on the surface.

Advantages: high speed of painting surfaces; low-power compressor, wide torch which forms a uniform application of the material.

Disadvantages: low transfer coefficient of sprayed materials to the surface; Also, increased pressure can contribute to the raising of dust during spraying, which can settle on the surface being painted.

HVLP spray guns

HVLP spray guns are characterized by low pressure and high volume, they are very common nowadays and are used when painting cars. The power of the spray gun depends on the compressor itself. Guns use a huge volume of air during operation, while spraying takes place at a fairly low pressure. Due to the low pressure during spraying, a large percentage of the material falls directly on the surface to be painted (about 80%).

Electric spray guns of the HVLP system have proven themselves well when coating with paints with Mother of Pearl or Metallic effects. Like all paint guns, spray guns of this type have their advantages and disadvantages.

Advantages: these include a good percentage of material transfer. Low level of fog formation during painting. Low pressure when spraying, will not raise a large amount of dust. High performance is also inherent in mini-pistols.

The disadvantages will include a high-performance compressor, which will need to be maintained in order to produce large volumes of air during operation. The need to use a large diameter hose to connect the compressor to the spray gun. When painting, paint and varnish materials must be applied at a short distance from the surface. The process requires a high degree of professionalism from the painter in order to carry out painting without smudges.

It is also useful to read: Choosing a tool for high-quality car painting

Manufacturers of spray guns

The TOP popular equipment suppliers include:

- “GAV” is a budget line for beginners learning the nuances of painting; the devices are used for applying acrylic and basic base;

- “Walcom” - used for professional auto repair shops, the manufacturer produces a variety of models;

- "SATA" - equipment is characterized by resistance to wear and long service life.

Important! In order not to wonder which spray gun you can choose for painting a car, you need to familiarize yourself with the characteristics of the models.

What requirements must the spray gun meet?

To achieve the best result when finishing the body, you need not only a unit with suitable characteristics, but also correctly selected components for it.

Compressor

It must be compatible with the air gun. For spraying to be effective, the compressor must produce 1.5 times more cm3 of compressed air than is consumed by the spray gun.

It is important to use the correct inner hose diameter. The 3/8" size will provide the best air flow.

Nozzle size selection

Paint is sprayed through the nozzle. And if you insert a needle into it, you can adjust the flow of the liquid mixture. The diameter of the nozzle should be selected according to the viscosity of the paint. The thicker the consistency, the wider the nozzle should be. Then the solution will not get stuck. But for a liquid mixture, on the contrary, a narrow diameter is required. Otherwise, the paint will fly out in large drops, creating blots.

Water-soluble paints

Special care must be taken with this type of mixture. If, when changing the material in the tank, its residue gets on the paintwork with a solvent, the paint will curl. When spraying, flakes will fly out. In addition, there is a risk of corrosion of the device. To avoid these problems, a separate device must be used for water-based paints.

Top spray guns for painting cars

The rating of popular devices for paint and varnish work includes:

- Devilbiss Flg 5 RP is a professional budget model that requires 270 liters of air every minute and produces a torch 280 mm wide. The device has an aluminum body, a needle and nozzle made of stainless steel. Works with all types of materials, with the exception of water-based solutions. The equipment is supplied without a case, in cardboard packaging.

- Walcom ASTUROMEC 9011 HVLP 210 is an inexpensive gun that allows you to paint surfaces with high quality. Requires 220 liters per minute of air, despite the built-in HVLP system. The package includes a gearbox, a convenient plastic case, spare parts: springs, retaining rings, gaskets, air valve rod. Additionally, oil for lubrication of contacting parts and a cleaning kit are supplied.

- Walcom SLIM S HVLP - has a high coefficient of solution transfer to the surface, within 85%. During operation, 200 liters of air per minute are used. The package includes a case, a regulator with a pressure gauge, oil, spare parts, a cleaning brush and a key.

- SATAjet 1000 B RP - the device is suitable for fine and large-scale processing. Requires a compressor with a capacity of 275 liters per minute, distributes about 60% of the solution. The package contains a cleaning brush and keys.

- Anest Iwata W-400 RP is a spray gun with standard pressure and high-quality assembly. It is characterized by a high speed of application of solutions, subject to high air consumption - up to 370 l/min, which requires choosing the right compressor (not all models can provide the required parameters). The torch width is 280 mm, the equipment is supplied in a cardboard package with a colorful filter and a cleaning brush.

It is necessary to select equipment based on build quality, tank capacity, its position and performance. The user must focus on popular models, in accordance with their purpose, and select devices that are suitable for hand.

Classification of spray guns by paint spraying

Comparison of spray patterns for paint transfer efficiency

HP system spray guns

The first type of spray guns that spray paint under high pressure and are marked “HP” are the most common. A special feature of these guns is the high pressure at the outlet of the nozzle (about 1.5 atm), while air must be supplied to the inlet of the spray gun at a pressure of 2.5-5.0 atm. Due to the high pressure, the air speed at the exit of the nozzle is quite high. Because of this, the torch is quite wide, which ensures a more uniform application of the paint layer, and also affects the speed of work. At the same time, the air consumption of the spray gun itself is relatively small, from 100 to 300 l/min.

- The main disadvantage of HP sprayers is the large loss of paint during operation. The high air speed at the exit of the nozzle leads to the fact that upon reaching the surface, drops of paint do not have time to stick to it and simply ricochet. Because of this, approximately 65% of the paint material is lost. The paint that flies off the surface forms a fine mist, which gradually settles on the surrounding surfaces. Only 30-35% of the paint and varnish material is transferred to the surface to be painted.

- Another disadvantage is that during operation, the air flow, pushing away from the surface to be painted, forms air vortices. They capture small particles of debris in the air, press them against a layer of paint, and they stick to it. As a result, after painting, grinding and polishing work will be required.

HVLP spray guns

This is not how HVLP sprayers work. Their outlet air pressure is much lower - about 0.7 atm. At the same time, the inlet pressure remains high - 2.5-3.0 atm. It is possible to achieve a pressure drop due to the special structure of the air channels inside the spray gun.

Video: How to choose a spray gun. Spray systems.

Due to the low outlet pressure, the speed of movement of air with paint particles is much lower. Because of this, drops of paint have time to adhere well to the surface. This achieves a high percentage of paint transfer to the surface - up to 70%; only 30-35% of the paint is lost from ricochet. In this case, there is no formation of vortices, so no additional work is required after painting.

But such a painting process is accompanied by a significant air consumption; the compressor must provide over 360 l/min of air.

An additional disadvantage is the need for a small distance between the spray gun and the surface to be painted. This makes painting difficult-to-reach surfaces and from a distance quite difficult.

LVLP system spray guns

When creating sprayers of the “LVLP” system, the positive qualities of the two types listed above are combined. In such spray guns, the outlet pressure is 0.7-1.2 atm, with an inlet pressure of 1.5-2.0 atm. Thanks to this, it was possible to ensure a high percentage of paint transfer - up to 75% with a low air flow - 15-350 l/min. Therefore, such pistols are now a priority.