Cleaning the heating element

To clean the heating element of the water heater from scale, use the means at hand: a metal brush, a knife, etc.

Has your boiler started making noise like an electric kettle? Does it heat the water poorly, continuously consuming kilowatts of electricity? The scale covering the surface of the heating element is to blame. It has low thermal conductivity, so heat from the heater is practically not transferred to water. As for the noise, it is the noise of the water in the thickness of the scale itself. Thus, all scale from here needs to be removed. We begin repairing the boiler by draining the water, then remove the water heater from the wall, remove the heating element and begin cleaning it.

Cleaning heating elements from scale can be done in various ways. The mechanical method involves removing the main layer of scale by hand while it is still wet. After this, we take sandpaper in our hands and carefully remove the remaining lime deposits from the heating element. As a result, we should get a clean and shiny heating element.

The mechanical method implies a careful approach - the heating element must be cleaned as carefully as possible so as not to make unnecessary holes in it. There is no need to hit the heating element on hard surfaces - this way it can be completely broken.

The chemical method involves the use of special reagents that dissolve or soften scale. They can be purchased at hardware stores, but be sure to check consumer reviews first. As for strong acids, it is better not to use them - they can damage the metal of the heater.

Replacing the heating element

Many factors indicate that it is time to change the heating element. For example, the boiler may stop heating water or begin to shock painfully. Replacing the heating element begins with draining the water and dismantling the boiler. Next, we open access to the heating element, pick up a tester or multimeter, check the resistance of the heater - it should vary from 40 to 70 Ohms, depending on its model. If the measuring device shows a break, the heating element can be safely changed.

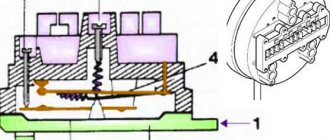

Set the multimeter to the audio test mode, and place its contacts on the heating element according to the diagram; if there is a squeak, then your heating element must be replaced.

If the boiler is experiencing electric current, you need to check the insulation resistance between its contacts and the body (one probe on the body, the second probe on one of the contacts). In megohmmeter mode, the measuring device should show an infinitely high resistance. If it is tens or hundreds of Ohms, then this indicates a breakdown. Since heating elements cannot be repaired, they simply need to be replaced. To do this, we buy a similar model and install it in the boiler.

If the problem is related to a lack of heating or extreme overheating, then the problem may lie in the thermostat. You need to check it with a multimeter and see how it reacts to heat. If a mechanical thermostat with a bimetallic plate is installed in the boiler, you should press the control button and heat the thermostat with a soldering iron or lighter. If the button bounces off after heating, then the thermostat is working. At the same time, you need to check the integrity of its contacts using a conventional multimeter.

Non-insulated coils in instantaneous water heaters

Uninsulated coils in storage water heaters pose a serious threat to human life. It is strictly prohibited to troubleshoot a heating element by simply winding nichrome wire over the rod.

The design of an instantaneous water heater is fundamentally different from a storage one: there is no tank as such, the heating element is placed in a container slightly larger than the heating element itself, made of copper. The device is equipped with two degrees of protection: a thermostat that maintains the water temperature; flow sensor that turns off the heating element when the water supply stops.

Electricity and water are no joke when it comes to human lives. It is forbidden, as they sometimes write, to place uninsulated nichrome spirals in copper tanks, which are often connected by copper tubes

It's called negligent homicide

Finally, an argument for the readers! It is specially coated with nichrome ceramics to reduce the formation of scale. Metal is an unsurpassed basis for salt deposition. It is not by chance that it is supplied with an inert shell.

Basic rules for servicing an electric heater

For long-term and trouble-free operation of the water heater, it is important to follow the rules of its operation and maintenance. Otherwise, breakdowns are inevitable

The fact that problems have arisen in the operation of the device may be indicated by some changes in its operating mode:

- increasing the time for heating water to a given temperature;

- the appearance of unusual sounds accompanying the operation of the device;

- the appearance of foreign impurities in tap water, changes in its color, smell or taste.

To do this you will have to perform the following operations:

- Disconnect the device from the power supply.

- Remove the protective cover.

- Disconnect the contacts of the electrical wires.

- Shut off the cold water supply.

- Use a hose to remove any remaining water from the tank.

- Unscrew the bolts that hold the heating element.

- Remove the heating element and descale it.

- Clean the inside of the drive from dirt and scale particles.

- Rinse the device thoroughly.

- Check the serviceability of the magnesium anode.

- If necessary, replace this element immediately.

- Wait for the cleaned tank to dry completely.

- Reinstall the heating element.

- Reassemble the device.

- Check the reliability of all fastenings.

- Connect the water heater to the power supply.

- Check for grounding.

The heating element should be removed from the tank carefully; the bolts may be too stubborn; sometimes the heating element is difficult to remove due to too much scale.

The heating element is cleaned by mechanical or chemical means, as is the removal of contaminants from the tank. If a large amount of scale is found inside the device, you should consider reviewing the operating mode of the water heater.

This phenomenon is often observed when the device operates at maximum power for a long time. It is recommended to set the maximum heating temperature no higher than 60 degrees to increase the life of the device and reduce the number of breakdowns.

If the body of the heating device receives an electric current, the heating element may be deformed and ruptured, or there may be a breakdown in the control system.

The fork is getting hot

If the plug gets hot, this can be considered normal, since the water heater is a powerful device.

But if the heating is so strong that it scares you, then you need:

- Check the extension cord where the water heater is plugged into. If you see damage or doubt the quality, it is better to replace it.

- Check the outlet. It happens that the plug begins to be pressed loosely against the contacts, so the temperature on the plug rises.

When only the plug and the wire near it heat up, then most likely the reason is poor contact of the wires inside. You need to tighten the terminals. But if the plug cannot be disassembled, then replace it

Usually the water heater does not work and the cord heats because:

- There is not enough wire section. Change to a powerful one.

- The connection points are burnt or there is a hole in the heating element.

Also read: How to fix a multicooker with your own hands: diagnostics at home

To prevent a fire, replace the heater or properly insulate the wiring.

Boiler malfunctions: the most vulnerable parts of the storage tank

After purchasing the device, you should carefully read the technical documentation before installing it. It will reflect the design of the device, the location of its individual parts, instructions for proper installation and operation.

To properly respond to the problem and eliminate it, it is necessary to find the location of the leak and determine the cause.

Possible malfunctions may be related to the following:

- The protective gasket in the housing is worn out

- The malfunction is caused by the operation of the heating element. It needs to be replaced.

- The thermostat and temperature sensor have failed. High quality boilers usually have several redundant devices installed that control each other's operation.

- The leak occurred in the area of connection of the cold water supply and hot water discharge pipes. Most likely the problem arose during the installation stage, due to poor sealing of the joints.

Often, to protect the drive, a safety valve is connected to the drive system. Thanks to this element, the number of device breakdowns is significantly reduced.

Causes of boiler malfunction

There are often problems with the wiring when the boiler does not turn on or off, and also does not heat the water, or, on the contrary, heats continuously. In such a situation, it is necessary, following the instructions when connecting the boiler, to properly plug it into the network and ground it so that current does not pass through the body.

There are cases when, if the water heater is connected incorrectly, water does not flow into the tank. This most often happens because the water from the water supply comes under too high a pressure and this leads either to the rupture of the tank due to water hammer, or the boiler is protected and does not allow water to pass through. It is recommended to install safety valves between the boiler and water pipes.

What to do and what to do if the storage water heater fails? To begin with, you shouldn’t panic, but try to figure out the cause of the breakdown. After finding out the reasons for the failure of the device, you need to understand how to disassemble the boiler - without this step it is impossible to begin repairs, because most of the problems are associated with the inside of the tank. We will describe below how to repair a storage water heater yourself.

Disassembling the water heater

It is recommended to follow one simple rule: if the boiler shows the slightest signs of malfunction, it is better to perform a complete disassembly and a comprehensive inspection. To do this, you need to drain the water through the cold water supply pipe, opening the “hot” tap to suck in air. With proper hydraulic piping of the boiler, this possibility is always provided. Unpack the connection fittings and loosen the anchor nuts to lift the tank up and away from the wall.

Classically shaped water heaters are serviced from the bottom. First you need to remove the protective cover of the control unit by unscrewing several screws and unfastening the latches. The task is quite delicate: not only can some fastening screws be hidden under stickers, a regulator knob or a nameplate, but also the fragile clips are located far from obvious places.

Having separated the tank and the electrical part, we tighten the nuts securing the technical flange. After removing them, you need to put some effort and tear the flange off the neck; it can become completely stuck. The tank must be in an inverted position to prevent any remaining water from leaking onto the floor.

When the flange, along with the devices attached to it, is removed, you will be able to clearly assess the quality of tap water. Scrape off the bulk of the dirt from the functional elements directly into the tank and set it aside for the time being; we’ll return to the heating element and anode a little later.

For stylish and modern tanks, the lower part of the body plays the role of a protective casing. Indication and control panels and a built-in thermometer are auxiliary equipment that is not directly related to operation; if they fail, they are replaced modularly.

How to troubleshoot a water heater?

Now let's look at how to properly fix some problems without resorting to the help of a wizard.

Cleaning the heating element

You can effectively clean the heating element with citric acid. You need to dissolve 50 grams of lemon in one liter of water. There should be enough water to completely cover the heating element. Keep the part in it for several days, and then remove the remaining scale with a coarse brush.

Replacing the heating element

If the water heater does not work and the reason is the heating element, which needs to be changed, then you can try to do it yourself.

To get started, prepare all the necessary tools:

- Pliers.

- Screwdrivers.

- Spanners.

If the water heater does not turn on, the procedure for replacing the heating element is as follows:

- Turn off the water, including the hot tap.

- Drain the water tank.

- Unplug the device from the outlet.

- Next, remove the cover and use a special screwdriver to check if there is voltage at the terminals. If the water heater is hanging on the wall, remove it and lower it to the floor.

- Unscrew the nuts, disconnect the wires, not forgetting to note the order in which they were connected. You can take a photo.

It is important that during the process of replacing the part, no water gets on the contacts. The anode is also often changed along with the heating element. Just in case, check the gaskets between the heating element and the tank. If they are damaged, replace them. Then you can install a new heating element. And before turning it on, be sure to check that there are no leaks.

Replacing the thermostat

If you find out why the water heater is not working and the problem is in the thermostat, then it needs to be replaced.

Also read: How to use a toaster: what it is and what it can do

Replacement procedure:

- Remove the ring near the heating element.

- Remove the sensors and unit.

- Install a new thermostat and ring.

- Assemble the device.

Please note that the water heater cannot be used immediately after changing the part. You need to make sure that cold water is flowing, check for leaks, and then open the hot tap and let out the air. And only then plug the device into the outlet and raise the temperature gradually.

Features of various designs

Before you start repairing a water heater with your own hands, you need to figure out what type of device it is. There are several varieties:

- electric boilers;

- flow-through;

- indirect heating systems;

- geysers.

Electric heaters

This type of boiler is considered the most popular. The design consists of a tank, a thermal insulation layer (polyurethane foam is often used), and an upper casing.

The heating element is located at the bottom of the device. The water is heated to a certain temperature, which is pre-set on the thermostat, the maximum value is +75°C.

If no water is drawn, the device maintains temperature readings by turning the heating element on and off. It is equipped with overheating protection, so when the maximum performance is reached, the device turns off.

The optimal temperature value is +55°C; it is in this operating mode that the structure will last longer and save electricity.

This device is the most common

Hot water is drawn through a tube located at the top of the device. The cold liquid inlet is located at the bottom of the device. The metal tank is protected from corrosion by a special magnesium anode, which has a certain working life. The element must be replaced once or twice a year, depending on the hardness of the water.

Indirect heating systems

Such products do not independently generate thermal energy; water is heated using a coil in which the coolant is located.

Cold water comes from the bottom of the device, hot water comes out from the top. Indirect heating devices can provide large quantities of hot water, which is why they are often installed in large houses. The operating principle is to exchange heat between liquids at different temperatures. In order for the output to be +55°C, heating is carried out to +80°C.

The process takes a lot of time, this feature must be taken into account when choosing a suitable device. Like their electrical counterparts, indirect ones are equipped with a magnesium anode. The structures can be wall-mounted or floor-mounted; in addition, they can be connected to a double-circuit gas boiler. More expensive models are equipped with additional electric heating elements, which reduce heating time as needed.

Gas and flow structures

Gas-powered appliances are only wall-mounted. There is a thermal insulation layer inside the structure. There is a chimney pipe at the top, and a gas burner at the bottom. The latter is a source of heating, in addition, it is helped by the heat circulation of combustion products. An automatic electronic system monitors and extinguishes the gas as needed. The column is equipped with a protective anode.

Gas water heaters produce large amounts of hot water in a short period of time.

Electrical systems carry out heating using heating elements of increased productivity. Despite their small dimensions, the products are high-power, so their scope of use is limited. Hot water flows regularly without interruption for heating.

Gas water heaters have greater efficiency

Construction of gas water heaters

To repair any equipment, you need to know its design features.

For municipal and domestic needs, gas water heaters of 3 main types are used:

- accumulative;

- flow-through;

- combined.

The most popular are gas instantaneous water heaters. Abbreviated as GPVN. GOST defines them as instantaneous water heaters. In such devices, water is heated only when the tap is turned on.

The standard HPGV circuit includes many elements grouped depending on the functions performed: gas path, combustion path, water circuit, etc. For example, burners belong to the gas path, and the heat exchanger belongs to the combustion path

Technical requirements for household instantaneous gas water heaters equipped with atmospheric burners are established by GOST R 51847-2009. Their classification is also given there.

The main causes of leaks and methods for eliminating them

In the process of leaking the device, it is first necessary to establish the source of the negative factor. They can differ significantly in characteristics, so they can be identified quickly and without professional skills. It is best to study the water heater according to the instructions included with the unit. Most models have a warranty card designed for such situations. To avoid aggravating the problem, the device must not be opened.

Hull deformation

The outer shell of the equipment may become deformed after installation. The cause of the unfavorable behavior of the device is considered to be incorrect installation of the unit. Often the consumer forgets to connect the safety valve. The product is located on the main liquid supply between the shut-off valve and the valve element. This part is designed to protect the tank from overfilling; it is during this process that deformation occurs.

Often the consumer forgets to connect the safety valve

If the valve is installed, but water also flows through the supply pipe, this fuse should be removed and a new one installed. Repairs will not take much time and do not require professional knowledge of the device.

Another reason for deformation is the use of low-quality pipes during installation. Powerful hydraulic shock with pressure changes slowly destroys the structure of the product.

Healthy! If the body is deformed, the boiler cannot be repaired; it must be replaced with a new model, while observing the correct connection technology.

Manufacturing defects

The leakage may be from the top of the housing; if in this situation there are no visual deformations of the unit, and the magnesium rod was mounted during connection, then a manufacturing defect of the equipment is possible. During warranty service, it can be returned back to the supplier.

Modern models are designed with designs in which the tank cannot be repaired. The container cannot be welded, because during the welding process, a layer of enamel breaks off, after which corrosion forms, spreading over the entire surface of the device.

Spent heating element

A leak may form under the tank cap, which indicates scale accumulation on the heating element. If this symptom is detected, it is necessary to replace this part with a new one. The purchase of a heating element should be similar to the outdated one; such a part can be purchased at a spare parts store for water heating devices. Before dismantling, you must thoroughly clean the inside of the device with a solution of vinegar and salt. This mixture quickly corrodes salt deposits without damaging the surface of the tank.

If there is scale on the heating element, the element must be replaced. Important! The heating element is replaced together with a special magnesium rod for long-term operation of the water heater

Poor installation of the device

Liquid leakage is possible from under the sealing ring of the heating element. To eliminate this problem, simply tighten the nuts more tightly. In some cases, leakage occurs under the mounting bolts of the heating element. It is impossible to eliminate this unpleasant factor; you will have to purchase a new unit, because the walls of the water heater will begin to warp during the welding process.

Leakage under the heating element mounting bolts requires installation of a new unit

Another reason that occurs quite often is a loose connection to the cold water inlet and hot water outlet pipes. Such signs may appear when installing the device yourself, when low-quality fittings or incorrect materials for seals are used.

Gasket wear

A leak in the inspection hole located in the plastic cover at the bottom of the equipment indicates a loss of elasticity of the rubber gasket on the flange. An accurate determination of this cause can be carried out after turning off the equipment: the lower cap is removed and the problem area is visually examined.

Replacement of the sealing gasket must be carried out strictly in accordance with the boiler model number, so that the product fits tightly to the working parts.

Replacement of the gasket must be carried out in accordance with the boiler model number

Disassembling the Termex boiler

Disassembling a Termex boiler is not difficult if you follow the established instructions. The same sequence of actions is typical for the procedure for dismantling similar devices. Of course, first the device is completely isolated from the flow of electricity. Next, you need to get rid of the presence of water in the tank using a special valve. When this work is completed, you need to unscrew the cap nut.

The following steps are aimed at dismantling the shields made of plastic, as well as removing the fastening screw, which should be located in the center. Sometimes a screw is hidden behind a sticker, so don’t be afraid of its absence; such security seals can also be found when you try to disassemble a Gorenje boiler.

After removing this screw, the bottom cover can be easily removed. Don't be afraid of the internal structure. It is really very complex due to the abundance of all kinds of electrical elements. It is recommended to photograph or otherwise record such a complex interior of the boiler. Do not neglect this advice, since disassembling a water heater is much easier than assembling it, and this close-up photograph or sketched diagram will help complete this time-consuming task.

The following steps involve disabling the control board and thermal protection element. This can be done by unscrewing the fastening screws. In addition, the bracket must be removed. Do not forget about the harmful factors of water, so it is recommended to put these elements in a safe, dry place. Be sure to disconnect the connector connecting the internal control board to the external one.

Both heating elements are attached to the flange using 6 nuts that must be unscrewed. It is recommended to handle electronic storage devices very carefully and dismantle them carefully and slowly. Often they are completely covered with scale. After the entire procedure has been completed, you can proceed to cleaning the device.

Many people try to dismantle the external control panel, but this process is not easy. The offending sticker is heated with a hair dryer and then peeled off. Under the sticker there is a protective strip secured with 5 screws.

By unscrewing these parts, you can remove the panel behind which the external control board is hidden. Assembling this device is not an easy procedure; disassembling it is much easier

It is important not to forget to use the recorded diagram of the assembled structure and carefully carry out installation work

Malfunctions and their possible causes

When operating a water heater, you may encounter various problems.

If the device functions intermittently, it needs repair

Those who are constantly faced with burning out heating elements should consider the only possible cause of equipment malfunction - the deposition of a large amount of lime in the heating tube.

If the boiler of the equipment “does not see” the boiler, that is, does not react to the flame, this can only mean one thing - a malfunction of the electrode.

When the owner of a boiler is concerned about the flashing of the display, he should check whether everything is in order with the thermostat, RCD and electrical cord of the equipment.

Table: the most common causes of boiler malfunctions

| Malfunction | Possible reasons |

| The equipment does not turn on |

|

| Poor or long water heating |

|

| Overheating and sudden shutdown after a few minutes of operation |

|

| Boiler leak |

|

| Boiler check valve stopped working |

|

| The water heater emits current through the water |

|

| Presence of air in the boiler |

|

| There is no water flowing into the equipment |

|

| Rapid waste of hot water in the boiler |

|

| The water heater turns on and off |

|

| The whistle of a gas water heater heating water |

|

| Black tap water |

|

| Bloating of the water heater, which can result in an explosion of the equipment |

|

| The boiler thermostat does not make a click when the temperature changes |

|

| Knocks out the thermal relay |

|

In an extremely dangerous situation, when a pipe breaks off a water heater, a faulty emergency pressure release valve or a broken thermostat should be blamed. In some cases, a pipe breaks off from a boiler due to the fact that both metal and plastic pipes were not used when installing the equipment.

Types of malfunctions and their causes

There are many reasons why boilers fail. Most of them can be fixed on your own. Main problems:

- The device does not heat water. The reason may be a failure of the heating element or the electrical system. If the heating procedure takes longer than usual, this indicates multiple scale that needs to be removed. In addition, due to deposits, the boiler may turn on/off more often.

- Overheating of water is a consequence of a broken thermostat.

- A leak from under the flange indicates damage to the container due to mechanical action or metal corrosion.

- If the device is constantly noisy, there may be a lot of scale on the heating element, or the check valve is broken.

- The display shows an error. Some devices are equipped with an electronic system that may malfunction due to power surges or module failure.

- Lack of hot water supply indicates a breakdown of the heating element or thermostat.

- Dark-colored hot water indicates the presence of corrosion, which can be caused by hard water. If the tank is damaged, you will likely need to purchase a new unit.

- The heater produces an electric current. This situation can happen due to damage to the cable or rupture of the heating element.

- The device does not turn on or off - the reason is burnt out contacts or melted buttons.

- Constant burnout of heating elements is caused by a large amount of scale or improper installation of the device.

- If air appears in the water heater, it means the gaskets are worn out or the check valve is broken.

Replacing the heating element or anode

If the temperature sensor or heating element has burned out, it is time to replace the magnesium anode. First you need to disconnect the device from the power supply, then:

Remove the plastic cover and disconnect the wires. Turn off the cold water supply and disconnect the pipes. Unscrew the mounting screws and remove the protective cover. Remove the temperature sensor and flange. Remove the heating element carefully so as not to damage the rubber gasket. Remove the appliance from the wall, place it in the bathtub, and then run a water hose inside to remove any remaining scale. To clean the heating element, stir 50 g of citric acid in 2 liters of water. Keep the heating element in the resulting solution until the deposits dissolve (10-12 hours). Unscrew the magnesium anode and assess its condition. If one pin remains, replace the part. After cleaning, return the parts to their place. If necessary, install a new temperature sensor. Reassemble the structure in reverse order

Particular attention should be paid to the condition of the rubber gaskets. If they become unusable, it is recommended to replace them with new ones to avoid leaks of the product after assembly. The product must be connected to the electrical network after it is completely filled with water.

Repairing leaks

If water drips from the device, the reason may be worn sealing gaskets or damage to the container. In the latter case, repairing heating tanks does not make sense; the purchase of a new device is required. If the problem is in the rubber seals, you need to replace them with new ones.

During installation of the water heater, specialists install shut-off elements. A check valve is installed at the cold water inlet, which is adjusted during operation of the system.

The safety valve is placed on the cold water supply pipe, following certain recommendations:

- It is forbidden to install shut-off valves between the valve and the boiler.

- For a flexible hose, you need to make a special hole in the sewer pipe.

- To quickly drain water from the device, it is permissible to install a ball valve with a tee.

- A leaking valve may indicate its failure. Complete replacement of components will help correct the situation.

- Another cause of leakage can be excessive water pressure. To prevent this, it is optimal to install a regulator that reduces the readings to normal.