Refrigerator compressor malfunctions do not always manifest themselves in a complete lack of cold. Your appliance may work and cool the space in the freezer and refrigerator compartments, but this does not mean that everything is happening correctly, as the design and operating principle of the refrigeration unit provides. The refrigerator compressor does not work and does not start usually after a fairly long period of overload or abnormal operation.

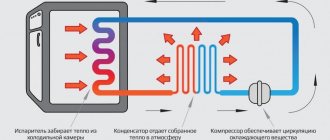

The operation of a refrigerator is primarily related to the circulation of refrigerant in the system, and this process depends on the compressor and its drive. It is customary to call this unit a motor-compressor due to the close functional connection between the electric motor and the compressor itself, which creates excess pressure of freon or other gas circulating in the system at the outputs.

The service technician will diagnose and repair the refrigerator at home, providing a guarantee for the work performed and installed spare parts.

You can call a specialist by phone +7 or through the form on the company’s website. Customer service hours are from 8:00 to 23:00 every day, regardless of holidays and weekends.

Signs of a broken refrigerator compressor

Symptoms of improper operation of the refrigerant circulation system in the refrigerator are, first of all, persistent temperature disturbances. The refrigeration unit operates cyclically, its start and stop depend on the temperature in the working chambers. A system of sensors and relays generates commands to turn the compressor on and off, but if the performance of the cooling unit is insufficient, there will be less than is necessary to turn off the relay.

The causes of the malfunction are sought sequentially - it is necessary to exclude the location of the possible problem from the chain. If the refrigerator compressor works without stopping, then the search area narrows noticeably, but this does not always mean that the breakdown occurred in this particular unit. Excessive cold, when the refrigerator freezes food, may indicate a malfunction in the temperature detection and control circuit of the unit.

It’s worth talking about a malfunction of the compressor itself if you notice characteristic signs of a breakdown:

- strong knocking, noise, vibration and grinding noise when starting and operating the unit;

- obvious overheating of the motor;

- the appearance of an oily puddle under the refrigerator;

- strong engine humming without signs of compressor operation.

These are a kind of signals indicating that there is a problem in the motor-compressor unit. But, since the unit consists of two devices, their malfunctions should be distinguished. This is the task of a specialist who understands how the refrigerator works, what circuits, compressor components and components interact when starting, operating and stopping the device.

Self-diagnosis of the compressor at home

Is it possible to independently identify the main malfunctions of the motor-compressor unit and take measures to eliminate them? The first part of the task can be completed relatively successfully, but a specialist will be required to solve the second part. You can determine that the compressor or electric motor is not working correctly by secondary symptoms, which manifest themselves in a violation of the normal operation of the unit.

- It doesn’t work, the compressor doesn’t turn on at all after the start relay clicks, initiating its start.

- The refrigerator compressor works, but does not freeze - this may indicate a lack of refrigerant in the system or that the mechanical part has become completely worn out; the compressor cannot create pressure in the tubes. In this case, the refrigerator runs non-stop, but does not produce cold.

- The unit either does not cool the chambers at all or overcools them, which may be a sign of a malfunction of the suction valve, temperature sensors and relay responsible for the start command. In a number of refrigerator models, the fault can be localized in the electronic control unit - this applies to refrigerators LG, Liebherr, Bosch, Indesit, Samsung, Gorenje, Sharp, Siemens.

- Ice freezes on the walls of the refrigerator - this phenomenon is possible when the unit’s operating cycle is disrupted or when there is excess refrigerant pressure in the system, which will result in compressor failure.

If you begin to notice that the refrigerator is constantly running, rattling at the bottom, producing too much cold or not providing it, the refrigerator compressor is humming but does not start - call a technician, because the malfunction will not go away on its own. Repair methods depend on the diagnostic results and the model of the refrigerator, since manufacturers may implement the circuit diagram of the unit differently.

What to check first

There may be several reasons why the above-described operational disturbances may occur. If you have at least minimal knowledge of the structure of household appliances, you can identify the breakdown yourself. Professionals advise sticking to the following operating algorithm, but here you need to take into account the type of thermostat.

View » How to repair a refrigerator with your own hands: frequent breakdowns and how to fix them

For devices with a mechanical thermostat, there are 3 possible causes of failure:

- damage to the start relay;

- thermostat failure;

- Compressor malfunction.

The order in which all the listed details should be checked is not very important. You can start with the node that is most accessible. This rule applies to those devices that stand against a wall or in a niche.

The thermostat should be checked after turning off the device. All those parts that may interfere with the inspection are removed. First of all, these are lampshades and covers.

The next stage is connecting the wires to each other (those that go to the contacts). In this case, the ground wire should not be touched (most often it can be recognized by the green winding). The types of thermostats located in the lighting shade also have a blue wire, which is also not used. After completing this work, the device is connected to the mains. If startup occurs, then the problem lies in the thermostat. If there are no changes, then proceed to checking other elements.

If the refrigerator has an electronic thermostat, then it can be classified as a more complex device. To identify faults, it may be necessary to check the entire module electrically. This kind of work should be entrusted to a specialist.

However, some details can be checked on your own. This is the presence of burnt out elements, the absence of damage to the cable, as well as the strength of the contacts. All these manipulations are carried out only after disconnecting the device from the electrical network.

If a breakdown has not been detected and the equipment does not want to start, then you should proceed to checking the start relay.

In this case, the refrigerator will have to be moved away. In addition, some models are equipped with a partition that completely covers the engine compartment - this must be removed. In most models, the relay is located on the left. After opening the lid you can get to the inside. If no external damage is observed, the connections are removed from the contacts and checked using a multimeter. The problem may lie in the compressor winding.

Repair or replace the compressor with a new one?

Replacement of the compressor must be justified - this is a matter of competent diagnostics. You won’t be able to check the compressor with your own hands and replace it with full compliance with the technology, but you can damage the unit’s tubes, release all the refrigerant, or upset the balancing of the unit.

Due to overload, the internal winding of the motor will begin to heat up, which will not withstand this operating mode for a long time. If it is not stopped by the overheating emergency relay, the winding will burn out. It can be changed, although this is a labor-intensive operation.

The experience of service center specialists suggests that repairs involving the replacement of a compressor are more reliable than attempts to restore an old, already worn-out unit. But if its individual parts wear out, for example, rings, sealing gaskets, individual parts of the motor, repair is still possible. Let the technician figure out the reasons for the breakdown, and he will offer you ways to solve the problem.

Prevention of refrigerator motor-compressor malfunctions

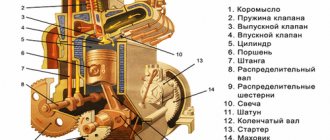

The components of a refrigerator compressor are divided into two groups - electrical (electromagnetic) and mechanical parts that interact during operation of the unit. A starting relay is responsible for the safe start of the system, smoothing out the currents when starting the motor. If the winding of the compressor starting relay has become unusable, then it does not work, does not direct current to the motor windings, and the refrigerator does not start. This breakdown can be prevented by competent operation, careful attention to the device, and timely calling a specialist for repairs.

If you notice a characteristic sign - the refrigerator compressor turns on and immediately turns off, then keep in mind that this will not go away on its own. The cause of the breakdown may be damage to the relay, wear of the bearings leading to jamming of the motor, or an emergency reset when the motor overheats. The most modern models of refrigerators can use an inverter motor control principle, in which a special unit changes the frequency of the current. These are very complex schemes in which the price of a compressor with a motor and an inverter is the highest among analogues. The cost of replacing such a unit is almost two-thirds of the price of the entire refrigerator.

Monitor the sounds and periods of operation of the unit - the linear connection diagram of the compressor motor with the start-protection relay is sensitive to voltage drops in the network, use a voltage stabilizer.

The most common causes of breakdowns

In order to determine the cause of the malfunction, you need to pay close attention to the signs of breakdowns. This will make it possible to independently determine their source and, if possible, eliminate it.

First, you should check whether there is electricity in the network and whether the refrigerator is connected to the outlet. If everything is fine here, but the following situations arise:

- The motor does not start, but the light bulb works, periodic clicks are heard from time to time - these signs may indicate a breakdown of the refrigerator compressor. A clicking sound when starting the refrigerator indicates a broken part and the need to replace it. Audible clicks are produced by the relay that starts the engine and is responsible for its operation;

- The refrigerator starts but immediately turns off. The light is on, but the motor is not running. If there are no clicks from the start relay, then it is most likely that the thermostat responsible for the temperature level in the unit has broken down. The refrigerator control system does not receive confirmation that the temperature in the refrigerator chamber is exceeded, so the system does not start;

- The light in the refrigerator does not work and the motor does not turn on. The cause may be a broken plug or a network fault.

These basic combinations of breakdowns are not always informative; based on them, it is impossible to accurately say about the cause of the breakdown.

To determine the exact location of the breakdown, it is advisable to call a specialist. He has the necessary equipment, tools and experience to accurately identify the breakdown.

Call the master

Refrigerator with one or two compressors

The load on the unit is reduced by a refrigerator design with two compressors, each of which serves its own area - the freezing and refrigerating chambers separately. A two-chamber refrigerator with two compressors can operate “halfway” if one of the main units malfunctions.

How to find out which compressor is installed in the refrigerator? If you do not have a device passport, then pay attention to the controls - in devices with two compressors, all controls are divided into two independent channels. In such refrigerators, the circulation system is divided into two independent circuits, and a refrigerant leak or a malfunction of the suction valve will lead to a loss of performance in only one of the refrigerator chambers.

Pay attention to the presence of the No Frost system - if it is “full”, then your refrigerator has one circulation circuit and one motor-compressor unit.

The refrigerator compressor has failed

The compressor is one of the most important parts of the refrigerator. If the motor does not turn on, then the refrigerator will not work. However, if you have certain knowledge and skills, you can independently determine the cause of the refrigerator compressor malfunction.

To determine why the refrigerator compressor is heating up, you need to know its structure. For most modern household refrigeration appliances, the motor design is not fundamentally different. This unit is a piston electric motor and winding located in a sealed housing and operating on alternating current. To understand the principle of its operation, it is enough to remember the school physics course.

Three conclusions are drawn from the sealed housing in which the motor is located:

- general;

- launcher;

- worker.

These three contacts, in turn, are connected to a relay, which starts the motor. The most modern refrigerator models have more complex electronic digital start systems.

Refrigerator compressor gets hot

A hot refrigerator compressor is a serious reason to contact a service center, since malfunctions in this unit will sooner or later lead to a complete stop of its operation. If the compressor overheats, you will have to look for a gas leak from the system, seal the tubes and connections, and then refill with refrigerant. If the refrigerator compressor gets very hot, it most likely no longer freezes.

Is the compressor overheating moderately or is it overheating? - this is quite difficult to determine, a lot depends on the type of device. For example, in Atlant, Minsk, Biryusa refrigerators, the block temperature may be slightly higher than in Beko, Vestfrost, Haier or Shivaki units.

We remind you that after any operations related to the refrigerator circulation system, when the refrigerant has been released from it, the compressor and lines will need to be evacuated so that there are no air bubbles or plugs left in the system. Only a specialist with special equipment can carry out such work.

Do not repair the refrigerator compressor yourself if you do not have professional knowledge about its structure! Contact our service center, get quality service and guaranteed results!