- Factors influencing climate in production and industry

- Where are industrial humidifiers needed?

- Humidity value

- Operating principles

- Types of industrial humidifiers

- Types of Humidifiers

- Ultrasonic humidifiers

- Automatic humidification system for air fogging in industrial premises

- Block diagram of an automatic high-pressure air humidification/fogging system

Send a quick request Air humidification is an important component of an optimal microclimate not only for humans.

Many technological and manufacturing processes also require maintaining optimal humidity levels to ensure the production of quality products. Air humidification in production areas is becoming increasingly important in many industries. Modern requirements for temperature and humidity conditions lead to the need to use air humidification systems in technological processes.

INTECH-Climate is ready to implement professional solutions for climate control and other engineering equipment. We will carry out a full cycle of turnkey work: design, selection, delivery, installation and maintenance. Call now: +7 (495) 146-65-64

. Submit your application

Factors influencing climate in production and industry:

- during the heating season, the level of air humidification at the enterprise is reduced to 12%-14%, with the norm being 45%-60%;

- when modernizing equipment, air exchange increases, which leads to a decrease in normal air humidity;

- Low air humidity increases the production of defects, leads to damage to raw materials and finished products, which sharply increases the cost of production.

Undoubtedly, creating a favorable climate in industry not only makes it possible to meet the high modern requirements for production premises.

In many industries, maintaining a certain level of humidity becomes one of the factors of production:

- air humidification in printing houses is becoming increasingly important during the printing process;

- in the woodworking and furniture industries, the moisture content in wood is directly related to the temperature and level of humidity in the room;

- in the textile industry, the level of fabric moisture is directly related to increasing the tensile strength of natural fibers and reducing the number of defects;

- Air humidification in agriculture and the tobacco industry also plays an important role.

And most importantly, additional air humidification in the company has a beneficial effect on the well-being of staff.

Air cleaning on an industrial scale

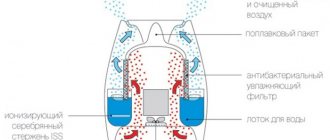

A large container filled with water with installed plastic discs that rotate and moisten. In contact with the air flow coming from the fan, it is moistened and cleaned at the same time. Hence the name “wash”.

There are devices with manual and automatic filling of the tank with water. All devices, as a rule, are equipped with a light indication of the fullness of the tank. The machines have a very important self-cleaning function. At a given time, the industrial air washer will independently drain the contaminated water from the tank through the connected pipeline system, after which it will independently fill it. In general, a completely autonomous humidification system. The device is easy to maintain and operate, and can serve premises with an area of about 300 square meters.

Application of industrial humidifying climate devices

Industrial equipment for increasing indoor humidity is used in:

- Residential premises, office centers and administrative buildings.

- Printing, woodworking and textile enterprises.

- Warehouses and product fermentation workshops.

- Vegetable storage facilities and greenhouse complexes.

- Wine cellars and ripening chambers for sausages and cheeses.

The use of devices in enterprises ensures a significant reduction in dust content in production facilities, a reduction in the spoilage of raw materials in warehouses, a reduction in the static charge of air masses due to its humidification, as well as a reduction in the incidence of respiratory diseases among personnel.

Advice! Industrial climate systems that regulate moisture content in the air are complex and expensive. Their choice is influenced by many factors, and it is best to entrust it to specialists.

Where are industrial humidifiers needed?

The presence of special climatic conditions is necessary in various production areas - problems with dry air are common in many production workshops and warehouses. The rooms that most need humidification of air masses are:

- Base and server stations. Since dry air allows the accumulation of excessive charges of static electricity, this contributes to the creation of threats to the normal work process.

- Museums and libraries. The presence of a stable microclimate will ensure the safety of exhibits and printed publications.

- Printing houses. During the production of printed products, air humidity must be maintained at an optimal level so as not to lead to a decrease in the quality characteristics of the paper.

- Textile industry. Since low air humidity affects the strength characteristics of fabrics, equipping workshops with humidifiers is simply necessary.

- Woodworking industry. Wood, in order to preserve all its qualities, simply needs to be in an optimal humidity environment so that cracks, splits and deformations do not occur.

- Medical and pharmaceutical purposes. An optimal level of humidity should be maintained both in places of production of medical drugs and in places of their storage, and even in places of direct use - in medical institutions.

The variety of applications leads to the availability of many types of industrial air humidifiers.

Choosing a humidification system for the office

Choosing an air humidifier for an office is not easy, since an office, as a rule, is not one separate room, but a whole complex of rooms for various purposes. An office humidification system must provide ease of use, high efficiency, reliable operation and a high degree of automation.

Conventional office humidifiers do not function well and are often dangerous themselves:

- Traditional duct humidifiers humidify the air by blowing it through a moistened cassette or filter; the main disadvantages of such devices are low performance, the need for regular cleaning, the growth of microflora on wet surfaces and their release into the blown air;

- duct ultrasonic humidifiers create a cold mist consisting of tiny particles of water, the key disadvantage is the appearance of a characteristic white coating on furniture when using insufficiently purified water, in addition, there is a possibility of a strong increase in bacterial contamination of the air due to the rapid growth of microflora in a container with water;

- duct steam humidifiers operate on the principle of boiling and the release of hot steam into the air, which leads to very high electricity consumption and an increase in room temperature; in addition, regular descaling or complete replacement of boiling containers is required;

- Household air humidifiers of all types cannot solve the problem of maintaining optimal humidity levels in office spaces due to low performance.

The task of effectively humidifying the air in the office can be handled by professional air humidification systems, which operate on the principle of direct fine spraying of highly purified water directly into the room, have a connection to the water supply, automatic water supply and can be used to create multi-zone air humidification systems in the office.

Humidity value

Air humidity plays an important role in the functioning of the human body. Using climatic devices it is possible to significantly extend the shelf life of vegetables, fruits and other goods. The general atmosphere in the room also affects the quality of the product. Manufacturers must carefully consider the appropriateness of the devices and the functions of the devices they purchase. An industrial steam humidifier has a positive effect on people's well-being. Labor productivity increases and the risk of fatigue decreases. Otherwise, depression may occur and the person may become ill.

Air humidification systems in industrial premises should be used in conjunction with the following units:

- Heating and other types of heating devices.

- Air conditioning in the hot season.

- The room requires long-term air exchange in dry weather.

- An industrial steam humidifier is necessary in certain industries and areas of human activity. The condition is considered mandatory. In the absence of a device, the risk of property damage increases or the quality of the finished product deteriorates.

Industrial air and its components are monitored using special instruments. Thanks to them, it is possible to achieve optimal condition in any room.

An industrial humidifier can have different capacities. The indicator is calculated depending on the area of the room. Its purpose and other parameters are also taken into account.

The role of humidification systems

Air humidifiers help keep food fresh longer and affect the quality characteristics of materials and products. In addition, they have a beneficial effect on a person’s physical condition, allowing them to maintain their performance and health.

Air humidification systems in production are recommended to be used in conjunction with other climate control units responsible for heating, air conditioning and ventilation, when necessary. For some industries, the use of industrial steam humidifiers is mandatory.

In the photo: Industrial air humidification systems in production

The humidifier used in industry plays an important role in production processes. Its performance is calculated based on the area of the room, as well as the tasks it serves to solve.

They monitor the level of humidity in the room using special sensors.

Operating principles

An industrial humidifier is a device whose main purpose is to provide proper humidification of air masses on a large scale. Despite the variety of devices for air humidification in production, they all work based on one of two principles:

- Adiabatic.

- Isothermal.

The action of humidifiers that have an adiabatic operating principle is based on the natural process of evaporation. The air flow absorbs moisture, subsequently converting it into steam. Since this process requires considerable energy consumption, it is accompanied by a decrease in the air temperature in the room.

The action of isothermal humidifiers is based on mixing air with the generated steam. This type of industrial humidifiers does not change the air temperature in the room during operation.

Types of humidifiers

There are different types of humidifiers, all of which have excellent qualities.

Cold

Traditional - air enters them through a water-saturated filter, while all minerals and useful impurities are preserved. This type of humidifier does not heat the air in the apartment, but is based on cold evaporation;

Ultrasonic humidifiers – break up air particles into a cool mist. Whether an ultrasonic humidifier is harmful can be determined by user reviews. It is considered the safest, almost silent and effective device for regulating moisture in the house.

Warm

The operating principle is based on heating air and releasing it in the form of steam. During the heating process, all bacteria are destroyed, and the steam comes out absolutely harmless. These can be used for inhalation. This type of device is perfect for apartments in the cold season, as it warms up the room.

There are several types:

- Desktop - a compact and mobile option that is small in size;

- Console - able to humidify the air throughout the house;

- Central - works without interruption and normalizes the level of humidity throughout the house.

There is also an evaporative type of humidifier, which is suitable for regulating the wet and dry background in a room. This device is aimed at creating healthy and natural hydration, and has no contraindications. It has special mats that generate steam for humidification.

A separate group should include combined devices that not only humidify, but also purify the climate. If we talk about the benefits and harms of the type, then they have a predominant number of positive characteristics.

Types of industrial humidifiers

The most commonly used industrial humidifiers are the following types:

- Sprayers.

- Working on ultrasound.

- Sinks.

Sprayers (also called atomizers) work on the principle of aerosols, spraying drops of moisture at certain time intervals. Devices of this type are equipped with a certain number of sensors, depending on the manufacturer and model. Sensors allow you to regulate the operation of the humidifier based on the specified temperature and humidity parameters of the air.

Classification of systems by pressure level

Typically, industrial-type humidifiers are divided into low- and high-pressure models. The first category is characterized by quick installation and the ability to start a humidification system by connecting a compressor that directs compressed air. These are compact units that provide an average output of 50 l/h. Such equipment in standard modifications is used in small warehouses where it is necessary to maintain optimal humidity levels for storing hygroscopic materials - for example, veneer, paper, etc. For more serious tasks, a high-pressure humidifier is designed. Industrial units of this type provide productivity up to 2,500 l/h. Equipment with such capabilities requires more energy consumption, but is capable of guaranteeing normalization of the air environment in difficult conditions at construction plants, large greenhouses, printing houses, etc.

We recommend reading: How to choose a turbocharged gas boiler: differences between turbo boilers and atmospheric boilers, design and principle of operation, review of the best models

Types of Humidifiers

The operation of all humidifiers is based on one of the methods of processing moisture into gas (isothermal or adiabatic); there are different types of humidifiers. Let's look at how different they are and what their positive and negative aspects are.

Types of humidifiers:

- Heating humidifier. It consists of several elements: a tank for heating water, a heating element, a hose that discharges steam into the air duct, a tube with holes that evenly distributes steam into the air. The resulting steam will be superheated to avoid condensation forming inside the device.

- Infrared humidifier. It is designed in the same way as the previous humidifier, only the heating element here is infrared lamps.

- Electrode humidifier. It produces steam due to the phenomenon of water dissociation, i.e. Voltage is applied to the electrodes (anode and cathode) lowered into the water, an electric current is released, the water heats up and begins to be converted into steam.

- Evaporative humidifier. Evaporation of moisture in it is achieved by blowing air onto water, which, in turn, is applied to the surface intended for this purpose (most often the surface is made of plastic or paper).

- Disintegrating humidifier. Splits water into many small particles under pressure (using a water pump or using compressed air). After this, the resulting fine particles are sprayed into the air stream and evaporate.

- Ultrasonic humidifier. The latest development works as a membrane that vibrates intensely, onto which water falls and is very quickly sprayed into a whole cloud of microparticles. The air that passes through this cloud is instantly saturated with moisture.

When using any type of industrial humidifiers, you should ensure that the water that is to be treated is purified. This is necessary to ensure that the air does not become polluted.

Types of industrial humidification systems

Today, there are several types of systems designed to maintain a certain level of humidity in industrial premises. Among the main ones we can highlight cellular, steam and ultrasonic units, as well as humidifiers with water spray and zone spray.

Cell humidifier

This type of adiabatic humidifier can be used for air humidification tasks both in winter and in summer, helping to relieve air conditioning systems.

Installed as an additional element in ventilation systems or air ducts. The humidifier consists of a cassette with honeycombs, a manifold with nozzles, a pump, and a system for filling and draining water. The case is made of stainless steel.

In the photo: The principle of operation of a cellular humidifier

The principle of operation is based on wetting by irrigating the porous surface of the nozzle with honeycombs through which air passes and comes into contact with the wet surface. Due to this, the process of saturating the air with moisture occurs.

At the same time, as a result of the evaporation of water from the surface of the nozzle with honeycombs, heat is absorbed from the air. Therefore, in winter, the supply air must be reheated - this will avoid heat loss.

A humidifier has both advantages and disadvantages. It is characterized by low energy consumption, which in this type of installation is spent only on pump operation, as well as compact dimensions, a high level of heat transfer and effective air purification from foreign odors, dust and other microparticles that settle on the honeycombs and are then drained into the pan. In addition, it is very easy to maintain and, provided the water quality is good, does not require pre-filtration.

But at the same time, if you do not regularly clean the tray, harmful microorganisms can begin to multiply in it, which are harmful to human health.

Steam humidifier

It belongs to the group of isothermal humidifiers and can be used effectively in the cold season. This steam humidifier is installed on the wall in close proximity to the ventilation system, and the steam distributor is mounted in the air duct.

A steam humidifier consists of elements such as a steam distribution manifold, a system for filling and draining water, a steam cylinder with electrodes and pipes for the passage of steam. The body is made of stainless steel.

In the photo: The principle of operation of a steam humidifier

The water in the steam cylinder is heated to a boil and converted into steam, which is discharged through special tubes into the steam distribution manifold, and from there it enters the supply air from the street and mixes with it.

This type of humidifier does not require reheating the air, as it saturates the air with moisture without changing its temperature. The set humidity levels are maintained by changing the amount of steam into the air duct.

Among the advantages of this model of industrial humidifiers, several are traditionally identified. Thus, they ensure maximum compliance with hygienic standards for air in industrial premises. Due to the absence of the need to reheat the air, they consume less heat. At the same time, they are very reliable, easy to maintain, flexible in control and do not require preliminary water preparation, provided that it is of good quality.

The disadvantages of the system include very high energy consumption compared to other air humidification systems.

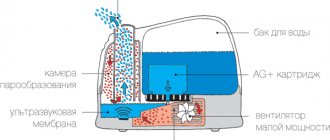

Ultrasonic humidifier

An adiabatic air humidifier, the operation of which is based on the principle of creating a fine “aerosol” cloud using ultrasound. This effect is created through the use of high-frequency and low-voltage alternating current, which supplies a signal to a membrane with water, where it is converted into high-frequency vibrations.

As a result, “fog” is formed. It takes heat from the air and turns into steam, humidifying the air coming from the street.

In the photo: The operating principle of an ultrasonic humidifier

Such a system consists of an external shield with automation, a hydraulic unit and a module for creating an aerosol cloud with vibrating elements.

When operating an ultrasonic humidifier in cold weather, it is necessary to reheat the air, since it actively absorbs heat. The set level of air humidity is maintained with maximum accuracy by the automatic system of the device.

The use of this type of humidifier provides significant savings in water and electricity, since the adiabatic operating principle is used to saturate the air with moisture. Other advantages of the system include high-quality air purification, including from harmful microorganisms, as well as maintaining humidity at the required level with extreme precision.

These are the most optimal air humidifiers for large rooms. The installation is quite expensive compared to other systems, but these costs are fully offset by the efficiency of its operation.

Water spray humidifier

Such humidifiers implement the adiabatic operating principle. They are installed on the wall in close proximity to the ventilation system, and the ramp with spray collectors is mounted in the ventilation air ducts.

It consists of a control panel, including a hydraulic unit and an automation unit, pipelines and manifolds with nozzles through which liquid is sprayed under high pressure created through the use of a piston pump.

In the photo: Operating principle of a water spray humidifier

Due to the function of changing the number of revolutions of the pump and partially turning off the spray collectors, a sufficiently high level of maintaining the set humidity level is achieved.

Just like other adiabatic humidifiers, it requires reheating the air entering the room from the street.

Using a water spray humidifier provides significant energy and water savings and low pressure loss. At the same time, the quality of the treated air is maintained at a high level, preventing the possible appearance of harmful microorganisms.

Among the disadvantages of the system are special requirements for pipelines due to the need to ensure high water pressure, as well as severe wear and tear on the system and the cost of maintenance.

Adiabatic humidifier with zone atomization

This type of humidifier does not belong to duct systems, however, it can also be used to solve problems of air humidification in industrial facilities.

In the photo: The operating principle of an adiabatic type humidifier with zone spraying

The operating principle of such a humidifier is based on the supply of water from the central unit of the system to nozzles located at different points under high pressure. From there, the water, in turn, transforms into a fine mist and is sprayed throughout the room. It can be used as an individual air conditioning and humidification system by setting up humidification in different areas of the room through separate channels.

Ultrasonic humidifiers

These are the most popular and in demand humidifiers today, let's figure out why?

As we said, with the help of ultrasound, something like fog is created, which spreads throughout the room, after which, in a natural way, this fog turns into steam, and this leads to an increase in air humidity.

To ensure that harmful impurities located in the separated water cloud (various salts, microorganisms, etc.) do not remain on furniture, clothing and technical devices, ultrasonic humidifiers are equipped with special filters. Typically, they are made in the form of cartridges that can be replaced when necessary.

In addition, ultrasonic humidifiers are capable of precise control over the humidity level of the entire room. Using an ultrasonic humidifier, you can achieve almost 100% air humidity. They are economical because they have an automatic control program and a capacity of more than 10 liters per day. Only an ultrasonic humidifier can produce warm steam at a low noise level.

But, like any device, industrial air humidifiers have their own characteristics and disadvantages. The disadvantages include the fact that the capacity of an ultrasonic humidifier is limited in size, which is why it needs to be constantly replenished with water. Also, if you do not replace the filter cartridge after 4 months of its operation, salt deposits will appear on various household items surrounding the device.

When choosing ultrasonic humidifiers, remember that their use is absolutely harmless to human health, because the ultrasound in them only causes the membrane to move. No other method except ultrasonic can achieve such frequent vibrations.

When thinking about purchasing an air humidifier, be it industrial or household, ultrasonic or electrode, remember that you cannot skimp on your own health and the health of others. You should choose the most suitable option, the most harmless and effective.

Industrial ultrasonic climate technology

An industrial ultrasonic air humidifier is a device that produces a finely dispersed water aerosol “cold steam” in large volumes, and delivers it through a pipeline system directly to rooms that require an increase in air humidity due to the peculiarities of the technological process.

The design of such climate control equipment is practically no different from household ultrasonic humidifiers. Everything is the same, only on an enlarged scale. Such climate control systems in production are much more profitable to use than spray systems, although they have less power.

The main advantage of such climate technology is the creation of tiny water particles, ranging in size from 1 to 5 microns. This prevents dew from forming on equipment, walls and products. These devices consume significantly less energy than steam ones. The power consumption of ultrasonic devices to produce 1 kg of steam averages from 50 to 100 W, while for steam devices this figure is at the level of 900 W.

Automatic humidification system for air fogging in industrial premises

Designed to automatically maintain a given air humidity in industrial premises.

The principle of operation of the system is to increase the water pressure of the system to a certain value using a high-pressure piston pump. Water under a pressure of 70-200 atm through a high-pressure pipeline is sprayed with special nozzles (nozzles) with particles up to 5 microns in size, i.e. When sprayed, the water turns into a state of saturated steam - fog. Water particles (fog) when sprayed absorb heat from the air and thereby humidify the air and reduce its temperature

The water spray nozzle is made using titanium alloy materials and has a pressure limiting valve. The body is made of copper materials or stainless steel. The nozzles have the following characteristics: atomizing water to sizes of 5...15 microns, no wear, small pressure losses, no water leakage, etc.

The main part of the automatic air humidification installation consists of a high-pressure piston pump, which can operate continuously for 24 hours. The injectors and pump do not have mechanical parts that are easily damaged, and therefore are not damaged at high impurity contents. The pump capacity can range from 5 kg/h to 900 kg/h of water and is continuously adjustable. Water for humidification requires special preparation and is in a sealed closed circuit, which avoids the growth of bacteria in this environment.

The automatic air humidification system consists of a water preparation/filtration station, a water temperature control unit (optional), an incoming water pressure level control, a water supply system under stable pressure, a humidity control unit with an LCD monitor, etc.

Water from an external pipeline is supplied through a filter to the tank, which has a water level control system, a water heating and temperature control system. Next, the purified water enters the high-pressure pump, high-pressure pipeline and nozzles (nozzles), where it is then sprayed in the form of fog. The high pressure pump drives an individual electric motor. An LCD unit control device, a humidity sensor and a high-pressure electromagnetic pump make up the humidity control system.

The number of nozzles of one module of JY high pressure automatic humidifier can be from 40 to 300, the amount of evaporated water is 140~1050 kg/h. The volume of the room for humidification is 1500~60000 m³.

The design of the nozzles (made in Taiwan) uses the principle of protection against backspray; they are manufactured using precision technology and have a long service life.

Depending on the required humidity parameters, you can automatically control humidification in different zones of the room through one or several channels, thereby ensuring individual humidity in a specific zone.

Rating of the best evaporative humidifiers

SABIEL MB215

A high-quality industrial model that will provide moisture in a minimum period of time. The device is distinguished by its versatility, low power consumption and attractive appearance. The equipment will create optimal conditions for storage or work in a minimum period of time.

In addition to humidification, the device is able to cool the air and clean it of various contaminants. The case is made of high-quality materials that will extend its life.

Sold at a price of 165,000 rubles.

SABIEL MB215

Advantages:

- Reliability;

- High quality manufacturing;

- Durability;

- Appearance.

Flaws:

- Not found.

Brune B 250

A professional evaporative humidifier suitable for most businesses. Production and assembly are carried out in Germany, which has a positive effect on the operation of the device. The maximum serviced area is 167 square meters, which is a good result. Consumes only 50 W per hour of operation, which is a small value.

Sold at a price of 90,000 rubles.

Brune B 250

Advantages:

- Assembly for years;

- Price;

- Noise level – 40 dB;

- Long working life.

Flaws:

- Not detected.

Venta LW62 WiFi

A premium model that can provide a good microclimate to almost every enterprise. For convenience, the system is connected to the water supply system, so a person does not need to constantly monitor the water level. In addition, the product is equipped with an excellent touch display that shows the current air condition. If a person is not satisfied with the value, then with one click he can correct the situation.

The average cost is 224,000 rubles.

Venta LW62 WiFi

Advantages:

- There is a wi-fi connection;

- Easy operation;

- Automatic topping up;

- Effective cleaning.

Flaws:

- Not found.