Gas instantaneous water heaters were popular in the last century, but even now they have not lost their relevance. During this time, the devices were improved, however, the basic structure of the gas water heater remained unchanged.

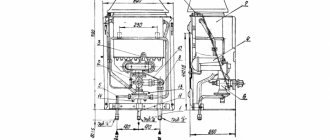

A gas water heater of any model operates on the principle of a flow-through heater. The design of devices from different manufacturers differs only in the presence of additional functions and design. The main components of the flow heater are as follows:

- frame;

- pipes for connecting gas and water;

- chimney;

- water and gas unit;

- heat exchanger;

- the combustion chamber;

- igniter and burner;

- ignition system;

- set of sensors.

Modern models with automatic ignition are equipped with an electronic control unit. Such devices include a column with a turbine. A blower fan has been added to the design of the water heater. A closed-type combustion chamber and a modulation burner are installed, which allows you to smoothly change the flame height.

The basic design of a flow-through gas water heater is the same for all models, so let’s look at the design of a Neva brand water heater.

External column elements

Externally, the gas water heater consists of the following components:

- Steel casing – covers the front and sides of the column. For visual control of combustion, a viewing window is installed on the front panel of the casing. Below the window there are gas and water adjustment handles. The temperature of the outlet liquid is displayed by the LCD display.

- The front panel usually houses the controls.

- At the top there is a chimney pipe.

- The pipes protrude from underneath the casing. A cold water pipeline is connected to one of them to supply cold water to the column. The other is a pipe for discharging heated water. The hot water pipeline is connected to it. The third pipe is used for gas supply. A pipe for connecting the chimney protrudes from under the casing on top.

The back wall serves as the basis of the device, since all working units and the casing are attached to it. The part is made of galvanized steel. On the back wall there are mounting holes for fixing the speaker to the wall with brackets.

Gas water heaters of the Neva and Astra brands are similar in design.

Installation of a gas water heater Neva Transit and other models

The Neva Transit VPG 10e atmospheric boiler does not stop working on batteries. It is distinguished by forced smoke removal, starting at low cold water pressure, and energy-saving forced ignition. The Neva Transit gas water heater (VPG 18) is equipped with a protective device that controls the burner flame, protects against overheating, protects against freezing, overheating, wind surge, and current leakage (in models with forced smoke removal).

The design of the Neva 4511 geyser is similar: ignition also occurs using an electric spark (battery powered), gas and water supply regulators are located on the front panel. The design of the Neva 4511 gas water heater implies the ability to operate on natural and liquefied gas (like the Neva Transit gas water heater). The design of the Neva 4513 geyser allows you to adjust only the flame strength.

The Soviet model of the geyser Neva 3208 is considered to be very simple in design, the frequent reasons for repair of which are breakdowns of the water block. At the same time, structural simplicity ensures reliable operation.

The design and operation of the Neva Lux 5514 water heater is similar to how the Neva Transit VPG 10e gas water heater functions. Ignition occurs using an ignition wick; only the supply force of the gas mixture changes. At the same time, professionals warn against continuous operating mode of the Neva Lux column, as this in any case may affect its productivity.

Column internals

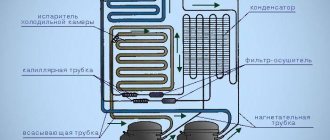

The working components of the gas water heater are hidden under the casing:

- The cold water supply pipe is connected to the water block. This unit has a mechanism with a handle for adjusting the liquid pressure. The water block has a plug with a safety valve. The unit is used to drain water in case of repair or release of excess pressure.

- A gas unit is located next to the water block. Together they form a single system. The gas block is equipped with an adjusting rod with a handle, which can be turned to achieve the optimal water temperature at the outlet of the tap. The gas pipeline connection pipe is connected to the block through a solenoid valve. In the event of a lack of draft, the burner flame goes out and other emergency situations, the shut-off unit shuts off the gas supply. In a normal situation, the valve simply cuts off the gas when the column is turned off.

- The gas block is connected by a pipe to the manifold. Nozzles are installed on the back of it, supplying gas to the burner. A spark plug is connected to the manifold at the front, supplying a spark to the igniter. A burner flame sensor located in the combustion chamber is installed nearby.

- A copper heat exchanger is located above the collector. It consists of a curved pipe with fins. The unit takes the heat from the burning gas and gives it to water. Cold water is supplied to the heat exchanger through the water unit. The outlet of the heating unit is connected to the hot liquid outlet pipe. Overheat protection and temperature control sensors are also installed here. One of them is a thermometer that sends readings to the LCD display.

- Between the combustion chamber and the chimney pipe there is a combustion product exhaust system. In essence, this is another chamber with partitions. The jumpers form channels that direct combustion products into the chimney. There is a chimney draft control sensor inside the chamber. It is connected via an electrical circuit to a sensor that monitors overheating.

- There are two blocks located at the bottom of the water heater body. One of them is for installing batteries. The second is the control unit. From the electronic control module, wires are connected to all geyser sensors.

The external and internal structure of devices of different brands is similar. The design of components and the presence of additional functions may differ.

The Oasis brand geyser has a similar device as the Neva. The difference is the presence of an additional “winter-summer” function. A switch installed on the front panel turns off some of the burners. In summer, this function helps save gas consumption.

Installation of a geyser Oasis

The Chinese manufacturer of water heating equipment Forte Technologie&Produktion supplies Oasis gas water heaters to the domestic market, customer reviews of which are in most cases positive. A chimney is required for installation since the firebox is open. Electric ignition does not stop working on batteries, the compartment with which can be rearranged if condensation from a section of cold water pipe gets on them. Does not stop working on natural and liquefied fuels.

The “Winter-Summer” operating mode option allows you to practically use gas. On the front panel there are flame and temperature controls, a mode switch and a monitor.

Types of burner ignition

A modern instantaneous gas water heater is produced with automatic ignition and a manual pilot ignition system.

For economic reasons, manual ignition is unprofitable. The system consists of a piezoelectric element activated by pressing a button. Pressing a key produces a spark that ignites the igniter. The operation is simple, but the igniter constantly burns throughout the day, consuming gas. It is irrational to turn it off, since you will often have to re-ignite it when you need to consume hot water.

Auto-ignition occurs immediately after opening the hot water tap:

- The first operating principle of electronic ignition is based on batteries. The waiting igniter does not light. When the mixer tap is opened, the pressure in the water supply changes and the sensor gives a signal to the electronic unit to ignite. The energy from the batteries creates a spark. The flame lit on the igniter ignites the burner. Having done its job, the igniter turns off until the next start. Battery ignition does not require much energy. The battery charge lasts for a year.

- The second operating principle of auto-ignition is based on a hydrogen generator. The instantaneous gas water heater is equipped with a turbine instead of batteries. It is driven by the flow of water created in the water supply when the mixer tap is opened. The hydrogenerator produces a spark that ignites the igniter.

Gas water heaters with automatic ignition are beneficial due to lower gas consumption and ease of use.

Types of combustion chambers

Combustion chambers are of two types:

- Manufacturers most often install an open or atmospheric chamber on hot water columns due to the simplicity and low cost of the design. The circulation of air required to maintain combustion enters the chamber naturally.

- Air is pumped into the closed chamber by a fan. Such geysers are called turbocharged.

The creation of forced draft allows the water heater to operate under any conditions. A unit with an open chamber will not ignite if there is no draft. A similar nuisance occurs in bad weather conditions when the wind blows into the chimney.

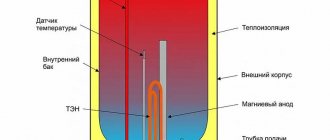

Types of boilers

Experts classify such household appliances according to several criteria:

- Combustion chamber type - open or closed.

- The ignition system is from a piezoelectric element or an electrical home network.

- According to the installation method - on the floor or wall option.

Next, we will take a closer look at all the varieties of the products described above.

With open combustion chamber

A gas water heater with an open draft is equipped with a similar combustion chamber. They work according to the following principle: oxygen, so necessary for stable operation, comes directly from the room where the boiler is located. All combustion products are removed through a chimney, which the user must install in advance.

The cost of this type of water heater is cheaper, but installing a chimney system will cost a pretty penny, which does not appeal to users.

With a closed combustion chamber

A boiler using forced draft is considered by experts to be a more economical option for placement in your home: its closed chamber has a special system for removing combustion products using a powerful pump. This type does not require a separate ventilation system because they do not use air from the room for sustainable combustion - this fact becomes decisive when homeowners choose private buildings.

With piezo element

To start a modern gas water heater, you no longer need matches or a lighter - each product has a special button, when pressed, the unit starts working. Products of this class are equipped with a piezoelectric element, which ignites the gas. Many users consider this an atavism, an outdated option, but these boilers do not lose their popularity due to their low price.

With electric ignition

Some homeowners are keen to purchase the latest model of gas boiler with the latest automatic start system, which works independently when you turn on the tap. Similar models are much more convenient to use and consume blue fuel very economically, and the piezoelectric element can be powered by electric power or Mars-type batteries.

Floor option

Installation of a gas water heater on the floor is carried out due to its rather large dimensions and weight: the product tank can hold 100-300 liters of water. Before purchasing such a massive device, you need to equip a place for it - ideally in a separate room where gas can be easily supplied. Such boilers are bought by owners of private houses to provide the whole family with hot water all year round; it would be problematic to place such a giant in an apartment in a city multi-storey building.

Wall placement

As a rule, with this option, water heaters have a more compact appearance: they are placed in the bathroom above the sink or toilet, which allows users to save space and use it more efficiently. These water heaters are designed for a small volume, so they can be installed in a city apartment of any size - the product will provide you with hot water without taking up much space.

The principle of operation of a flow-through gas device for heating water

The principle of operation of a gas water heater can be briefly described as follows: open the hot water tap - the burner lights up, the water flow stops - the burner goes out. In more detail it happens like this:

- When the tap is opened, water begins to move. The action of the flow triggers the water unit. The mechanism acts on the gas unit. The valve opens and gas is supplied to the burner, where it is ignited by the igniter.

If the pressure in the tap is weak, the column burner will not light.

- The water is heated in a heat exchanger. The liquid circulating through the coil is heated, after which it flows through the pipeline to the mixer.

- During combustion, air enters the chamber naturally through the technological openings of the casing and the viewing window. Exhaust gases escape through the chimney. Natural air circulation creates draft. If it is not there, the sensors give a signal to turn off the burner.

- When the water tap is closed, the water and gas units are activated. The gas supply will stop, followed by the burner going out.

Turbine-type geysers work similarly. The only difference is the method of supplying air inside the closed chamber. The blower fan is responsible for this function. The chimney and discharge pipeline are double-walled pipes. She is taken outside. Combustion products are removed through the internal channel, and clean air is supplied from the street through the external passage.

The principle of operation of the gas water heater

In gas water heaters, which are controlled using an electronic system, several conventional batteries are installed in a special compartment. These batteries power the electronic unit that controls all geyser systems.

The principle of operation of the gas water heater is such that when the hot water tap is opened, a flow is formed in the water main of the water heater. This duct moves the membrane, which is installed in the water unit. This membrane is connected to a rod that opens a mechanical gas valve and turns on a microswitch. The switch energizes the solenoid gas valve, which also opens. Both of these valves provide gas supply to the burner.

The microswitch also supplies voltage to the ignition unit, which, in turn, supplies a spark to the ignition electrode. With the appearance of a spark, the gas in the combustion chamber ignites, and the flame completely engulfs the heat exchanger. The water that passes through the heat exchanger quickly heats up and is supplied to the hot water main through the outlet fitting of the column. When a flame appears in the combustion chamber, the ionization sensor reacts to this flame and the spark stops.

When you close the hot water tap, the flow in the water unit instantly disappears. The membrane of this unit returns to its original position, dragging the rod with it. This rod closes the mechanical gas valve and also disables the microswitch that supplies power to the gas solenoid valve. The gas supply to the burner stops.

Main malfunctions of the flow unit

Among the main malfunctions, the most common is the attenuation of the burner flame. There are 4 common reasons:

- there is no draft in the chimney;

- the sensor has failed;

- the membrane of the water unit is damaged;

- poor water flow due to a clogged filter installed on the inlet pipe.

The user encounters the problem of weak water heating after 1–2 years of using the column. The heat exchanger coil inside becomes overgrown with scale. The harder the water, the faster this happens. They get rid of scale by washing the coil with acid solutions.

In the event of depressurization of connections, the column overheats immediately after the water supply stops. The cause and location of the leak is determined by the droplets formed. Connections are tightened and gaskets are replaced.

Modern geysers are manufactured with a variety of sensors to ensure safe use of the unit. The main disadvantage is the complexity of installation. You will need to cut out a window in the walls for the chimney. Gas service workers have the right to connect the water dispenser only when the owner has completed all permits.