An iron is a fire hazard, and we have already written about this in detail. If used incorrectly, it can burn through the fabric, or even the ironing board, stick to clothes so that you cannot remove it, and over time it becomes covered with soot, which happily melts into your white shirt. Modern manufacturers are struggling with the problem by creating new sole material - the very part with which we iron. In this article, we will try to figure out which sole it is better to choose an iron with, so that things suffer as little as possible.

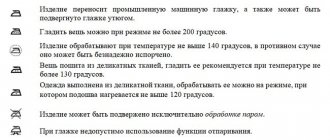

Of course, it would be useful to remind you: follow the ironing recommendations indicated on the product tag, and try to choose the proper temperature setting suitable for the fabric you are ironing.

- Which sole is considered the best?

- Aluminum: cheap and very cheerful

- Stainless steel: strong and inexpensive

- Teflon: does not spoil things until the first scratch

- Ceramics and metal ceramics

- Titan: An Unexplored Innovation

Which iron sole is considered the best?

The requirements for sole material are not so great. A good material glides easily over the fabric (that is, it should be as smooth as possible), durable, heats up evenly and is gentle on clothing, while smoothing out wrinkles.

Modern irons can have the following soles: aluminum, stainless steel, Teflon, ceramics, cermet and titanium. In addition, there are proprietary alloys, such as Eloxal or Sapfir from Braun.

Let's try to consider each of them from the point of view of the requirements that the best sole material should have - and figure out what to take.

Stainless steel

Don't know which soleplate is best to choose an iron with? We advise you to pay attention to stainless steel - a familiar material that has pleasant features:

- Excellent glide;

- Perfectly smoothes out any wrinkles;

- Does not corrode;

- Quite cheap;

- Warms up evenly;

- Does not leave unpleasant marks on things.

There are also small disadvantages:

- Quite impressive weight;

- Long warm up.

We cannot answer unequivocally which soleplate for an iron is considered the best - after all, users are guided by their own wishes and capabilities. However, stainless steel is the best choice among budget options.

Modern manufacturers make irons better by adding sapphire powder, aluminum, chromium and treating the surface with laser - this allows you to get rid of burning and improve strength.

That's not all - let's continue to decide which iron sole is best to choose and buy right now.

Aluminum: cheap and very cheerful

Aluminum is the first sole material for electric irons (before that they were made of coal and cast iron). It is a very light and soft metal that sands well, so aluminum soles are perfectly smooth.

In addition, this metal is almost instantly heated by electricity to the desired temperature. Therefore, many modern inexpensive irons have soles made of this material. For example, this Philips Azur, which we cited as an example:

However, that's where the benefits end. Due to the softness of aluminum, the soleplate is very easy to scratch, and damage reduces the quality of ironing. In addition, it is this metal fabric that can be “smoothed” to a shine that no amount of washing can remove.

By the way, modern manufacturers fight this with the help of a special aluminum treatment - anodizing. If it is indicated that the sole is made using Careeza, Anodilium or Eloxal technologies, then that is what it is. This Braun iron has a patented Eloxal Plus sole:

But rapid heating has too many risks: if you set the temperature incorrectly, your silk blouse will instantly stick. Therefore, in the rating of sole materials for irons, aluminum is most likely at the bottom.

Non-stick iron

Each manufacturer in its line of models necessarily produces irons equipped with soles with non-stick properties. This can be a certain material (titanium, Teflon) or an in-house developed coating that is applied to the surface of the working plane in the form of spraying. For example, Philips has soles made using the T-ionicGlide system, which involves a titanium oxide coating. According to the manufacturer, such a sole not only provides non-stick properties, but is also 25% more scratch resistant and glides better on fabric.

The presence of several removable soles ensures the variability of ironing for various textile items

For housewives who iron often and a lot, we can advise choosing iron models with removable soles. This ensures the choice of the optimal shape and size of the working surface for ironing various items of clothing or home textiles.

Stainless steel: strong and inexpensive

The most popular iron sole material is stainless steel. Strength and resistance to corrosion allow it to be considered one of the most successful materials for the soles of irons, especially steam ones.

In addition, steel smoothes out any wrinkles well without “smoothing”, and also heats up quite quickly. This is again both a plus and a minus - as soon as you forget the iron, sole down, on the ironing board, and behold, the board is already “fried.”

Irons with steel soles are quite heavy - this is not surprising, because steel has never been a light material. Although compact models weigh less than a kilogram, for example, this small Scarlett iron:

How gentle is stainless steel on fabric? Unlike aluminum, if the temperature is violated, it does not stick, but “leaves a burn” on the fabric. Of course, after this the item can also be considered hopelessly damaged, but the damage is still less - at least the iron will remain intact.

Steel

The iron with a steel sole moves smoothly across the fabric, easily smoothing out wrinkles. They can safely iron things with metal fittings without fear that it will leave scratches on the surface of the sole. Even if minor damage appears, your things will not be affected by them. Steel holds heat well and lasts a long time. Irons with steel soles are relatively inexpensive.

The steel sole does not have non-stick properties, and this is its main disadvantage. If carbon deposits form on it, it will be difficult to clean. It is better to prevent the soles from getting dirty: choose the right temperature for your clothes and linen, carefully read the tags with information about caring for the item. However, this rule should be observed regardless of the sole material.

And steel irons are quite heavy. But if you are looking for a small device for travel, choose an iron with a steel sole: it will survive the rigors of a trip much better than ceramic or Teflon.

Teflon: does not spoil things until the first scratch

The only difference between these irons is the coating: a non-stick layer is applied to an aluminum or steel sole. Everyone knows the advantages of Teflon frying pans: it is extremely difficult to burn anything with them when cooking. This also applies to irons, so a Teflon iron can be called gentle on fabric.

The Teflon coating is smooth and glides easily. Teflon on aluminum is less effective at smoothing out wrinkles than on metal. So if you buy a Teflon iron, then on a metal backing, for example, like this:

But where the disadvantages of Teflon are hidden is in its poor resistance to contact with metal parts. By analogy with Teflon frying pans, the sole of a Teflon iron is easily scratched and immediately loses its non-stick properties, and things begin to “burn”. In addition, it is these models that especially “love” to become covered with soot. Fortunately, with most modern models it can be washed off with a regular rag.

But there is good news: Teflon irons include Braun irons with Sapfir coating. Sapfir soles are made of a stainless alloy, onto which a special coating of corundum powder is applied, which is akin to sapphire (sapphire chips are a marketing ploy). Thanks to this, they not only acquire non-stick properties, but also significant resistance to damage. If you are wondering which iron coating is better, then Sapfir is at least close to ideal. For example, this Braun iron has just such a sole:

Iron sole material

The iron will work as efficiently as possible if all the requirements listed above are met. Particular attention should be paid to the materials used to make the soles. Currently, different options are used - from the simplest, budget ones, to high-tech ones designed for expensive models.

Ceramic

Ceramic coatings (Fig. 1) in their pure form are quite rare due to the high fragility of the material. Ceramic is used in conjunction with various admixtures such as chromium or nickel and applied to a steel or aluminum base. This material glides well and does not get stuck in folds. Such products are affordable for many consumers.

Teflon coating

Teflon (Fig. 2) is considered an effective non-stick coating. Previously it was used only in frying pans, but now this material is applied to the soles of irons. Thanks to its smooth coating, the iron glides easily over fabrics, allowing you to smooth out even very old fixed folds. Teflon completely protects against burning and is easy to clean.

Ceramics and metal ceramics

Ceramic or metal-ceramic coating of the sole is quite popular. Customers like ceramic soles based on the same principle as Teflon ones: nothing sticks to ceramics.

Ceramic irons provide easy gliding, while metal-ceramic irons also provide high quality ironing due to a heavier sole. The corresponding models are not very expensive. This Galaxy iron will cost less than a thousand:

However, ceramics is an even more fragile material than Teflon. Both it and metal ceramics require very careful handling. Any damage - for example, dropping an iron - or a scratch quickly leads to peeling of the ceramic coating, and with it, “burns” on the clothes.

In addition, carbon deposits also form on ceramics, and they are so corrosive that removal requires a special cleaner for irons. An exception was invented by Tefal - the Ultragliss Diffusion sole, which can be cleaned with a regular damp cloth:

Which sole is better

Nowadays cast iron is no longer used for the production of irons. Common materials such as aluminum or stainless steel are also becoming a thing of the past. They have many advantages, but their improper use at high temperatures leads to burning of the fabric. Without a special coating, such irons can leave yellow marks and burn holes in things.

Judging by consumer reviews, this technique is no longer popular. People try to choose models that have non-stick properties.

Several varieties are considered the best:

- Nickel plating is applied to aluminum and steel soles. It gives them a golden shine and non-stick properties.

- Ceramic and metal-ceramic heat up evenly and provide easy sliding. They do not burn when ironing synthetics and silk and are easy to clean.

- Teflon coating is considered the best for protection against burning. These irons are lightweight, durable, and do not form carbon deposits even at high temperatures. Teflon is ideal for ironing synthetics and wool, but is easily damaged by metal parts of clothing.

- Titanium soles have high thermal conductivity, glide easily and do not burn. They are strong and durable, resistant to carbon deposits.

Types of non-stick coating