Description of linear refrigerator compressor

When we close the refrigerator door, we hear a characteristic noise made by its operation.

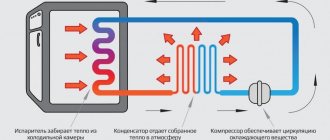

When the compressor starts working, it creates a pressure difference inside the chambers. During operation, it cools the refrigerator compartments, removing heat by compressing and pumping the refrigerant. It transfers heat from the internal chambers to the outside, thereby cooling them. The linear type of equipment itself is a small device that operates using an internal piston driven by electricity. It is not big and takes up little space. The entire mechanism is well hidden under its box. The design provides special holes for fastening to the machine body.

What is a linear refrigerator compressor used for?

A linear compressor, as we noted earlier, creates a pressure difference inside the refrigerator. Depending on the type of equipment, they are divided into several groups:

- screw type;

- piston type;

- rotational;

- centrifugal;

- spiral type.

Each type of equipment has both positive and negative sides. But their purpose is one, to transfer heat from the internal chambers to the outside. It should be noted that heat transfer from the camera may differ depending on the type of camera. It's no secret that the temperature of the freezer is different from the storage chamber, therefore, heat transfer inside it is carried out more intensively.

Principle of operation

The compressor is the main part that makes the freezer and refrigerator compartments work; the operating principle of refrigerators is largely the same.

It creates a difference in pressure between individual parts of the refrigerator cooling system.

The unit compresses the refrigerant and pumps it through the heat exchange system, ensuring the operation of the refrigeration unit.

To understand what a linear compressor is, you need to know what types of these parts there are.

There are several different types of this part depending on the design: screw, spiral, rotary, centrifugal and piston type. Some of them are no longer in use; they have been replaced by linear and inverter compressors. They are simpler designs, the ability of which was created on the basis of modern advanced technologies.

The linear design can be called a middle ground between older installations and the latest inverter models, combining simplicity and performance.

It differs from them in quieter operation and more economical use.

The operating principle of a linear device is quite simple, and it is not difficult to explain how a linear compressor works.

A special sensor is installed that compares the temperature in the refrigerator with the one selected by the user. If the temperature is different, the compressor begins to lower it as quickly as possible. After reaching the indicator, it turns off, continuing the comparison, and, if necessary, turns on again.

View » Is it possible to place a refrigerator next to the radiator with its side wall

A feature of these types of devices is the absence of a motor and crankshaft. They are replaced by a coil with an electromagnetic rod connected to the pump piston.

When an alternating electric current flows through the winding of the coil, it creates a field that sets the rod with the piston in motion. There is a spring at the end of the rod; it returns the rod to its original position after compression. Then the process repeats again.

This process eliminates additional friction of parts due to the electromagnetic field and eliminates the noise of the refrigerator during startup.

How does a linear compressor work on a refrigerator?

We have looked at the operation of the linear model on surfaces, now we will consider in more detail the principle of operation depending on its type. Let's start in order:

- Screw type compressor , for this type of design a screw part is used, which ensures the circulation of refrigerant throughout the entire structure. During operation, the screw helps create high pressure inside the system.

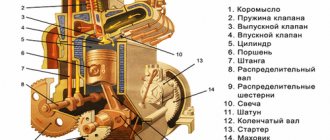

- Electricity is supplied to a special rotor connected to the piston using a special connecting rod. The piston, in the process of translational movements, creates pressure inside the system, which allows for more efficient cooling of the system.

- For rotary type operation, a special rotor is used , which drives an electric motor. When the rotor begins to rotate, the eccentric flows to the inner surface of the cylinder. Where it compresses the refrigerant gas and pushes it out through the release valve.

- Centrifugal-type equipment is a system that operates on the principle of compressing a gaseous medium using a rotor with a shaft. The rotor has special wheels that are located symmetrically to each other. When the wheels with blades rotate, the gas begins to move from the center of the wheels to the edge. Then the gas is compressed, acquiring inertia, and begins further movement through the system. This process helps the refrigerator operate and maintain the optimal temperature.

- When operating spiral-type equipment , the refrigerant is compressed in the space between two spirals. One of them stands, moves forward, and the second rotates around it. It is important to note that the rotation has a non-standard trajectory; when the engine operates, which drives the movable spiral, it will mix along the walls of the first spiral, sliding along the oil film. The point of contact shifts from the edge of the spiral to the center, which facilitates the absorption of the substance. High gas pressure is achieved in the center of the equipment, and then the gas moves through the discharge line throughout the system.

Depending on its type, the principles of operation are slightly different, but despite this, all types of linear compressors are designed for one specific purpose, to regulate the pressure in the refrigerator chambers and maintain the temperature regime.

In addition to the linear type of compressor, there is also an inverter type, which is also very popular; below we will take a closer look at their differences.

Technical characteristics of linear compressors used in refrigeration units

Let's talk in more detail about the linear type of compressor - what it is, what are its technical characteristics and operating principle.

Approximately 80% of household refrigerators operate on linear compressors , which are characterized by low noise levels and energy savings.

The linear installation consists of the following main parts:

- cylinder;

- electromagnetic coil winding;

- piston;

- spring.

The principle of operation of the mechanism:

- Voltage is applied to the winding of the electromagnetic coil.

- The winding creates an electromagnetic field around the piston.

- The piston begins to move under the influence of an electromagnetic field. There is a spring at the end of the piston, which, after compression, returns it to its original position. The process is repeated.

- After the process is completed, the coil turns off and the piston stops.

- After a certain time, the cycle repeats.

A refrigerator with a linear compressor operates in three stages:

- Inclusion. A sensor in the chamber monitors the temperature, and as soon as it exceeds a specified level, the compressor turns on.

- Cooling. The compressor starts circulating refrigerant in the system. The refrigerator compartments are cooled to the set temperature values.

- Shutdown. While the mechanism is operating, the sensor continues to check temperature values. Once the required temperature is reached, the compressor turns off.

The cycle is repeated continuously as long as the refrigeration unit is connected to the mains.

Technical indicators

There are three main technical indicators of the operation of compressor units : operating pressure, cooling capacity and electrical power.

Reference . The value of the indicators varies depending on the model of the refrigerator.

The operating pressure pumped by the compressor is 2-4 atmospheres . This is the level of pressure needed to circulate the refrigerant through the system. For safety, regulators are installed that keep the pressure at the required level, otherwise the refrigerant pipes may rupture.

The cooling capacity indicator is related to electrical power , and depends on the compressor model and the brand of refrigerant.

For example, LG refrigerator models running on R12 freon refrigerant have the following characteristics :

Differences between linear and inverter refrigerator compressors

Unlike linear models, the inverter model does not heavily load the refrigerator systems; it does not need to be turned on to maintain the temperature regime and turned off every time, it simply works stably and smoothly.

This principle of operation loads the electrical network noticeably less and reduces the percentage of possible short circuits to a minimum. When you turn on the equipment, the inverter model quickly reaches the desired temperature and maintains it throughout the entire operating time. It practically does not turn off, but simply reduces the power of operation. It should be noted that power changes occur gradually and smoothly, without loading the system. As a result of such work, large fluctuations in the temperature of the chambers are not observed. Let's break down its advantages:

- due to the fact that there is no need to work at maximum power, the noise level becomes less;

- The service life of such a refrigerator is noticeably longer, due to the fact that there are no periodic switching cycles.

But, it would seem, why have refrigerators with an inverter system not yet squeezed out models with linear compressors? But not everything is so simple; these models also have weaknesses:

- the inverter model is more sensitive to voltage drops;

- the cost of such models is noticeably higher than that of refrigerators with linear compressors.

Features and principle of operation of an inverter compressor in a refrigerator

The inverter compressor is a relatively new invention. The need to use the development was based on the fact that linear structures no longer cope with their functional purpose. The creators tried to take all this into account and correct them in the future generation of equipment.

The compressor is the main component of any refrigerator. It is designed to transport coolant throughout the system. This allows you to maintain the same temperature in the middle of the chamber for a long time.

When starting, the engine power reaches its maximum value. After this, the speed of the motor is restored and adjusted to the desired parameter.

An important principle of operation of an inverter refrigerator compressor is the ability to set the required temperature. To do this, the user independently marks the necessary parameters on the panel.

In accordance with the specified indicators, the motor begins to accelerate and then operates in its own mode. When the maximum indicator is reached, it slows down and begins to produce a minimum of energy.

Additional Information. Modern manufacturers claim that this system is the future of technological development in the world of refrigeration units. The largest companies have long switched to the new system.

It is necessary to consider the main points of the compressor operating technology in a refrigeration unit:

- Using switches, the user sets certain settings. Sensors pick up this signal and transmit it further. It reaches the motor, which causes it to start. The refrigerant activates the compressor, and it begins to accelerate to its maximum value.

- When the specified temperature parameters are reached, the sensor transmits this signal to the motor. After this it slows down significantly. But the rotation does not stop; it occurs with less speed and intensity.

- The coolant begins to move at a lower speed. At the same time, the system continues to cool the chamber as before. Therefore, the temperature does not change until the initial equipment settings are changed.

- If the door is opened, sensors detect the slightest change in temperature and signal that the data is incorrect. The compressor still continues to work. When a signal is received, the number and speed of revolutions increases to restore the mode. That is, the system operates constantly, but with varying intensity depending on external conditions and input signals.

Advantages of refrigerators with linear compressor

A refrigerator with linear equipment is more productive; its electromagnetic circuit can significantly reduce electricity losses during equipment operation.

Important! When operating this equipment, “direct current” circuits are used, which improves the energy saving class. This equipment has a quiet start system, which reduces the noise level and keeps it to a minimum. If we compare environmental indicators, this model is significantly ahead of the inverter model in many respects. And most importantly, its price is noticeably cheaper than its competitor, which is a strong argument in its favor.

Subscribe to our Social networks