Start relay functions

It is necessary for timely turning on and off of the engine. When the compressor reaches the specified speed, the coil is switched off, for which the start-protection relay is responsible. If the power supply increases, the contacts open, which leads to the start of the electric motor.

When the supplied electricity increases, the motor turns off.

Types of relays:

• In tablet form. The material used in production expands when heated. When the temperature reaches maximum values, the contacts open; • Induction model. The flow of current into the electromagnets causes the contacts to close; • Bimetallic type. The supply of electricity causes the plate to bend and the electrical contacts to close.

How to test a refrigerator relay with a multimeter yourself

Almost all home refrigerators have single-phase electric motors that use a starter to start them. When it fails, the compressor will not start. Provided you have the tools and know how to check the refrigerator relay, you can try to fix the problem.

All about the start relay in the refrigerator

The article was written for specialists with relevant competence. Refrigerator diagnostics and repairs should be performed by professionals. Do-it-yourself repairs can be hazardous to health and destructive to equipment.

Disclaimer

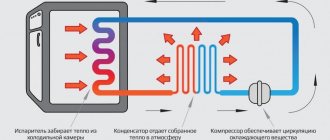

Refrigerator start relay connection diagram

This part is needed to start an asynchronous single-phase compressor motor . There are no difficulties in connecting the relay. The starting and operating windings are connected to the motor stator. The first is involved in starting and starting the compressor, the second keeps the rotor in working condition and continuously supplies alternating current. There is a start-up relay that regulates the supply and turns off the power to the working and starting windings.

Inductive short circuit

Power is supplied to the input of the device: “zero” and “phase”, at the output the latter is divided into 2 lines. One is connected to the starting winding through the starting contact, the other is connected to the working winding of the motor. In the relay, current is supplied to the working winding through a spring, the resistance of which is quite high, then through a connection with a bimetallic jumper.

This element has the property of bending in one direction under the influence of elevated temperature. As soon as the current in the circuit increases significantly, for example, if a short circuit occurs between the turns or the motor jams, the spring that comes into contact with the jumper heats up.

The latter changes shape, after which the contact opens and the compressor turns off.

In order to start the motor in this circuit, a coil , connected in series with the working winding. When the rotor is stationary, voltage is applied, which causes an increase in the current in the coil.

A magnetic field is formed, it attracts the movable core , which in turn closes the starting contact. After the rotor picks up speed, the current in the network decreases and the magnetic field decreases.

The starting contact is opened by a compensating spring or gravity.

Posistor switching

The starter consists of a capacitor and a posistor, which is a type of thermal resistor. In the compressor circuit, the capacitor is installed between the buses of the starting and working windings. This mechanism provides the phase shift necessary for the compressor motor to turn on.

The posistor is connected in series with the starting winding. When starting, its resistance is insignificant; at this moment a large current flows through the winding. When it passes, the posistor heats up and its resistance increases greatly. Because of this, the auxiliary winding is almost completely blocked.

The part cools down after the voltage supply to the compressor stops.

How to test the refrigerator start relay

The refrigerator start relay is checked if:

- after a short period of operation the motor turns off;

- the device does not turn on if there is current and good wires;

- the temperature in the chambers is higher than expected.

You can repair the relay at home if there are problems with the contacts: they are burnt, oxidized, or covered with rust. Before checking the refrigerator start relay for functionality, you need to check whether this device is located correctly.

It must be strictly vertical. In an inclined position, the coil core does not have time to retract within the allotted time. If the relay for turning on the refrigerator compressor is set as it should be, the reason is different.

The part is removed, for the DHR it is positioned with the terminals facing away, LS-08B - with the back surface up, RTK-X and RTP-1 - with the arrow pointing down. Check the condition of the contacts.

Heavily dirty or oxidized ones cannot work normally. If there are burnt marks on the sockets, there is no point in carrying out diagnostics; the relay must be replaced.

The tester checks whether there is contact between the terminals . If not, then sand the ends with sandpaper. The plate is lifted to inspect the guide rod. If there is rust, treat with a special solution.

Signs of a broken compressor relay

The following signs indicate the need for repairs: 1. Inoperability of the compressor, i.e. it won't start. This “symptom” also occurs when there is a refrigerant leak; 2. The motor turns on for a short time, a maximum of 10 minutes, after which it turns off. Frequent clicking sounds are also heard; 3. The electric motor runs without interruption, and the user-specified temperature has been reached in both chambers of the refrigeration unit.

Sequence of work to replace the relay

- turning off the current supply;

- unscrew the hose located at the back of the refrigerator;

- remove the back cover by unscrewing the screws;

- remove the relay clamps using pliers;

- unscrew the relay from the compressor;

- disconnect the wiring from the relay;

- install the new relay by performing all the steps in reverse order;

It is not always necessary to change the relay for repairs. Sometimes the contacts simply oxidize and you just need to clean them.

Making repairs yourself is not that difficult. You just need to understand a little about the structure of the refrigerator. This can significantly reduce costs. And yet, if you have doubts about your abilities, it is safer to contact a household appliance repair shop.

Repair of refrigerator start-protection relay

A specialist performs diagnostics of refrigeration equipment. If there are traces of melting or burning of wires/connectors, a decision is usually made to replace the compressor start relay.

The quality of knot fixation must be checked. If the fastening is loose, it is tightened. If individual fastening elements break, they are replaced with new parts. Contacts are also cleaned and clamped. Upon completion of the repair, the technician conducts a comprehensive inspection of the refrigerator.

SUBMIT A REQUEST FOR REPAIRS

Reasons for failure of the refrigerator relay

It is better not to try to repair components such as the motor-compressor and evaporator yourself. If you are good with electrical engineering, you can try to save money and time on a trip to the service center and replace the refrigerator start protection relay yourself. A relay is a fairly simple device, and there are few reasons for its failure:

- Damage (burnout) of the heating winding

- The moving group of contacts is jammed. In this case, the contacts do not complete the circuit. Or, conversely, don't open it.

- Loss of flexibility of the bimetallic sheet.

Externally, the device malfunction appears as follows:

- The engine runs for a while, usually no more than 10 minutes, and then stops.

- The compressor motor does not start.

- The engine starts but does not turn off even if the set temperature in the freezer and refrigerator compartments has already been reached.

To determine that it is the relay that is faulty, it is recommended to disconnect the terminals from the relay and connect them directly to the engine. If it worked, the problem was in the relay. Another diagnostic method is to connect a known faulty device. If the engine was working normally, with periodic shutdowns after 10-20 minutes, you can simply leave the faulty device in its place. The cost of parts for the most popular brands is in the range of 500-1000 rubles. Similar symptoms are observed in the case of a refrigerant leak, which makes diagnosis difficult. Before you start removing the device from the refrigerator, there are a few more things to check.

- The device is loose. In this case, the moving contact groups may jam. In this case, the engine begins to vibrate. Fasteners need to be tightened or replaced.

- Traces of burnt or melted wires and connectors are visible. This device is an absolute replacement.

- Connectors are loose. The pins must be cleaned and tightened.

If self-diagnosis and repair fail to resolve the malfunction, do not attempt to disassemble the refrigerator components, especially the motor-compressor. It is better to contact a service center.

Problems with contacts

There are two known causes of the malfunction in question. This is the absence of current in the circuit on apparently closed contacts, and their sticking together due to the loss of flexibility of the plates. The first case is typical for a situation where the contact heels are heavily oxidized. This problem can be solved by sanding them with sandpaper. Another reason is the deformation of the pressure plate itself. In this case, it will be necessary to restore its shape to ensure normal clamping and contact. A more complex fault is pin pin jam, which occurs when current flows through the coil and does not exit when turned off. To resolve this problem, you need to clean the switching unit controls.

Vibration during operation

If the device is noisy, you should first rule out any minor causes of the “sound effect.” If the self-diagnosis does not produce results, you must call a service center technician to repair the Atlant refrigerator. Noise from household appliances. Possible causes of excessive noise:

- operation of the unit at maximum power - if the thermostat is set to the maximum value, the load on the motor-compressor increases;

- sudden voltage fluctuations.

- Start-up - during the first week of operation, the device is noisier than usual;

- The refrigerator cabinet is located very close to the walls and furniture - due to the vibration of the motor, neighboring elements rumble;

A more serious cause of hum is damage to the electric motor. Possible wear of rings and piston. Rattling and vibration. Rattling and slight shaking can be caused by an uneven floor or improper placement of dishes inside the refrigerator. The motor-compressor may also rattle if the shock absorber mounts are loose. To restore silent operation, simply tighten the screws. Sometimes the lights on the back of the device make noise. They cannot be moved, but you can place a spacer under them to reduce rattling. A possible reason for the rattling noise in a new refrigerator is that the shipping brackets for the electric motor have not been removed. If the measures taken do not help resolve the problem, it is better to invite a technician from the nearest service center to diagnose. A metallic knocking sound when the refrigerator compressor turns on/off may indicate that it is damaged and requires replacement. Creak and crackle. These sounds may indicate that: When the temperature in the kitchen changes, the plastic walls of the compartment may creak slightly - this is not critical and does not require elimination. A characteristic creaking noise can be observed if the refrigerator is installed incorrectly. The refrigerator hisses and whistles. These sounds are usually caused by clogged capillary tubes or debris on the fan blades. A faulty compressor also makes similar sounds. Any problem requires the help of a technical specialist. Brief gurgling and whining noises are sometimes caused by strong movement of the refrigerant.