Quite often, the size of a stationary freezer does not make it possible to accommodate all the necessary products that require low temperatures for storage. To solve this problem, the easiest way is to buy a ready-made freezer, but you need to remember that the price of such a product will be quite high.

The best way out of this situation would be to make your own freezer. All you need is an old refrigerator, effort and a little time.

What does the equipment consist of?

To understand how to make a cooling chamber yourself, it is important to first understand what such equipment consists of. This will make it possible to meaningfully approach the solution of the task, not waste your time and avoid making mistakes. Also, understanding the structure of such an installation will make it possible to further improve it.

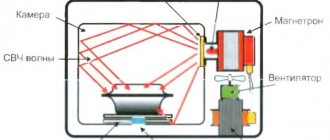

The cooling chamber includes the following elements:

- Capacitor.

- A tube.

- Directly the refrigerator itself.

- Evaporator.

- A compressor that moves refrigerant through the pipes.

- Thermostat. It maintains the required temperature level inside the equipment. It is also the thermoregulatory system that periodically turns the compressor off and on.

Moreover, new refrigerators may be equipped with filters, dehumidifiers and devices for automatic temperature control and regulation. This allows you to maintain stable operation of the device and avoid problems.

Worth knowing! You can store a ready-made homemade freezer in different rooms, but it is best to place it in a dry basement with electricity.

What materials can a freezer be made from?

Before you start creating your own project, you need to study the basic principles of operation of a freezing unit. This will allow you to meaningfully approach the task at hand and, if necessary, improve the equipment you assembled yourself.

The freezer, which is manufactured at home, consists of the following elements:

- compressor;

- evaporator;

- cooling chamber;

- thermostat;

- capacitor;

- a tube.

Freezer elements

How the design works

All of the above-described elements of the freezer are connected to each other by tubes and form a kind of closed system. It is through this that a substance circulates during operation of the device, which freezes at sub-zero temperatures.

A fairly large role in such a process is played by the refrigerant pressure inside the cavity of the tubes. Thus, the lower the pressure, the lower the “boiling” temperature will be.

When the freezer is constantly running, steam from the evaporator enters the condenser. There it is cooled by air and converted back into liquid. Large freezers also use fans that greatly reduce the overall temperature of the device's radiator.

Today, modern automation systems make it possible to carry out the process of freezing and defrosting products without human intervention. It is quite easy to achieve this level even with a homemade unit. To do this, you just need to strictly follow the instructions presented below.

Remember! When purchasing new refrigerator parts, it is better to make a list in advance. If a person does not know much about what exactly he needs to purchase, it is better to additionally consult with a specialist so as not to buy too much.

What can a freezing unit be made from?

Experts identify the following simplest and at the same time effective ways to create a freezer yourself:

- from the basement or cellar;

- from premises, empty containers;

- from an unwanted old refrigerator.

To implement such projects, you will certainly need different materials and tools. According to reviews, it is easiest and most profitable to convert an old refrigerator into a freezer, since other product options will require the additional purchase of new cooling systems.

The duration of such work will largely depend on how well the person understands the structure of refrigerators. Thus, some may need two weeks or more to make a camera, while others will be able to cope with this task in just a couple of days.

The performance of the finished device will depend on the following factors:

- strict adherence to instructions (step-by-step execution of tasks);

- the original condition of the old refrigerator and its cooling system;

- the quality of new built-in elements and their correct installation (following the required algorithm of actions, features of the new cooling system).

How to disassemble a refrigerator

The first thing you need to take care of when disassembling an old refrigerator is safety. For this reason, before starting work, you should disconnect the device from the electrical supply and only then get down to business.

The general scheme for remodeling the camera includes the following steps:

- Dismantling an old refrigerator. No details need to be thrown away just yet, even if at first glance they seem unnecessary. Most likely, these are the elements you will need when assembling a new camera.

- Removing the evaporator.

- Fixing the evaporator.

- Installing a new temperature sensor.

- Functionality check.

Remember! You need to check how well the converted camera works gradually.

It would be unwise to immediately load the device to the top with products, because it may not work properly, as a result of which everything that was frozen will spoil. In such a case, it is recommended to place only a couple of foods or just bottled water in the chamber. By the level of its freezing, you can determine how well the freezer is working.

You should also know that all refrigerator models are disassembled differently. This is due to the structural features of the devices, as well as the types of installed cooling systems.

If the equipment being converted is inoperable, then when working with it you should handle the tubes very carefully, avoiding their kinks. It is better to release the refrigerant altogether and refill it after reinstalling the system. Of course, this will complicate the process somewhat, but getting a new camera to work is often the only way to do it.

In some cases, a non-working camera requires a preliminary search for the cause of the malfunction. It may also happen that repairing and further reworking the device will simply be pointless.

Important! It should be understood that homemade designs that were made from old refrigerators will require more energy than their new store-bought counterparts. This is justified by the fact that they have lower efficiency.

Freezer device

Before you begin assembling the freezer, you need to understand its structure. Without this knowledge, you will not be able to assemble your freezer correctly because you will have no idea what parts are required for it to work correctly.

So, the freezer includes:

- refrigeration chamber;

- capacitor;

- evaporator;

- compressor;

- suction tube;

- thermostat.

Also, modern freezers are equipped with filters, dehumidifiers and devices for monitoring and regulating temperature conditions.

Step-by-step instruction

If you have an old refrigerator at home that leaks all the time, then this is not a reason to throw it away. It would make a great freezer. To do this, do the following (analysis of the chamber using the example of the Nord refrigerator):

- Remove the device cover.

- Remove the thermostat.

- Release the refrigerant (if it is still there) through the tube.

- Using a grinder, cut the freezer 5 cm higher from the refrigerator compartment. If the evaporator of the device is in working condition, then it can be safely used. To do this, one side should be mounted with a capillary tube under a pressure of 15 atm. Connect the other side to a copper tube with a length of 1.5 m and a diameter of 6 mm.

- Make two holes in the freezer. The first with a diameter of 8 mm for the suction tube. The second is for a thermostat tube with a diameter of 3 mm.

- Install the evaporator into the chamber and thread the suction tube into the hole.

- Mount the thermostat behind the device and insert its tube into the hole. Secure to the evaporator from below using two clamps.

- Secure the evaporator itself with stainless steel screws. In this case, you need to be careful not to get the screw into the tube, otherwise it will be damaged.

- Bend the suction tube down towards the compressor and put insulation on it with a diameter of 10 mm.

- Fill the finished holes with silicone.

- Attach a capacitor behind the device.

- Install the entire refrigeration system and charge it with refrigerant.

- Install the electrical wiring (one wire for powering the network on the start-up protection field, and the second on the start-up protection relay).

- Place the cover on the camera.

- Insert standard shelves.

In the finished device, the temperature should normally be minus 18–25 degrees.

Another popular refrigerator for its transformation into a freezer is the Snige. It has a simple design, so it does not cause problems for craftsmen. The scheme for converting it into a chamber is the same as that of the Nord refrigerator.

Interesting! Many people ask what else can be made from an old refrigerator. In fact, you can use it to build a mini-cellar for storing fruit, a smokehouse, or a cabinet for storing small items. That is why, before throwing away your old refrigerator, you should think about whether it will be useful for any other purposes. The flight of imagination is unlimited.

How to assemble a camera from an old refrigerator?

If an old two-compartment refrigerator is collecting dust somewhere in the garage and is no longer usable, you can put it to use and turn it into a freezer. To do this, you will need to disassemble the equipment, dismantle the old evaporator, install a new one, replace the temperature sensor and check the chest freezer for functionality.

We share step-by-step instructions for converting an old refrigerator into a freezer container:

- First of all, remove the cover of the old device.

- Then remove the thermostat.

- If there is still refrigerant in the refrigerator unit, release it through the tube.

- Then remove the old evaporator and cut off the top of the refrigerator 5-10 centimeters above the freezer.

- If the old evaporator is in working order, it can be used for the freezer. To do this, we connect one side of it to a capillary tube, and the other to a copper tube.

- Then we make two holes in the freezer - one for the suction tube, and the second for the thermostat.

- Now we install the evaporator. It needs to be placed in a chamber, we insert a suction tube into one hole, and a thermostat into the second (we attach it to the evaporator using clamps).

- Next, we bend the suction tube to the compressor and put insulation on it.

- Fill the finished holes with silicone.

- Then we install a condenser behind the freezer.

- Next, install the refrigeration unit, fill it with refrigerant and install the electrical wiring.

- Finally, replace the lid of the device and check the operation of the freezer.

Reference! When checking your freezer, pay attention to the temperature inside it. In a normally operating device, it should be maintained at a level of -18 to -25 degrees Celsius.

Recommendations for using and setting up the camera

In order for a homemade freezer to work smoothly and not cause trouble, it is important to adhere to the following recommendations from specialists for using this device:

- Set the modes correctly. According to the standard, the chambers have a freezing mode and a storage mode. The first should be used for quick freezing of fresh vegetables, meat, fish, various semi-finished products and vegetables. The second mode must be installed after a day.

- Regulate the temperature. This can be done using a special regulator (usually they have a scale from 1 to 7). After setting the regulator in the desired position, the temperature in the chamber will be maintained automatically.

- Select the temperature regime based on the required storage conditions of the products. The temperature of the camera is also affected by the location where it is installed and the general temperature in the room.

- Properly arrange food in the freezer. Thus, the upper compartments are intended for primary freezing of products, and the lower ones are for storing already frozen products.

- Do not open the chamber door too often, as this may disrupt the temperature of the device.

- Regularly defrost the freezer and clean out the cabinets. This will keep it clean and prevent unpleasant odors.

- Do not place products in the chamber whose quality or expiration date you are not sure of. It is also important to label the name and date of freezing for each product, especially if it is meat or fish.

- Properly remove odor. Some cameras that are used for a long time may develop a bad odor. To eliminate it, it is best to wash the inside of the camera with a regular baking soda solution. The refrigerator itself must be disconnected from the network.

- Install an audible alarm. It will operate if the door is open for 30 seconds. This will allow you to maintain optimal temperature conditions for storing food.

- The camera should be turned on at least 24 hours before placing food. It should reach the desired temperature. Otherwise, the freezing may be of poor quality, which will negatively affect the shelf life of semi-finished products.

Moreover, it is important to check the power supply in advance. If there are problems with this (insufficient electricity, frequent power outages), then this can cause the camera to be “knocked out” of power and the wires to burn out.

Let's make the refrigerator body

Avoid using polyurethane foam: you will need special clothing. Buy a can of insulation (spray foam). There will be no need to look for a respirator. Polyurethane foam expands and gains volume relatively slowly. More airy material means better insulation.

To insulate with polyurethane foam, you will need to make a box with double walls and a similar door (lid). Not an easy task, since you need to fill the bottom with insulator. Decide for yourself how best to proceed; we recommend leaving technological holes in hard-to-reach places. After the polyurethane foam has hardened, cut off excess and patch unnecessary holes. The problem of insulation is being solved. Avoid contact of the polymer with the product.

Popular articles Updating old bracelets

DIY refrigerator

Polyurethane foam will seal the cracks where the Peltier elements enter the chamber. Ideal insulation, which is difficult to achieve in any other way. Peltier elements are expensive. The refrigerator should be smaller, better insulated

We suggest paying attention to Penofol with double-sided foil. Availability of material, check with the manufacturer or dealers for details, take it with double-sided foil, ignoring the complexity of installation

The material can be glued, avoid nailing, it will create heat leakage bridges.

We finish the outside of the box with polyurethane foam, eliminating the slightest cracks. Peltier elements do not fit inside the compartment. They are fenced off with a gasket of food-grade aluminum. It will prevent contact of food with polyurethane foam, as in a factory refrigerator. We recommend using a regular, passive thermostat that measures pressure. You can buy it on the market at the request “refrigerator thermostat”, remove it from old equipment. It looks like a small metal cube with a long thin tube, the end of which must be attached to the cold side of the Peltier element.

Select the position of the sensitive area of the sensor so that the modes are maintained. The advantage is that such a device turns off the power at the right moment and is itself configurable. A purely passive element, as mentioned above, consisting only of a membrane and a contact group. The design is sealed, do not worry too much about the device. The whole story is about how to make a refrigerator with your own hands. It is better to store food on shelves, with the insides lined with food-grade aluminum. Avoid plastic.

Don't forget the grounding; it won't hurt to install thermal fuses in the right places. The story showing how to make a refrigerator with your own hands is over. We hope the text was useful. We believe that every reader will be able to make a refrigerator with their own hands.

What not to do

To avoid damaging the device, do not do the following:

- store glass containers that contain freezing liquids in the chamber;

- place products close to the installed temperature sensor, which is located on the back wall of the chamber;

- use metal objects to remove snow deposits;

- defrost the device without using a special spatula (melt water can cause leakage and lead to breakdown).