The heart of any sewing machine is the shuttle device. The ease of working with equipment, its reliability and performance depend on it. The design of the shuttles differs from each other (vertical, horizontal, pendulum), they have their pros and cons, which will be discussed in the article. The choice of this element determines what the sewing machine will be capable of.

Description of the shuttle device

In order for the element to remain operational, it needs care

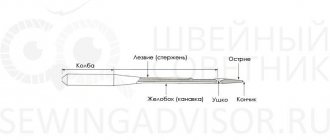

The hook used for a sewing machine is an element that directly interacts with the needle. And the more “accurate” it is, the better the quality of the sewing work. A properly functioning device will not cause skipped stitches, broken threads (upper, lower) or looping.

In order for the element to remain operational, it needs care. For example, if scratches, mechanical damage, rust, dust or oily stains appear on the surface of the shuttle, all this will affect the ability of the thread to slide. This causes the top buckle to be pulled out, causing weak stitch tension.

In stores that deal with sewing equipment and related accessories, you can find a variety of equipment. The shuttles produced differ in design and functions assigned to them.

Features of the horizontal shuttle

When determining which type of shuttle is best for a sewing machine, you should take a closer look at the features of horizontal shuttles. Such parts are almost always made of durable plastic. This feature determines the operating rules of the machine.

The manufacturer's instructions clearly indicate what types of thread can be used in the equipment. If the manufacturer's recommendations are violated, the shuttle will quickly become unusable, and in this case it will be possible to configure its operation. A worn-out shuttle causes skipping, looping and a number of other problems. In this case, the part requires replacement.

The cost of this type of mechanism is low. Therefore, when purchasing a sewing machine with a horizontal shuttle, it is better to buy another one (or a couple) in reserve.

Principle of operation

The rotation speed can reach 900 rpm, which depends on the equipment settings

The design of the sewing equipment determines what type of shuttle mechanism it contains. Traditional - vertical, which is a cap with a bobbin.

It works like this: a bobbin with thread is fixed in a groove, when the sewing machine starts, the shuttle moves vertically and horizontally, while pulling the thread along with it. Here the lever and the body of the sewing equipment are rigidly connected, so the mechanism is characterized by high reliability.

A vertical type rotary shuttle works differently: the bobbin case, together with the bobbin, moves around its axis.

The rotation speed can reach 900 rpm, which depends on the equipment settings. The good thing about the device is that it can be quickly set up and at the same time has a convenient location to the needle shaft.

The most widespread is the horizontal mechanism, which forms a stitch only after two full revolutions of the shuttle.

There is a built-in bobbin case, so the user is able to quickly “charge” the consumable by simply inserting a spool of thread into the case. The parts of the horizontal device are automatically lubricated, and it is characterized by its quiet, silent operation.

Features of the vertical shuttle

Before purchasing sewing equipment, you need to decide which sewing hook is best. It is recommended to consider a vertical shuttle as one of the preferred options. It is installed in expensive machines such as Brother PR 655, VR, Bernina 880, as well as Bernina 5th and 7th series.

The vertical shuttle moves in a circle and is the most durable type, which can work almost without failure.

In addition to a long service life, machines equipped with a vertical shuttle are characterized by high operating speed. They exclude the possibility of looping or thread breakage, provided that the equipment was initially put into operation correctly. If deviations occur in the operation of this type of shuttle, it is easy to adjust.

Device types

There are several types of shuttle mechanisms, each of which is good for working with certain tissues. Knowing which shuttle is installed in the equipment will make it easier to use. This is also a key parameter by which sewing equipment is selected.

Horizontal

Horizontal shuttle

Found in most sewing machines sold at an average price. The device is equipped with a rotation mechanism - two full turns form a stitch. There is no separate bobbin case; the bobbin sits directly in the device, which makes threading the lower thread easier.

Advantages:

- the plate with the needle is hidden by a transparent window through which the color of the thread wound over the bobbin and its quantity are visible (it is more convenient for the user to determine when it needs to be replaced);

- it works quietly, looks and is designed simply (no stitches are skipped, needles and threads do not get tangled);

- The machine does not require oil lubrication.

On many sewing machines with a horizontal shuttle, you can adjust the stitches: width - up to 7 mm, length - up to 4.5 mm.

Flaws:

- It is difficult to adjust the bobbin thread. The nut is located on the device itself, which is plastic, so it only works with standard threads;

- The mechanism cannot be modified (only replaced with a new one).

Brother sewing equipment is equipped with a horizontal shuttle mechanism.

Vertical

Vertical shuttle

The classic type of shuttle mechanism (pictured), which was installed in old Soviet cars. Such a shuttle is still found today - in almost all cheap models, as it is convenient, simple and reliable.

It works like this: a bobbin with thread, installed in a cap, is placed in a groove and, when you press the lever, it swings like a pendulum, up and down, drawing the thread with it. The lever is rigidly connected to the body of the equipment, which reduces the likelihood of the shuttle breaking. In this case, the machine can be threaded with any thread, the mechanism will not jam.

The vertical device has two disadvantages: it is noisy and imposes restrictions on the sewing speed. The swinging vertical mechanism is found in machines from Brother and Janome.

The advantage of working with such a shuttle is that the machine is capable of performing many operations, and serious skills are not required.

The swinging vertical mechanism is the choice of creative people who, in addition to sewing, do quilting, embroidery, or create decorations.

Rocking

Swing shuttle

This is a type of mechanism that also uses a bobbin case with a bobbin. The peculiarity of the system is that it rotates around its axis, which is why its second name is “rotational”. The advantage of the solution is the rotation speed, which reaches 1000 rpm. There are other advantages:

- easy to set up and can be fixed “on the needle” without much difficulty. During sewing, stitches are not skipped, the thread does not break, or get tangled. A good machine with a swinging shuttle can work with almost any type of fabric;

- reliability, quiet operation;

- increasing the technical capabilities of the machine: increasing the stitch width to 9 mm, length – up to 6 mm.

Machines with a rotary mechanism are chosen by those who prefer to sew a lot, with virtually no interruptions during breaks.

Varieties

There are three types of shuttles: swinging, vertical and horizontal. In varieties of industrial equipment, a vertical shuttle is installed.

Modern sewing machines are mostly equipped with a horizontal hook. The part has a special design. The spool in such a machine is installed on top and placed in a shuttle under the cover.

It is believed that the most common is the swinging type of shuttle. It is installed in such well-known equipment models as Chaika, Veritas, Bernina. Having become more familiar with the characteristics of each type of part, you can accurately determine for yourself which type of shuttle is preferable to choose in a sewing machine. Expert advice will also help you figure out which one is better.

Which type is better to choose

Rotating vertical shuttle

When buying a sewing machine, it is worth understanding that the shuttle installed in it depends on its cost:

- economy class appliances – vertical;

- middle class, cars with functions – horizontal;

- industrial or professional models used for intensive work - swinging.

If you read the reviews, users praise the type of shuttle mechanism they are used to working with. To purchase a suitable machine, take into account your own specialization:

- pendulum, rotational type is suitable for those who have little experience in sewing. Such machine models do not have a set of functions, but their shuttle is simple to use, reliable and durable. Equipment with such a system is taken for rare use;

- horizontal should be chosen by those who want to create a small number of things from different fabrics, without finding fault with the sewing speed. Sewing machines with such a mechanism have good functionality, and their price starts at 8,000 rubles;

- a rotating vertical mechanism is the choice of professionals and studio employees who value stitch selection, quality and comfort.

A “home” option when you want to sew for yourself is a horizontal shuttle. If you properly monitor the condition of your sewing machine, it will remain operational for a long time.

What is the main part of a sewing machine?

The shuttle mechanism should not have any damage or defects, as they can ruin the sliding of the thread.

Due to this, excessively elongated upper threads appear, the stitch has a weak tightening. In professional language, this phenomenon is called looping of the thread from the bottom side. The shuttle plays a big role in the stitch formation process. Its nose grabs the loop of the upper thread and pulls it further to form a stitch, the walls expand it, it goes around the shuttle, comes off its walls and forms a shuttle stitch.

Expert advice

When determining which type of hook is best for a sewing machine, you should read reviews from professionals. This will allow you to make the right decision in the process of choosing sewing equipment.

Experts say that the swinging shuttle is made of durable, reliable materials. It is an order of magnitude more durable than modern horizontal types of parts. However, it also has a number of disadvantages. It will take longer to remove the spool than with modern types of equipment. The part will also make noise during operation.

The swinging hook limits the sewing speed. But the cost of such machines is significantly less compared to modern analogues. For sewing clothes in small quantities, it is still better to prefer this option. For professionals, experts recommend using a vertical or horizontal type of shuttle.

How to choose the right shuttle

Those who seriously decide to take up sewing do not choose the type of shuttle, but the type of sewing machine as a whole. However, it is best to choose a device if you understand its capabilities, and for this it is still worth focusing on the type of shuttle mechanism.

If the machine will be used rarely and only for household needs, the option of a swinging shuttle device is quite acceptable. Moreover, such a unit is the best budget option.

If a seamstress plans to engage in continuous sewing at home or open her own atelier and carry out complex orders from different types of fabrics, it is better to focus on units with a horizontal shuttle mechanism. This option is more expensive, but speed and variety of features are important factors in favor of choosing it.

When using an industrial sewing machine, the most correct choice is a vertical shuttle device.

Subscribe to our Social networks