Sewing machine diagram

The user can only see the outside of the machine and its working parts, which are located outside the device.

However, inside there is a complex mechanism that only professionals can understand. The main part of any model, even the most modern, is considered to be the shuttle. It is made from high-quality wood, its main task is to transfer cross-fibers in the fabric production procedure. The basic parts that no unit can do without include the following components:

- Flywheel;

- Sleeve;

- Winder;

- Platform;

- A wheel that regulates the required type of stitching;

- Sleeve stand;

- Reverse stroke (receiver);

- Needle holder;

- Needle plate;

- Paw;

- Handle for raising and lowering the presser foot.

Sewing machine device

These elements are related to the external part of the device, so the basic workflow seems quite easy. A complex internal system powers the shuttle using many additional parts. The shuttle device allows you to create unusual stitches of various shapes, while manipulations are carried out quickly and efficiently.

Differences between different types of sewing machines

A wide range of modern models makes it possible to choose the optimal specimen that will satisfy individual needs. Among the huge range of models there are different types of sewing machines:

- with manual drive - used at home, due to mechanical control they are easy to operate. The manual drive allows you to process different fabrics, even leather and jeans. Such devices rarely require repairs and are durable and reliable;

- electromechanical - designed with an electric drive, the device is controlled manually and activated using a switch. Such units are divided into two types: vertical and horizontal. The first models are cheap, there is quite a strong vibration, and the stitch width is limited. Horizontal ones have advantages - the device does not resonate, so there is no tangling of the thread. Electrical appliances are intended for small jobs, repairing things;

- electronic - intended for professional purposes. The built-in display with a microprocessor transmits commands to the screen. Such models do an excellent job with all types of fabrics, even corduroy and guipure. The control is carried out by a pedal and a lifting lever. With independent machine control, the sewing comes out of high quality;

- Overlock - used for finishing the edges of fabrics with loose weaves. The main part of the models has knives for removing excess allowance. This option significantly saves time during the sewing process. There is no shuttle in such devices; its options are provided by special loopers. The display provides recommendations for the correct installation of threads;

- embroidery - such a machine is necessary for creating masterpieces. A computer program allows you to decorate fabric with embroidery using different techniques. When uploading files, you should select the required hoop size, and then thread the threads of the required colors. The procedure itself does not require human supervision, it is carried out independently;

- flat-seam is an industrial device with household modifications. The most suitable option for processing elastic types of fabrics. The stitch is done in a special way to prevent stretching of the material. This type can be used for knitwear, polyester, stretch.

Paws and needles

It is easier to sew when the machine is equipped with good feet. We will tell you about the most popular types. But, please note, you need to select it individually; not all paws will fit your car model.

Also read: How and how to clean a refrigerator at home: the best ways

The device already comes with a minimum of claws, so you will have to buy new claws to replace them or if you are missing some.

TOP 5 presser feet for any type of sewing machine:

- Straight line (needed for silk and other similar fabrics).

- Zigzag (you can do a regular stitch, zigzag and some for finishing).

- Universal zipper (needed to sew the zipper next to the teeth).

- Overlock foot (very necessary if you don’t have a separate overlocker).

- Blind stitch (when you need to make invisible stitches).

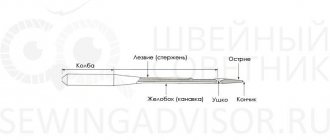

The needle affects the quality of the stitch.

When choosing a sewing machine for home use, consider:

- There must be needles 80, 90, 100.

- Take the time to read the tips in the device instructions.

- Do not confuse European and American sizes - these will be completely different needles.

Classification of sewing machines by type of control

All sewing machines are divided into three main classes:

- Mechanical;

- Electromechanical;

- Electronic.

We all remember our grandmother’s old “Singer” with a simple hand or foot drive that set the sewing mechanism in motion. Later, the Soviet “Chaika” and “Podolsk” appeared with an electric drive and backlight bulbs. These and similar machines belong to the mechanical class. They are simple and quite reliable, can sew almost any fabric, and are easy to maintain and repair.

On the other hand, mechanical sewing machines are usually equipped with the most primitive swing-type shuttle, which limits the speed of work and increases the noise level. The disadvantages include poor functionality, a small number of stitches produced and exclusively manual settings.

The electromechanical sewing machine has evolved significantly from its predecessor. It is equipped with an electronic unit that controls all functions and settings. The most inexpensive models of electromechanical sewing machines are still equipped with oscillating hooks. The new generation equipment is equipped with two modern types of shuttles: horizontal, which provides high speed and soft movement, and vertical, an almost perfect mechanism that produces perfect stitches.

The productivity of electromechanical machines with modern shuttles is incomparably higher, the noise level is quite comfortable, and the range of possibilities and variety of stitches is incomparably wider. The electronic control unit has a certain set of programs, and also allows you to independently select and save settings for certain operations in memory.

As for the disadvantages of such machines, there are very few of them. Firstly, they are much more expensive than mechanical ones. Secondly, they require a more attentive attitude in terms of maintenance, and in the event of a breakdown, repairs in the workshop will also be expensive.

An electronic sewing machine has even more functionality, and each of them is controlled by a built-in microprocessor. Working on such a machine is as comfortable as possible: you just need to select any of the programs stored in memory and press the appropriate button. Depending on the model, there may be several dozen built-in programs. The tailor does not need to manually adjust the length or width of the stitch, or look for the desired type of stitch in the settings - the machine will do all this for him. The processor controls the stroke of the needle, regulates the speed of work regardless of pressing the pedal, controls the thread tension, etc. Electronic sewing machines are equipped with the most modern shuttles, so their stitch quality is impeccable.

As for the disadvantages of such equipment, first of all, buyers may be put off by the very high prices for cars of this class. Electronic “filling” is very sensitive to failures and voltage drops in the electrical network. Most models are not designed to work with very dense and thick materials. And, of course, the cost of repairs can amount to a very impressive amount.

The era of seamstresses

Massive and simple mechanical ones have been replaced by lighter, more compact and functional electric sewing machines. Their engine is built into the body. And only the cable with the control pedal protrudes outside. The first models were popularly called “seamstresses” because they were intended for fine work.

In a modern store, you won’t find sewing machines sorted by drive on the shelves, because they are all driven by an electric motor. Instead, there is sorting by control type:

- mechanical - lever switch system, characterized by a small number of options;

- electromechanical - buttons and levers, greater functionality and an increased number of lines;

- computer - buttons and a sensor, it is possible to set various programs and often an embroidery module is already built into such equipment.

When choosing a household sewing machine, it is better to focus on mechanical or electromechanical control, as they combine performance, simplicity and reliability. Electronic (computer) ones are a tool for professionals whose work cannot be done without complex stitches.

Subscribe to our Social networks

⇡#Types of sewing machines

All sewing machines are divided into industrial and household. Usually a household one can do a lot of things at once, and an industrial one can do one thing - but it can do this one thing very well and for days, years, kilometers - without breaking down. At least that's the idea.

However, industrial machines are unlikely to interest you, unless you intend to open a small sewing enterprise - they are very expensive, bulky and noisy in operation - so in this material we will concentrate on household ones. Household machines are divided into:

- electromechanical,

- computer,

- sewing and embroidery

- embroidery,

- overlockers,

- cover,

- carpetlocks.

What does all this mean, and which category should you choose?

1. Electromechanical sewing machines are the simplest of all. The entire internal filling of such a machine is mechanics, that is, levers, shafts and gears. Only the motor that drives it all is electric.

Example - Minerva M832B:

- 32 types of stitches

- semi-automatic loop

- vertical shuttle

- stitch length 4 mm

- stitch width 5 mm

The undoubted advantages of this type are reliability, low price, and inexpensive repairs in case of breakdown. Conventional electromechanical machines are inferior to computer machines in the speed of operation and number of functions, since the technological design features do not allow for stitching of complex shapes, but are perfect for beginning seamstresses, or those who want to have a reliable assistant for small household needs. However, a coat, jeans, and a ball gown are quite capable of a good and properly adjusted electromechanical machine. The approximate price category of such machines is 3–5 thousand rubles. Simple, affordable, reliable.

2. Computer sewing machines are distinguished by the presence of a computer board that provides overall control of the process, which allows this type of machine to carry out quite intricate stitch programs. The movement of the needle relative to the fabric is controlled by a microprocessor. What a particular model can do depends on the amount of memory and the number of programs of this machine “brain”.

Example - Minerva DecorExpert:

- 197 types of operations

- automatic loop

- horizontal shuttle

- stitch length 4.5 mm

- stitch width 7 mm

Their starting price is approximately two to three times higher than the price of electromechanical ones. At first glance, the huge number of stitch types seems to be an undoubted advantage. These include 15 types of different loops, and chains of different flowers and leaves, and a dozen overlock stitches, and knitted seams. But take a closer look at this list and think about which ones will you personally actually use? It turns out that you don’t need some of it at all, and some of it is just numerous duplicates of the same thing with minor deviations.

Personally, I regularly use six or seven of the 56 stitches I have in my machine, and use two more from time to time. However, one cannot help but notice that this already greatly expands my capabilities in comparison with working on an electromechanical sewing machine. So don’t be tempted by the excess of functions - it’s not at all a fact that you will need all of them. Or rather, the fact is that you are unlikely to ever try many of them.

Several types of overlock stitches, a knitted stitch, a triple reinforced stitch, a knitted loop and a loop with an eye will be useful in your work - in addition to the regular loop, of course. The rest of the features are up to you, just don’t let the variety go to your head. It's a shame to pay extra money for something you will never use.

The undoubted advantage of a well-functioning computer machine is the speed and accuracy of its work. If your plans include kilometers of frills and sewing to order for 8 hours a day, a computer machine will significantly save you time and give you additional opportunities for creativity. A buttonhole with an eye is, of course, a small thing, but this little thing affects the entire look of the coat.

The disadvantages are the high price, capriciousness in setting up, and repairs, if something happens, more expensive.

3. Sewing and embroidery machines . Everything is simple here, unlike industrial embroidery machines, which can, in fact, only embroider; such combines often combine two functions.

In my personal opinion, budget versions of sewing and embroidery machines combine these functions very poorly. They are too capricious compared to regular sewing machines, and compared to full-fledged embroidery machines, they are too limited in embroidery capabilities. And more expensive models are also scary in price. Therefore, I recommend considering this class of machines exclusively as embroidery machines and purchasing them based on these purposes.

Also, don’t think that if you buy an embroidery machine for 100-300 thousand, you will immediately create a masterpiece. Embroidery on a sewing machine is also an art that needs to be learned. In courses or independently, using books or online lessons. In general, working with it is somewhat reminiscent of working in Photoshop. You can go to a specialized website, type in motifs drawn by someone there, quickly read the instructions and glue them together as best you can, adding stars and hearts with a stamp. But if you look at the masterpieces created by professionals, it becomes clear that this is not even a third of the capabilities of this tool.

So, think carefully about whether you need this, and to be honest, in most cases it is much easier and incomparably cheaper to order embroidery from a workshop that already has serious equipment and a good craftsman. Outsourcing is everything to us. Personally, this is what I usually do.

4. Coverstitch sewing machines . They are also flat-seam machines .

Designed to make an elastic flat seam used to close the hem edge of a knitted product. This whole complex verbal construction refers to that seam that you can see on the hem and sleeves of almost any T-shirt.

Among household machines, flat stitches can be made by two types: flat stitch machines and carpet lockers. A regular stitch looks the same on both the front and back sides, as the top thread is wrapped around the bottom thread (bobbin) and tightened. A flat or chain stitch looks different. It is obtained by simultaneous operation of two or more needles and loopers.

This type of sewing machine is designed to work with elastic “stretch” fabrics. If your main goal is T-shirts, swimsuits and tracksuits, this is your choice. Price category from 10–15 thousand.

5. An overlock is a machine with one or two needles, equipped with a trimming mechanism and designed for overcasting the edges of a wide variety of garments. When choosing an overlocker, you should first of all focus on ease of threading and sewing. We should also not forget about the possibility of overcasting with different numbers of threads. Most overlockers perform 3- and 4-thread overcasting, suitable for most types of fabrics, and rolled edge overcasting. On higher-end overlockers there is a 2-thread overlock designed for the finest fabrics - such as silk or chiffon - as well as for decorative finishing.

In principle, overlocking functions are also available in computer sewing machines. But a seam made with a real overlocker is much more accurate and reliable. In addition, the overlocker is equipped with knives that themselves cut off the excess allowance, leveling the edge, which significantly saves time. In general, if you sew regularly and the free space allows you to place two units, an overlocker will be a very useful acquisition, but if not, you can do without it. In any case, it does not replace a sewing machine, but only complements it. It is not intended for assembling product parts. The price for overlockers starts from 6 - 7 thousand, for 10 you can buy a quite decent model.

6. Coverlock is a relatively new invention that many are not particularly familiar with. Pfaff marketers came up with this name for their range of such machines and patented it, after which it firmly entered into everyday use. It combines the word “overlock” and the English term coverstitch, that is, “covering” or “closing” stitch. This machine can perform both overcasting of garments, and flat seams and straight chain stitch, that is, it combines an overlock and a flat stitch machine. The price for carpet locks is quite high and starts from 25–30 thousand.

Like a cover sewing machine, a carpet locker is designed to work with knitwear. The design also assumes the presence of several (from 2 to 10) upper threads and loopers, with the help of which you can create various, sometimes very complex seams, indistinguishable from industrial ones.

What to choose for working with knitwear - a carpet locker or a pair of overlockers plus a cover-stitching machine? On the one hand, a carpet locker has a larger number of loopers, which allows you to make more complex seams; it alone takes up much less space, and its high price is quite comparable to the total cost of a cover stitcher and an overlocker. On the other hand, when processing a garment, you may first need an overlock, then a flat seam, again an overlock, again a flat seam, and so on every five minutes.

In the case of two machines, this will not present any difficulty, and each time the carpet lock will have to be reconfigured from a flat seam to an overcast or overcast stitch and back. And this is a rather long and painstaking process, which even with skill takes several minutes. It's up to you to decide what's more convenient.

Classification of household sewing machines

In this table we provide a conditional classification of household sewing machines, intended only to expand your knowledge about sewing machines. In fact, if you give a complete list of all types and types of sewing machines and their differences in the form of a table, you will get a very large list, which is boring and useless to study.

In practice, it is only important to know that an ordinary sewing machine can be mechanical, that is, devoid of any electronics, with the exception of a light bulb and an electric drive. The shuttle of such a machine, as a rule, is of the swinging type (Shuttle of the Chaika sewing machine), which limits its speed and increases the noise of operation, but expands the range of fabrics and materials for sewing.

A sewing machine may also have a more complex control system (switching stitches, selecting operations, etc.) Then it will already have a built-in electronic unit and therefore belongs to electromechanical sewing machines. Most often, such machines have a horizontal shuttle type, which improves the quality of stitching and reduces the operating noise of the machine.

And the last type of sewing machine can be called a computer one, since almost all processes are monitored by a computer program. The shuttle of such a machine is of a rotating or horizontal type. And its main feature is that such a machine can sweep out an eyelet loop. To “appreciate” this feature, it is enough to say that an industrial eye-loop machine costs about ten thousand dollars.

Sewing device control type

What types of sewing machines are there? There is a general division of this technique, which includes three types:

- working on a mechanical principle;

- electromechanical models;

- computer controlled devices.

Mechanical models

Already from the name it is clear that this option works thanks to manual action on all structural elements. Almost all of them are old-style devices, but even on machines of the nineteenth century it is quite possible to sew, having first debugged the equipment.

The operating principle of a mechanical machine is basically predictable; such a machine is capable of sewing only along a straight line (mostly these are models like Podolsk or Singer). There are both manual and foot drives among them. Among the mechanical heroes there are also those who are able to work with a zigzag stitch, for example, Chaika.

The advantage of such machines is that they almost never break down. A significant disadvantage of working with them is the limited functionality and the requirement for customization for each type of fabric.

Electromechanical assistants

This technique refers to most modern devices. Unlike mechanical analogues, their operation involves an electric drive located in the pedal. The electromechanical machine is endowed with many talents: it is capable of performing a large number of different seams, sewing on buttons, darning and even making buttonholes. The choice of stitch can be done using a special wheel.

Popular brands of such devices are Bernina, Janome, Family, Brother Pfaf, Juki, Singer and others. Prices for such models are quite affordable for the average consumer. An example of this is the Brother LS-2125, which can be purchased for 7,300 rubles. Fourteen sewing operations, the ability to work with blind and elastic stitches make the model a necessary purchase for dressmakers of any level.

Sewing mini computer

Devices that have software claim unlimited functionality of their capabilities. Each such device is a mini-computer with a microprocessor. There is a built-in screen for user convenience. The variability of capabilities for many of the models exceeds a hundred. With such a device it is impossible to make a mistake; the system will give recommendations on the selection of fabric and puncture force.

Among the proven models are the brands Bernina, Brother and others. The cost is several times higher, starting from 20,000 rubles, but in this case, it is compensated by the ability to perform more complex elements (even recording the sequence of steps and embroidery).

For example, the popular Janome DC 4030 will cost 22,500 rubles. The control is completely electronic and includes 30 sewing operations and the ability to work with quilting, sewing in feet and overcasting.

More expensive models also include an embroidery unit, which makes the machine simply an indispensable device. There is a completely different level of assembly and production of parts, and electronics are invested at about two-thirds of the cost of the device.

Types of sewing machine engines

What is the difference between sewing machine motors and what types of motors are used in each case? Let's try to answer these questions in a simple form, but with some explanation. So, let's define the terms:

AC - alternating current

DC - direct current

Universal motors

operate on both alternating and direct current (AC or DC). Universal motors have been used successfully in sewing machines for almost a century. These engines are durable, compact, and provide good starting torque. Their design is better suited for frequent starting and stopping of the machine. It is not uncommon to find sewing machines with motors that operate trouble-free for 50, 60, 70 years or more. The universal type of engine is used in the railway industry. The speed controller for such motors is very simple - it uses a variable resistor. Using the pedal, you control the amount of electricity supplied to the engine.

Controlled DC motors began to appear in the 1970s.

(DC).

The main advantage of this type of motor is that it can be precisely controlled through sophisticated electronic control systems or computers. All computerized sewing machines have DC motors. These machines also have a series of stepper motors

that move various parts of the machine according to the instructions of the computer. Hundreds of decorative stitches can be produced on a computerized machine with a controlled DC motor.

Let's look at engine power

. Grandma's old electromechanical sewing machines used large flywheels. Not a lot of electricity was required to spin such a hulk due to the high gear ratio. Such machines had remarkable penetrating ability, but this also had its drawbacks. A large wheel develops strong kinetic energy, making it difficult to stop instantly. New sewing machines are more compact, but they use gear ratios that provide maximum punching power at any speed. But a much larger role is played not by engine power, but by correctly selected threads and needle thickness.

In industrial sewing machines, the motor is installed separately from the sewing machine. Read more about industrial sewing machine engines.

Source

⇡#Model capabilities

This question is most acute when choosing a specific model of computer sewing machine. It is with this type of machine that the number of lines often exceeds two hundred and causes ripples in the eyes and dizziness. You don’t need to start your choice with the number of lines. There are more important parameters that you should decide on first.

1. The type of fabrics the machine is designed to work with. There are machines for working with all types of fabrics; there are models designed for light and medium, or vice versa, for medium and heavy fabrics. If you definitely know that your main area of activity will be, for example, dance dresses made of silk and chiffon, take a machine for light fabrics, it will work with them better than a universal one. If your choice is a coat and jeans, consider models for medium and heavy fabrics. Usually they have a larger gap between the foot and the needle plate, which allows you to put a thicker layer of fabric under the foot, and a more powerful motor that can sew this layer.

2. Maximum stitch length (up to 5 mm) and maximum zigzag width (up to 7 mm). The larger these parameters are, the better: it expands the field of possibilities.

3. Shuttle type: the shuttle can be vertical, with a removable bobbin case, as well as horizontal, where there is no bobbin case. The second option is more modern and reliable - it has fewer parts that can break.

4. The loop can be automatic or semi-automatic. The “full” machine allows you to make up to 7 different types of buttonholes, in one operation you can sew a buttonhole exactly to the size of the button, remember the size and repeat a buttonhole of the same size the number of times you need.

Automatic buttonhole foot

Semi-automatic buttonholes are usually performed by simpler models. Here you determine the size, guided by the markings on the foot, the loop is sewn in 4 consecutive operations. It’s not difficult and it’s not that long, but if you multiply it by 10, 20, 30 buttons per suit, the difference is quite significant.

Foot for semi-automatic buttonhole

5. Optional, but very convenient features are a built-in needle threader, the ability to sew with a double needle, a needle positioning button and a spot fastening button. If you are going to sew a lot, you should pay attention to the possibility of working without a pedal and external speed adjustment; this greatly saves your leg, which after four to five hours of continuous pressing the pedal begins to complain, and besides, the pedals fail faster than the machines themselves, and they do this, as a rule, at the most inopportune moment.

This is where the general recommendations end and all that remains is to choose from the mass of proposed lines, fonts and flowers the set that will be useful to you personally, and I will finally tell you about another very important point.

Shuttle and sewing loop processing modes

One of the main parts in the machine is the shuttle; it determines what the lines will be. Therefore, when choosing a sewing machine, it is important to pay attention to this. But let’s say right away, no matter what shuttle you choose, it will have its strengths and weaknesses. It is important to find the one that suits you.

The shuttle happens:

- Depending on the movement - oscillating or rotating.

- Depending on the location - vertical or horizontal.

The waver appeared a long time ago. It is easy to use, reliable, inexpensive and easy to replace with a new shuttle. But it creates unnecessary noise, does not allow you to sew faster, the stitching is up to 5 mm and is not of the best quality.

The rotating vertical one is the most expensive and is installed on professional devices. Reliable, with convenient thread adjustment, high speed, and settings depending on the fabric. But you need to lubricate it regularly, the thread can often get tangled and it’s not immediately obvious how much is left.

Rotating horizontal is suitable for electromechanical and computer types of sewing machines. The shuttle is also easy to use, but quiet.

Change the bobbin very quickly. The thread does not get tangled so often, you can keep track of when it runs out. Users in reviews of which sewing machine to choose note that you need to get used to pulling the thread.

Also read: Universal methods for setting the time on ovens: tips for users

A sewing loop is needed to sew buttonholes.

When choosing a sewing machine, you can choose the following mode:

- Automatic . Suitable for experienced seamstresses. All you need to do is set the size of the eyelet with your foot.

- Semi-automatic . For less self-confident and more budget-friendly cars. Here you make a loop, switching operations; it is important that you do not need to move the fabric with your hands.

- Manually . If you need to do zigzags. In this mode, you do everything yourself.

Shuttle type

There are two main characteristics that determine the type of shuttle. The first of these is the movement that the shuttle performs when forming a stitch: oscillation (oscillating) or rotation (rotational).

Sewing shuttle

Important! In the process of swinging, the shuttle moves first in one direction, and then begins to move back. The rotary type moves around the stud only in one direction.

The second characteristic is the orientation of the shuttle. It can be vertical and horizontal. The vertical shuttle is located in the side or rear of the machine, facing forward, and in a horizontal orientation, the bobbin is inserted only at the top.

You may be interested in this: Creating a pattern for sleeves for dresses

Type of shuttle in a sewing machine

⇡#Additional accessories

The capabilities of the basic machine you purchased are far from the limit. Accessories play a huge role in the quality of the result and the speed of achieving it. The fact is that for a high-quality result it is very important to choose the right foot, needle and thread for each fabric and operation. The table for the ratio of the thickness of needles and threads is in the instructions for the sewing machine - and here you are unlikely to go wrong.

But in addition, there are special needles for difficult fabrics - for example, they will be needed for working with leather, denim, stretch fabrics and jersey. Different sharpening of the tip allows them to work most accurately with the material for which they are intended. Very often, situations arise when a novice seamstress scolds the machine for missing stitches or other seam defects, but the problem is simply the wrong choice of needle.

There is also a huge variety of paws. On one of the largest Russian-language forums dedicated to needlework, the topic about various paws occupies more than 200 pages and is regularly updated. At the same time, only the bare minimum is included in the basic package. And this is where the initial choice of the machine begins to play a role - your capabilities may ultimately be limited by how easily you can purchase additional legs.

I would like to draw attention to the most frequently used ones that are usually not included in the basic package.

1. Teflon, with this foot you will not have problems when sewing items from difficult-to-transport materials, such as leather, plastic, suede, faux fur, etc.

2. The roller hem foot allows you to subtly roll and hem the edge. They are available for hemming in widths of 2, 4 and 6 mm.

3. Feet for gathering and sewing on ruffles.

4. Foot for sewing bias tape.

5. Foot for sewing, beads and sequins.

And hundreds more types of paws, attachments and devices designed to do what previously could only be done by hand. Make your work easier and turn sewing into a fun process.

General characteristics of modern sewing machines

Before comparing devices with each other, it is necessary to talk about their common features. We will only talk about electric-powered machines, and not about manual or foot-operated mechanical ones.

All new types of devices have a light plastic or lightweight metal body . This makes them no less reliable, since there is a frame inside. Chassis parts are still made of metal.

Modern devices are highly powerful . They easily sew through thick fabric, even folded in several layers. They also cope with leather, but there’s no need to talk about light materials (silk, knitwear, etc.). Power is one of the main requirements for technology.

Sewing speed is also considered an important characteristic . Over the past few years, it has increased noticeably: it began to be regulated by the force of pressing the pedal or set to special modes. All units now have a free arm platform for processing trousers, cuffs or other narrow parts.

The last quality can be called functionality . Any unit makes at least five seams, including special elastic ones for knitwear, imitating overlock, and some even carpet. The kit also includes a basic set of feet to expand its capabilities.

How to disassemble the sewing motor housing

Once you have removed the brushes, you can begin to inspect the other parts of the engine inside. Typically, this requires unscrewing two nuts at the front and two at the back that hold the two ladles of the housing together.

Carefully remove the front half of the housing.

Please note that this motor model does not have bearings. Instead, bushings are installed, the inner surface of which must be lubricated.

Be sure to pay attention to the number and sequence of installation of washers on the shaft.

Now you can carefully remove the motor rotor from the stator and inspect it.

Dimensions and weight

Width

from 9 to 64 cm

The width of the sewing machine in centimeters. When choosing this option, it is worth considering that manufacturers, as a rule, indicate the overall dimensions of the device without taking into account the protruding parts of the case.

Depth

from 8 to 44 cm

Sewing machine depth in centimeters. When choosing this option, it is worth considering that manufacturers, as a rule, indicate the overall dimensions of the device without taking into account the protruding parts of the case.

Height

from 16 to 56 cm

Height of the sewing machine in centimeters. When choosing this option, it is worth considering that manufacturers, as a rule, indicate the overall dimensions of the device without taking into account the protruding parts of the case.

Popular sewing machine brands

Many well-known European and Asian manufacturers supply sewing equipment to our market and are constantly fighting for buyers. As a result of this competition, clear leaders have emerged whose products are in great demand due to their reliability, convenience, functionality and high quality of operations performed. We offer you a short overview of the most popular brands of sewing machines.

It is not for nothing that Japan is famous for its products, which embody the most high-tech and innovative ideas. Sewing machines produced from Japanese factories are distinguished by their durability, high build quality and a wide range of operations. Appliances from the Janome, Juki, Brothers, and Jaguar brands are in constant demand among both professional tailors and needlewomen.

Other Asian manufacturers are not lagging behind the leaders. Taiwanese brands AstraLux, Merrylock and Chinese machines Yamata, Zoje, Jack captivate with their affordable prices and quite a decent set of operations. In recent years, the quality of Asian technology has increased significantly, and this is reflected in an increase in sales volumes. Among industrial sewing machines, the Typical and Type Special brands are popular.

Bernina, Pfaff, Husqvarna are some of the most reputable European brands, which are traditionally famous for their perfect build quality, highest reliability, wide functionality and flawless operations. However, the cost of cars of these brands is often too high for the mass Russian buyer.