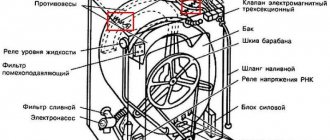

Purpose and design of the tank

This is the main element of the washing machine. Often the breakdown of such equipment is associated with it. It happens that there is a foreign object in the tank that makes unpleasant sounds during rotation. It happens that such an object causes the drum to jam, or it causes cracks to appear in the tank.

The method of fixing the tank is similar in different machines. To create movable fastenings, shock-absorbing devices and springs are used.

Washing machine shock absorber

To reduce vibration, counterweight elements in the form of weighted concrete blocks are used.

The laundry drum of the washing machine together with the tank constitute a kind of automatic “abdominal cavity”:

- the drum receives the laundry to be washed;

- The tank is filled with water containing detergents. Liquid gets onto the laundry through perforation holes.

The drum of a washing machine is always made of stainless metal material. Its side surfaces are perforated, and the same holes may be present on the back wall. And various materials can be used to make the tank itself.

Washing machine drum

Until recently, washing machines were made with an enameled steel tank. But the operating period of such a machine did not differ in length; with small cracks in the enamel coating, corrosion began to form.

Because of this, most manufacturers of household appliances abandoned such unreliable raw materials and began manufacturing tanks from plastic and stainless metal. Today, the material of the washing machine tank varies. Its strength and durability are the key to good operation of the machine, as it experiences significant loads and temperature changes.

Plastic

Each manufacturer of washing equipment has its own special polymer material from which plastic tanks for automatic washing machines are made. Their main advantages are resistance to corrosion, lightness and relative strength.

Products made from this material help reduce noise when the drum rotates. In energy efficiency tests, models with plastic parts show significant energy savings. But when compared with stainless steel models, such products look more brittle and susceptible to mechanical stress. But the composition of the polymers from which the elements are made is constantly being improved, they become stronger and more reliable.

As already noted, each company producing machines has its own patented polymer composition. The characteristics of these types of plastic are also different. Thus, in terms of strength and durability, carborane is quite comparable to stainless steel, but in terms of thermal insulation and vibration damping it is much better. As a rule, all polymer materials (carborane, carbotec, silytek, carferon, polynox, polyplex) are based on polypropylene with calcium carbide, which increases the strength and resistance of the part to chemicals in detergents. The fewer additives a plastic contains, the more fragile it is.

Since plastic itself is inexpensive, manufacturers have the opportunity to reduce prices for their equipment with polymer tanks. Not only are these parts lightweight and better at keeping the machine quiet, they are also resistant to chemicals found in powders and bleaches.

But fragility and susceptibility to splits still remain the main disadvantage of polymers, no matter how hard manufacturers try to improve the composition of these materials and make it better. Improper transportation, failure to remove the transport bolts before the first start, or the entrapment of small elements between the drum and the washing machine tank can damage the integrity of the structure and lead to such breakdowns that will make further operation of the equipment impossible.

What material is the tank made of?

Further in the article we will consider all known options.

Plastic

Each company has its own secrets and uses plastic raw materials with certain characteristics. For example, carborane is reminiscent of stainless steel material in its durability, strength and reliability. And the thermal insulation and vibration reduction properties are even superior to stainless steel.

The most commonly used polymers are carborane, carbotec, carferon, silitek, and polynox. They all have one common feature - the main component is considered to be a special polypropylene material containing calcium carbide. This additive significantly increases the strength of the plastic and makes it resistant to detergents used in washing. The quality of the tank itself changes depending on the amount of special additives in the plastic.

The main advantages of raw materials include:

- resistance to corrosion;

- high strength indicators;

- moderate weight;

- the material is not exposed to moisture;

- the noise level decreases during element rotation;

- electrical energy is saved;

- resistance to aggression of chemical compounds.

There are many positive qualities, but you should know that household products with plastic tanks fail more often and are of little use for mechanical impacts.

It would be fair to note that the development of plastic raw materials does not stand still, and each manufacturer adds its own “zest” to such raw materials, which allows improving strength and reliability. In addition, the raw materials are considered cheap, which affects the overall cost of the washing machine.

In addition to the positive characteristics, there are also negative aspects. It has already been noted that companies are trying in every way to improve plastic tanks. But the material still remains brittle and susceptible to splitting, which is its main weak point.

If transportation rules are violated or the bolts securing the drum are left behind, the container may be damaged. After this, the machine will no longer be able to be used. You will have to purchase a new unit or look for a similar replacement tank.

With good quality plastic raw materials and compliance with operating rules, the tank will last from twenty to twenty-five years.

Stainless steel

This high-quality metal is considered traditional and is very popular as a raw material for tanks. It will be enough to remember the old models of cars that are still found in garages and sheds. The unit has long since lost its functionality, but the stainless steel tank continues to maintain excellent external characteristics. And a long operational period is not considered the only advantage of such raw materials.

Positive points include:

- strength and resistance to mechanical damage;

- excellent resistance to high temperatures and chemicals;

- complete absence of mold and mildew from wet conditions, minimal opportunities for the development of harmful microorganisms.

It may seem strange that there are also negative aspects. The main one is the high pricing policy, depending on the quality of the material. A metal tank has a higher level of heat transfer; the water in it cools down much faster, which results in unnecessary consumption of electrical energy spent on heating. Another significant problem with a metal assembly is vibration. At maximum speeds, you can hear quite strong sounds, which cannot be said about models with tanks made of other materials.

Polynox tank

Quite often you can hear stories from sellers of laundry washing machines that contain this term. It immediately becomes clear that the material is new. It remains to be seen what exactly is made from it, and how such components affect the performance of household appliances.

The name of the material implies a commercial version of the name of polypropylene raw materials, the characteristics of which are slightly modified by the addition of special chemical compounds.

Today, polynox is used in the manufacture of tanks for washing machines, and the raw material has already gained well-deserved popularity. There are reasons for this:

- reasonable cost;

- ease of processing;

- The manufactured elements have excellent characteristics.

Polynox is not considered the only plastic option used to make tanks. Some manufacturers use more durable and ductile carborane, however, its cost increases by one and a half times.

In the model range from Kandy, the tanks are made of silitek. In its qualities it resembles polynox.

Metal enameled version

Such tanks have long been discontinued. Distinctive features are considered to be a good level of reliability and protection from corrosion. This tank weighs quite a lot. The element is durable and does not crack during transportation and temperature changes. The tank is reliable when washing any laundry.

During prolonged use, chips may form due to impacts from foreign objects caught in the drum. Damaged enamel coating ceases to perform its main function, crumbles, becomes covered with rust stains and is destroyed. The tank begins to leak and needs to be completely replaced.

Today, enamel tanks are not sold separately. If your machine with such an element begins to leak, you will have to purchase a new “helper”.

Metal

Metal tanks coated with enamel have long been discontinued. Such products are quite reliable when washed, and the protective layer protects the part from corrosion. An automatic machine with a metal enameled tank weighs quite a lot. But at the same time, the strong part will not crack during transportation, washing or sudden temperature changes, as sometimes happens with a plastic product.

But with long-term use, such parts often develop chips from impacts after foreign objects get under the drum. The enamel in damaged areas ceases to protect the tank, crumbles, and the metal rusts and collapses. Over time, the corroded part begins to leak, and equipment owners are faced with the question of replacing a separate element or purchasing new washing equipment. But since such tanks have long ceased to be produced, most likely, you will have to throw away the old automatic machine and think about purchasing a new one.

Other qualities of the machine element

Before you buy a washing machine, you should find out how much laundry it can wash in one load. For a large family, it is recommended to purchase models with a load of at least six kilograms.

Often the surface of the tank is coated with a special composition that brings benefits by having a disinfecting effect on the water.

Plastic raw materials and stainless steel are popular today. Each of the materials is quite acceptable and has a long service life. Everything is clear with the advantages; for comparison, here are the negative points:

- a stainless steel tank makes more noise compared to its plastic counterpart;

- elements made from plastic raw materials are considered brittle and cannot withstand mechanical stress.

Note that plastic raw materials are gradually pushing stainless steel out of the production process. It is quite possible that such machines will soon cease to be produced. Which option is better is up to you to decide.

Stainless steel

Stainless steel tanks can rightly be called classic. This material tolerates contact with water better than others and is very durable. When compared with plastic products, stainless steel elements turn out to be much noisier, since metal is not able to dampen vibration, and are heavier; but their reliability overcomes these shortcomings, which makes these models one of the most popular.

Due to the fact that metal has almost no thermal insulation, energy consumption for models of washing equipment with a stainless steel tank will be significantly higher than for machines with a polymer part.

The cost of high-quality stainless steel tanks that will serve you for many years is quite high. If you come across an inexpensive model of such equipment, it is better to refuse such dubious savings. The quality of steel and welding of seams and assembly of components in cheap equipment leaves much to be desired.

Cellular novelty

The honeycomb-shaped drum is considered an unusual invention by Miele, patented so timely that you won’t find anything like it in washing machines from other companies. According to the manufacturer, this model reduces the cost of electrical energy and is more careful with things. The complete absence of welds extends the operational life of the element.

A distinctive feature is that the inner surface of the drum has hexagon-shaped holes, concave inward. During washing, a thin film is created between the laundry and the drum, protecting the material.