The self-diagnosis function, which is equipped with almost all washing machines, simplifies the troubleshooting process as much as possible.

The machine displays all information about the failure that has occurred on the display in the form of a digital value or signals it with a certain combination of flashing LED lights on the front panel.

All that remains is to decipher the digital code and begin troubleshooting. We will explain below what the error codes for the Indesit washing machine mean.

Decoding the signals produced by the Indesit washing machine with display

All models of Indesit washing machines with a display are equipped with a special problem diagnostic system. As soon as a malfunction occurs, the washing machine pauses washing and an error code appears on the display.

F01

Error F01 is a signal about a communication failure between the control unit and the washing machine motor.

Causes:

- short circuit,

- low voltage,

- engine malfunction.

Solutions: checking for broken cord and plug, restarting the household appliance.

Read more in this article.

F02

Failure (of the speed sensor) is displayed on the washer’s dashboard with error F02. Causes: problems with the control board.

Solutions: check the sensor contacts . In case of broken contacts or failure of the device, it is better to entrust the restoration of the washing machine to a specialist.

F03

A problem with the temperature sensor is indicated by error code F03. Problem: the machine does not heat the water, the washing process stops a few minutes after it starts.

Solutions: It is better to entrust the replacement of the temperature sensor to a service center specialist. Why the washing machine does not heat the water when washing, you can find out here.

F04

Error F04 is a signal about a malfunction of the water level sensor. Problem: the volume of filling the tank with water is not regulated.

Solutions:

- check the water pressure in the water supply system at home;

- clean the fine filter.

If the above manipulations do not help eliminate the error, you must use the services of a specialist who will carry out the necessary diagnostics.

F05

Error F05 may indicate either a malfunction of the water level sensor or a more serious failure of the drain pump.

Problem: The washer does not drain water from the drum. Solutions:

- clean the drain filter;

- Turn the drain pump impeller (it should turn with force).

If cleaning the drain pump does not lead to the resumption of operation of the washing machine, you must invite a technician to diagnose the sensor (possibly repair) the water level sensor. Read more in this article.

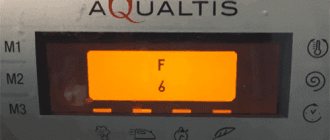

F06

Error F06 is a signal that the control unit is malfunctioning. Problem: the washing machine does not respond to given commands, the indicators on the panel flash randomly.

Solutions:

- check the network voltage;

- inspect the outlet and cord for breaks;

- restart the washing machine.

If restarting the washing machine does not help eliminate the error, you need to check the contacts on the control unit (it is better to entrust the work to a professional). Read about repairing the control unit in this article.

F07

Error F07 indicates that the water level sensor does not provide the required signal.

Problem: The washing machine does not draw the required amount of water.

Solutions:

- check the water pressure (pressure) in the water supply system at home;

- clean the water inlet filter.

If the error cannot be eliminated on your own, you must call a technician who will diagnose and, if necessary, repair the heating elements and pressure switch.

Read about replacing the heating element here, and about repairing the pressure switch here. This article will tell you why the washing machine does not fill with water.

F08

Error code F08 of the Indesit washing machine indicates a malfunction of the heating element. Problem: The water does not heat up to the required temperature.

Solutions: replacing the heating element (if there is no experience, the replacement process must be entrusted to a specialist).

Details are in this article.

F09

With error F09, the Indesit washing machine signals a malfunction of the control module . Problem: None of the programs start. The solution is to restart the washing machine.

If restarting does not help restore normal operation of the washing machine, you need to use the services of a technician who can remove the microprocessor from the module, test it and, if necessary, replace it.

F10

Error F10 indicates that the washing machine tank is not filled with water. Problem: The washer does not draw enough water to wash.

Solutions:

- restarting the washing machine;

- checking the water supply tap (must be open).

Dirt adhering to the fine filter can also cause insufficient water supply to the tank. Periodic cleaning of the filter will help avoid the problem.

F11

Failure of the drain pump will indicate error F11 on the washing machine display. Problem: a few minutes after the start of washing, the washing machine blocks the program, the water does not drain and the laundry does not spin.

Solutions: cleaning the drain filter . Why the machine does not spin clothes, read here.

F12

Error F12 indicates a violation of communication between the indicators and the control module. Problem: The machine does not respond to running programs.

Solutions:

- reboot;

- Simultaneously pressing the “Start” and “Pause” buttons (rebooting the control module).

The reboot did not lead to the desired result - more detailed diagnostics by a specialist is required. Details are in this article.

F13

Problems with the temperature sensor are displayed on the washing machine display as error F13. The problem is that at the end of the wash, the laundry drying process does not start .

The solution is to restart the washing machine. If such manipulations do not help fix the problem, qualified diagnostics of the control module’s performance is necessary.

F14

Malfunctions in the operation of the heating element are indicated by error F14. Problem: Drying process missing .

The solution is to restart the washing machine. A more detailed diagnosis of the cause of error F14 can be carried out by a service center technician (tests the performance of the heating element).

F15

Error F15 signals a break in the contacts between the drying relay and the heating element. The problem is that at the end of the wash, the laundry drying process does not start.

The solution is to restart the washing machine. If this method does not help get rid of the error, the car should be tested by a specialist.

F16

Failures in the control module are displayed on the washing machine display with error F16. Problem: The wash process stops mid-cycle.

Solutions:

- checking the drum for clogging with foreign objects (the drum must be rotated by hand);

- checking the tightness of the hatch closure (perhaps it opened during the washing process, which blocked the rotation of the drum).

If independent steps to resolve error F16 did not help, you must use the services of a service center.

F17

Error F17 indicates a locked hatch. Problem: The washing process cannot be started.

Solutions:

- check the availability of electricity in the house;

- Inspect the hatch door tongue for blockages.

Alternatively, debris accumulated in the rubber cuff may prevent the hatch from closing. Read how to open the door here.

F18

A failure in the control board process is indicated by error F18. Problem: there is no response to starting any washing program, spinning and drying mode.

Solutions:

- check the network voltage;

- check the tightness of the hatch closure;

- restart the washing machine.

If none of the above actions lead to the desired result, it is recommended to use the services of a service center technician. This article will tell you what to do if the machine does not turn on.

H20

Damage to the drain hose or a clogged water drain filter is displayed on the washing machine display with error H20.

Problem: The washing machine does not draw water . Solutions: check the pressure in the tap.

If the manipulations did not lead to the desired result, the Indesit washing machine must be turned off from the network for fifteen minutes, then turned on and started the washing process again. Details are in this article.

Door

The door error is in many ways similar to error f17 and indicates incomplete closing of the loading hatch. Problem: The washing process does not start.

Solutions:

- check the door seal for blockages;

- check the tightness of the hinges (loose fasteners do not allow the tongue to accurately fit into the locking joint).

If, as a result of self-diagnosis, it was not possible to eliminate the door error, the help of specialists is required (repair or replacement of the UDL is possible).

Error codes Ariston, Indesit

Modern household appliances are not only capable of helping people make their work easier, but also, if they break down, they can test themselves independently. At the same time, indicating the malfunction in the form of symbols. Please note that the errors for Ariston and Indesit are the same, with the exception of Ariston Dialogic (models AD8, AD10, AD12)

We have already published in a previous article how to decipher flashing indicators and calculate them using a table.

- F01 - the signal between the control board and the engine is lost:

EVO-II board model Indesit wisl 103, wisl 83, wisl 82, wisl 102:

Relays K1, K3, K7 - reverse and engine speed.

Arcadia board - Indesit models (WIN - WIB):

Control board with asynchronous 3-phase Ariston motor:

1 NTC thermistor. 2 Capacitor. 3 Throttle. 4 Diode bridge. 5 Power supply. 6 engine control processor. (Q1-Q6) - IGBT transistors.

Using a tester, we measure the control voltages on the block:

The thyristor may have become unusable. Check the motor terminals.

- F02 - lack of signal from the engine tachogenerator and electronic module:

The tachometer monitors the speed of rotation of the engine rotor.

When it rotates, an alternating voltage is generated at the terminals of the tachogenerator coil.

The frequency is compared by an electronic board and the rotation of the drum is controlled. It may be enough to tighten the sensor mounting screws or glue it to restore proper engine operation.

We make sure that the tachogenerator is working properly:

The resistance of the contact group in a quiet state should be about 70 Ohms (example with Indesit). Without removing the probes from the coil terminals, rotate the motor shaft. The resistance must change. If this happens, then the tachogenerator is working.

We check the engine block and connector J09 of the module.

EVO-II board model Indesit wisl 103, wisl 83, wisl 82, wisl 102:

Relays K1, K3, K7 - reverse and engine speed.

Arcadia board - Indesit models (WIN - WIB):

Using a tester, we measure the control voltages on block J09:

- F03,F09 - break in the temperature sensor (thermistor), closing of the washing heating element relay:

Depending on the brand and year of manufacture of your equipment, one of three types of sensors can be installed: gas-filled, bimetallic thermostat or thermistor.

This device signals the machine when it needs to heat the water. Depending on the model, it can be located either in the electric heater or on the surface of the tank.

If the sensor is located on the heating element, it is necessary to loosen the fastening of the heating element, disconnect all the wires and remove the sensor from the rubberized seal.

The bimetallic thermistor is checked for changes in resistance (the sensor is freed from the wires and the tester measures the resistance twice: at room temperature and after contact with hot water - there should be a jump in the readings). For a gas-filled sensor, the tube and the element itself are checked for damage.

The sensor itself rarely fails. Usually there is no signal from the board (NTC Thermistor connector contacts)!

In addition, the board's memory card (EEPROM) may be faulty.

- F05 - the drain pump or pressure switch (level sensor) does not work:

About 80 percent of the time, a clog (filter, drain pipe) or pump is to blame.

We clean the filter by removing the front panel with a flat screwdriver and twisting it:

The pump impeller must be clean and free of debris:

Place the washing machine on its side and separate the pipe from the tank and pump:

The pressure switch controls the amount of water. It is also called a water level relay (sensor).

Remove the tube and blow out the pressure switch. Switching clicks should be heard.

F06 - in Diagnostic models, indicates non-working buttons.

A rare mistake and here everything is clear.

F07, F08 - the heating element is not in the water, does not work (burnt out or broken).

Make sure there is water in the tank by looking into the drum. Next, remove the back wall and check the heating element with a tester:

F04, F08 - pressure switch (water level switch).

Presence of signal from connector J3.

Check the condition of the level sensor:

- contacts 2-4 are closed - level "EMPTY TANK" - contacts 2-3 are closed - level "FULL TANK" - contacts 2-1 are closed - level "OVERFLOW" (not less than half the level of the glass of the loading hatch.

Remove the top cover by unscrewing the two screws at the back. This sensor is located on top:

Why is it needed?

To adjust the water level in the tank: low, medium and high. Protection against overflow of the tank is also provided.

How to check? We just blow into it. You should hear clicks. There can be three of them. It depends on the water levels provided by the program: economical, delicate, half load.

F10 - water intake time exceeded.

The filler pipe from the detergent cuvette to the tank may be clogged, or the water fill valve may not be working properly.

Also check the level sensor (see above).

F11 problem with the drain pump.

The pump winding resistance should be about 170 Ohms - measure with a tester. Follow the instructions for error F05

F12 - there is no signal between the control board and the program selector.

Check the integrity of the connections between the power board connections and the indication board.

To convince us, we take an oscilloscope and look at the signals on the buses between the modules: ground, +5, +12, and two signal signals with identical bursts of pulses.

If error F12 occurs, try the board, alcohol, or sushi, but 99.99% the processor is dead and will need to be replaced.

F13, F14, F15 the drying element is faulty (washers with a drying function).

F16 - the breakdown is due to the blocking of the drum (vertical loading machine).

F17 - problem with the hatch lock.

There is no power to the door lock - ring the contacts.

F18 - board processor.

Module diagnostics required.

H20 - error no water flow.

It often happens that the inlet filter is clogged and there is no water passage due to dirt.

Unscrew the inlet hose and clean the filter mesh at the inlet

In addition, check the water pressure at the inlet of the solenoid inlet valve and its serviceability.

What can break in your washing machine:

Indesit washing machine signals without display

To understand what kind of problem a washing machine without a display is signaling, you need to decipher the combination of flashing indicators located on the front panel. Details are in this article.

IWSB, IWUB, IWDC, IWSC

The error code is determined by a combination of flashing indicators responsible for washing, rinsing, spinning, draining, and locking the hatch (lock):

| Error code | Flashing indicator number |

| F01 | 1. |

| F02 | 2. |

| F03 | 1,2. |

| F04 | 3. |

| F05 | 1,3. |

| F06 | 2,3. |

| F07 | 1,2,3. |

| F08 | 4. |

| F09 | 1,4. |

| F10 | 2,4. |

| F11 | 1,2,4, |

| F12 | 3,4. |

| F13 | 1,3,4. |

| F14 | 2,3,4. |

| F15 | 1,2,3,4. |

| F16 | 5. |

| F17 | 1,5. |

| F18 | 2,5. |

WISL, WIUL, WIDL, WIL, WITP

The error code is determined by the lighting of the function indicators (without the “Spin” option), as well as by the flashing of the “Lock” indicator.

Error codes can be recognized by the following combinations of flashing indicators:

F 01—ind. 1 and lock;- F 02 - ind. 2 and castle;

- F 03 - ind. 1.2 and lock;

- F 04 - ind. 3 and castle;

- F 05 - ind. 1.3 and lock;

- F 06 - ind. 2.3 and lock;

- F 07 - ind. 1,2,3 and lock;

- F 08 - ind. 4 and castle;

- F 09 - ind. 1.4 and lock;

- F 10 - ind. 2.4 and lock;

- F 11 - ind. 1,2,4 and lock;

- F 12 - ind. 3.4 and lock;

- F13 - ind. 1,3,4 and lock;

- F 14 - ind. 2,3,4 and lock;

- F 15 - ind. 1,2,3,4 and lock;

- F 16 - ind. 5 and castle;

- F 17 - ind. 1.5 and lock;

- F 18 - ind. 2.5 and a lock.

Since control panels for different models may differ slightly in appearance, indicator numbers are determined by counting from left to right, and not by function. Why the “lock” is on and the machine does not turn on, read here.

Call the master

Engine breakdown, electronic malfunctions, problems with the heating element require the help of professional technicians.

You can call a specialist to your home using the services of service centers (telephone numbers and addresses are not difficult to find in the operating manual for household appliances or on the Internet).

To avoid scammers, it’s not enough to study reviews (most of which may be untrue). There are a number of points by which you can distinguish an honest master from a false specialist:

- At the time of filling out the application, the technician always inquires in detail about the brand and model of the washing machine, and asks in as much detail as possible about the problem that has arisen.

- The specialist never announces the amount to be paid without inspecting the washing machine (the cost of the work depends on the type of breakdown, urgency and complexity of the repair).

- A real master always issues a Certificate of work done with a full breakdown of the cost of all actions.

Before letting a stranger into your home, it would be a good idea to ask for a document proving his identity.

How can I prevent problems in the future?

A few simple recommendations will help you operate your Indesit washing machine for as long as possible without breakdowns:

upon completion of the washing process, the laundry must be immediately removed and the drum wiped with a dry cloth;- during the period between washes, the hatch of the washing machine is left open;

- At least once a month, the powder receptacle tray is cleaned of soap deposits;

- drain filters are regularly inspected and, if necessary, cleaned of accumulated debris;

- By eliminating washing at the highest possible temperatures, you can not only extend the life of the washing machine, but also save your clothes from premature wear;

- Do not overload the washing machine.

The use of special tap water softening agents will help reduce the layer of scale on heating elements and, as a result, extend the life of household appliances without failures or repairs.

Prevention of the Indesit washing machine

Absolutely any equipment, if used incorrectly, will not last even the 7-10 years stated by the manufacturer.

Let's look at what needs to be done to extend the life of the SMA:

We invite you to watch a video about error codes for Indesit washing machines: