Nowadays, choosing a washing machine is quite difficult. Thousands of different models with different characteristics. Not so long ago, models of washing machines with direct drive appeared, what are the differences from a conventional drive, what are the advantages and, most importantly, are there any disadvantages of such machines. Let's figure out whether it's worth buying without a belt, as the advertisement says?

What is the difference between direct drive and conventional drive?

Direct drive units use an inverter motor that is mounted directly on the drum and does not require the installation of a belt drive. A special clutch is used as a mechanism for changing speeds.

Direct drive eliminates the need for additional transmission elements such as fasteners and pulleys, making the design more compact. Such washing machines may not visually differ at all from units with a belt, however, models with different types may also have their own inherent advantages and disadvantages.

Advantages of machines with a new drive

It is difficult to find real reviews from consumers who have tried direct drive in action. Most comments repeat advertising slogans. If you combine all the information you come across, then direct drive machines have the following advantages.

- Compact with greater capacity. Quite likely, since the missing belt, brushes and pulley allow the drum to expand while the body shrinks.

- Ten-year engine warranty. This is debatable, since in addition to the motor, other elements of the machine may break.

- Reduced noise and vibration levels. True, it is very insignificant, since the rustle from the constantly working belt is replaced by too noisy intake and drainage of water.

- Washing efficiency. They say that the expanded capabilities of the inverter motor with sharp stops and rotations in the opposite direction clean laundry better and fight the most stubborn stains. It is difficult to compare, since there were few complaints about traditional machines.

- Accelerated wash. The previously mentioned sharp operation of the inverter motor allows you to cycle faster, which saves a little time.

- Saving energy consumption. Due to the exclusion of some elements from the rotation chain and the ability to automatically control the required power by “reading” the weight of the loaded laundry.

- Diagnosis of the problem. The “Direct Drive” system is capable of signaling an excess of laundry in the tub by displaying a corresponding error, refusing to start the cycle, or randomly flashing indicators on the control panel.

In traditional machines, everything is different - the wash will begin and end due to a burnt or broken belt due to excessive load.

There are many “advantages”, but it is worth understanding that most of the listed advantages are relative and do not depend on the type of drive. So, with high-quality factory assembly, proper operation, ideal installation and the correct selection of detergents, even a belt machine will wash well and not make noise. Therefore, we take our time and compare specific models.

Pros and cons of direct drive washing machines

It is difficult to find real reviews from consumers who have tried direct drive in action. Most comments repeat advertising slogans. If you combine all the information you come across, then direct drive machines have the following advantages.

- Compact with greater capacity. Quite likely, since the missing belt, brushes and pulley allow the drum to expand while the body shrinks.

- Ten-year engine warranty. This is debatable, since in addition to the motor, other elements of the machine may break.

- Reduced noise and vibration levels. True, it is very insignificant, since the rustle from the constantly working belt is replaced by too noisy intake and drainage of water.

- Washing efficiency. They say that the expanded capabilities of the inverter motor with sharp stops and rotations in the opposite direction clean laundry better and fight the most stubborn stains. It is difficult to compare, since there were few complaints about traditional machines.

- Accelerated wash. The previously mentioned sharp operation of the inverter motor allows you to cycle faster, which saves a little time.

- Saving energy consumption. Due to the exclusion of some elements from the rotation chain and the ability to automatically control the required power by “reading” the weight of the loaded laundry.

- Diagnosis of the problem. The “Direct Drive” system is capable of signaling an excess of laundry in the tub by displaying a corresponding error, refusing to start the cycle, or randomly flashing indicators on the control panel.

The advantages of direct drive washing machines look very significant, but before making a final decision, it is worth considering the obvious disadvantages; alas, they also exist. Those who are going to buy a washing machine of this type should take into account the following disadvantages:

- Obviously higher price of purchase, operation, repair;

- Sensitivity to power surges, such a washing machine needs to be turned on only through a stabilizer;

- Quick erasing of the sealing gland.

More: Eco Bubble washing machine review, description, instructions

Pros and cons of direct drive

Direct drive washing machines have a number of advantages. First of all, there are fewer fragile parts, which primarily include the belt. Thanks to this, repairs need to be made much less frequently.

Reference. Due to the fact that the service life of many parts in such structures is longer, many manufacturers provide a guarantee for their products from 10 to 15 years.

Among other advantages it is worth highlighting:

- Low noise level. Belt drums knock loudly during spinning, and sometimes even drum (especially older models). The drive machines are so silent that during washing you can only hear the rustling of clothes or the draining of water.

- Stability of the structure. Belt-driven washing machines can vibrate a lot, especially during spinning. For this reason, the entire structure is relatively unstable, and the machine can simply move out of its place. The drive units do not vibrate during operation.

- The engine does not require frequent lubrication. In addition, maintenance needs to be carried out much less frequently.

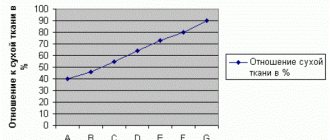

- The system automatically determines the weight of the laundry, i.e. the degree of loading of the drum. This makes it much easier to select the optimal modes. This allows you to avoid overspending, save water and electricity.

Reference. Drive washing machines can save up to 30% of water and electricity.

However, in addition to the advantages, drive “automatic machines” also have some disadvantages. First of all, the price is high. Some models can be $100–$300 more expensive than belt-driven machines.

Also, the disadvantages include vulnerability to power surges. Therefore, for safety reasons, it is best to use voltage stabilizers with such washing machines.

Direct drive design

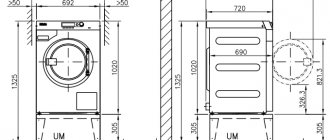

In direct drive washing machines, the motor is attached to the drum without the use of belts and pulleys; instead, a special clutch is used, which plays the role of the driving mechanism of the gearbox. The absence of additional transmission elements in such a machine makes it compact.

In most cases, direct drive washing machines use a three-phase brushless motor. It consists of a permanent magnet (rotor) and a stator equipped with 36 inductors.

The rotor is attached directly to the drum shaft. The rotor shaft is at the same time the drum shaft of the washing machine. The engine is controlled by sending signals from the electronic module.

How the mechanism works

Direct drive washing machines are characterized by a connection between the motor and the drum in the tub without the help of wires or belts. This happens without the use of pulleys and belts. Their functions are assigned to the clutch, which is the moving part for the gearbox. Due to the fact that this device does not use unnecessary parts and connecting and transmission elements, it is very compact.

Now it is time to analyze the main advantages and disadvantages of direct drive in a washing machine.

The best direct drive washing machines

High-quality direct drive machines are produced by such well-known brands.

LG

It produces excellent machines with electronic control, economical consumption of water and electricity. The equipment is high-quality and durable, equipped with a large number of necessary modes and programs.

Samsung

This brand offers durable and practical devices with an attractive design, large tank capacity, and a high level of all-round safety.

Bosch

It produces high-quality direct-drive machines with improved functionality, good spin power, and economical consumption of water and electricity. Bosch equipment can have not only large, but also compact dimensions.

Hotpoint-Ariston

Machines with a maximum load of up to 7 kg, a digital display, a high class of washing efficiency and low energy consumption - RST 702 X and VML 7023 B. Spin within 1000 rpm, 16 modes and equal power in other aspects.

Direct drive washing machine

Meaning of the mechanism

A direct drive acts as an electrical device that can convert electromagnetic energy into linear or rotary movement.

The design of such an engine transfers action to the rotor due to the air gap, which completely eliminates the possibility of wear of moving elements.

Direct drive is recognized as the most reliable electric motor.

The drive is the main structural element of any washing device. At the moment, direct drive and its device are used in the manufacture of their washing machine models by such manufacturers as LG, Whirlpool, Sears and many others.

Differences between direct drive and other converters

Less noise

In conventional machines, belt-type drum rotation transmission is common. It turns out that in such devices the drum is fixed on belts, which ensure the transmission of torque from the shaft.

The most vulnerable part of this system are the belts, which wear out from time to time and need to be completely replaced. In addition, washing and spinning in washing machines with belt drive are accompanied by high levels of noise and vibration.

The main distinguishing feature of machines equipped with direct drive is the complete absence of any brushes or belts in the motor, which are called contact units.

To find out if your washing machine is equipped with a direct drive, inspect the body - if there is a drive, then you will see a “Direct Drive” sticker on the front side.

More things

Due to the fact that there will be more free space in the case, and the electric motor of the washing machine is more powerful, direct drive models differ in that they can load more things than analog machines without direct drive.

Uniform cleaning of things

In conventional washing devices, the washing process is concentrated on things that are located in the lower part of the drum, while in direct drive washing machines, dirt is removed by spinning the drum back and forth.

Design features of the device

In direct drive washing machines, the motor is attached to the drum without a belt or pulleys, and instead of them a special clutch is used, which plays the role of an electromotive device for the gearbox.

The absence of unnecessary transmission elements in such models makes it more compact.

In many cases, direct drive washing designs use a three-phase brushless motor. Its components are a rotor (permanent magnet) and a stator, which is equipped with 36 inductors.

The rotor is attached to the drum shaft, and the permanent magnet shaft is also the washing drum shaft. The engine is controlled by sending meanders from the electronic module.

Operating rules

As you know, trouble is often easier to prevent than to eliminate its consequences. This also applies to washing machines. If you know how to properly care for your washer, and most importantly, don’t be lazy about doing it, the equipment will serve you faithfully for many years:

- To begin with, don’t neglect prevention. Even if nothing bothers you about the operation of the machine, once every three to four years it is worth inviting a specialist who will inspect the machine, carry out preventive maintenance, where it is necessary to lubricate and tighten connections, and replace worn parts.

- To avoid leakage on the engine, you need to change the oil seal in a timely manner. It is also better to entrust this procedure to a specialist.

- Bearings also require regular replacement. You should not bring them to the point where they crumble on their own.

- To protect an expensive electronic control system from sudden power surges, it is recommended to equip it with a separate outlet and protection against voltage surges. This may seem like an unnecessary expense, but if the washer’s “brains” burn out as a result of a power surge, repairs will cost a disproportionately large amount.

- To protect internal parts (heating elements) from scale and salt build-up, it is worth installing a special filter at the inlet. It will soften the water and extend the life of the equipment.

How to Extend the Life of a Direct Drive Machine

As you know, trouble is often easier to prevent than to eliminate its consequences. This also applies to washing machines. If you know how to properly care for your washer, and most importantly, don’t be lazy about doing it, the equipment will serve you faithfully for many years:

- To begin with, don’t neglect prevention. Even if nothing bothers you about the operation of the machine, once every three to four years it is worth inviting a specialist who will examine your assistant, carry out preventive maintenance, where it is necessary to lubricate and tighten connections, and replace worn parts.

- To avoid leakage on the engine, you need to change the oil seal in a timely manner. It is also better to entrust this procedure to a specialist.

- Bearings also require regular replacement. You should not bring them to the point where they crumble on their own.

- To protect an expensive electronic control system from sudden power surges, it is recommended to equip it with a separate outlet and protection against voltage surges. This may seem like an unnecessary expense, but if the washer’s “brains” burn out as a result of a power surge, repairs will cost a disproportionately large amount.

- To protect internal parts (heating elements) from scale and salt build-up, it is worth installing a special filter at the inlet. It will soften the water and extend the life of your home assistant.

Now you know what direct drive is in a washing machine and, taking into account all the above conditions, you can choose the best option for yourself. It’s worth approaching the issue responsibly and a direct drive washing machine will serve you faithfully for many years.

See also:

- 7 best washing machines under 20,000 rubles according to customer reviews

- 8 best narrow washing machines according to customers

- 8 best BEKO washing machines according to customer reviews

- 10 best washing machines from Samsung

- 10 Best Top Loading Washing Machines

Features of choosing a model

If the question of purchasing has become an issue, then the pros and cons of direct drive have already been described. This arrangement of the mechanism elements made it possible to significantly improve the quality and speed of washing. This is an important aspect when choosing household appliances, since there is no such thing as too much time.

Again, the maximum service life has increased. This, in turn, will allow you to use one machine longer, in which a lot of money has been invested.

The price of the machine will be paid off by the time it operates. But you should handle the unit carefully so that you don’t have to spend money on repairs. Is this type of washing machine better? Of course better. Less noise, washes faster, breaks less often and lasts longer. A housewife's dream.

A direct drive washing machine is an excellent purchase for home use. It is more convenient than other types, although it costs more. Of course, the design has its drawbacks, but its advantages are greater.

Rating of direct drive washing machines

- Washing machine LG F-14B3PDS7. Designed for 8 kg of laundry, has 14 washing programs and energy consumption class A++.

- Washing machine Siemens WD 15H541. Designed for 7 kg of laundry, has 15 washing programs and energy efficiency class A+++.

- Washing machine Siemens WM 14W740. Designed for 8 kg of laundry with 14 washing programs and energy class A+++.

- Washing machine LG F-14U1TBS2. Designed for 8 kg of laundry, has 14 washing programs and energy efficiency class A+++.

- Washing machine Bosch WAW28740OE. Designed for 9 kg of laundry with 8 washing programs and energy consumption class A+++.

- Washing machine Bosch WAW 28740. Designed for 9 kg of laundry, has 8 washing programs and energy consumption class A+++.

- Washing machine Bosch WAW 28590. Designed for 9 kg of laundry with 14 washing programs and energy class A+++.

- Washing machine Siemens WM 12N290. Designed for 8 kg of laundry, has 14 washing programs and energy consumption class A+++.

- Washing machine Bosch WAN 24290. Designed for 8 kg of laundry, has 8 washing programs and energy consumption class A+++.

- Washing machine Bosch WAN 28290. Designed for 8 kg of laundry with 15 washing programs and energy consumption class A+++.

When wondering whether to buy a direct drive washing machine, you need to weigh the pros and cons. The design of these types is constantly being improved, which eliminates the inherent disadvantages of washing machines.

As for cost, well-known brands offer lines of direct drive washing machines of both premium and economy class.

What is the difference between the design

Which washing machines are better?

The drum is driven by an electric motor installed on the washing machine. The torque is transferred from the device through the connecting belt or directly.

In the first case, the engine is located separately from the drum, a pulley is attached to the tank, onto which a belt is put, transmitting rotation from the motor.

This connecting part can be made of rubber or polyurethane. The latter are often yellow in color, stretch easily, but are short-lived, as they tend to dry out and crumble.

Rubber belts are black, durable, stretch worse than polyurethane ones, but last longer. The engine pulley has grooves for a specific type of belt, so the profile of the part and the connecting element must match.

The following execution options are available:

- Wedge-shaped. This is a monolithic belt containing one tooth, made in the form of a trapezoid, and has profile markings 3L/3LS (in foreign models), Z/A (in Russian brands).

- Polywedge-shaped. It is used more often than the first variety. It contains several rows of teeth or “streams”, representing the letter V, and has profile markings J (for large equipment, large wedge cross-section) or H (in small models, smaller cross-section).

The belt drive can be used with two types of motors:

- Collector. The mechanism is single-phase, there are two brushes charged with current, providing electrical connection of the rotor and stator circuits (the whole circuit is called a brush-collector unit). This type is quite noisy, the service life of the brushes is not very long.

- Asynchronous. The motor is three-phase, contains a stator, which is stationary, inside it there is a magnetized armature that rotates and creates a magnetic field. This option is less noisy and more durable.

Read more ► Washing machine pump: what is it for, how to remove and replace it yourself, do-it-yourself repairs

In direct drive washing machines, there is no pulley or belt; the electric motor is placed directly behind the drum and is connected to it using a clutch, which acts as the driving mechanism for the gearbox.

This connection is installed on inverter motors (another name is a three-phase brushless DC motor).

When buying a washing machine, you need to be guided by your own needs, but you should not purchase a too cheap model from a dubious manufacturer

They have a built-in moving rotor with magnets and a stator with windings. The engine speed is controlled by an inverter, which converts the voltage.

The rotor shaft is also the drum shaft. The design is able to determine the heaviness of the laundry and adjust the required rotation speed.