LG washing machine device

The design of the unit consists of several main components:

- Frame. Protects the mechanisms and serves as the installation frame.

- Display and control panel, program block. Designed to select a mode and monitor execution.

- Tank with drum for laundry.

- Electric motor. Rotates the drum with laundry.

- Electric heater (TEH). Heats water to the specified temperature.

- Water intake and drainage system. Supply and drain hoses, valves, pipes, filters, pumps ensure water circulation during washing.

- Balancing system. Vibration accelerates wear of parts. To reduce vibrations, counterweights, shock absorbers and springs are used.

Rating of the TOP 15 best LG washing machines

| Place | Model | Price |

| Direct Drive Models | ||

| #1 | LG F-12B8WDS7 | |

| #2 | LG FH-0C3ND | |

| #3 | LG F-1296TD4 | |

| #4 | LG F-10B8MD | |

| Washing machines with a capacity of 4-5 kg (narrow) | ||

| #1 | LG FH-0G6SD0 | |

| #2 | LG FH-0H3SD1 | |

| Washing machines for 6-7 kg | ||

| #1 | LG F-2J6NM1W | |

| #2 | LG F-1096ND3 | |

| #3 | LG F-10B8ND | |

| #4 | LG F-2J6WS0W | |

| Washing machines from 7 kg | ||

| #1 | LG F-1096TD3 | |

| #2 | LG F-2H5HS6W | |

| Steam wash | ||

| #1 | LG Steam F2M5HS4W | |

| #2 | LG Steam F2M5WS4W | |

Page navigation:

Types of faults

Let's look at the main defects of LG washing machines that can cause them to not work correctly.

Rattling and knocking

The appearance of such sounds indicates the following malfunctions:

- Foreign objects (coins, keys, buttons, etc.) between the drum and the tank.

- Damage or wear of the drum bearings.

- Destruction of the counterweight or imbalance.

- Shock absorbers defect.

Water leak

It manifests itself in the formation of smudges on the back wall of the drum, under the loading hatch, under the bottom. Leakage is caused by:

- Damage to the inlet or drain hoses.

- Distortion of the drain filter.

- Leaking valves or hoses in the powder receptacle.

- Worn drain pipe.

- Deformation of the central bearing seal.

- Damage to the tank.

- Pump failure.

Water does not drain

The automatic machine works in accordance with the program, but at a certain stage it stops and the water does not drain. Possible reasons:

- The pump pipe or drain hose is clogged.

- A small object has fallen into the pump.

- Pump failure.

- Level sensor problem.

- Incorrect operation of the electronic module

No water heating

Problems in which the water does not heat up:

- Incorrect operation of the pressure switch - there is no signal about a sufficient water level, the command not to turn on the heater is not issued.

- Damage to the electrical circuit of the heating element.

- Broken heating element.

- Temperature sensor problem.

- Control module malfunction.

The drum does not spin

The drum stops:

- Problems in the control module.

- Engine failure.

- Hall sensor malfunction.

- Drive belt rupture.

- Destruction of tank bearings.

Sunroof won't open

The reasons why the door does not open after the end of the program are:

- Malfunction of the drainage system - water in the tank, the door is blocked.

- Water level sensor failure.

- Damage to the door handle.

- Malfunction of the UBL (hatch locking device).

- Control module defective.

Blockages

The water drains slowly or does not drain at all. Causes:

- The drain filter or drain hose is clogged.

- The pipe is blocked by foreign objects or lime deposits.

- Damage to the pump impeller.

Mechanical wear

The moving parts of the device are subject to severe mechanical wear. The following nodes are critical in this regard:

- Bearings. Signs: extraneous sounds during operation (hum, creaking, grinding, whistling, etc.).

- Drive belt. Signs of stretching: slight rotation of the drum, weak belt tension on the pulley.

- Pump impeller. Signs of depletion: extraneous sounds when draining water, slow pumping.

- Balancing and damping mechanisms. Signs of wear: significant increase in vibration, extraneous sounds, loose drum.

Electronics failures

The electronics in LG washing equipment are convenient and reliable. However, failures in management do occur. The reasons are voltage fluctuations in the network, pressing buttons while executing a program, etc. Signs:

- The machine does not start washing, the hatch does not lock, the drum does not spin, error code is LE, EE, E3.

- Stop washing, sound and light alarm, error code AE.

To fix this, just unplug the machine for a few minutes and restart the washing program.

Breakdown of the pressure switch

Measures the water level in the tank to automatically fill or drain water. Signs of malfunction:

- Washing in an empty tank.

- Endless repetition of the rinse cycle.

- The machine spins the laundry, but the water does not drain.

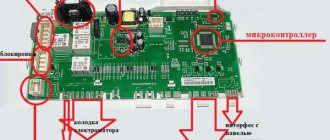

Problems with the module

In LG machines, the module is placed in a plastic box and filled with a compound to protect it from water. When a module fails, it is determined by the following signs:

- Maximum rotation of the drum at the beginning of the wash, an endless cycle of filling and draining water.

- The module freezes, the indicators do not light up, and the error codes change chaotically on the display.

- The wash doesn't stop.

- Incorrect operation of the heater.

Advantages and disadvantages of LG washing machines with inverter motor

Units with direct drive have a number of undoubted advantages over those equipped with a belt drive. It is the belt drive that is the source of noise and vibration during operation of the laundry washing machine. This creates discomfort for the owners; proper installation of the machine and adjustment of the legs are required. The increased noise level does not allow washing to be carried out at a convenient time, for example, at night, as this can disturb the neighbors and prevent them from sleeping normally.

If the motor is in direct contact with the tank, this problem does not occur. LG washing machines based on the Direct Drive principle are truly silent, they do not shake from side to side during the spin cycle, and a minimum level of vibration is ensured.

Another advantage of direct drive is a more automated washing process. If you exceed the maximum weight of laundry loaded into the drum, the system will detect the excess and refuse to execute the program, which will inform the owner by displaying an error code on the display. With a belt drive, washing will still begin, which creates a threat of failure of the unit and damage to parts.

A very important advantage of the Direct Drive system is the smaller number of spare parts included in the design of the mechanism. Replacing belts is one of the main reasons for contacting a washing machine repair service. They fray and become unusable due to prolonged and frequent use. With direct drive there is no such need, since the engine is directly attached to the tank.

The design features of the belt drive require more space to accommodate the rotation transmission system, and energy losses occur. Direct drive is more compact and economical.

Disadvantages of an inverter motor

Now about the cons. The most important of them is the greater sensitivity of direct drive devices to changes in the power supply. The current characteristics must be constant and correspond to the norm, otherwise the system begins to “be capricious” and the program goes astray. Russian power grids cannot always provide constant performance.

Since the motor is attached directly to the tank in which the washing takes place, if the seal is defective, water can harm it. It is not uncommon for LG machines to end up in a workshop where rust is found inside the rotor for precisely this reason. For a traditional system, this problem is not so pressing, since the motor is located relatively far from the drum, at the bottom of the machine body.

Otherwise, owners are usually satisfied with washers equipped with Direct Drive.

DIY repair

Knowing the typical breakdowns and having the skills of plumbing and electrical installation work, you can carry out quite complex repairs of LG washing machines with your own hands.

Before starting work, the device must be de-energized and disconnected from the water supply.

Replacing bearings

Repair using the example of a 6 kg model of laundry from the WD series with direct drive:

- Remove the top and rear covers, indicator panel, sealing collar, front panel.

- Disconnect pipes, wires, shock absorbers, counterweights.

- Disconnect the Hall sensor, remove the motor rotor and stator.

- Remove the tank and drum.

- Unscrew the screws from the mounting sockets at the joint of the tank and separate the halves.

- Remove the drum.

- Remove the oil seal and knock out the bearings.

- Install new ones, lubricate, install oil seal.

- Place the drum.

- Apply sealant to the joint, connect the halves, and tighten with self-tapping screws.

- Reassemble the machine in reverse order.

Replacing the heating element

The heater changes when it burns out, which is determined with an ohmmeter. To replace you need:

- Remove the back cover.

- Remove the wires from the heater and temperature sensor

- Unscrew the fastening nut.

- Remove the heating element by carefully prying it with a screwdriver and pulling it towards you.

- Insert the new heater into the socket. The part should fit along the guides with little effort.

- Tighten the fastening nut, connect the wires

Pump replacement

Procedure for replacing the drain pump:

- Remove the top cover, door seal, indicator, front and bottom decorative panels, counterweight and power control unit.

- Unscrew the drain filter.

- Loosen the clamps, disconnect the drain hose and pipe from the pump.

- Unscrew the pump mounting bolts.

- Remove the pump.

- Install and secure the new pump.

- Reassemble the car in reverse order.

Electronic module repair

The difficulty of repair is that the board is installed in a non-separable plastic box filled with silicone compound. To troubleshoot the problem you will need:

- Remove the module.

- On the reverse side, mark the projection of the faulty part on the plastic bottom.

- Use a soldering iron to burn a rectangle around the projection.

- Remove a section of plastic, opening access to the board.

- Using a screwdriver, carefully remove the layer of compound at the soldering site of the faulty part.

- Unsolder the part, replace it with a working one, solder it.

- Put the removed section of plastic back in place and glue it.

Replacing the pump

Repair work includes (using the example of the WD-80150HUP model with a load of 5 kg of laundry):

- Place the machine on its side, allowing access to the pump from below.

- Disconnect the pipe, drain hose, wires, unscrew the bolts, and remove the pump.

- Install a new one (the same or with the same characteristics).

- Fasten, put on the pipe, hose, connect to the electrical circuit.

Direct Drive Repair

Problems with direct drive are manifested by a loud hum, jerky rotation of the drum, and vibration. Repair work:

- Open the rear hatch.

- Unscrew the mounting bolts and remove the rotor and stator.

- On the stator, use a sharp tool to carefully remove the compound from the Hall sensor board.

- Find 4 resistors 681 on the board (labeled R01S, R02S, R03S, R04S in the diagram).

- Unsolder, solder in working ones.

- Fill the board with silicone sealant. Let dry.

- Install the stator and rotor, turn on the Hall sensor and power wires.

Hall sensor repair

A malfunction of the Hall sensor leads to uneven rotation of the drum, vibration, and hum. Repair:

- Carefully remove the silicone fill on the sensor board.

- Ring resistors R01S, R02S, R03S, R04S.

- If faulty ones are found, replace them with the same ones or select similar ones.

- Check the resistance between the sensor terminals: between 5 and 1, 5 and 2 there should be 10 kOhm.

- Fill the board with silicone and let dry.

Handle repair

The door handle is a plastic part that breaks easily. It can be repaired in this way:

- Apply superglue to the crack, forcefully connect the broken parts of the part, wait a few seconds.

- Apply superglue to an area 1-2 cm on both sides of the crack and sprinkle evenly with baking soda.

- Do the same on the back side of the part.

- Reinstall the handle.

The gluing area is reinforced with soda and acquires the necessary rigidity.

Drum rib repair

Plastic ribs in the drum make it easier to turn the laundry. Over time, they become loose and play appears. Defect fix:

- Heat the rib with a heat gun, remove it from the clamp, and remove it from the drum.

- At a distance of 1 cm from the bottom cut of the rib and 5 cm from each edge, make two holes, 0.5 - 1 cm long on each side.

- Slide two plastic clamps, teeth up, through the holes on one side of the rib.

- Pass the free ends of the clamps through the drum at the rib attachment points and pass through the holes on the other side of the rib.

- Warm it up with a hairdryer, fix the rib in the mount, tighten the clamp. Trim the ends.

- Do the same with other ribs.

Engine repair

A direct drive motor does not rotate in the opposite direction. Repair:

- Remove the stator.

- Remove the silicone from the Hall sensor board and ring the resistors.

- Unsolder the damaged one, and instead solder a working resistor with a resistance of 331 Ohms.

- Ring the terminals: on pairs 1 and 5, 2 and 5, the resistance should be 10 kOhm.

- Fill the board with silicone.

- Assemble the engine.

Replacing the cuff

A worn or damaged cuff is replaced in the following order:

- Remove the powder receptacle and top cover.

- Separate the indicator panel.

- Use a screwdriver to pry up the clamp securing the cuff and remove it.

- Remove the front panel.

- Unscrew the counterweights.

- Remove the cuff from the drum.

- Install a new one, paying attention to the alignment of the holes for the sensors.

- Assemble the car.

Advantages

- When working, the machine does not make much noise. If we compare direct drive with classic drive, then the first does not have a belt and pulley, which create noise during washing.

- Excellent balancing. There is almost no vibration during operation. There is not even a possibility that the car could roll into another room. In order for the unit to operate silently, it is not necessary to buy a special mat or stands for it.

- LG direct drive has a longer service life. Since parts shake less, engine wear slows down.

- It washes clothes better than standard machines, as the drum rotates faster and performs more precise movements.

- Less electricity is consumed during washing, but the difference is insignificant.

- The laundry tank is slightly wider than that of a machine with a classic drive.

Differences between standard and direct drive models

Features of LG washing machine repair

The LG washing machine range includes devices with direct drive and belt drive. The repair of both types is similar, since the designs are largely the same. However, there are differences that need to be taken into account when starting troubleshooting.

Direct drive

- Installing the motor on the drum axis leads to heavy loads on the bearings and reduces their service life. Therefore, repairs to the bearing assembly of an LG direct drive washing machine are done more often than in belt driven machines.

- When the central oil seal leaks, water enters the motor stator and damages it. A complete replacement is required. On the positive side, it is easier to get to the engine than in units with a transmission belt.

- The devices are sensitive to voltage surges, which damage the Hall sensor. Radio installation skills are required for repairs.

Belt driven

- The use of a belt and pulley reduces the mechanical load on the bearing assembly - replacement is required less frequently.

- Belt-driven units generate significant vibration, so repairs to balancing and shock-absorbing systems are carried out more often than for direct-drive machines.

- Regular replacement of the motor commutator brushes is required.

- Regular checking of belt tension, inspection and timely replacement are necessary.

HOW DIRECT DRIVE WORKS

Drive is a system for transmitting energy from its source to the actuator.

In a conventional SMA there is a drive with a belt drive, the components of which are a belt and a pulley. This has been the case since the invention of the electric motor washing machine. The engine is located in the lower part of the body, the energy for rotating the container with water and laundry is transmitted from it using a belt put on a pulley, which is attached to the tank.

Direct Drive machines do not require gears because the motor is attached to the tank. This is a completely different operating principle. In such an energy source there are no parts that rub against each other (brushes, etc.); it is constructed of a permanent magnet and 36 alternating current coils located at the same radius from it. The control unit sends a signal to each of them in turn, and they rotate around the core. This entire structure is located in a special housing, which can be disassembled if necessary. Such a generator can be immediately seen by removing the back panel.

LG also uses the inverter principle in such motors, which makes them even more economical and durable. Such designs provide for current frequency conversion. It should be noted that a direct drive motor and an inverter motor are different concepts. The latter can also supply energy via a conventional drive. It’s just that for Direct Drive, the inverter principle turned out to be one of the most optimal solutions, increasing its useful properties.

Top-loading models also come with Direct Drive generators. The principle of operation is the same.

✅ Call our master to your home for FREE: +7-982-231-69-66 .

LG washing machine with direct drive. Advantages

There are actually many advantages to this technology. Let's consider the main ones:

- Low noise level during operation of the device. Compared to the classic version, the new technology is much quieter. This is achieved due to the absence of a belt and pulley, which make additional sounds during washing.

- Better balancing. The LV direct drive washing machine is more balanced and causes less vibration during operation. This is possible due to the fact that the motor is located in the center of the unit and is directly connected to the drum.

Important! With such a washing machine, you don’t need a rubber anti-vibration mat to operate silently.

- Long working life. Such a motor does not require additional maintenance, and due to the absence of rubbing parts, the unit can last longer than classic models.

- Improving the quality of washing. An asynchronous motor rotates the drum faster and performs movements more accurately. Due to this, the quality of washing increases.

- Energy saving. The consumption of electrical energy by the LV direct drive washing machine is more economical. The difference is insignificant, but still it exists, thanks to the absence of rubbing elements.

Important! The inverter also determines the weight of the laundry, thanks to which the machine controls the drum rotation speed, engine power and the amount of water used. Thus, the amount of water used during washing is used more thoughtfully and economically.

Important! Do you want to know what the different letters and numbers in the names of washing machine models mean? We have prepared a separate review “Deciphering LG washing machines.”

Features of direct drive machines compared to others

One of the world leaders that has won a significant share of consumer sympathy is the South Korean company for the production of household appliances LG.

LG's direct drive washing machine is one of the company's latest patented developments.

The technology can significantly improve the quality of the product, reduce dimensions and minimize the amount of noise emitted during operation.

The constant search for the optimal design of a washing machine influenced the processing of the usual connection between the motor and the drum of the machine.

The standard connection between the motor and the drum implies the presence of additional belts that provide rotation.

The relatively short service life of belts leads to the constant need to lubricate moving parts and replace them in a timely manner as they wear out, which is quite inconvenient.

The direct drive of the LG washing machine means the motor is directly connected to the drum, without additional elements. The official name of the technology is “direct drive”.

Due to direct clutch, the size of the machines is reduced. Dimensions in laundry washing units are one of the key parameters, so an inverter machine has narrower widths compared to an analogue with a standard drive form.

Direct Drive Top Load Washing Machines

Today, Direct Drive technology in LG washing machines is successfully used by other manufacturers of washing appliances. It is worth noting that this design is suitable not only for front-loading units.

There are also top-loading direct-drive washing machines on the home appliance market. They have all the advantages and disadvantages of front washing machines with this drum rotation technology.

Important! Among the variety of models, the world-famous brand LG produces washing machines with steam. Why is this function needed in a car? What are the advantages and disadvantages of this feature? We discussed all these issues in our review of LG washing machines with steam.

Direct drive design

In direct drive washing machines, the motor is attached to the drum without the use of belts and pulleys; instead, a special clutch is used, which plays the role of the driving mechanism of the gearbox. The absence of additional transmission elements in such a machine makes it compact.

In most cases, direct drive washing machines use a three-phase brushless motor . It consists of a permanent magnet (rotor) and a stator equipped with 36 inductors. The rotor is attached directly to the drum shaft. The rotor shaft is at the same time the drum shaft of the washing machine. The engine is controlled by sending signals from the electronic module.

The best LG direct drive washing machines

A review of direct drive washing machines is distinguished by certain models. Which one is best is determined by the user, depending on personal requirements. There is no consensus on this matter.

Based on reviews from owners, the following models of washing machines can be distinguished:

- LG FR296WD4 – built-in machine, maximum load 6.5 kg. It has 13 washing modes (from delicate washing to cleaning complex stains). Spin power 1200 rpm. Users note the quiet operation and high quality of the device and do not identify any serious shortcomings.

- LG F12B8WDS7 is the most budget model from the presented list. The built-in stain removal program, wash and spin program allow you to deal with even heavy soiling. The capacity of the machine is 6.5 kg. Power 1200 rpm. Owners in reviews note the successful design of the drum, which makes it possible to conveniently load the machine, which is especially convenient for large families. In addition, there is a virtual complete absence of noise during operation and an excellent price-quality ratio.

- LG F1296ND3 - maximum load 6 kg, spin speed up to 1200 rpm. Number of washing programs -13. Owners of the machine note the high quality of washing and a large selection of programs. Among the shortcomings is the lack of a drying function.

The best LG washing machines have certain features that make housekeeping easier, such as:

- The turbowash feature allows you to finish cleaning items in less than an hour, while ensuring high quality washing.

- Remote control using a smartphone.

- The built-in program for detecting errors in washing devices allows you to save money and time in case of breakdown.

- An automatic machine load indicator helps determine the optimal amount of water and machine operating time.

- The high-quality washing function is supported by the international quality class of washing, spinning and energy consumption not lower than level B.

- The direct drive machine is narrower than the standard system.