Why do you need a surge protector?

Repairing home appliances is expensive, so it’s better to protect your assistant in advance with a special device that:

- smoothes out voltage drops directly in the machine;

- prevents high frequency currents from entering the electrical network from the washing machine.

The principle of operation of the device is to block oscillations, with the exception of 50 Hz. During the working process, the asynchronous motor of the machine produces dips or peaks of electric current that pose a danger. The interference filter, in turn, catches them and sends them to a resistor, which transfers the currents to grounding.

SMA surge protector

Protective devices save equipment not only from increases, but also from decreases in voltage. When the indicator is low, the drum stops rotating, while the current continues to flow. As a result, the engine overheats and burns out. To prevent this, the noise filter stops the power supply.

In the event of a short-term voltage drop, the device does not block the operation of the washing machine, but uses the energy accumulated in the capacitors. A short decline is observed when other powerful devices are turned on in the apartment.

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Ask a Question

Many people consider a filter to be a more expensive extension cord with a switch. But do not confuse a regular extension cord and a surge protector. Only the second device protects a complex system of household appliances from breakdowns. Unlike an extension cord, the protective filter has a complex design and is manufactured with grounding.

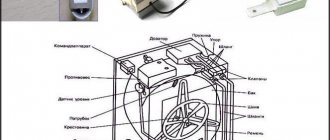

Internal filter

Modern washing machines, especially touch-sensitive ones, are high-tech, but at the same time quite sensitive to power surges. Without protection, the machine can burn out, receiving overestimated or underestimated impulses.

Therefore, manufacturers equip devices with internal surge protectors. They are built into the machines at the time of manufacture or purchased later and connected via a power source.

Internal interference filters vary in degree of protection, which is determined by:

- maximum load indicator;

- passable voltage level;

- rated electric current;

- time before response after the occurrence of fluctuations in the network.

A built-in interlocking device in a shockproof, non-conductive housing is located next to the electrical cord. If it breaks, it is not repaired, but replaced with a serviceable original part.

Online diagnostics of a washing machine

If your machine stops washing or rinsing clothes normally, then some kind of malfunction or breakdown has occurred.

You can try to find the problem yourself. Run diagnostics

Select which operation your washing machine does not perform:

1. Doesn’t drain 2. Doesn’t rotate the drum 3. Doesn’t spin clothes 4. Noises, knocks, buzzes when spinning 5. Doesn’t turn on

Checking the operation of the drain pump Is the drain pump of the washing machine working? Yes No I don’t know << Back

Clogged hoses in the washing machine If the sound corresponds to the normal sound that has always been observed when the device is working, the cause is probably a clog.

Was there a blockage in the drain hose? Yes

<< Back

The drain pump does not work! If the sound matches the normal sound of the drain pump, it is recommended that you check the drain filter first.

After cleaning, does the drain pump work and does the washing machine drain water? Not really

<< Back

Operation of the drain pump The sound of the pump is usually immediately audible and noticeable. If there is no sound, the pump is not working. We are looking for how to separately enable the water drainage program. As a rule, this is a separate option. After the program has been turned on, the pump should start working in 1-3 seconds. If everything is done correctly and the pump is operational, a buzzing sound will appear. If you hear no buzzing or other sounds when you turn on the program, the pump is probably faulty.

Is the washing machine drain pump working? Not really

<< Back

Clogged car hoses If you have identified a clog in the hoses, you need to disassemble them, clean them, and then reassemble everything.

Does the washing machine drain well? Not really

<< Back

Hurray, you did a great job, you fixed it.

<< Return to the beginning of diagnostics

The drain pump is faulty, call a professional.

<< Return to the beginning of the diagnosis.

The washing machine does not rotate the drum. During the operation of the washing machine, such a problem may occur. Each model has a different drum operation. It rotates according to a given algorithm, which is set by the program. This principle applies to spinning and washing. If you are not sure whether the drum is not spinning or whether it is working, put the laundry in the washing machine. Start the spin program. If the machine is running, it will first drain the water and then start spinning. In this case, a rotational process will be observed. If rotation is not visible, then check the belt. First, turn off the program, then unplug the wire from the outlet so that power does not flow into the device. Now you need to remove the back cover. You will need to carefully inspect the drum belt. It is quite easy to determine whether it is in the wrong position or damaged.

Is the washing machine belt torn or stretched? Not really

<< Back

Broken drum drive belt If the belt breaks, it will be immediately visible. There are also often cases when the belt simply stretches, which is why the drum, accordingly, does not rotate. Do not allow the machine to operate if the belt breaks. It is important to check whether it has wound around the engine pulley or broken the wiring to the engine. The heating element and temperature sensor may also be damaged if the belt does catch the wires. It is imperative to ensure that the belt model is original. If you choose an unsuitable or low-quality product, this will affect the performance of other devices. How do you know what kind of belt you have? There will be a marking written on the old one, compare it with the one indicated on the belt offered to you. You can also find out belt information by car model.

<< Return to the beginning of the diagnosis.

Washing machine motor malfunction If a malfunction is not found, the block with wires must be disconnected from the electric motor. Carefully remove it. We visually evaluate the engine. It may have melting, cracks, or other effects that clearly indicate damage. We call the windings of the tachogenerator and the engine. It is important to understand that you can fully study how correctly the engine operates and whether there is a malfunction only at the stand. If rotation does not occur, there may be a problem with more than just the motor. Sometimes the cause is a malfunctioning electronic module. If a short circuit occurs in the engine, the module could be damaged, while the engine remains operational. Also, the wires could be damaged.

<< Return to the beginning of the diagnosis.

Repairing a washing machine that does not spin clothes After completing the washing process, the washing machine may not spin properly or may not start spinning. Firstly, look, perhaps another mode is set, which does not involve turning on the spin cycle at all. This happens, for example, with programs related to washing woolen items and delicate fabrics. To check, run the spin cycle separately. If the washing machine does not drain water, we proceed to check the pump.

Does the washing machine now spin clothes? Not really

<< Back

Congratulations, you have solved your problem!

<< Return to the beginning of the diagnosis.

Repair of washing machines, imbalance Modern washing machines place the laundry on the drum before spinning. This is necessary for quality work. Check if this feature works. Sometimes a situation occurs when things get wrapped up in a ball that cannot be unwound automatically within a certain time. At this point the work stops. You need to unwind this laundry yourself, lay it out and continue operating the washing machine. In this case, it is important to turn off the machine, and then, when the laundry is laid out, turn on a separate spin program.

Does the washing machine now spin clothes? Not really

<< Back

Washing machine repair, drum drive repair Now you need to check the drum drive belt. We remove the cover and visually assess the condition of the belt. There should be no damage. If the tension is weak, the spin may not turn on. If you need to replace the belt, you should only replace it with the original one. After replacing, we try the program again.

Fault found, does the washing machine spin? Not really

<< Back

The engine or electronic module is faulty, call a repairman to your home.

<< Return to the beginning of the diagnosis.

The washing machine hums, makes noise during the spin cycle, rumbles, and makes a jet plane noise. If the washing machine makes noise during operation, making unusual sounds, it’s time to pay special attention to it. In this case, a visible breakdown or lack of functionality may not be observed, but the appearance of strange sounds indicates that it is time to look for a malfunction. It is important to understand that a new car that has just been delivered should be inspected for shipping bolts. If you forget to remove them, noise and vibration are inevitable. So, let's begin! We turn the washing machine drum and listen to extraneous sounds.

When rotating, do you hear extraneous noise, hum, balls rolling, does the drum move unevenly with slight jamming? Not really

<< Back

If the drum rotates and uncharacteristic sounds appear, including vibration, it’s time to check the bearings. If they malfunction, they will have to be replaced.

<< Return to the beginning of the diagnosis.

The counterweight of the washing machine has come loose. The fastening of the counterweights must also be of high quality. If they are “loose”, it’s time to eliminate this defect. In some cases, you can notice that the bolts that secure the stones are completely missing. In this case, the connectors for mounting will be visible. The bolts need to be found and put in place - they probably simply came loose. A rumble heard while the washing machine is operating may indicate that the bolts have partially loosened. To check the bolts, you can simply push the drum. If it is secure, the bolts are fine. If it moves, there is a defect.

Do you hear any noise, clanging or rattling noises when moving the washing machine tub? Not really

<< Back

The counterweight has come off

<< Return to the beginning of diagnostics

Checking the shock absorbers of the washing machine Checking the shock absorbers. If you hear vibration or excessive noise during the spin cycle, there may be a problem with the shock absorbers. Sometimes the washer moves. Now let's check the functionality. Remove the top cover. Click on the tank, move it five to seven centimeters down. A normal reaction will be observed if the tank rises sharply, jumping a little and stopping in its normal place. If this does not happen, the shock absorbers need to be replaced.

Are the shock absorbers of the washing machine working? Not really

<< Back

If a visible defect has not been identified, check whether a foreign object may have entered the machine. Replacing shock absorbers. The problem with shock absorbers wearing out occurs quite often over time.

<< Return to the beginning of the diagnosis.

Replacing washing machine shock absorbers. Malfunction and wear of shock absorbers is a fairly common phenomenon.

<< Return to the beginning of the diagnosis.

The washing machine does not turn on. It is worth trying to find the cause of the problem yourself and fix it. We start by connecting the device to the network. Next, click on the “network” button. In different car models, different indications are triggered: here either the display will start working, or, on the contrary, some other button.

Does the washing machine have an indicator? Not really

<< Back

Hatch lock lock (UBL) You can check it by turning on any of the programs. We choose what we will use. Click on the corresponding button. Don't forget to pay attention to the inclusion. As a rule, the process of activating a function is characterized by the presence of a certain sound, for example a click, with which the device makes it clear that pressing again is not necessary and the machine is already working. If there is no sound, the button may be broken. In this case, the main thing that must be done is to block the hatch and start working. If this happens, everything is fine.

The washing machine is blocking the hatch and the UBL is triggered? Not really

<< Back

Water fill valve malfunction

<< Return to the beginning of the diagnosis.

The washing machine hatch does not lock

<< Return to the beginning of the diagnosis.

No indication Checking the electrical circuit. If you notice that the washing machine does not respond to being turned on, it is first recommended to check the power supply. The outlet may be faulty. Try connecting another device. If the outlet works, you need to check whether the circuit that conducts energy through the washing machine from one element to another is intact. To do this, you will need a multimeter, which will help you fully analyze the ability to respond to an electrical signal at several stages of operation. If there is no network connection anywhere, this is probably the problem. We carry out this manipulation until we reach the electronic module. If we are talking about an old washing machine, here it will look like the device’s program. When you turn on the button, there should be no breaks in the circuit. If the circuit works, everything is fine electrically.

Is the washing machine's power supply OK? Not really

<< Back

Repair of electronic module (unit)

<< Return to the beginning of diagnostics

Contact circuit fault

<< Return to the beginning of diagnostics

External

Externally, the filter device, based on the level of protection, is:

- basic;

- professional;

- advanced.

The number of sockets can be different: from 3 to 8, the cord length ranges from 1 to 5 meters. Some models have on/off buttons and child safety locks.

124gsm.ru

livolotouch

wint.kz

The more powerful the device, the higher its cost. The range of vibrations absorbed by the blocker is determined by such a characteristic as the maximum load. Also of great importance is the speed at which the filter responds when differences occur.

Using an external filter requires compliance with certain rules:

- The device cannot be connected to a 380 V power supply.

- Never use an ungrounded outlet.

- The power of the household appliance should not exceed 3.5 kW.

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Ask a Question

In addition, it is not recommended to connect interference filters one after the other in order to extend the cord.

Replacing washing machine drum bearings

Many owners of Indesit machines have encountered this situation - the washing machine filled with water and stopped. The situation is typical for both front-loaders and Indesit machines with vertical loading. Error code F07 appears on the display, restarting the machine does not help, cold wash programs work without failure.

In a small percentage of cases, the cause of the malfunction is oxidized contacts, but you must be prepared for the fact that you will have to buy and install a new heating element.

The heater of the Indesit washing machine is located at the bottom of the tank. To access it, simply remove the back wall. It is important to remove water from the machine before starting work, prepare rags and a container to collect its residue, otherwise a small flood is guaranteed.

Before dismantling the heater, you need to check it with a multimeter. To do this, the device is switched to resistance measurement mode; if it shows an infinite value, the heating element must be replaced. It's not difficult, you just need to unscrew the mounting plate and pull it towards you.

Next, install a new heater and reassemble the machine, proceeding in the reverse order.

We suggest you familiarize yourself with Diesel particulate filter: do-it-yourself cleaning

Signs of this malfunction are easy to notice without any indication - a strong hum is heard during operation, at low speeds it gives way to a characteristic crackling sound. This can only mean that the bearings have served their purpose and need to be replaced.

If you hear third-party sounds, you should not delay repairs; the car may jam, resulting in engine failure, then repairs will cost an order of magnitude more.

Replacing bearings in a washing machine is a labor-intensive task, the main difficulty of which is that the drum of most models, for example, Indesit wisl 102, is not designed for repair. It will have to be removed, carefully sawed and then re-glued. Despite the obvious difficulties, such repairs will cost much less than buying a new drum.

Compared to the cost of other units, bearings cost pennies, so you shouldn’t try to save money on them; it’s better to overpay for products from famous manufacturers than to have to deal with repairs again in a month.

How to check

Manufacturers have provided a function to automatically turn off the washing machine when the noise filter fails. The device will not resume operation until the part is replaced with a working one.

- If, upon inspection of the cord and plug, no damage was found, it is worth checking the interference filter:

- Test all contacts in pairs with a multimeter. The resistance should correspond to 680 kOhm.

- The input impedance directly on the plug should be approximately at the same level.

- Try testing the capacitors by measuring the capacitance between the inputs. Normally, the indicator corresponds to 0.47 μF.

If deviations from the norm are found during the check, then the surge protector is damaged and requires replacement.

Multimeter

How to choose the right one

Technical devices that protect household appliances are widely represented on the market. You can find a suitable surge protector for your domestic or imported washing machine not only from the official supplier of “original” spare parts, but also in any store with the appropriate assortment.

Are you unplugging your washing machine?

Oh yes! No

Be sure to pay attention to the indicators:

- maximum pulse overload current, which affects the device’s ability to smooth out voltage surges;

- maximum current consumption corresponding to the power of the machine multiplied by 2 or 3.

A faulty internal noise filter can be temporarily replaced with an external one, connected to the network through an outlet.

Undoubtedly, every washing machine needs an RFI surge filter. The importance of protecting equipment from power surges cannot be underestimated. Modern devices that smooth out interference will protect the entire system of household appliances.

What can damage the filter?

Like any device, a surge protector for a washing machine can fail. Most often this happens because the working life of this electronic component has expired. The filter device contains capacitors. Over time, their capacity decreases and the filter stops working. Other factors also lead to failure:

- burnout of contacts;

- filter breakdown caused by an extremely large voltage surge in the electrical network.

Sudden and significant voltage drops will occur if, for example, you connect a welding machine to the same power line as a washing machine or remove the plug from the outlet while it is running.

A filter failure results in the washing machine being completely inoperable. Manufacturers specially program the electronics in such a way that if the surge protector is faulty, the operation of the machine becomes impossible. This was done to protect other electronic components of the device. But the reason why a machine fails to work is not always a malfunction of the filter. Therefore, at a minimum, before checking whether the filter is working, make sure that the network cable is intact and the socket is working properly.