The washing machine has malfunctioned: the wash does not start, the drum does not rotate? You may need to check the health of the washing machine motor. When a motor failure occurs, the SMA stops working completely.

You can determine the malfunction by external signs - we described each in detail in this article. You will also learn how to properly check the motor in a washing machine with a multimeter.

Types and principle of operation

There are three main types of washing machine motor:

- Asynchronous (single-phase, three-phase). Single-phase was used in older SM models. Its quiet operation and simplicity of design made it popular in the 2000s. The part consists of a stator and a rotor. However, larger sizes and low efficiency have been replaced by more compact models.

- Collector. The most common type today. The motor is compact, silent in operation, and rotates at high speeds. It operates on a belt drive, and most importantly, does not depend on the frequency in the electrical network. Easy to disassemble, allowing you to carry out repairs yourself. However, its graphite brushes wear out quickly and require replacement.

- Direct drive (brushless). Modern development of manufacturers. This type does not require a belt to rotate the drum. A three-phase motor and a magnetic rotor allow you to reach high speeds with high efficiency. Thanks to the compact size of the motor, washing machines have smaller dimensions.

It is important to know which motor is in your washing machine and what to do if it does not start.

Before checking the performance of the electric motor, let's consider its operating principle and main components.

What motors are used in a washing machine?

As already noted, automatic machines use three types of motors. They all have different structures and also differ in operating principles. This will be discussed further.

Asynchronous electric motor

Asynchronous motors for washing machines also have a division:

- Two-phase or capacitor;

- Three-phase.

Two-phase ones are considered obsolete and have hardly been used since the 2000s. They were replaced by more advanced three-phase ones. They consist of two main parts: a stationary stator and a rotor placed inside it. It is the latter that drives the drum. How does this happen? The rotor is connected to the drum by a belt that transmits rotation. So when the rotor turns, the drum also turns. The number of revolutions per minute can reach up to 2800.

An asynchronous electric motor has the following advantages:

- Low cost;

- Simple design;

- Low noise level during operation;

- Easy maintenance. The most you have to do is lubricate it or change worn bearings.

Among the shortcomings we note:

- Low efficiency;

- Large dimensions;

- Difficulty in managing electrical circuits.

Such a motor is found in cheap models of automatic machines, as well as in semi-automatic washing machines. More modern and powerful models do not have them.

Commutator motors

A commutator or universal electric motor is used in most automatic machines. It can operate on both direct current and alternating current. This is where its versatility lies.

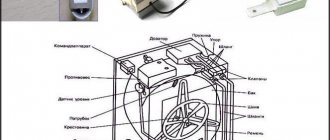

The main components of the motor are:

- Rotor (armature), which is the moving part;

- Stator - stationary part;

- Brushes. Provide electrical contact between the armature and the stator;

- Tachogenerator. Controls the speed of rotation of the armature.

Some models of automatic cars from Bosch and Siemens have a Hall sensor instead of a tachogenerator.

The transmission of rotation is ensured by a belt that connects the drum pulley to the drive.

The advantages of a universal electric motor are as follows:

- Simple control scheme;

- The ability to smoothly control the speed, the frequency of which is regulated by decreasing or increasing the voltage;

- Compact dimensions;

- Low cost;

- Maintainability.

The disadvantages include:

- Noisiness;

- Short service life;

- The need to replace brushes and belts, which are prone to rapid wear.

Low efficiency is also a disadvantage. This is due to the fact that part of the energy is spent on overcoming the frictional force of the belt transmitting rotation.

Direct Drive Inverter Motor

The South Korean company LG first began using an inverter electric motor or Digital Inverter in its cars. They can be of two types:

- Inrunner - rotor magnets are placed inside the stator;

- Outrunner - magnets are placed on the outside.

The main thing to distinguish them is in the drive. In the first case, a belt drive is used, in the second, the drive is connected directly.

It is the latest technology that is used in LG automatic machines. Over time, other manufacturers of household appliances began to use it, since automatic machines with direct drive were liked by consumers for a number of significant advantages. But we'll talk about them a little later.

What is special about Digital Inverter? It, like the commutator, consists of a rotor and a stator, but there are no brushes in it. Its operating principle is completely different.

An inverter is used to connect the machine to the electrical network.

This element controls the speed of the electric motor, converting alternating current into direct current. This allows you to control the mechanism with extreme precision.

Advantages of washing machines with Digital Inverter:

- Compactness;

- Low noise level;

- Durability - due to the absence of wearing parts;

- High efficiency (95%);

- A large number of drum revolutions, as well as the ability to configure different modes of its rotation. Example: 6 Motion technology in LG cars.

The disadvantage of Digital Inverter is its high cost. And in the event of a breakdown, repairs will require equally expensive components. This is due to a more complex control scheme. However, most manufacturers provide a 10-year warranty on these engines.

How does the motor work in a washing machine?

Stator. This part consists of steel plates with copper windings located between them. The stator itself is motionless, but the magnetic field it produces interacts with the field of the rotor, causing it to move.

Rotor (armature). The element consists of a core, winding, and collector. The rotor interacts with brushes, which transmit voltage to its commutator.

Tacho sensor. This part is located on the engine housing. The sensor measures the speed of revolutions and transmits data to the main module. Depending on the selected mode, the module adjusts the rotation speed.

Causes of malfunction

- Every user should know how to check motor brushes. By transmitting current, the brushes quickly wear out, which can cause the washer to stop.

- The cause of MMA failure may be worn lamellas. Their connectors become rubbed and nicks form, which requires replacement or repair of the washing machine motor.

- If there is a break in the stator or rotor windings (this may be the result of a short circuit), then repairs also cannot be avoided.

Before resorting to replacing parts, let's find out how to check the commutator motor in a washing machine.

Inverter washing machines: is it worth buying?

Everyone knows that inverter-type washing machines cannot be called affordable. Now let’s figure out whether it’s worth paying exorbitant amounts of money for a washing machine with an improved engine.

The indisputable advantage of inverter machines is energy efficiency. Compared to conventional washing machines, improved models consume 20% less electricity (at least as advertised).

Let's look at an example. You have loaded 2 kg of dirty laundry into the washing drum. If you have a regular washing machine, the drum will operate at maximum speed. By choosing an inverter-type machine, you will ensure “reasonable” operation of the engine: by adjusting the speed, the motor will not be spun up to the maximum. Thus, by stabilizing the rotation speed, the device will consume less electricity.

Considering that the bulk of the energy goes to heating water, using such units, you can actually save 2-6% if you do not load the drum to its fullest.

Let's look at such a criterion as “silence”. Direct drive washing devices (for example, LG Direct Drive ) are much quieter because the drum rotates without the use of a belt. In addition, you may not like the whining and whistling noise that inverter motors make.

Direct Drive system - direct drive

Spinning at high speed is a very good argument in favor of a quick wash. But you should be aware that 1600-2000 rpm per minute can have a detrimental effect on the integrity of your clothes. Sometimes it turns out that you do not take out a well-wrung item, but its individual pieces.

Developers of inverter motors claim that their brainchild will ensure the longevity of the washing machine. This begs a completely logical question: “How long are you willing to use your washing machine?” Perhaps 10-15 years. Almost every washing machine in the mid-price segment can cope with this indicator. Moreover, nothing stands still, especially scientific progress. In ten years, washing machines will be more advanced, and you will 100% want to purchase some modern model. Now think about whether you need durability at a great price.

Machines with inverters: breakdowns are rare

As for the accuracy of revolutions, this advantage is very doubtful. The unit you purchased should simply wash clothes well and spin clothes well. And what difference does it make with what accuracy this will happen?

Inverter washing machines are devices with a modern engine. If its components break down, you will need to pay a tidy sum for replacing individual parts.

Stages of inspection

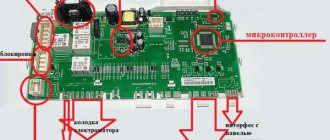

Why are we going to check the commutator motor? Because other types cannot be tested at home. You can determine their breakdown only by external signs, or by the error code on the machine display.

The first step is to remove the motor from the car body. To do this, turn off the power to the washing machine and disconnect all communications. Now:

- You need to remove the back cover from the case. In some models, you will first have to remove the top cover. To do this, unscrew the two screws from the back and set the top panel aside.

- Unscrew the bolts around the perimeter of the back cover and remove it.

- Below, under the tank, you will see the engine.

- Take photos of the connectors, disconnect the wiring.

- Remove the bolts holding the motor. Pull it out of the case.

To check whether the electric motor has burned out, it is enough to inspect it superficially. Next, proceed to a serious check: connect the stator and rotor windings alternately, connect the remaining ends of the wire to a 220 Volt voltage source. Proceed according to the diagram below.

This way you will check the electric motor of the washing machine. If it rotates, it means it is still working, if not, it must be replaced.

However, it must be taken into account that in the working environment the part rotates under load. Therefore, you need to fully check all components.

Checking electric brushes

Signs of brush wear:

- When the SM is operating, noise and grinding noises are heard.

- The drum rotates only at low speeds or stops altogether.

Rapid wear is caused by overloading the washing machine with laundry and constantly turning on the spin cycle only at high speeds.

When checking the motor on a washing machine using the voltage connection method, you may notice that the brushes have begun to spark. A visual inspection will help you verify this: they are located on the sides of the body. Disconnect their wires and pull them out. The photo shows what a new and worn brush looks like:

Be sure to change both brushes at once, otherwise the impact on the rotor will be uneven. You can buy a suitable product by naming the brand and model of your washing machine.

The elements are installed in the reverse order, then the wiring is connected to them.

Problems with slats

Let's look at how to check the electric motor commutator. By visually inspecting the commutator along which the brushes slide, you may notice small delaminations. The lamella is peeling off due to the jamming of the engine.

When you lightly turn the rotor, you can hear a scraping sound - this indicates problems with the collector.

If these are small peelings, a groove on the machine will help. The lamellas are sharpened, all burrs and chips are removed.

Advantages of an inverter motor

Inverter washing machines boast:

- lower energy consumption and better efficiency (this is due to the fact that the number of rubbing parts in the design has been reduced);

- high durability (you don’t have to change engine brushes from time to time);

- low noise level (achieved, again, by eliminating parts rubbing against each other);

- reduction of vibrations during the washing process, which contributes to better distribution of laundry in the drum;

- instant access to the desired speed and its support;

- smoother start, which wears out the engine less;

- spin at high speed;

- almost dry laundry at the exit due to the large number of revolutions per minute (up to 2000).

Dry laundry out