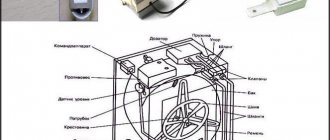

Operating principle and types of locks

Today, two types of locks are commonly found:

- Electromagnetic.

- Bimetallic.

The first type is used less and less. Its main drawback is that the lock only works properly as long as there is electricity. If the light is turned off, the washing machine will not be unlocked.

The operating principle of a bimetallic lock is very simple: voltage is applied to the thermal element and heats it up. The hot thermocouple heats up the bimetallic plates; under the influence of heat, they expand and press on the lever. It goes off and blocks the door. At the end of the program, the voltage supply to the lock stops, the plates cool down, narrow and the latch returns to its original place. The washing machine hatch is unlocked.

The second type of locks has a number of advantages. Firstly, there is a delay in unlocking the hatch at the end of the program. This is necessary so that the washing machine completely drains the water and all its elements complete their work. Secondly, even if the power goes out, the lock will unlock, and the door can be opened and the laundry taken out. This type of UBL is used by many modern manufacturers of washing machines - LG, Samsung, Indesit, etc.

Operating principle and diagnostics of the washing machine lock

The washing machine lock is a safety mechanism that ensures it remains sealed during operation. The lock prevents the lid from opening inadvertently during operation, and also stops the washing program if the hatch is not closed tightly. Like the main part of the parts, the lock is subject to wear, so it is necessary to replace it in a timely manner.

Reasons for lock failure

There are several reasons why the door lock of a washing machine breaks.

- Firstly, this is the wear of bimetal plates as a result of prolonged use of the equipment. As a result of regular deformation, their functional properties are lost.

- Secondly, the reason may be a short circuit.

In some cases, the problem may not be with the UBL. If the washing machine has finished working, but the door does not open, the triacistor on the central board responsible for the operation of the lock may be faulty. In this case, voltage continues to flow to the locking device and as a result the door remains locked.

What if the device is broken?

A non-functioning UBL, among other breakdowns, may prevent the washing machine from starting a new cycle. To accurately determine whether a lock needs repairs, you only need to take a couple of steps.

First, open the door, expose the lock and find the movable plate. We move it to the “working” position and connect the multimeter probes to the contacts. We evaluate its performance by checking the displayed values with the established norm. Then we don’t relax and pay attention to how the locking mechanism behaves after the tension is relieved. If the click does not occur automatically, there is a problem.

Faulty constipation leads to unpleasant situations. For example, after the wash is completed, the hatch door does not open and the washed items cannot be removed from the drum. To solve the problem you will have to:

- Disconnect the washing machine from the power supply and water supply.

- Unscrew the screws from the back of the case and remove the top panel.

- Tilt the machine back.

- Move the metal bolt from the hatch hook by hand.

There is also an absolutely opposite situation, when even with strong pressure the UBL does not work and the door does not close. Accordingly, the washing does not start - the control board does not receive a signal about the drum being tight. In such cases, most likely the lock has become worn and weakened. To find out, you need to unscrew the hatch door and check the condition of the blocker with a multimeter and visual inspection.

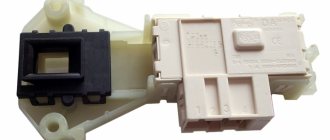

If a defect is detected, the UBL should be replaced. To do this, the lock will have to be dismantled and a similar copy installed in its place. The algorithm is as follows:

Important! It is recommended to record the disassembly on the camera to facilitate the assembly process and avoid errors and confusion.

- We open the hatch.

- Remove the outer clamp from the cuff.

- We fill the rubber seal inside the drum.

- Carefully unscrew the bolts holding the lock.

- We get UBL.

- We install the new device in the reverse order.

Having figured out how the washing machine hatch door lock works, you can not panic when the door is locked, but quickly and correctly assess the scale of the problem on your own. The main thing is not to let the operation of the machine take its course, do not forget about prevention and careful care. Then the machine will last a long time and save its owners from accidents, floods, mold and unpleasant odors.

Interesting:

- Washing machine door closing sensor

- How does the UBL of a washing machine work?

- How to check the lock of a washing machine

- Replace UBL on a top-loading washing machine

- How to check the lock of an Indesit washing machine?

- Beko washing machine door won't close

Reader comments

- Share your opinion - leave a comment

Symptoms of a problem

The owner of a washing machine can determine if the lock is broken by the following signs:

- The equipment completed its work and turned off, but the hatch was still blocked. This indicates a malfunction of the UBL or central module.

- After selecting and turning on the mode, the door does not lock and the washing machine does not start executing the program.

- The washing machine displays a code or reports a UBL malfunction by flashing indicators in a certain sequence.

You can determine what the cause of the breakdown is using a multimeter.

How it works and why the lock breaks

A locking structure has been created for our safety. If the door opens unexpectedly, there is a risk of being in the path of a hot stream, and the neighbors below will not like it.

As soon as the laundry is loaded into the drum, the detergent is added, the program is selected, the shutter is slammed, and the machine is given the command to wash, the mechanism is locked. Only a minute after the cycle completes, the lock will click and the hatch can be opened. However, this is in a situation with properly working equipment.

There are two types of UBL:

- thermal locks with biometric plates;

- electric locks with electromagnets.

They have an important difference. If the power goes out while washing, after a few minutes the thermal lock will unlock the hatch and the laundry can be taken out. In the case of an electromagnetic mechanism, the situation is the opposite - you can get to things in the drum only when the power supply is restored.

Modern models of machines are mainly equipped with thermal locks, which are more reliable and safe. The principle of their operation is simple: the thermoelement heats up under the influence of voltage and causes the bioplate to bend until the latch operates. When the contact is established, the control module receives a command that “the border is locked” and the washing can begin. If the lock does not work, the module will display an error message.

After the washing is completed, you need to wait for the reverse process - the plate cools down and returns to its original position. That is why, after finishing work, the door does not unlock immediately.

Constant heating and cooling gradually destroys the structure, causing it to jam one day. The items cannot be restored and can only be replaced.

You cannot turn on the washing machine without a locking device - the program will not allow it. This function can only be bypassed in a repair shop, when it is necessary to close the contacts to test the condition of the equipment. Doing this at home is dangerous and difficult. It is much easier to replace a faulty part, especially since it is inexpensive and is always in stock.

Diagnostics and repair of the lock on your own

To check the serviceability of the lock, it will need to be removed. Necessary:

- Unplug the washing machine.

- Open the hatch, bend the cuff, pry up the clamp and remove it.

- Pull the cuff to the side to gain access to the lock.

- Unscrew the fasteners securing the device.

- Disconnect the wiring and pull out the UBL.

This method is suitable if the door opens. Otherwise, you need to open the base panel on the front of the washing machine and find the emergency cable for opening the hatch. It is usually yellow or red and is located near the filter. If the cable is missing, you need to unscrew the fasteners holding the top cover, remove it, and then put your hand between the body and the tank, find the lock latch by touch and unlock it. Now you can open the door and begin removing the UBL.

Now you can start checking the blocker using a multimeter. To determine where the neutral and common contacts are located, you will need a diagram of the lock. Hatch locking devices are produced by various companies that arrange the contacts in their own way. Without knowing the diagram, it is impossible to understand the contacts and diagnose the lock. You can find the diagram on the Internet.

At home, you can only check the thermoelement that heats the plates. To do this you need:

- Set up the multimeter to measure resistance.

- Find the neutral and phase contacts and install probes on them.

- If a three-digit number appears on the tester display, this indicates that the blocker is working.

- Now you need to move the probes to the neutral and common contacts.

- If one or zero appears on the screen, the device is broken.

If the blocker is working properly, you need to inspect it for mechanical damage or manufacturing defects.

To replace, you need to purchase a new lock. This can be done at the manufacturer's service center, in a specialized store, or via the Internet. To avoid mistakes when purchasing a part, you need to tell the seller the make and model of the washing machine.

Installing the hatch lock is performed in the following order:

- Connect the wiring to the UBL.

- Place the lock inside the washing machine and insert it into the seat.

- Screw in the fastener.

- Return the cuff to its original place and install the clamp.

If after replacing the UBL the problems continue, this indicates a malfunction of the system board. It is not recommended to repair it yourself, because it can only worsen the situation. To diagnose and repair the breakdown, you should contact a service center or call a professional.

Some washing machine owners are interested in whether it is possible to bypass the lock and start washing. Theoretically, there is such a possibility, but in this case, everyone who has access to the technology will be at risk of electric shock. Also, if you open the unlocked door during washing, there is a risk of being scalded by hot water. It is for these reasons that it is recommended to carry out repairs and replace a part that is inexpensive, rather than searching for a way to bypass the blocking.

How to check if it's working properly?

Despite the reliability and durability of the washing machine UBL, experts recommend paying attention to the following reasons for its breakdown:

- long period of operation;

- mechanical wear;

- frequent power surges;

- failure of the locking tongue;

- violation of operating rules and regulations;

- skewed fastening;

- laundry getting stuck between the door and the body;

- triac failure on the central board.

The following signs may indicate a lock malfunction:

- inability to open the hatch after finishing the wash and turning off the device;

- no hatch locking after setting the washing mode and pressing the start button;

- the appearance on the display of an audio and digital message about the failure of the UBL.

In order to check the element and determine whether the device is working or not, you must perform the following manipulations:

- disconnecting the device from the electrical network;

- opening the hatch and removing the rubber clamp;

- opening access to the lock by moving the cuff to the side;

- dismantling the fasteners fixing the element;

- disconnecting wiring;

- removing the hatch locking device.

This technology is only suitable if the hatch door is open. If an element breaks when the hatch is closed, it is necessary to remove the base panel and use a special cable to carry out an emergency opening. The design of many models does not provide for the presence of a cable; then experts recommend removing the top cover and sticking your hand inside the drum and lifting the latch.

After all preparatory measures have been completed, you can proceed to the diagnostic stage.

This work must be carried out using a special tester - a multimeter. To determine the central and common contact, it is necessary to use the lock diagram, which may have a different design in different models.

At home, you can only check the thermocouple and the heating plate. To carry out diagnostics, you must perform the following manipulations:

- setting the multimeter to measure resistance;

- installing probes on the neutral and phase contacts (a three-digit number on the tester is a sign of no breakdown);

- connecting the probes to the common and neutral contacts (the appearance of 1 or 0 on the tester display is a sign of failure).

If there is no breakdown, it is necessary to conduct a visual inspection of the device for the presence of mechanical damage and manufacturing defects . All diagnostic work must be done as carefully and carefully as possible so as not to cause harm to the device.