Decoding error F17 (E17)

Error F17 (E17) means that the washing machine was unable to draw water within the allotted time. In reality, it looks like this: the machine is plugged in, the mode is selected, but water does not flow into the machine. It is worth considering that there is also no sound of water supply. Due to a prolonged lack of water, the system cannot start or continue the washing process.

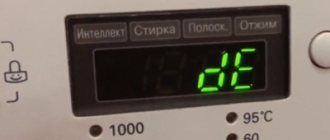

On a Bosch washing machine without a display, the 800 or 1000 rpm indicator and plus the “Rinse” light will light (blink) simultaneously.

Causes and solutions to the problem

If error code F 17 is displayed on the Bosch washing machine display, this means that the time for filling the tank has been exceeded. The fault code may appear both at the beginning of the wash cycle and before the rinse cycle.

Note! For some Bosch washing machines, error F17 is indicated as code E17.

You’ve figured out what the error means—now you need to understand how to fix it. To do this, let’s look at the reasons for the appearance:

How to correct the situation if actions did not help? Continue troubleshooting.

What caused the malfunction

Let's consider the reasons that may cause a malfunction:

- Lack of water. You need to check if there is water in the tap. It is possible that the water supply has been turned off or is blocked.

- Shut-off valve closed. It is necessary to check the shut-off valve that shuts off the flow of water into the washing machine. It may not have been opened before the wash started. Water does not flow into the washing machine, which causes the error.

- The shut-off valve is not fully open. This results in a long time to collect water, which causes an error. The shut-off valve must be fully opened.

- Weak water supply. The washing machine does not have time to draw water and displays an error.

- Kinked, tangled or pinched inlet hose. This is an obstacle to the supply of water to the washing machine, which also causes error F17 (E17). It is necessary to straighten the hose for unimpeded flow of water.

- Clogged filter mesh. Often, the filter mesh, located at the point where the inlet hose is connected to the washing machine itself and protects it from small particles contained in tap water, becomes clogged. The washing machine will not draw water well and display this error. It is necessary to remove and clean the filter: put it in a solution of citric acid for several hours, and then put it back in place.

- Failure in the control unit. Quite often, failures occur in the control unit. It is necessary to unplug the washing machine for 15-20 minutes and then turn it on.

The above methods will help you troubleshoot the error yourself.

In all other cases, it is better to contact a specialist, since the breakdown occurred in the internal parts of the washing machine. See also -

Bosch washing machine errors

Causes

As mentioned above, code E17 in Bosch washing equipment indicates that water is not entering the tank. Therefore, the washing process may not start. For some washing machine models, this malfunction corresponds to error F17. This is what the manufacturer intended. If the Bosch washing machine does not contain a display, then this error can be determined by two indicators that are lit: rinse and spin at 1000 rpm. However, deciphering the E17 code is not enough. You should find out why the error occurred.

There are several of them:

But when looking for the cause, you should first check the simplest options. First you need to check if there is water in the tap. Perhaps it is missing. You should also check the water supply tap. It is located in the place where the inlet hose is connected to the water supply.

How to clean the mesh filter

Let's look at a step-by-step method to fix the problem in the filter mesh. Blockage is the most common cause of error. You can get rid of the blockage in this way:

- turn off the power to the washing machine;

- close the water supply tap to the washing machine;

- unscrew the end of the hose that is attached to the machine itself;

- if there is water left in the hose, then it is necessary to prepare a container for this water;

- remove the mesh and rinse it thoroughly;

- screw the hose back;

- then unscrew the hose from where the water enters the washing machine;

- we get rid of dirt, if there is any, of course;

- screw the hose back.

So, if you turn on the machine and do not hear the sound of water being drawn for a long time, and error F17 appears on your display, this means that the water supply time has been exceeded. Let's look at the causes of the malfunction that require repair.

Causes of malfunction and ways to eliminate them

Error E17 - what is it? Stopping the wash cycle due to lack of water supply does not always indicate a complex Bosh failure.

In some situations, the problem can be solved quite simply , without requiring disassembly of the washing machine and calling a technician. In rare cases, a malfunction of the washing machine may be caused by a one-time power surge or a coincidence.

In this case, a simple reboot can help - unplug the washing machine for 20-30 minutes (pull the plug out of the socket), and then turn it on and start again. If the reboot does not help, move on to diagnosing the failure.

Self-draining during washing

Self-draining is characterized by the intake and immediate discharge of water . This situation indicates a violation of the Bosh connection. This can happen either with a recently installed washing machine or with an old one that has been moved or moved to a new location.

When installing the machine, the drain hose must be raised above the level of the tank. This point is stated in the instructions for the washing machine. If the hose simply spreads along the floor, the collected water will flow out spontaneously. As a result, the tank remains empty, and after a certain time the washing machine issues an alert E17 (F17).

Weak pressure

The Bosh washing machine produces water, but the process is very slow. It is necessary to make sure that there is sufficient pressure in the water supply system . You also need to see if the tap that shuts off the water supply to the washing machine is fully open.

Clogged water supply filter

If the filter is clogged, the Bosh washing machine may draw little water or not draw it at all. Functionally, a filter is a mesh that is designed to capture and retain small fractions that may be in tap water.

If water does not flow to the washing machine, you need to clean the filter. To do this, perform the following steps:

- Turn off the water supply valve to the device.

- Pull out the washing machine so as to gain convenient access to the rear wall.

- Place a rag on the floor from the back wall and place a bucket.

- Unscrew the plastic nut, disconnecting the hose.

- Carefully remove the mesh.

- Clean in water.

- Reassemble the assembly in reverse order.

When performing a test run of the washing machine, you must ensure that the connection is tight.

The device does not draw water

If the washing machine tries to draw water, but it fails, you need to make sure that there is water in the water supply. This is very easy to do - you just need to try opening the tap in the bathroom or sink. If there is no water in the system, washing will have to be postponed.

Another possible reason is turning off the water supply tap to the washing machine. Make sure that the shut-off valve is turned to the “ON” position .

A more rare, but quite possible situation is a severe bending/squeezing of the hose. It is advisable to check its condition along its entire length, including behind the furniture.

Inlet hose clogged

In order to check the condition of the inlet hose, it should be disconnected from the washing machine and from the water supply. Remove it after the water supply to the device is turned off.

Fill valve problem

The fill valve has a rather complex structure - it consists of an electromagnetic coil, a membrane and a housing.

To access the valve, the washing machine will have to be partially disassembled. If the unit fails, the valve is replaced with a new one.

The valve in Bosch washing machines can be two sections - one of them is designed to draw water for washing, the other for rinsing. Depending on which section is out of order, the washer may either not rinse or not start washing.

Breakdown of the pressure switch

Pressostat is a part that measures the water level in the washing machine tank . If the sensor fails, it does not provide objective information to the control module, and water is not drawn. The solution to the problem is to repair or replace the pressure switch.

Control unit malfunction

If the control unit fails, the Bosh washing machine does not draw water. Repair of the module is carried out by partially disassembling the washing machine and removing the unit.

In most cases, repairs can eliminate the damage. But if the module is badly burned out, it is replaced with a new one .

Wiring irregularities

If the wiring in the washing machine is defective, various malfunctions can occur. One of them is the lack of water supply. For diagnostics, the washing machine is partially disassembled to check the condition of the wires and terminals.

Inlet valve faulty

In order to check the valve, you need to turn off the water and disconnect the washing machine from the electricity. Next, you need to prepare a container to drain the water and disconnect the hoses from the inlet valves. You need to unscrew two screws and remove the top panel. The next thing to do is remove the clamps and unscrew the fixing screw. Remove the valve and check if it is clogged. Perhaps there was some damage on it. Check everything and reinstall the valve. If everything goes well, then error F17 should disappear.

Water intake valve

The problem looks like this: the user turned on the program, but no water flows. If the washing machine is equipped with a display, then F17 appears on the display. If there is no screen, the speed and rinse lights blink. It is worth noting that in some models, for example Bosch Maxx 5, Maxx 7, this error is designated as E17. This is how the washing machine signals that there is not enough liquid required to start the program.

There may be several reasons for this malfunction. First, you should check the connections of all hoses and valves; they can cause a fault code to appear, and also rule out a failure of the electronic controller by turning off the machine for half an hour.

If there is water in the system and its supply valve is open, all hoses are correctly connected, and the filters are cleaned, then the next most common cause of failure may be the inlet valve.

In this case, you need to disconnect the machine from the electrical network, turn off the water supply and prepare a container for liquid, and then check the valve for serviceability:

- disconnect the hoses from the water intake valves;

- remove the top cover by unscrewing the bolts from the back;

- disconnect the connectors from the valve coil;

- bend the clamps and remove the hoses;

- unscrew the fixing screw and pull out the valve;

- inspect it for blockages or damage;

- After elimination, perform installation in reverse order.

The pressure switch is broken

A pressure switch is a pressure sensor that controls the amount of water in the tank. To get to the pressure switch, you need to remove the top cover of the machine. To check, you need to disconnect the clamps and hoses from it, insert a tube and blow into it. If there are no clicks, you must disconnect all connectors and remove the broken part. It cannot be repaired, so if you find the cause of the breakdown in it, then you need to replace the pressure switch with a new one.

Error e17 in a bosch washing machine

Most Russian consumers associate Bosch with consistently high German quality and exceptional reliability of household appliances.

One of the oldest in Europe, the German company Bosch today successfully exports its washing machines to 150 countries around the world.

Russians have been using Bosch washing “helpers,” which are indispensable in everyday life, for many years, not realizing that this equipment sometimes breaks down.

All models of Bosch washing machines are equipped with a self-diagnosis system. In order to prevent accidents, serious breakdowns and situations dangerous to the life and health of its owner, the Bosch washing machine stops working at the moment of breakdown, and an error code is displayed on the screen.

Knowing the error code and its decoding, you decide whether to carry out the repair yourself or call an experienced technician to your home.

| Code | Problem | Causes | Solution |

| F01 | The hatch door is not closed | The door does not fit tightly to the body | Open and close the hatch again, checking whether the laundry immersed in the drum is in the way |

| F02 | Water does not flow into the unit | Lack of water in the water pipe or low pressure | Turn off the water tap, check the presence and pressure of water |

| The washing machine valve is closed or not fully open | Check the water supply tap to the washing machine. It must be in the open position (parallel to the pipe) | ||

| The inlet hose is pinched or squashed | Check the location and condition of the hose through which water enters the machine | ||

| Clogged filling filter | Clean the filter mesh | ||

| F03 | Water does not drain from the machine or drains too slowly (did not drain within the allotted 10 minutes) | Blockages in the water drainage system | Check and clean the drain filter, pump impeller, hose from dirt and debris |

| Blockage in the sewer | Check the connection between the drain hose and the sewer, remove the blockage yourself or call a plumber | ||

| Failure of the drain pump (pump) | Check the integrity of the pump, the stroke of its impeller, and the winding resistance (should be 200 Ohms) | ||

| Control module malfunction | Checking, flashing or replacing the module with a new one | ||

| F04 | Water leak | Depressurization of connections or parts in contact with water | Inspect the washing machine to locate the leak. Repair or replacement of faulty parts with new ones |

| F16 | Hatch door not closing tightly | Open and close the door tightly until you hear a characteristic click. | |

| F17 | Water does not flow or fills too slowly | The water supply tap to the washing machine is closed | Open the tap completely |

| The pressure in the water supply is less than 1 bar | After 5 minutes, after it fails to fill, the machine will drain the water. Take measures to adjust the pressure and restart the wash | ||

| Clogged filling filter | Clean the water inlet filter | ||

| F18 | The water is draining for too long | The drain pump is clogged or malfunctioning | Clean the pump and check its functionality. If any damage is found, replace it with a new one. |

| Damage to the water level sensor (pressostat) | Check the pressure switch, repair or replace the sensor with a new one | ||

| F19 | Unacceptably long water heating | Low voltage in the electrical network supplying the unit | Check the voltage, troubleshoot problems (yourself or invite an electrician) |

| Scale on the heating element (heating element) | Clean the heating element from scale using special means | ||

| Failure of the heating element | Replace the water heater with a new one | ||

| Malfunction of the water heating temperature sensor (thermistor) | Check for damage and replace the sensor with a new one | ||

| F20 | Water heats up at the wrong time | Damage to the heating element relay | Check the heating element, replace it with a new one |

| Water temperature sensor (NTC) malfunction | Replace NTC with a new one | ||

| F21 | The electric motor does not rotate or its rotation is uneven (accordingly, the rotation of the washing machine drum is difficult or stopped) | Short circuit in the control triac | Check and test the motor, its contacts and connections. Repair faulty elements or replace the entire motor with a new one |

| Motor reverse relay malfunction | |||

| Tachogenerator failure | Check, if faulty, replace the generator with a new one | ||

| F22 | Temperature sensor is faulty | NTC short circuit | Checking wiring, repairing burnt out elements |

| Break in NTC connecting circuits | Verification, repair | ||

| NTC failure | Replace the sensor with a new one | ||

| F23 | Activation of the AquaStop water leak protection system | Water leakage (it collected in the pan) | Find the leak, restore the seal of the washing machine |

| AquaStop malfunction, including broken connecting circuits | Check the electrical circuits and the entire AquaStop system. Repair or replace AquaStop | ||

| F25 | Aquasensor (water turbidity sensor) is faulty | Cloudiness of the water entering the washing machine | Check the water and take corrective action |

| Dirt and limescale deposits on the aquasensor | Clear sensor | ||

| Breakdown of the pressure switch | Check and replace with a new one | ||

| Clogged water drain system | Checking and cleaning the drain filter, hose, pump | ||

| F26 | Analog water pressure sensor (pressostat) is faulty | Broken circuits leading to the sensor or its breakdown | Reset the error by pressing the “On/Off” button. Check the connecting circuits for breaks and the sensor itself. If there is a malfunction, the pressure switch is repaired or replaced. |

| F27 | The pressure switch is faulty | Errors in sensor settings | Check the pressure switch and connecting circuits, reconfigure |

| F28 | Flow sensor registers impossible value | Damage to the flow sensor or loss of integrity of its wiring | Check, repair or replace the sensor with a new one |

| F29 | Flow sensor detects lack of water | The water supply valve to the washing machine is closed | Open the tap completely |

| Water pressure is insufficient (less than 1 bar) | Check the water pressure in the water supply, adjust the valve if it is not fully open | ||

| Clogged filling filter | Clean the water inlet filter | ||

| The pressure switch is faulty | Check all components, parts and their wiring. Repair or replace faulty elements with new ones | ||

| Faulty solenoid valves (intake or Aquastop) | |||

| Failure of the AquaStop system | |||

| F31 | There is an unacceptable amount of water in the tank | The drain hose is pinched or kinked | Check and adjust the hose |

| The drain filter, pipe, drain pump impeller, or itself is blocked by debris | Clearing blockages in the water drain system | ||

| Malfunction or incorrect setting of the pressure switch | Check, reconfigure or replace water pressure sensor | ||

| Damage to the water supply solenoid valve | Check the valve and its wiring. If a breakdown is detected, replace the part. | ||

| F34 | The loading hatch door does not lock | The lock tongue is broken and stuck | Press the “On/Off” button. Open the hatch, check all door and lock mechanics, UBL electrics, and the condition of the cuff. Eliminate malfunctions or replace failed parts with new ones |

| Door stuck | |||

| The rubber seal (cuff) of the hatch is worn out | |||

| The hatch locking device (UBL) is faulty | |||

| F36 | The hatch lock is faulty | Failure of the triac or relay responsible for locking the door | Check the electronic control module (triac and UBL relay) and wiring |

| F37 | NTC temperature sensor failure | Check NTC and its wiring. Repair the elements or replace the sensor with a new one | |

| F38 | NTC fault | Wiring short circuit | |

| F40 | Synchronization error | The voltage in the electrical network supplying the washing machine is unacceptably low or high | Check the voltage in the electrical network and take measures to normalize it |

| F42 | The engine rotates at high speeds | The triac on the control module is faulty | Using diagnostic and measuring equipment, check the triac and the entire control module. If the part cannot be repaired, replace it with a new one. |

| F43 | The electric motor does not rotate | Tachogenerator failure | Checking the generator, replacing with a new one |

| The movement of the motor (and therefore the drum) blocks the laundry caught in the space between the tub and the drum. Possible overload by weight | Check the possibility of mechanical blocking, eliminate interference, in particular, unload some of the laundry from the drum | ||

| Motor movement is blocked | |||

| The triac on the control module is faulty | Check wiring, control element and entire board. Board repair or replacement | ||

| F44 | The drum does not spin in the opposite direction | Triac or reverse relay faulty | Checking, repairing or replacing the control module |

| F59 | Reduced motor speed | 3D sensor malfunction | Check the 3D sensor, power module, wiring, control module (in particular, its firmware) |

| F60 | Water flow sensor detects value too low or high | Sensor malfunction | In addition to the flow sensor itself, check the filling filter and wiring. Replace faulty parts |

| Swirl in the pipes or the sensor itself | |||

| F61 | Incorrect signal from the door lock about opening or closing | The door lock is mechanically damaged | Press the “On/Off” button. Check all mechanics and electrical wiring of the door lock |

| The hatch locking device or its electrical circuits are faulty | |||

| F63 | Functional protection error | The processor on the control module is faulty | Check the control module, repair or replace with a new one |

| Software errors | |||

| F67 | Control board fault | The card was encoded incorrectly | Checking the module, replacing software, recoding or replacing the card |

| Incorrect software between control and power module | |||

| E02 | Electric motor is faulty | The brushes are worn out, a short circuit has occurred, the motor contacts are broken | Check the performance of the motor, repair it or replace it with a new one |

| Control module error | Check electrical circuits, main module and motor module | ||

| E67 | Incorrect module encoding | Firmware failure | Reflash or replace the control module with a new one |

Malfunction in the control module

The control module is one of the main parts of the washing machine, a kind of brain that gives commands to start washing, spinning or rinsing. If moisture gets in or a voltage drop occurs, some elements of the module may fail. To check the control board you need:

- turn off the power to the washing machine;

- remove the top panel (cover);

- take out the dispenser (powder tray);

- Unscrew all the screws holding the front panel.

- remove the front panel;

- disconnect the board from the front panel and inspect it.

Burnt-out capacitors, resistors, diodes, microcircuit tracks, oxidized contacts - all this can be replaced or soldered. If the microprocessor is faulty, the control module must be replaced.

Possible faults requiring repair

We repair Bosch washing machines every day and have accumulated a huge amount of experience. Here are the most common breakdowns that cause error E17.

| Signs | Breaking | Repair or replacement | Cost* (work only) |

| The washing machine does not draw water at all or only during rinsing. Error F17 or E17 is displayed on the case. | Fill valve. It supplies water to the SMA. The valve consists of a body, a membrane and an electromagnetic coil, which opens the membrane when water is drawn in. The coil usually fails. |

- the pressure switch tube has fallen off, become clogged or damaged;

- the pressure sampling chamber of the level sensor is clogged with dirt;

- The sensor itself has failed.

*Parts are not included in the price and are paid additionally.

Can't deal with error E17 or F17 on your own? Use the services of professionals. Call the RemBytTech service:

Or submit a repair request electronically.

The technician will arrive within 24 hours, identify the cause of the error, fix the problem at home and issue a warranty for up to 2 years.

Causes

Coding E 17 (in the newest models - F17) means that the time allotted for filling the washing machine tank with water has expired. In this case, there are no interruptions in the power supply, the start button for the selected mode is pressed, but the flow of liquid does not begin, as evidenced by the absence of the characteristic “murmuring” sound. The system reacts to a prolonged absence of water, cannot start or continue the washing process and signals this. The most common reasons why error e17 appears on the display include:

- Lack of water supply. Identified by opening any tap in the apartment, the washing process is started again or resumed after water appears.

- Complete or partial shutdown of the valve on the water supply system to the machine. Before starting the wash, the shut-off valve must be fully open, otherwise water either does not flow at all or does not have time to fill the tank in the allotted time.

- Low pressure in the water supply. Low pressure does not allow the machine to fill the tank with water in time.

- Problems with the inlet hose. This element of the water supply to the machine must be in a straightened state and clean from the inside: crushed or twisted places prevent the passage of liquid.

- The mesh filter is clogged. The part located where the inlet hose is fixed to the body of the washing machine and is designed to purify tap water from small particles periodically becomes clogged.

- Internal faults in the Bosch washing machine, including breakdown of the inlet valve and pressure sensor (pressostat).

A failure can also occur in the control unit. Sometimes it helps to fix the problem by disconnecting the device from the power supply for 15-20 minutes and then turning it on. Otherwise, the unit needs to be repaired.

This is interesting: PF error on an LG washing machine - what to do, what does it mean, how to fix it yourself?