Most washing machine breakdowns result in puddles on the floor. Damage to the hose can be one of the reasons for improper operation or breakdown of the washing unit. Let's figure out what to do if the water supply hose (filler) breaks, bursts, or becomes unusable over time. We will analyze the most common breakdowns and methods for eliminating them.

The manual is relevant for: Ardo / Ardo, Beko / Beko / Veko, Bosch Avantixx, Classixx, Logixx, Maxx, SportLine / Bosch Avantix, Classic / Classic, Logix, Max, Sportline; Brandt / Brandt, Candy Aquamatic, Holiday, CNE, CTS / Candy Aquamatic, Holiday; Daewoo / Daewoo, DEXP / Dexp, Electrolux Time Manager / Electrolux, excuse me, Timemanager, Evgo / Evgo, Gorenje / Gorenje, Haier / Hayer, Hansa / Hansa, Hotpoint Ariston Margherita, RSM, ARSL, ARWM / Hotpoint Ariston Margherita, Indesit IWSB , WISL, WISN, WITL, Innex / Indesit Wisl, Inex; LG / LJ/LV; Miele / Miele, Samsung Diamond, WF, EcoBubble, Bio Compact / Samsung Diamond, Eco Bubble, Bio Compact; Siemens / Siemens, Vestel / Vestel, Whirlpool AWG / Whirlpool, Zanussi Aquacycle, EcoValve / Zanussi Aquacycle, EcoValve; Atlant, Vyatka, Desna, Donbass, Malyutka-2, Saturn, Siberia, Fairy-2, Eureka-3 and other brands with vertical and horizontal loading, automatic and semi-automatic.

So, let's go!

Causes of leaks

Shell damage

One of the reasons for damage to the inlet hose may be damage to the casing (rubber part) caused by kinking, movement of equipment, external mechanical impact or long service life of the unit.

Sometimes it is quite difficult to identify the cause of a leak by dripping water. Microcracks in the material often occur in hard-to-reach places, for example, in the places where fittings are connected, or during the transition from metal to rubber. It all starts with the formation of “condensation” and small droplets on the floor and ends with a flood.

In this case, it is necessary to disconnect the connectors and carefully check for leaks in a visible place, in good lighting. If leaks are detected and the rubber shell is not sealed, it is recommended to say goodbye to the old product and buy a new one. In this case, sealing or sealing cracks is ineffective, since the filler tube, when the washing machine is operating, will periodically be under water pressure and most likely a leak will occur again.

The internal filter is clogged

If water does not flow well into the tank, the inlet valve filter may be clogged. A clogged filter must be removed from the machine and cleaned. On all machines, this filter is installed in the process hole in front of the fill valve. It looks like a round plastic mesh with small holes.

Due to the impurities and suspended particles contained in tap water, there is a high chance that the filter will become clogged over time. The pressure will become weak and it is possible that the connections to the water supply will begin to be undermined. Installing additional water filters on the incoming pipe will reduce the load on the filter, but does not completely solve the problem. The filter still requires periodic cleaning.

The cleaning procedure is not complicated, does not require experience or specialized knowledge, and can easily be done without turning to specialists.

How to fix the fill valve in a washing machine with your own hands

The nuts are loose

If none of the previous problems occur, vibration may have caused the lug nuts to become loose. To fix it, tighten the clamping nut.

10 reasons why the washing machine shakes and rattles during the spin cycle

Other damage

A leak in the washing machine can be associated not only with problems in the inlet hose, but also with a number of other reasons:

- Wear of rubber gaskets or seals in the connection;

- Plastic fittings pinch the rubber gasket, because of this the seal is not level and allows liquid to pass through;

- Leakage from pipes inside the housing;

- Torn hatch cuff;

- Accumulated condensation;

- Rotten heating element;

- Hole in the tank;

- Strong pressure changes in the water supply system, sometimes the pipes can twitch;

- And others.

Incorrect position

Another reason for a leak associated with the inlet hose may be incorrect placement - at the junction with the pipe it is strongly bent and pinched. In this case, it is necessary to move and install the washing machine correctly so that there is no tension or kinks.

If the length is not enough, buy a repair kit for extension, but more on that below.

How to replace

If you need to replace the hose, use the step-by-step instructions:

- turn off the water supply in the water supply pipes using the inlet valve;

- remove the old spare part by unscrewing it from the connection point to the water supply;

- install the gaskets from the kit;

- attach the new part, tighten it well at the fastening points - do not apply too much force, as the plastic parts may burst;

- turn on the water supply;

- check for any leaks (if you screw it on tightly enough, the gasket is at the right angle and the nut goes along the threads, then there should be no leaks or “snot”);

- if it leaks, tighten the nuts at the fastening points more tightly. It is necessary to pay attention to the fact that you cannot apply strong forces, so as not to break the thread (do not overdo it, especially with plastic components). It is better to unscrew the structure, adjust the rubber band and try again, tightening the nuts along the threads.

Before starting the procedures, be sure to close the water supply tap to reduce the pressure and wait a couple of minutes. If this is not done, the forces applied when unscrewing can lead to defects in both the tap and the fitting. After dismantling the damaged element, a new one should be installed in accordance with the instructions provided.

Before purchasing, be sure to check the length of the hose and the diameters of the fittings for connection. Alternatively, you can take the old pipe with you to the store and use the advice of specialists when selecting a new one.

Replacing the hose

Replacing the inlet hose is very simple. You just need to turn off the water supply. Then unscrew the old hose from the water supply and from the washing machine. And then screw on the new hose. After this, open the water supply and examine the hose for leaks.

If you did everything correctly, then they will not exist. If they appear, it means that you did not tighten the connections tightly enough, or you lost the gasket. You also need to pay attention to the fact that these places cannot be twisted. Because if you tighten it too tightly, you can strip the threads or damage the gasket. And if you have a lot of strength, then do it carefully.

It also happens that there is a leak from the rubber part of the hose. It appears due to improper use, mechanical damage and other cases. With such a breakdown, there is no need to be too smart. You can simply replace the damaged hose with a new one.

Interesting:

- Why does my washing machine leak? Below it...

- LG washing machine is leaking from below

- Haier washing machine is leaking from below

- How to Replace Dishwasher Fill and Drain Hose

- Washing machine leaks when rinsing

- Why does my LG washing machine leak from the bottom during the spin cycle?

Reader comments

- Share your opinion - leave a comment

How to lengthen

If you have a situation where the length of the water hose to connect to the water supply network is insufficient, you can buy the required length, or lengthen the existing one.

To do this you need:

- measure the length of the missing part;

- purchase a product of the required length;

- buy an adapter or coupling of a suitable diameter;

- disconnect the old one from the connecting insert;

- connect the products through special adapters (to seal the connection, it is recommended to use fume tape for water connections; you can apply sealant on top);

- connect the extended hose to the tap and install the machine in place.

When installing the water intake hose, do not install it under tension. If the washing machine vibrates or moves, it may break. If this happens in the absence of the owners, the need for repairs may arise, both at home and at the neighbors on the floors below.

For normal operation of the machine, it is not recommended to install a part longer than 3 meters. There is a large selection of hoses at the plumbing store, so you can easily purchase a new one.

Most often, difficulties arise with the acquisition of spare parts of non-standard sizes, that is, longer than the standard length of 1-1.5 meters. In this case, it is easier to connect two tubes into one using couplings.

When does the drain hose need to be replaced?

The drain hose serves to drain waste water, so it is attached to the drain pump, next to the pipe. It is made of polypropylene, so it can withstand water of different temperatures and also remains resistant to chemicals.

For what reasons does he need a replacement?

- Inappropriate element. Often, when you purchase a washing machine, you receive a hose included. However, it may be short during installation. Of course, you can lengthen the element, but this increases the risk of water leakage.

- Mechanical damage. Replacing the washing machine drain hose may be necessary if there is a fracture or a leak. It is recommended to replace the part immediately.

- The hose is so clogged with debris and scale that it needs to be replaced.

Right choice

Before replacing the drain hose, you must select a suitable replacement. You have three options:

- Standard option. This is a classic, according to which the length of the part is from one to five meters. This is quite enough to connect the washing machine.

- Telescopic option. The name speaks for itself: a compressed hose measuring 0.5 meters stretches to a length of 1.5 meters. In addition to the advantages of mobility, there are also disadvantages. When stretched, large corrugated folds are formed, which vibrate strongly during operation.

- Coiled option. Collapsible type, consists of modules measuring 50-55 centimeters. Convenient because you can adjust the length.

Don't know how to remove the drain hose from your washing machine? Lift the top panel and see where it is located. To do this, unscrew the two screws on the back and, moving the panel in the opposite direction, remove it.

Dismantling may differ for different SM models, so we will consider replacement in each of them.

Connection diagram

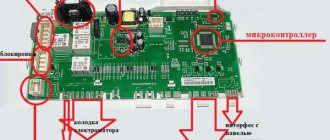

When connecting a hose for water supply, you can either invite a specialist or do it yourself. All standard washing machines are connected to the cold water supply pipeline using the one included in the standard delivery package (the length of foreign manufacturers is 120 or 150 cm). To do this, a pipe with a diameter of ¾ inch, bent at an angle of 90 degrees, is screwed to the back wall of the machine (for this purpose, there are protrusions for fingers on the threaded nut), and the second end, using an American pipe having a seal with a plumbing gasket, is connected to the water supply pipe. At the place where the inlet hose is connected to the water supply pipeline, a tie-in is made in advance by installing a tee and a separate valve for local shut-off of the water supply.

To correctly independently connect the washing machine to the water supply network, we recommend using step-by-step instructions.

Step-by-step instructions for connecting any washing machine

Possible causes of water leakage

A washing machine is a rather complex household appliance that combines many components. The water flow path is quite large, which is why there are plenty of places where unpleasant leaks can occur. Let's look at the most common problems that many users of this technology have to face:

- The reason why water flows from the washing machine is a broken drain pipe.

- Also, one of the reasons why a leak may occur from under the washing machine is a worn out oil seal.

- Defective rubber seal.

- Damaged or incorrectly installed water tray.

- Broken water supply hose, damaged thread.

- Faucet malfunction.

- Damage to the receiving tray with valves.

- Defective drain corrugated hose.

- Drum overfilling, etc.

The washing machine directly interacts with water, so there can be many reasons for its leak, as well as places where this defect manifests itself. The first step is to carry out a careful inspection to identify a specific location or approximate area of failure.

A little theory

Purpose

One of the important components that ensures the smooth and reliable operation of washing machines is hoses. Each washing machine is equipped from the factory with: inlet and drain. During the installation process, it is important to check that there are no cracks, bends, punctures or other defects. The filler connects directly to the water supply. The drain, which can also be extended if necessary, is connected to the sewer pipeline, through a siphon or directly.

How to choose

In order for a new hose for a washing machine to last a long time, you need to make the right choice when purchasing it and take into account several important points:

- length, as mentioned above, is a very important parameter affecting the reliability of the washing machine;

- the operating pressure is selected taking into account the pressure in the water supply network in your home, usually 2.5-7 atmospheres;

- The maximum temperature must be designed for temperatures greater than 90°C.

The most popular and less high-quality brands: Aquatechnician (Russia), Magic Power (China), Swedish Electrolux with aquastop, Turboflex (Russia), Reflex (Italy).

Varieties

Regular

The most common inlet hoses, without a leakage protection system, which are sold in any hardware store:

- rubber water pipe - standard for connecting equipment to the water supply network, usually included in the kit, service life 3-10 years;

- reinforced (available in corrugated metal braid), which is a standard rubber tube protected by an additional layer, which gives additional strength. Metal and nylon are used for reinforcement.

With mechanical valve

The rubber hose for water supply with the Aquastop system is one of the first with protection against leaks.

Aquastop is a valve with a special spring that is instantly activated when the pressure changes. If the Aqua-Stop system detects an unexpected leak in the washing machine, then the water that at that moment enters the unit is immediately shut off.

A special feature of this system is a thick water supply tube that can withstand up to 70 bar, when a standard water supply can only withstand 10 bar. This mechanism contains a solenoid valve (safety valve). Its normal position is normally closed.

Water Block # Blocking valve

The principle of operation of the Water Block water shut-off valve is to determine the volume of water that has passed through the sensor. "Water Block" is installed at the water inlet. The valve does not allow more water to pass through than specified in the program; it blocks the access of liquid. This system reacts even to small leaks, since the pressure inside the water supply does not matter to the device. After an alarm is triggered, the system starts a new operating cycle only after it is reset by pressing the “Reset” button.

The user of the system can adjust the permissible water level independently - the delivery set includes a key for setting the required parameters. For correct settings, you need to know information about the water consumption of the washing machine for one operating cycle.

With powder adsorbent

Some modern manufacturers equip washing machines with inlet hoses containing absorbent powder. This system is equipped with an internal channel through which water flows, and an external tube hermetically seals the internal flow. If the internal channel is damaged for some reason, water will begin to flow into the outer shell and rise to the automatic blocker. The mechanism is located at the point where the hose connects to the water supply pipeline. There are two types of protective devices in such systems:

- a plunger that performs the function of a shut-off valve. The absorbent component is connected to the plunger using a spring. When the absorbent powder comes into contact with water, it expands and begins to press on the spring and the plunger closes the entire system;

- magnets ensuring a stable position of the plungers. Dry absorbent powder keeps the system in balance. When wet, it expands in volume and separates the two magnets. As a result, the field between the magnets weakens, and the flow is cut off by the plunger.

Such a system gives results only if there is a leak in the hose. If the depressurization occurs on the threads or inside the washing machine, the mechanism simply will not work, as with small leaks.

Another disadvantage of the system is its disposability, i.e. After an emergency, the system requires complete replacement.

With float sensor

Another leakage protection system built into washing machines by manufacturers is a float sensor with a switch (much like dishwashers). In this case, the lower part of the household appliances is covered with a decorative plastic tray. If a leak occurs at the junction of the pipes or a leak occurs inside the unit, the liquid begins to collect in a special container. The float sensor, protection system, rises as the liquid level in the container rises. After some time, the mechanical leak valve will activate the switch, stopping the flow of water into the tank.

The disadvantage of such a system is that the protection mechanism only works when water collects in a special container. If water accumulates on the floor, the switch will not work. In addition, the mechanism does not respond to small leaks.

Types of breakdowns

There are various reasons why a washing machine leaks from below. Some breakdowns can be fixed on your own, while others need to be repaired by contacting a service center specialist.

Let's trace the path of water, starting from its entry into the washing machine. Sometimes a malfunction is detected already at the first stage of examination.

Hose is leaking

The washing machine may leak when water is added to the machine. Take a close look at the inlet hose. Cracks and breaks are not always visible to the naked eye. An easy way to determine if there is a leak is to disconnect the hose from the machine, plug the bottom end, and wrap the hose in toilet paper. When you pour water into it, you will immediately see the leak. The faulty hose will have to be replaced.

The water supply hose is leaking at the junction of the tube and the machine body. In this case, it makes sense to replace the gasket in the connection between them. Gaskets often deteriorate due to hard, chemically aggressive tap water.

The drain filter is leaking

The most common cause is an improperly closed plug. This happens if the filter has already been unscrewed and not turned back enough when put back in place. Try repeating this operation again, carefully and tightly tightening the fasteners.

Water leaking from the dispenser

Water can flow through the dispenser tray into which powder is poured during washing. Reasons for dispenser malfunction:

- clogging with undissolved powder residues;

- the grate is overgrown with deposits of calcium salts due to poor quality water;

- excess water pressure in the pipe when entering the machine.

A container malfunction is diagnosed if the washing machine leaks when filling with water. In this case, it is not difficult to eliminate the leak.

- Pull out the container and rinse it carefully under the tap.

- Salt deposits can be easily removed with a solution of citric acid.

- The pressure is easily adjusted using the water supply tap.

Pipe malfunction

It happens that manufacturers skimp on the quality of the connecting pipes inside the device. Bursting low-quality parts cause leakage.

The malfunction of the pipe leading from the fill valve to the dispenser or to the tank is determined as follows: when water is filled, the machine begins to leak, after filling, the leak stops.

A rupture of a similar pipe leading from the tank to the drain pump will be noticeable if a leak occurs when draining water or during a spin cycle.

The door seal is leaking

This type of leak occurs in front-loading (door on the side) machines. Water leaks out due to a rupture or displacement of the rubber sealing cuff. They occur during long-term operation, as a result of rubber wear, careless closing of the hatch cover, or injury from sharp objects caught in the drum.

The malfunction occurs during washing when the machine is filled with water. Inspect the hatch door - you may find streaks on the body. If the inside of the cuff is leaky, water flows from under the washing machine.

Not every car owner can replace the seal on his own. It is better to entrust this matter to a repair specialist.

Tank is leaking

The tank structure is usually made of durable materials, so tank failure is a rare cause of water leakage. Cases where the drum wall leaks are sometimes caused by hard metal objects getting into the machine.

Repairing a tank is almost impossible at home; only a few craftsmen can solder it on their own. To fix the problem, you must contact the service center.

The drain pump is leaking

The problem occurs during the spin cycle. Water flows out from the bottom of the machine when the draining and spinning process begins.

Possible causes of the problem:

- malfunction of the drain pump seal;

- drain pump failure.

Replacing a worn pump seal will help eliminate leaks during spin cycles. If the pump fails, you will have to replace it completely.

Incorrect operation

Sometimes water leaking from a car can be caused by reasons unrelated to the breakdown:

- overfilling the tank with water;

- incorrect choice of detergent and excess foam;

- kinked or disconnected drain hose.

An overfilled car tank is a problem caused by improper operation. Choose the correct operating mode, detergent dosage and load of laundry for your type of machine.

Check that the end of your machine's drain hose is securely attached. If the hose is kinked or broken, water flows onto the floor when draining.