A washing machine, like any technical device, is a complex device, the “heart” of which is the power unit. It is this that ensures the rotation of the drum, converting electric current into mechanical movements. Any asynchronous type power unit has brushes in its structure, which often fail. Replacing the motor brushes of a washing machine is not such a complicated process; it can be done independently.

What are they needed for

So, as it became clear, brushes are required for normal operation of an electric motor. This is a small but necessary part, which ensures the transfer of electrical energy to the rotor winding of the power unit, due to which, in fact, it rotates.

Brushes wear out over time, so they need to be replaced from time to time. And if you delay this, the problem may turn out to be much worse and the power unit itself will have to be changed.

Loss of motor power

The “coals” ensure the transmission of electricity to the motor rotor windings, thereby causing it to rotate. The typical service life of electric motor brushes is at least 7 years (with proper use).

Characteristic signs of brush wear:

- Extraneous noise when rotating (spinning) the drum

- Motor power loss

- The smell of burning, burning

- The machine freezes during the spin cycle and an error code is displayed

- Draining water after starting the program

Brushes for Indesit, Kandy are available with parameters 5x12, 5x32 mm.

For Bosch and Siemens, longer brushes are produced - 5x12, 5x32 mm.

It happens that the wear of the coals is slight, but they are jammed - pinched in the body by dust accumulated in the cracks.

Each ember is installed in a brush holder. It can be disassembled into two halves. Pay attention to how much the brush protrudes.

If the working reach of the brush is less than 7 mm, it must be replaced (both should be replaced).

To do this, disconnect the wire and pull out the contact to remove it. Remember in which direction the graphite contacts are ground.

Remove the back panel and drive belt. Unscrew the mounting bolts and separate the motor from the washing machine tank.

Motors come in three types - single-phase asynchronous, direct drive and commutator.

We determine the serviceability of the engine itself, otherwise replacing the brushes will be a wasted repair.

Using a tester, we measure the resistance of the collector contacts for a short circuit and to the housing. A break in the rotor windings can be easily detected using an ohmmeter by connecting the latter to any adjacent collector lamellas.

Rotating the rotor manually, we measure the resistance between adjacent lamellas - it should be the same. If the resistance increases, there is a winding break.

If everything is in order, we inspect the condition of the “coals”. If the working overhang is less than 7 mm, it must be replaced (both should be replaced).

To do this, disconnect the wire and pull out the contact to remove it. Remember in which direction the graphite contacts are ground.

We clean the collector lamellas with sandpaper. We remove dust with a vacuum cleaner. We install new ones, making sure that they fit tightly to the collector.

If necessary, grind off the graphite with sandpaper. Attach the motor to the tank, connect the power wires, but do not put on the drive belt.

We start the spin cycle and rub it in to reduce friction. Next, we assemble the remaining parts.

Additional articles:

- The washing machine does not spin - all faults

- Should I repair or buy a new washing machine?

Replacing brushes on an Indesco commutator motor, which is installed on Arison, HAIER, SAMSUNG, Indesit, Candy:

Types of parts

The main difference between all brushes is their pressing element, which can be:

- copper-graphite;

- carbon-graphite;

- electrographitized.

Washing machines often use carbon types, which are not so expensive, but quite reliable.

When to replace

There are several signs by which you can definitely recognize brush wear:

- Unexpected cessation of operation of the electric power unit, for example stopping during washing. If this is not accompanied by a voltage surge or mechanical damage, then the reason is precisely the wear of the brushes.

- During washing, a crackling or other unknown noise appeared.

- Significant reduction in power of the electric power unit.

- The smell of burnt wiring and burning from the washing machine.

- An error code appears on the display.

These are just the most basic reasons for brush abrasion, but there may be others that only a specialist can recognize.

Replacing brushes will not present any difficulties even for those people who have never encountered this problem before, but the process must be approached as responsibly as possible.

How to choose replacement brushes

The functioning of the washing machine and the service life of the graphite elements directly depend on the correct choice of brushes. All brushes must be the same size, since installing parts with different spring stiffness or other material carries a high probability of failure of the entire unit.

You should only buy brushes from trusted sellers, making sure to write down or remember the brand of your washing machine. The easiest way to purchase spare parts is through online stores or service centers. Original products can cost from 800 to 3000 rubles, but to reduce the cost you can buy universal brushes, they cost from 300 to 500 rubles. By purchasing brushes for a specific model, you eliminate the possibility of poor-quality repairs, which are often carried out with mechanical adjustment of the brushes to the required dimensions. Even considering that replacing brushes is not a complex repair, it is better to have it done by specialists who provide a guarantee for the repair.

Preliminary manipulations with the machine

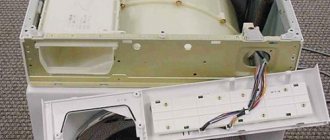

First you need to disassemble the washing machine:

- Disconnect the device from the power supply and water supply/discharge system.

- Remove the rear protective cover.

- Remove the belt from the pulley.

- We disconnect the motor from the power supply.

- We remove the engine itself.

It is worth understanding that the disassembly process may be slightly different, based on the specific manufacturer and model of the machine.

Step-by-step instructions for replacing brushes

Let's take a step-by-step look at the steps required to gain access to the motor brushes:

- Unscrew the bolts of the rear panel and remove it;

- remove the top cover by pushing it to the side and then up;

- Unscrew the fastening bolts around the perimeter of the rear wall;

- below the drum you will see an electric motor;

- to remove the drive belt from the pulley, pull it towards you, slightly turning the pulley;

- Mark with a marker or take a photo of the location of the wires and terminals so that you do not make mistakes during the reassembly process. Disconnect the wires;

- Using an 8 mm socket wrench, unscrew the bolts securing the engine (there are 3-4 of them in different models);

- lightly rock the engine to the sides and pull it towards you to remove it from the housing. Do this carefully so as not to drop or damage the engine, as it has significant weight;

- Inspect the motor brushes, which are located on both sides of the motor. To remove and replace them, disconnect the wires going to them and slide the contacts down. Then pull the spring and remove the elements;

- To install new parts, first insert the graphite tip into the socket and check the tightness of the fixation. Then compress the spring and insert it into the socket, fixing the contact. Insert the wiring;

- After installing the brushes, you need to return the electric motor to its place. To do this, insert it into place and screw in the mounting bolts. Connect the wires to the terminals according to the marks or photographs;

- attach the drive belt to the motor pulley, then to the drum pulley, these actions must be done in parallel with the slow rotation of the pulley;

- insert the back cover into the groove and screw it in place;

- put the top panel back in place.

After completing all assembly steps, it is imperative to perform a check before starting a standard washing program with items.

Replacing motor brushes is not a difficult task, especially if you follow the instructions provided. Watch the video on the topic:

The features of replacing brushes on a top-loading washing machine are described in the video.

Replacement process

The entire replacement process will be shown using the Gorenye brand as an example, but it is actually suitable for other brands:

- The power unit is laid on its side and the mounting bolts are removed from the brushes, after which the latter are removed.

- On the other side of the engine, identical manipulations are performed.

- Brushes that have exhausted their working supply have a rod length of no more than 1.5 cm (if the brushes are longer, then the problem is not with them).

- The power unit manifold is being cleaned.

- New parts are mounted and secured with screws.

Attention! The brushes must be replaced in pairs.

Next, you need to put the engine in place and do all other manipulations in reverse order. Once everything is connected, be sure to check the quality of its operation. If it works a little better or even louder, most likely everything was done correctly. If there is an unpleasant or unusual sound, the problem is most likely not solved.

Attention! It is not recommended to overload the drum for the first 10 washes after replacement.

We disassemble the washing machine

To replace the brushes of the electric motor of the washing machine, you need to prepare for the upcoming work by studying the instructions and the layout of the main components. All operations must be carried out with the utmost care. When disassembling, try to remember well the location and method of fastening the affected components. Expert advice! It will be useful for a beginner to take a photograph of the internal structure of the opened machine in order to know exactly what and where should be after assembly.

Required Tools

To get to the motor and replace the brushes, you will need:

- Screwdriver Set;

- spanners;

- pliers;

- sandpaper.

Preliminary disassembly

All repair work on household electrical equipment must be carried out when it is completely disconnected from the network. First, remove the plug from the outlet. In preparation for replacing brushes you will need:

- disconnect the automatic machine from the supply and sewer water pipes;

- unfold the unit in order to achieve convenient access to its rear side;

- remove the back cover, which is usually secured with self-tapping screws;

- dismantle the belt connecting the electric motor to the drum shaft for loading laundry, which will require pulling it towards you while carefully rotating the pulley;

- disconnect the motor from the power circuit by opening the corresponding connector;

- Unscrew the bolts securing the engine to the frame and remove it.

Need to know. Models from different companies may have their own design features. That's why you studied the manufacturer's instructions before starting work.

Collector motor diagram

Replacing brushes on a washing machine

It is better to carry out work with a dismantled engine on a table in conditions of sufficient lighting. The procedure for replacing brushes is as follows:

- place the motor on its side to gain easy access to the brush installation location;

- unscrew the mounting bolts;

- remove the brush from the socket, remembering the direction of sharpening the tip;

- repeat the above operations with another brush;

- inspect the rods (if there are no visible damages and the length of the graphite exceeds 1.5 cm, then the reason for the failure is not them);

- check the condition of the engine manifold by sanding all irregularities;

- install new brushes, securing them in the desired position with standard bolts.

Do not forget! The bevel of the brushes should provide the maximum area of their contact with the commutator. If this is not the case, you need to rotate them 180 degrees.

Shutdown

Reinstalling the engine is done in reverse order. To do this you need:

- place the motor on the frame, securing it with bolts to the mounting holes;

- connect the power cable;

- tighten the belt by slightly turning the motor and drum shafts;

- replace the back cover;

- restore the water supply and sewerage connections and insert the plug into the socket.

Any repairs made must end with startup tests. They will consist of the initial start-up of the washing machine in one of the gentle modes. In this case, you should make sure that it is in good working order and listen to the noise of the motor. The brushes will take some time to grind the surfaces to the shape of the commutator. In such a situation, it is possible to slightly increase the operating volume without particularly sharp sounds or increasing vibration of the unit.

Advice! For the first few washes after replacing the brushes, it is not recommended to load the drum to the limit to avoid triggering the emergency protection.

If you are unsure of your ability to correctly determine the cause of the breakdown and replace the brushes on the electric motor of your washing machine, then use the services of a customer service . This kind of work is done fairly quickly and is paid at minimal rates. Most likely, knowing the make of your car, the technician will arrive with the necessary spare parts, and you won’t have to look for them yourself by calling or visiting stores.

Watch a video on how to replace the brushes in your washing machine yourself