The principle of operation and the internal structure of the iron, at first glance, do not raise any special questions: the electric current leads to heating of the nichrome spiral, which, in turn, transfers heat to a massive metal plate - the sole. But how do you regulate the heating temperature, supply steam or spray water? Modern models of irons can be equipped with a variety of systems to prevent scale formation, electronic components and regulators, the presence of which significantly complicates the design.

Understanding the structure of a modern iron on your own is quite difficult, but having such information can help in troubleshooting minor problems. Considering the high complexity of the iron’s design, for major repairs (replacing the coil or electronic components, cleaning the water supply pumps, restoring the electrical wire), it is recommended to contact specialized workshops, since the operability of the device after unauthorized intervention is not guaranteed.

What parts does the iron consist of?

Such a familiar household appliance as an iron is a rather complex device, from a technical point of view. The iron circuit includes several dozen elements, the main ones of which are a heating element, a thermostat, an overheating protection system, as well as various regulators, indicators and other electronic components, without which it is impossible to imagine the normal operation of a modern iron.

How does a modern iron work, many models of which can be seen on store shelves today? First of all, the following components should be highlighted in its structure:

- electrical wire;

- steam supply system;

- water chamber and steam generators;

- sole;

- thermostat.

When considering each of the elements separately, special attention should be paid to the internal structure and operating principle of the parts, since such information makes it possible to determine the cause of breakdowns and ways to eliminate them.

Electric wire

Although at first glance the wire for an iron is no different from a similar element of other household appliances, some features can be traced in its appearance and internal structure: first of all, the wire has a fabric braid, which prevents chafing of the polymer shell during ironing.

It is difficult to imagine any other device that is subjected to the same heavy loads as an iron, because when using it you have to twist the cable several times in different directions, stretch it, bend it at unimaginable angles, and even inadvertently roll it into a knot.

An ordinary cord would not be able to withstand such manipulations for long, while the wire from an iron copes with its duties perfectly for several years or even decades.

The secret lies precisely in the fabric braiding: it reduces the coefficient of friction between different sections of the cable several times, and also increases its rigidity. As an additional element that gives maximum reliability to the system, a plastic stopper is used, which is located near the base of the iron and is designed to prevent possible kinks in the wire.

The internal part of the wire for the iron is represented by three wires, one of which is used as grounding. This safety measure makes it possible to reduce the risk of electric shock in the event of a short circuit and extend the life of the device.

Steam supply system

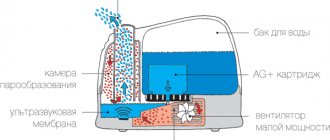

Most modern iron models are equipped with two buttons that are located in the front of the device: one of them is responsible for supplying steam, and the other makes it possible, if necessary, to moisten the fabric by spraying water through a special hole located on the nose of the iron. The transformation of water into steam occurs in a separate chamber, which is equipped with powerful heating elements. After pressing the button, liquid under pressure penetrates into the chamber, where it is instantly heated, and is distributed through the perforations on the sole of the iron.

The use of untreated tap water often leads to excessive formation of carbonate deposits on the surface of heaters, which naturally leads to a decrease in heating efficiency and failure of heating elements. The appearance of traces of rust, dirt or scale fragments on the fabric during ironing is an alarming signal that indicates that it is time to pay additional attention to cleaning the iron.

Sole and heating system

Not only the quality of ironing, but also the overall level of comfort when using the device largely depends on the sole, as the main component of the iron. Manufacturers of modern irons equip them with soles coated with Teflon, ceramic or even sapphire - this technical solution reduces the coefficient of friction between the sole and the fabric, thereby facilitating the ironing process. Inexpensive models of irons are equipped with an aluminum sole, the main disadvantage of which is considered to be the excessive malleability of the metal, which often leads to noticeable scratches.

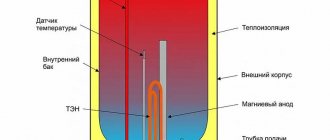

Inside the sole there is a heating element - a nichrome spiral, complemented by ceramic rings that evenly distribute heat and help retain it for a long time. The heating temperature is set by a separate thermostat, the main function of which is to timely turn off the power supply in accordance with the set mode.

Thermostat and heating shut-off system

Using an iron on various types of fabrics requires careful selection of the appropriate temperature conditions.

In most cases, ironing requirements are indicated by clothing manufacturers on a separate label, which is sewn into the folds of the product.

Heating is adjusted by setting the rotary wheel of the iron to the required position, corresponding to the permissible ironing parameters. When the temperature reaches its maximum value, the contact opens, causing the voltage supply to stop.

How does the regulator turn off? The electrical circuits of irons require the presence of a special element - a bimetallic plate, which consists of two parts made of metals with different coefficients of thermal expansion. When heated, the metal is deformed, and differences in the properties of the component parts of the plate lead to slight deformation, as a result of which the plate moves upward and stops contacting the electrical circuit. A similar operating principle is used not only in irons, but also in kettles, boiler shutdown relays and other heating elements.

Choosing a functional and high-quality iron

Modern models of irons cannot be different. Manufacturers have learned to make excellent devices, but it is worth paying attention to the fact that most companies supplement their irons with absolutely useless functions.

For example, why do you need a steam generator in everyday use if it is only needed when steaming things in dressing rooms and costume theaters and modeling studios.

Moreover, the price for such devices will be significantly higher than the standard and acceptable.

How does an iron with a steam generator work?

There are two varieties of iron with a steam generator, at least significant ones. The first is a device with a built-in tank and a steam generation system. The second is models with a separate tank. It contains not only a container with liquid, but also heaters and a steam flow control system. The reservoir is connected to the iron by steam-conducting tubes.

Steam generator design

A steam generator is a rather dangerous device. The risk of emergency situations is unacceptable for a household appliance. Therefore, a number of safety devices are used in the generator design. The unit, built-in or placed in a separate tank, consists of the following parts:

- liquid tank;

- heaters section;

- thermostat to control the heating process;

- electrical fuse;

- steam supply mode switch, operating pressure setting;

- emergency valve cover;

- steam release valve.

In inexpensive models, everything works quite simply. To ensure a uniform supply of steam with constant energy consumption by the heaters, the steam generator unit is equipped with a dispenser. It works in tandem with a thermostat, supplying water as its volume is depleted through evaporation and stopping this process when the temperature drops.

In expensive irons with a steam generator, the emergency stop system in the form of a safety valve is supplemented with pressure gauges. In this version, the unit not only supplies steam more consistently in a constant flow, but also provides greater safety.

Types of generators based on the principle of using liquid

There are two types of steam stations. A simple option is gravity. Here the liquid is supplied directly to the heating zone. With its intense evaporation, steam is formed, which is released through holes in the sole.

Advanced design - pump-type generators. They heat the liquid in a separate tank, where it is supplied by a dispenser. The steam generated during evaporation is released by a pump. This ensures not only feed stability, but also controlled high jet pressure.

Depending on the design, irons with steam generators are designed for different tasks. Gravity models are not capable of providing high, controlled quality of the final ironing result. But their price tag and overall characteristics are attractive to housewives who deal with a small amount of laundry. When you need an ideal, consistently good ironing result for large volumes of items, you simply cannot do without a more expensive pump model.

Professional iron with pump-type steam generator

Iron with steam generator

Models come with a built-in generator and a free-standing one. For devices with a free-standing steam generator, the supply system is connected using wires and steam-conducting hoses.

Device

The product is equipped with a special station with a heating element and a water tank. The hot air flow is supplied through a special hose. The main role here is assigned to the steam station, where heating occurs to the specified values. Its structure is as follows:

- water container;

- heating element (heating element);

- thermostat;

- fuse;

- pressure regulation toggle switch;

- cover to protect the safety valve;

- the valve itself;

- dispenser;

- pressure gauges (in some models).

We list the main elements of the entire structure:

- The back cover is secured with screws to the body. Sometimes it is attached to a block, in this case the cover is straight. If it is not secured to the block, then when disassembling the cover must be pulled up. The latches release the fasteners.

- The block secures the cable in the housing. Can be monolithic or collapsible. The monolithic one can be removed by unscrewing the screws on the block and clamp. To remove the collapsible block, you need to release the latches.

- The top cover is secured with special devices with squeezers. Removal from both sides is provided.

- The housing is screwed to the steam station with recessed fasteners. They differ in shape and length.

- The sole contains conductive and heating elements.

By type, steam stations are divided into gravity and pump. First, the liquid gets to where the heating element is located. There, at high degrees, the liquid evaporates. In pump pumps, water is heated directly in a separate container. After steam generation, hot air under high pressure is supplied to the sole.

If you need to iron a small amount of laundry and there are no high demands on the result, gravity-fed products are suitable. If you need to have perfectly ironed items, it is better to use a pump model.

Principle of operation

To ensure proper functioning of the steam station, you must perform the following steps:

- unscrew the valve cover;

- fill the container with water;

- connect the station to the network (voltage 220V);

- turn on the heating element button on the panel to start heating the water to 160 degrees.

The operating principle of an iron with a steam generator is a whole system of supplying hot air without heating the sole. When the specified values are reached, the water turns into steam. Pressure within 0.35 MPa. After 150 seconds the system is ready for use. The models provide overheating protection; these functions are provided by a thermostat and a fuse. If the steam mode exceeds the standard values, the heating element automatically turns off. When the degrees drop, the heating automatically turns on. If the thermostat breaks down, the fuse ensures safe operation. If it burns out, the entire circuit shuts down. After replacing the fuse, you can continue to use the device.

Electrical diagram

The circuit of an electric iron with a steam generator consists of the following parts:

- Euro plugs with grounding;

- relay KM - with winding power circuits;

- SK – position sensor;

- thermostat;

- connection block;

- thermal protection;

- heating element;

- indicator lamps.

The position sensor with the KM relay performs protection functions. There is also an LED power indicator.

Types of generators based on the principle of using liquid

There are two types of steam stations. A simple option is gravity. Here the liquid is supplied directly to the heating zone. With its intense evaporation, steam is formed, which is released through holes in the sole.

Advanced design - pump-type generators. They heat the liquid in a separate tank, where it is supplied by a dispenser. The steam generated during evaporation is released by a pump. This ensures not only feed stability, but also controlled high jet pressure.

Depending on the design, irons with steam generators are designed for different tasks. Gravity models are not capable of providing high, controlled quality of the final ironing result. But their price tag and overall characteristics are attractive to housewives who deal with a small amount of laundry. When you need an ideal, consistently good ironing result for large volumes of items, you simply cannot do without a more expensive pump model.

Professional iron with pump-type steam generator

General procedure for starting to work with the iron

A specific algorithm for handling a steam generator is always outlined in the instructions for the model. It is worth remembering that there is a danger in using this device, which simultaneously operates with high temperature and pressure. Therefore, the manufacturer’s recommendations should not be ignored. The general algorithm of actions looks like this:

- unscrew the lid with the emergency valve built into it;

- pour water into the tank;

- plug the steam generator into the outlet;

- press the heating start button.

The iron is not immediately ready for use. The time for heating the first portion of water to 160 degrees may vary. In simple models it is 2 - 2.5 minutes. After this, the device is ready for use.

The operating pressure in the steam supply system is about 0.35 atm (value for conventional steam generators). The safety structure is always in effect during heating and operation of the device. It is represented by several components. There is integrated overheating protection in each heating element. If the heater breaks down or short circuits, the electrical fuse trips.

Boiler safety systems

A bimetallic thermostat is responsible for the temperature regime . Its contact plate changes configuration when heated, closing and opening the circuit. If none of the above measures work, steam is released through the safety valve in the lid. This is a potentially dangerous phenomenon, but it helps prevent another high risk - pressure rupture of the housing and the release of huge amounts of superheated fluid over a large area.

How the iron functions work

All irons have a basic set of functions. This does not mean that all devices are the same. Some models can perform more operations, others are limited to only the basic list.

Automatic shutdown

An iron with a steam generator has heaters and a water treatment zone, a pressure vessel. Therefore, in order to ensure fire safety, an automatic shutdown system is built into all models. It is built on a simple gyroscope. The iron turns off:

- after 30 seconds of being on a horizontal surface without moving;

- after 10 minutes of inactivity in an upright position.

The iron will turn itself off when idle on a horizontal surface

These values are averaged. They are recommended as a safety standard. However, individual models of steam generators may differ.

Thermostat

The thermostat performs two functions at once. This is one part of the overall safety system of the iron, and at the same time the main function. The thermostat sets the heating level of the sole . The unit works simply: when the set temperature is reached, it breaks the voltage supply circuit to the heating elements, and when it decreases, it closes it again.

Liquid and steam supply

The simplest irons can only supply steam. More complex functions have two. When you press one button, a stream of steam is released. On the second, the iron begins to spray hot water through the spout to work with heavily wrinkled fabric.

More complex models have a steam boost. This is an extremely intense jet. At this time, the device quickly consumes water from the heating zone. Depending on the capacity of the latter and the power of the heaters, the duration of operation in the steam boost mode may be longer or shorter.

Steam and water spray buttons

Anti-drip system

It is worth understanding that during pauses in steam supply, the liquid remains inside the nozzles on the sole. While the iron is in use, its quantity is small. But if you turn it off, all the liquid condenses. And the next time you iron, drops of water may fly out when steam is applied.

The anti-drip system performs two tasks:

- blocks the flow of water from the container;

- ensures blocking of the heating zone exit after the iron is turned off.

Models with an anti-drip system use a shortened steam path from the generation zone to the holes in the sole . All with one goal: to minimize the accumulation of water in the absence of heating.

Anti-drip system helps prevent water from leaking from holes in the sole

Vertical steaming

Irons with a vertical steam function have distinctive design features. This includes the position of the heating elements, the placement of the heating zone, and the length of the steam path before being released from the sole. The flow is less than in impact mode. But more intense than normal work.

Vertical steaming makes it easy to iron delicate fabrics. Indeed, in this mode, the iron may not touch its surface. You can also iron things that cannot be removed or are difficult to remove. For example, blackout curtains.

How does an iron work?

The basis of the iron is an electric heater. It is a spiral made of metal, which becomes very hot when exposed to electric current. For domestic purposes, a heater with a power of 1500 W is sufficient. It is controlled using the thermostat knob, which is connected to the thermostat strip. As it rotates, the strip moves away or approaches the contact, and the temperature of the thermostat depends on this.

The main working surface is the soleplate of the iron. It can be made of stainless steel (a very durable material, heats up well and cools quickly) or have aluminum (low cost), Teflon (high cost) and metal-ceramic (the most modern, particularly durable and high cost) coating. When its temperature becomes too high, the automatic shutdown system is activated. To prevent a fire, this system will turn off the heating of the iron when it is in a horizontal position for more than 30 seconds or in a vertical position for more than 8 minutes.

Iron device

The reservoir contains water for the steam humidification system. An anti-scale protection system is also installed here: an anti-lime rod or a water softening cartridge. The steam humidification system may include a sprinkler or a steam generator. The latter can operate in continuous steam generation mode or in pulsed steam supply mode (for example, when smoothing heavily wrinkled fabrics). Thanks to it, the iron no longer needs to be pressed tightly against the fabric; the result will be impressive even without it.

One of the main parts of the iron is the thermostat. It turns the heater on or off, maintaining the set temperature. Inside the thermostat there is a strip consisting of two different metals. When heated, they expand and the strip bends, breaking the electrical circuit.

Typical iron malfunctions and ways to solve them

Iron breakdowns are mainly associated with improper operation, sudden changes in voltage or insufficient tightness of the water compartment, from which moisture leaks onto the electronic components of the device. Determining the cause of the malfunction, given the significant complexity of the design of modern irons, can be difficult, but there are a number of typical signs that reduce the search range:

- When the iron is connected to the mains, the indicator light does not light up and the soleplate does not heat up. First of all, you should check the serviceability of the socket, since it is often the cause of breakdown. If the network turns out to be working properly, then the next source of the problem may be a violation of the integrity of the network cable. In addition, a break is often found directly in the sole area of the iron, where a small fuse is located that blows when overheated.

- The indicator light is on, but the heating does not work. In this case, the cause of the malfunction should be sought in the heating element or the fuse described above, since the supply of energy to the sole depends on these elements.

- When steam is supplied, rusty water with scale fragments begins to leak out of the holes in the sole. A similar problem occurs when a certain amount of moisture gets directly onto the electronic components of the iron: when the device is turned on, it comes into contact with moisture, an electrochemical reaction occurs, which leads to the slow destruction of the metal. The process is enhanced by the use of water, which contains a large amount of salts, organic and inorganic impurities.

How to extend the life of your iron?

In order for the iron to serve you for as long as possible and not cause problems with its operation, you should follow a few simple tips:

- Avoid careless handling of the iron: the electronic components of the device do not withstand sudden shocks, drops or temperature changes. If your iron is equipped with a ceramic sole, then its vulnerability, due to the fragility of the material, increases significantly.

- To refill the iron, it is recommended to use distilled water or a special flavored liquid, which can be found in departments with household chemicals. It is completely unacceptable to use even purified water or refill the iron directly from the tap, since such treatment leads to the rapid accumulation of carbonate and ferrous deposits.

- If you store the iron on a balcony or in another place where the temperature differs significantly from room temperature, then after moving the iron to a warm room, it is recommended to allow it to “acclimatize” a little, so that all the condensation that settles on the contacts will have time to evaporate.

- Any dirt that appears on the metal sole should be immediately removed using special means. Ironing of plastic elements, zippers, decorative patterns, sparkles and prints is also not allowed, as they melt quite easily and can seriously contaminate the sole.

The main operating principle of irons is to uniformly heat the metal sole and distribute water vapor throughout the fabric. By following simple precautions, you can not only significantly extend the life of your equipment, but also avoid most common breakdowns.

Who invented it and when?

No one will say for sure exactly when and who invented the device that is now commonly called the “iron” and in which specific country in the world it first appeared. The very first analogue of the iron, as researchers believe, was born when people created the first woven clothes. Although some eminent archaeologists are completely sure that primitive people also smoothed the skins of animals - most likely with mammoth bones, and this may mean that the name of the creator of the first analogue for ironing will forever be hidden from us.

But it is known how the iron was gradually improved. Even in quite ancient times, people quickly came up with and implemented various methods of ironing clothes so that crumpled items after any wash would look stylish and not be too wrinkled. One of the simplest and oldest methods, which was actively used by ancient people, is still used by many women in the world - simply stretching a damp cloth on a stone under the scorching rays of the sun. Then most of the washed items will look unwrinkled.

The very first recorded evidence that devices such as irons were actively used in everyday life has a date of February 10, 1636, although according to experts, the iron appeared in the homes of ordinary people much earlier than this date and today we can safely assume that it is already more than 2 years old. .5 thousand years. This is precisely the age of those devices that, in their functional features, resemble the now familiar iron, that is, their origin can be dated back to approximately 500 BC. e.