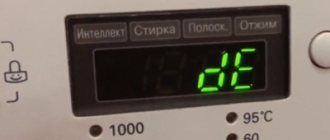

The IE error on the LG washing machine occurs at the beginning of the wash cycle, when the laundry is loaded and the program is selected. But the water has not started to fill up or is pouring in very slowly, never reaching the required level.

A problem like this needs a timely solution. Sometimes it is possible to correct the situation even on your own, but in difficult cases you cannot do without the help of a specialist.

Causes, diagnosis, solution to the problem

IE does not always mean that LG is broken. In some situations, troubleshooting is so simple that you can easily do it yourself.

Lack of water

If there is no water in the literal sense of the word in the system, it physically cannot get into the machine. The following points should be analyzed:

Is the water supply tap to the washing machine open or not? Incomplete opening of the tap will also prevent high-quality water from entering the tank.- Is there water in the plumbing in the apartment?

- Weak water pressure in the plumbing system, as well as a not fully open water supply valve, can lead to an error appearing on the display, since the machine simply does not have time to draw water in the allotted time.

Crushed hose

A water supply hose that is kinked or squashed by something can also prevent it from flowing into the tank. To correct the situation, the hose must be straightened, released, and positioned freely.

Clogged inlet hose mesh

The mesh filter is located in the area where the inlet hose enters the LG washing machine. The purpose of this small part is to retain small debris (pieces of rust, grains of sand, etc.) so that it does not get in with the water coming from the water supply.

The solution to the problem is cleaning the mesh. To do this, you need to disconnect the washing machine from the communications and remove the inlet hose. The mesh filter is removed, washed, and after processing is installed in its original place.

Remove the mesh carefully so as not to damage it, using small pliers. Rinse it under high pressure of water. It can only be replaced after complete cleaning.

During active repair work on main water pipelines, there may be a lot of small debris in the tap water.

You can watch the video on how to clean the filter:

Random failure in the control module

A power surge or other accident may cause an IE error code to be issued. To reset the settings, the washing machine should be unplugged for 20 minutes . Pulling the plug out of the socket. If the error does not go away when you turn it on again, diagnostic measures must be continued.

Intake valve failure

If the LG machine does not draw water at all, or does so very sluggishly, the problem may be due to a broken inlet valve. If there is a failure, it does not open to the command of the control module and, as a result, water does not fill. If it does not work completely, water may flow into the washer, but very slowly and a little at a time.

The solution to the problem is to replace the valve. To carry out the work, partial disassembly of the device from the rear wall is necessary.

This article will tell you why the LG washing machine doesn’t draw water well or doesn’t do it at all.

Clogged pipes

The pipes through which water enters the LG powder receptacle can also become clogged. In this case, you will have to partially disassemble the washing machine, detach the pipes from the powder receiver and clean it.

The pressure switch is broken

If the sensor breaks down, water is not added to the LG machine. For diagnostics, the pressure switch needs to be removed and examined . If the tube is clogged, it can be blown out. In other cases, the part is replaced with a new one.

Control board problems

The LG control module gives signals to the nodes, coordinating their coordinated work in accordance with the program specified by the user.

If the board fails, almost any error can appear on the display, including IE.

To analyze the condition and performance of the board, as well as to carry out repairs, it is removed by disconnecting it from the contacts. In most cases, this unit can be repaired , but it is better to entrust such important work to a specialist.

In extremely rare cases, the control module is replaced completely.

Constant drain of water

An error indicating insufficient water in the LG tank may be due to the fact that liquid constantly flows out of it without stopping. Self-draining causes the pressure switch to constantly send a signal to the control module about a lack of water, and the operation of the washing machine stops, and the IE command is issued to the display.

In such a situation, you will have to figure out why the water is draining . Most often, the problem lies in incorrect installation, including violation of the manufacturer's requirements regarding the location of the drain hose. With proper installation (with the obligatory raising of the drain hose above the level of the tank), the problem will go away on its own.

How to fix the problem

To troubleshoot the problem yourself, you need to perform several steps that do not require special knowledge. Where should you start if the error is not related to water pressure, much less its absence in the house.

The first step to troubleshoot a machine is to turn it off and on again. If, after turning it on again, you cannot hear the sound of water pouring into the tank, then it is recommended to start studying the causes of the failure from the Aquastop hose. It is necessary to understand whether the leakage protection has worked. If the indicator on the block shows that the protection has worked, then the hose must be replaced.

Then you should inspect the hose to make sure there is no squeezing or other impact on it and proceed to cleaning the filter. To do this, you need to turn off the water supply tap and unscrew the hose to collect it. At the junction of the hose with the machine body there is a mesh filter, the microscopic holes of which may be clogged. To clean, you need to immerse the mesh for 30-40 minutes in a solution with citric acid, followed by rinsing with running water. After installing the mesh in place and connecting the hose, you need to make sure that error E1 has disappeared.

If the car continues to signal an error, then you need to inspect the intake valve.

To do this, you will need to partially disassemble the SMA. After disconnecting the washing machine from the communication connections, remove the top cover to find the inlet valve. Inspect the wire going to it and check it with a multimeter. If a malfunction is detected, the valve must be replaced.

If the malfunction is related to the control module, then it is recommended to entrust its repair to a specialist.

Calling a technician: where to call and how much to pay?

If the repair cannot be carried out on your own, you must call a specialist. Companies that provide washing equipment repair services can be found on the Internet by narrowing the search to your city.

It is advisable to choose companies that have been operating in the market for a long time and have a good track record. This will allow you to protect yourself from scammers and unscrupulous businessmen.

The cost of repair (the price of replacement parts is paid separately) for an LG machine will depend on the complexity of the breakdown and the complexity of the repair.

On average, MSK prices start from the following indicators:

- replacement of the water supply valve – from 2,000 rubles;

- clearing the blockage/replacing the pressure switch – from 2,000 rubles;

- repair/replacement of the control board - about 2,500 rubles, etc.

After the repair is completed, the technician performs a test run of the washing machine and issues a warranty.

Call a professional

The table below describes the types of malfunctions for this error, which can be eliminated by a technician by repairing or replacing spare parts, as well as the cost of this work:

| Signs of an error | Possible cause of error | Necessary actions | Cost of repairs, including spare parts, rub. |

| There is no water flowing into the tank of the machine; the display shows code 1E, 1C or E7. The first error signal can occur at any time during the washing process | The most common breakdown is failure of the pressure switch due to one of the following reasons:

| Replacing the pressure switch or repairing the pressure level sensor hose using one of the following methods:

| 1500-3800 |

| The monitor shows error 1E,1C when starting the machine | Failure of the control module due to problems with the processor in the chip. The resistors may have burned out and there is no contact between the control board and the pressure switch. | Resoldering resistors on the control module or replacing the control module if the processor fails | 3900-5600 repair 7100 replacement |

| In the first minute of operation, the display displays code E7,1E. A machine without a display displays an error using a combination of indicators (see above) | The wiring in the area from the pressure switch to the control module does not work; the contacts are likely damaged or oxidized. | Cleaning contacts at the water level sensor, replacing internal wiring if twisting is ineffective | 1600-3000 |

**All repairs are typically covered under a two year warranty.

Error e7

You can leave an online request to the master 24 hours a day. In it you can briefly describe your problem, making sure to indicate the model of your washing machine, and leave contacts for feedback.

A specialist will arrive at your chosen time from 9.00 to 21.00, diagnose your household appliance, calculate the cost of repairs taking into account your model of Samsung washing machine and carry out all the necessary work to eliminate error 1E (1C, E7). If you are not satisfied with the price, you can refuse the repair, in this case you are not obligated to pay a specialist for repairs, only 400-500 rubles for diagnosing the problem

TOP stores of washing machines and household appliances:

- mvideo.ru / - household appliances store, large catalog of washing machines

- holodilnik.ru – Inexpensive store of household appliances.

- techport.ru - profitable modern online store of household appliances

- citilink.ru is a modern online store of household appliances and electronics, cheaper than offline stores!

- ru.aliexpress.com - spare parts for washing machines

Preventive measures

In order to be less likely to encounter the problem of detecting an IE error on an LG display, the following preventive measures will not be superfluous:

If the water in the water supply system is very dirty, it makes sense to install main filters at the entrance to the apartment. This will protect the washing machine from the entry of rust particles and other impurities that can cause clogging.- If there are constant power surges in the house, it is advisable to connect the washing machine through a voltage stabilizer. This will protect the control board and other components from burnout and prevent costly repairs.

- It is advisable to clean the filter at the entrance to the washing machine, like the hose, from time to time. With active use, the best option is once a year.

- The pressure switch tube often becomes clogged with water containing foreign inclusions. If the water has quality problems, the pressure switch tube must be cleaned once a year, without waiting for problems to appear.

Problems with fill valves

These devices operate on the following principle. The fill valves are constantly closed by default, and when you need to add water, the control module supplies voltage to the valves. And the coil located inside opens the shutter.

Sometimes they burn out and cannot perform their functions. In this case, replacement with new ones is necessary. This work can be done with your own hands, without the involvement of third-party specialists. The main thing is to buy a valve that matches the mounting and shape of your washing machine model.

Triple fill valves

You will need the following tools:

Recommendations

When using an LG washing machine, the following recommendations will be useful:

- The washing machine and supply lines should be protected from children's pranks and pet mischief.

- The installation of the washing machine must be carried out initially according to the rules established by the manufacturer. This also applies to the location and installation of the inlet hose.

- After finishing washing, it is advisable to turn off the water supply tap to the washing machine so that it is not constantly under pressure.

- There is no need to immediately disassemble the washing machine when an IE error code is detected on the display; first you need to check accessible and simple components (water supply, filter mesh, hose) and only then proceed to diagnosing more complex areas.

The IE error is always associated with a lack of water in the tank or its complete absence, which makes it impossible to start washing.

You will find a lot of important and useful information about error codes for LG washing machines in this section.

How to fix serious problems

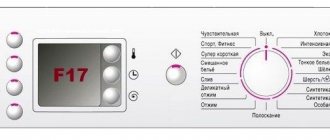

Errors 1E, 1C or e7 most often result from the failure of some elements. The table will help you figure out how to fix problems.

| Malfunction | Possible reasons | What to do |

| The machine does not fill with water, error E7 on the display. | The hose is clogged, incorrectly connected or mechanically damaged. The relay is broken. | Check the tightness of the connection between the drain hose and the washing machine outlet, and remove any kinks. Make sure the hose is intact. Replace the damaged hose or relay (with the help of a technician). |

| Error codes appear on the display immediately after the equipment is started. | The problem is in the electronic control module of the washing machine. | An accurate diagnosis will require a specialist. If a resistor in a module is burned out, it is enough to re-solder it. If the problem occurs in the washing machine processor itself, the unit needs to be completely replaced. |

| The equipment shows errors some time after the wash starts. | The sensor contacts have oxidized, the integrity of the wiring of the pressure switch or electronic unit has been damaged. | It is necessary to establish the current supply by cleaning the contacts, re-twisting the wires, and changing the cable. |

If you couldn’t reset the errors yourself, E7 is still lit on the screen and you don’t know how to fix the problem - it’s better to entrust the repair to a specialist.

Trying to fix a problem caused by a faulty electronic system by a non-specialist may result in a more complex (and more expensive) repair.

Reasons for appearance

In rare cases, the reason for the appearance of the he2 code or its analogues are:

- problems with the electrical cord;

- short circuit in the electrical outlet;

- failure in the machine program;

- violation of contacts of wires from the heating element.

Practice shows that these reasons occur only in one case out of ten. Most often, the appearance of the he2 error indicates that the heating element itself has burned out.

Power supply problems

If there are power outages, the machine will display an error. Figures below 200 V and above 250 V are considered critical.

U.C.

This value can be displayed on the display at any stage of the wash. UC is an abbreviation for voltage control system. It protects electrical components, wires and washing machine programs from sudden voltage surges. If a letter code appears, it means the control system has worked.