It’s somehow even strange to remember that once upon a time automatic washing machines seemed almost a luxury. And not everyone could afford a rather expensive device. And how good it is that everything has changed now. The modern market is replete with a huge range of washing machines for a wide range of consumers - from the most budget machines to expensive luxury models. An automatic washing machine has long become not just an affordable, but rather an indispensable home appliance. And for almost any family.

Unfortunately, the usual trouble-free operation of the washing machine may at some point be interrupted due to various problems. A fairly common complaint from owners of various models of washing machines is a decrease in spin efficiency. For unknown reasons, the machine simply cannot reach the drum speed required for effective spinning.

Is something really broken? Or is this a harbinger of a serious breakdown? Don't rush to conclusions. Let's put aside premature worries. And let’s not rush to contact the service. It’s better to figure it out first - what are the reasons that cause problems in the washing machine, and how can it be eliminated?

Simple problems that do not require repair

Undervoltage

To spin the drum when spinning clothes, the washing machine motor requires more energy than when washing. If the voltage in the home electrical network is too low, the motor simply will not be able to function at full capacity.

Or don’t start the spin cycle at all. You will need to check the outlet with a voltmeter. If the assumption is confirmed, you will have to use a voltage stabilizer. Either “shake” the energy workers or the management company.

Wash program set incorrectly

Almost all automatic washing machines have programs with limited spin speed. Naturally, programs for delicate washing also include a delicate spin. Or its absence altogether. It is possible that the speed control on the control panel was accidentally set to a lower setting or to the “no spin” position. You just need to check the correctness of the set washing parameters.

Protection against unbalance of laundry in the drum is triggered

Most modern washing machines are equipped with an imbalance sensor. This type of protection allows you to avoid serious damage if excessive load occurs on the drum. In any case, it will definitely extend the “life” of bearings and shock absorbers.

Imbalance protection works precisely on this principle: when there is excessive load, the speed is automatically reduced. And if the laundry is not distributed correctly throughout the drum and at low speeds, the spin cycle is completely turned off.

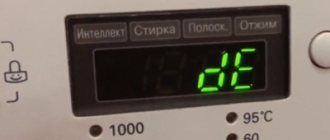

A machine equipped with self-diagnosis will display a signal on the display when the imbalance sensor is activated. In any case, you need to open the door and distribute the laundry evenly in the drum manually. After this, check the spin operation. In most cases it works.

What to check initially if the washing machine does not pick up speed?

Do not rush to call a professional if you notice that the washing machine does not pick up speed during the spin cycle. First of all, make sure that you do not make mistakes when using the equipment:

A no-spin program has been selected - every modern machine has no-spin modes that allow for operation at low speeds. Switch to exactly the program that suits you.

The drum is overloaded with laundry - the instructions for the equipment state what the maximum weight the machine is designed for. If the permissible values are exceeded, the spin drum will not reach the required speed to avoid breakdowns.

Things are distributed unevenly - if there is an imbalance in the load of laundry, the machine will not be able to gain speed, the rotation speed of the drum will be low. In this case, items for washing need to be selected of equal weight and size.

The speed control is affected - the spin may not be effective due to the fact that the low speed button is pressed. It is enough to switch to the desired number of revolutions per minute.

Note! If the washing process is normal, but the spin speed does not increase, it is possible that the voltage in the network is low and there is not enough power to achieve the required drum rotation speed. A stabilizer will help solve the problem.

If among the above reasons why the washing machine does not pick up speed, your case was not found, this indicates an internal malfunction.

Situations requiring repair

We will consider the problem in increasing complexity. First, of course, with a simpler one, where you can repair a washing machine yourself.

The drive belt is deformed

The belt connecting the washing machine motor drive and the drum has stretched. The speed may not be gained due to belt slippage. You will have to remove the back cover of the car and check the external condition and belt tension. If necessary, replace with a new one.

The drum pulley mount has come loose

In this case, the connection between the shaft and the pulley may be lost. And the latter can simply scroll. The solution is simple - tighten the fastening bolt.

Problem with water level sensor

Due to its breakdown, the control unit will assume that there is water remaining in the car. And he will try to kick her out. The drum rotates at minimum speed. This sensor is located under the top cover of the washing machine. Replacing it will not cause any difficulties.

Engine brush wear

Symptoms may include strange noises and a burning smell. When the brush overhang becomes less than 7 mm, they need to be replaced. You'll have to remove the engine. And changing brushes is not particularly difficult. Of course, this is not relevant for machines with an inverter brushless motor.

The tachometer of the washing machine motor is faulty

It is located directly on the engine. It is precisely this that is designed to control the speed of the engine rotor, and therefore the rotation of the washing machine drum, according to a given program.

Typically the problem occurs due to the tach sensor coil being misaligned. To restore normal operation, you need to fix the coil in its proper place and check the wires. A more serious problem will require replacement.

Washing machine motor problem

A common problem is interturn short circuit. With such a malfunction, the motor “has enough strength” to rotate the drum in the washing mode, but it is no longer able to gain the required speed during spinning. The engine may need to be restored or replaced.

Failures in the control unit

And the last option is that the control unit is “buggy”. It may simply give incorrect commands to the engine. And the spin cycle occurs at the wrong speed. The control unit can be “reflashed” or replaced at the service center.

This is a list of probable causes of weak spin and ways to solve the problem. Almost everything can be easily fixed on your own. Now you know how.

The washing machine does not pick up speed: the cause of the problem

A breakdown of the most important assistant in the house - an automatic washing machine - is akin to a disaster for a woman. This is understandable, because we are unaccustomed to hand washing, and there is nowhere to wash, rinse and dry as much laundry as accumulates in a week for one single family. To immediately determine whether a malfunction is worth serious repairs or buying a new machine, you need to know the main reasons for the strange sounds and actions that your machine produces. Perhaps all is not lost and this is a simple blockage that you can remove with your own hands?

Why isn't it gaining momentum?

Malfunctions when the washing machine does not pick up speed

Here are the breakdowns due to which the washing machine does not develop spin speed.

The motor brushes are worn out - from RUB 1,300*

The brushes are responsible for rotating the motor. Over time, they wear out, come into poor contact with the engine manifold, begin to spark, and the rotation speed drops. If the reason is in the brushes, in addition to the slow spin, you will hear crackling and noise in the motor. Sparks can be seen when the machine is operated in a dark room. Brushes are consumables, so they are replaced with new ones. Brushes need to be changed when their length becomes less than 1 cm.

The bearing is destroyed - from 3000 rubles*

Bearings ensure smooth rotation of the drum. They fail due to natural wear and tear. Regularly overloading the machine with laundry speeds up breakdowns. The oil seal wears out, loses its seal, water gets into the bearings, and they rust and collapse. You will notice a malfunction of the bearings by the play of the drum, it will swing more strongly, and by the rattling sound during the spin cycle. The bearings need to be replaced to fix the damage.

The drive belt is slipping - from RUB 800*

In machines with a commutator motor, the drive comes through a belt. As the washer ages, the belt stretches and begins to slip, especially during the spin cycle. The drum spins more slowly and does not reach the required speed. Sometimes the belt comes off, but then the washer just stands up. The technician will install a new belt so that the SMA can push well.

The tachometer is acting up - from RUB 1,800*

The sensor measures the speed and reports it to the control module. When the readings are incorrect or the sensor is broken and does not “respond” to commands from the control module, the machine cannot spin the drum. The faulty tachometer is replaced with a new one.

The pressure switch does not work correctly - from 1500 rubles*

Although the water level sensor is not directly connected to the drive, the acceleration of the drum depends on its readings. The “full tank” error prevents the washing machine from spinning. The machine constantly pumps out water, but does not reach the required drum rotation speed. A functional malfunction of the pressure switch can be eliminated by repair: the technician cleans the pressure sampling chamber, blows out the level sensor tube if it is clogged, and changes the tube if it is damaged. In case of mechanical failure of the sensor, a new one is installed. The specialist will decide what to do in your case after checking the SMA.

Control unit - from 1800 rubles*

The module usually works reliably, but when the voltage surges, the electronics fail. The section of the board responsible for the engine can be repaired if the problem is burnt elements, damaged tracks or contacts. When the processor fails, the module must be replaced completely. The technician will tell you the exact “diagnosis” of the control board after checking it.

*Spare parts are not included in the price and must be paid separately

Is your washing machine not spinning at high speed? For technical assistance, call Wash Man! Repair within 24 hours after application, warranty on work and spare parts for two years.

We wish your equipment health!

The washing machine motor does not work

Post by vukin » 12 Sep 2009 19:40

Post by asgard » 12 Sep 2009 20:09

I do not see

Post by vukin » 12 Sep 2009 21:05

Post by asgard » 12 Sep 2009 21:31

Post by asgard » 12 Sep 2009 21:36

engine

Post by vukin » 12 Sep 2009 22:55

asynchronous engine

Post by vukin » 12 Sep 2009 23:16

Post by asgard » 13 Sep 2009 09:09

Post by volna2m » 13 Sep 2009 10:13

A gentleman is a person with whom you feel like a gentleman. Repair of washing machines, dishwashers, sewing machines and boilers in Nizhny Novgorod

Post by vukin » 13 Sep 2009 12:17

Post by vukin » 13 Sep 2009 12:18

Post by SKORPION » 13 Sep 2009 13:31

How to take it apart?

Post by vukin » 13 Sep 2009 21:14

Post by asgard » 13 Sep 2009 21:55

Post by vukin » 14 Sep 2009 10:26

Post by asgard » 14 Sep 2009 17:30

Re: air conditioner

Post by volna2m » 14 Sep 2009 20:03

A gentleman is a person with whom you feel like a gentleman. Repair of washing machines, dishwashers, sewing machines and boilers in Nizhny Novgorod

Source