Suspicions that the cuff for a washing machine has become unusable arise when water drips from under the door of a working unit. If the cause of the leak is indeed a violation of the integrity of the rubber gasket, do not be too upset. If desired, the tightness of the tank can be restored independently.

We will tell you how to replace this important type of seal yourself, which ensures the tightness of a tank filled with water during washing. In our article, the process of removing and installing a new cuff is described step by step. Our advice will help you achieve an impeccable result.

What is a cuff?

The main purpose of the rubber part installed on the hatch of an automatic washing machine is to hermetically seal the loading tank during operation of the machine. This layer does not allow even a drop of water to seep out.

The location of the cuff and its appearance completely depends on the model of the machine. If loading is frontal, a rubber layer connects the tank to the front wall of the unit and has a round shape. In models with vertical loading of laundry, the part combines the tank with the upper wall and has the shape of a rectangle.

Without a door seal for loading laundry, the machine door cannot be closed tightly. The special composition of rubber or silicone from which the part is made ensures complete sealing of the tank during washing

Previously, seals were made of very flexible rubber. In modern models, cuffs are almost always installed from a similar material of artificial origin - silicone. It does not lose its elastic properties over a wide temperature range and does not “tan” over time.

Cuffs of different models differ in size and shape. If the washing machine has additional functions, for example, drying and aquaspray, the part may have additional holes.

What is a washing machine cuff?

In simple words, this is a rubber part that is installed in the area of the unit hatch. It provides sealing during the process of clogging the loading tank during operation of the device. It is due to this layer that not a single drop of water can leak out.

Where the cuff is located and what type it is depends on the model of the automatic washing machine. If we are talking about front loading, it ensures the connection of the tank to the front wall, and the shape is round. If the loading type is vertical, the part connects the tank and the upper wall, and is also presented in the shape of a rectangle.

Some time ago, seals were made from highly flexible rubber, although today the situation has changed. Currently, cuffs have a similar material, but it is mainly silicone. It retains its elastic properties, regardless of temperature. It is also worth noting that the cuffs belonging to different models are different in size and shape.

What are the reasons for wear of a part?

There are not many reasons why the cuff stops performing its functions. Moreover, most of them occur when the rules for using household appliances are not followed.

The main ones are the following:

- mechanical damage from rough objects;

- strong vibration of the drum during spinning;

- exposure to aggressive agents;

- mold on rubber;

- inaccurate loading of dirty items or removal of already washed items;

- natural wear and tear.

Damage from objects occurs when rough items are often washed in the machine, for example, sneakers, outerwear with hard “snakes,” etc. Metal products (nails, keys) and plastic that have fallen into the drum due to user carelessness can also cause the formation of significant defects on the rubber.

Cracks, cuts and tears in the rubber part can appear either as a result of a malfunction of the washing unit or due to the carelessness of users. Before loading clothes into the machine, be sure to check pockets for rough or sharp objects. They can easily damage the cuff

The washing machine drum tends to vibrate strongly if the machine is not installed correctly. Accordingly, the cuff attached to it suffers. The use of bleaching agents frequently and in high concentrations causes the rubber to become rougher. And the loss of elasticity, as is known, is fraught with the rapid appearance of defects.

The acids and alkalis used to clean the machine act in the same way. But again, if they are used incorrectly. For example, some users believe that the higher the concentration of the product, the more effective the cleaning. At the same time, they do not take into account the aggressive influence on the parts available for processing.

Mold is microscopic fungi that live in colonies. Having settled on soft rubber, the mycelium of these tiny creatures is able to germinate deeply. If the damage is severe, dark gray spots that emit an unpleasant odor cannot be removed with anything. In this situation, only replacing the cuff with a new one will save you.

The washing machine does not last forever. Even if you handle it very carefully, the parts gradually wear out. The rubber seal is no exception. It constantly experiences friction from the rotating drum of the washing machine and laundry, temperature changes, and exposure to detergents. All these factors make rubber brittle and brittle over time.

How to properly replace?

First you need to check the condition of the cuff. To thoroughly inspect the seal for damage, it must be almost completely removed from the machine. To do this, simply remove the clamp that holds the part of the cuff that is attached to the front wall.

After the inspection, a decision may be made to replace the rubber band with a new one or to repair the existing one. Consider instructions for step-by-step cuff replacement.

Step #1 - remove the front clamp

The clamp is attached to the front wall in different ways for different models. It all depends on the material used to make the part.

There are 3 options:

- using latches;

- spring tension;

- screw fastening.

The first method is used for plastic clamps, the rest for metal ones. In any case, you will need a flat-head screwdriver to remove the part.

On most models, in order to pull the cuff towards you for inspection, it is enough to remove the clamp holding the curved part of the elastic in the front groove. By slightly moving the edge of the cuff, you can always determine whether it is plastic or metal

Then they act depending on the fastening: the screw is unscrewed, the spring is pulled back and weakened, and the plastic clamp is pulled towards itself in the place where the latches meet. After this, using the same screwdriver, removing the clamp will not be difficult.

However, not all so simple. Some companies produce models of washing units in which dismantling the “elastic band” requires necessarily removing the front wall.

These include:

- Samsung;

- Beko;

- Siemens;

- LG;

- Bosch;

- Hansa.

It is quite difficult to perform this manipulation on your own, but it is possible if you wish. The main thing is to act very carefully to avoid damage to the wires and contacts connected to the lock located on the wall.

Step #2 - remove the front panel

The first thing you absolutely need to do is disconnect the device from the power supply and make sure that there is no water in the drum and sump. Only after these steps can you proceed directly to removing the front panel.

To get to the screw holding the wall at the top, you should remove the powder receptacle. For this purpose, pull out the tray all the way, press the locking key inside and remove it from the machine.

In most models of washing machines, the powder container has a so-called “tab” located above the conditioner filling compartment. This powder receptacle can be removed without any problems. You need to simultaneously press the button and pull the tray towards you

Now you need to open and disconnect the hatch located at the bottom of the front wall of the machine. To do this, use a screwdriver to unscrew the fixing screw of the base panel, move it to the right until it clicks and move it toward you.

Next, open the hatch door and remove the clamp securing the cuff to the front panel. This is done by prying up the tension spring with a slotted screwdriver and removing it together with the clamp from the groove of the rubber seal.

Afterwards, the edge of the cuff is pulled out of the recess in a circle, the elastic is “sinked” into the body and the hatch door is latched. All the above actions provide access to the lower and upper screws. They are unscrewed, after which the panel is moved a few centimeters forward and carefully separated from the body.

Holding the front wall suspended, disconnect the plastic wire fastenings from it, and then the hatch locking contacts. Now you can safely put the front panel of the machine aside, remove the clamp and begin examining the cuff by pulling its front part towards you.

Step #3 - pull out the working cuff

After removing the front clamp (how to do this was discussed above), the rubber seal is completely removed.

It is necessary to remove the old cuff both in case of replacing the old cuff with a new one, and if minor repairs of this part are necessary

Proceed as follows:

- Carefully pull out the front part of the rubber seal, which is held on the machine body, due to its own tension.

- Find the mounting mark. It is located on the cuff itself.

- Using a marker, mark the response mark on the tank.

- Remove the second clamp in the same way as the first.

After the work is done, the cuff can be easily removed from the machine. The part just needs to be pulled well towards you.

Step #4 - inspect the rubber seal

At this stage, you will carefully examine the removed elastic band from all sides, paying special attention to the places on the folds. If, after examination, cuts, holes, cracks and other damage are detected on the cuff, it is advisable to replace the part with a new one.

The replacement cuff must match the machine model exactly. Otherwise, the seal may not fit, and all the work will go down the drain.

When selecting a new part, you should keep in mind that you cannot purchase rubber bands from other models of washing machines, even if they have significant similarities in appearance. Only a cuff designed for a specific brand of unit can be absolutely suitable. Only a master can select analogues and only in a hopeless situation.

Step #5 - prepare the installation site

When the cuff requires replacement, as is clearly evidenced by cracks and other damage, you can safely begin installing a new “elastic band”. The preparatory step before installing a new cuff is to thoroughly clean the edge of the tank. Typically, dirt and detergent residues accumulate in this place.

In order to clean the area of upcoming installation, a saturated soap solution is ideal. Alternatively, you can simply soap the sponge heavily.

It is better to clean the edge with a sponge, moistening it generously in a soap solution. In this case, there is no need to wash off the remaining foam and wipe the part dry. The soap will serve as a kind of lubricant and will help you complete the installation faster.

Step #6 - install a new cuff

Putting a new seal on the tank is not entirely easy. The material is difficult to stretch very much, and besides, it “exerts resistance”, stubbornly refusing to fall into place.

The first step is to apply the cuff to the upper edge of the tank so that the mounting marks coincide. Next, sliding the thumbs of both hands over the rubber, pull the seal onto the edge.

Movements when putting on an elastic band proceed from the center to the sides. It is important to show patience and maximum accuracy here.

At the next stage, soapy lubricant comes to the rescue. The cuff is stretched at the bottom and is quite difficult to put in place. Therefore, here the seal is forced onto the tank. After these manipulations, the “elastic band” is held tightly on the edge.

The last point is to check that the part is installed correctly. If the cuff does not adhere tightly to the metal in some places, leaks will occur while the machine is running.

Step #7 - tighten the inner clamp

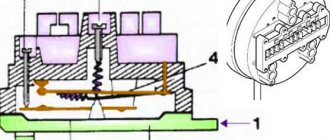

Installation methods for internal clamps vary depending on the mounting. If the tension is spring-loaded, then installation is carried out using a screwdriver. The tool is inserted into the hatch blocking hole and a spring is put on it. Thus, the fastening stretches freely and the clamp is easily put on in the right place.

Clamps removed from the cuff can be put back in place only if everything was done without damage. If defects appear on the parts, they need to be thrown away and new ones purchased instead.

If you have a clamp with a screw, the task is somewhat simplified. The tension is almost completely unscrewed, and the clamp is placed in its seat. To strengthen the part, all that remains is to tighten the screw back.

If the washing machine is equipped with a wire clamp without tensioners, round nose pliers are used as an auxiliary tool. They carefully tighten the metal ends, and the resulting knot is hidden in the recess on the cuff provided for this purpose.

The easiest way is to put on a plastic clamp. It is secured using special latches. After the work has been done, the cuff is pulled onto the edge of the front panel of the machine and also secured with a clamp.

Finally, check the seal for leaks. To do this, start the fastest washing program. If no leaks are observed during operation of the unit, the cuff is installed correctly.

Replacing the rubber seal on a washing machine

A washing machine consists of a large number of parts, many of which break down over time, but they can be easily replaced to extend the life of the equipment for a long time. For devices from Bauknecht, Bosch, Brandt, Braun and others, replacing the sealing collar on the loading hatch is considered a frequent operation.

Masters will carry out this event quickly and at an affordable price.

Why do you need a sealing cuff?

The latest generation washing machines use various rubber seals and protective cuffs.

- The rubber cuff on the washing machine Kaiser, Lg, Miele, Renova, Rolsen, Rosenlew, etc. provides a seal between the washing machine tank and the body of the machine. If the rubber base of the drum is torn, the hole should be repaired as soon as possible, because this can result in water getting into the electrical part of the machine and causing the device to fail.

- A rubber rim is used on the washer door to securely and tightly close the hatch after loading laundry. Even the smallest holes in the rubber seal are dangerous due to the leakage of water when the washing machine is operating, which can cause a short circuit.

If the rubber of the door has burst or there are difficulties with the seal sticking to the drum, you should call a technician for repairs as soon as possible. Our technicians will help you repair the rubber gasket on washing machine models of all generations, we will find new spare parts specifically for your washing machine, carefully remove the faulty part and replace it with a new rubber analogue. Why does the cuff on the hatch deteriorate?

Replacing the rubber cuff is necessary in two cases - in case of physical wear of the part and in case of mechanical external damage. A hole in an elastic band most often appears due to:

- using inexpensive detergents when washing in Atlant, Candy, Daewoo, Electrolux machines;

- frequent loading of hard and heavy objects into the drum (sneakers, caps with hard visors, oversized outerwear, etc.), this not only deteriorates the rubber cuff of the hatch, but also the rubber on the drum can come off;

- the elastic band flies out and wrinkles due to careless handling of equipment from Zanussi, Vyatka, Malyutka, Riga, Slavda, Fairy, Chaika, Beko, etc. - careless loading and unloading of things, use of elevated operating temperatures, etc.;

- A crack in the rubber part is often caused by foreign objects accidentally falling into the tank from pockets (keys, nails, paper clips and similar sharp parts).

To repair a rubber rim on a washing machine, you need to know how to properly disassemble and reassemble the equipment, so the best choice would be to turn to professional craftsmen and change the rubber gasket quickly and inexpensively.

Signs of a burst rubber rim

The following external indicators will help determine whether the rubber seal is deformed or a piece has come off:

- during the washing process, a puddle of water forms near the Euronova, Evgo, Gorenje, Haier, Hansa machine (exactly near the loading compartment);

- the hatch door is difficult to close - when the rubber gasket falls out and does not stay tightly in place, problems will arise with closing the doors;

- During washing, a crackling and hissing sound is heard - a very dangerous sign, this is how the friction of the rubber band in the drum manifests itself; if there is a cut on the rubber membrane, a leak may occur, which will finally close the washer.

At the first sign of a malfunction in the Liliya, Hoover, Sanyo, Reeson, Oka clippers - the elastic has fallen out, the edge has come off, it is crumbling or stretched too much - call a specialist. It is much easier and cheaper to restore the rubber band in a timely manner or to repair a hole in the rubber cuff than to completely change the overall part later.

Replacing or repairing the loading hatch cuff

Replacing the rubber around the door is not that difficult, but it is better to entrust this operation to professionals, since it is quite cumbersome. To change the rubber band to the drum, you need to properly disassemble the cuff and put it back together.

How to remove and repair a seal

- You need to pull out the fixing clamps - the front one is pryed off with a screwdriver and unscrewed; if it is fastened with latches, pull the connection points towards you. With the internal clamp the situation is more complicated; in many models of Samsung, Saturn, Siemens, Toshiba, Veko, Vestel, Whirpool, in order to get it, you will have to unscrew the front panel of the machine.

- When removing the cuff, special attention should be paid to the location of the mark. This is a small triangle; when installing the part, it must coincide with a similar pattern on the body of the machine, otherwise the seal of the washing machine will malfunction.

- We check the part, if it is worn out, the rubber is frayed, it just needs to be changed. But when it is possible to repair the rubber rim, the technician will carry out a high-quality repair of the seal using glue and patches. Having received a working cuff, you can reassemble the washer.

How to put an elastic band on a drum

To change the rubber band to the drum, you need to install it correctly, otherwise the cuff will not fit tightly to the body and may allow water to pass through. The assembly process is almost the same for all models Aeg, Ardo, Ariston, Asko, Indesit, Favorit, Siltal, etc.

- The groove under the cuff is cleaned with detergent; only after this is it possible to replace the rubber rim with a new spare part.

- Replacing the drum cuff begins by inserting it into the grooves with its larger side and stretching it along the upper edge of the tank. After completing the stretching, you need to make sure that the elastic has not moved away from the drum. Only then is the inner clamp installed on the seat and secured with a bolt until it stops. Do not press the clamp tightly against the rubber, otherwise it will rub off.

- Afterwards, the cuff with the side with the smaller diameter should be put on the edge of the front wall and straightened well so that the rubber cuff does not wrinkle, and finally insert the front clamp.

- The replacement of the rubber band is completed, all that remains is to close the door and turn on the test wash.

If the rubber band has come unstuck from the drum or you notice a tear in the cuff, call the experts, our telephone contacts: 8. The company’s specialists work from home, will provide quality guarantee certificates and will not charge extra money.

Subtleties of cuff repair

Sometimes situations arise when the “elastic band” located on the hatch of the washing machine breaks, and it is not yet possible to replace the cuff.

When might repairs be needed?

For example, at the moment it is impossible to find a part suitable for the existing car model, or it is on order, and delivery will take a long time.

There are also circumstances when right now it is impossible to allocate money from the family budget to purchase a new part. In such situations, repairing the cuff, that is, sealing the damage site, will help out.

High temperature, detergents and constant friction of the laundry will soon take their toll, and the hole in the cuff will make itself felt again

Please note that gluing the patch is a temporary measure. Therefore, you need to try to replace the worn seal with a new one as quickly as possible.

How to select and prepare a cuff?

First of all, you need to inspect the leaky cuff and determine the cause of the damage. This is the only way to find out whether it is advisable to repair the seal or whether there is no point in it. To do this, you will have to remove the cuff from the machine using the method described above.

Only by removing the front clamp and pulling the cuff towards you can you detect damage, assess its size and the possibility of repair

If the cut, puncture or abrasion is small, then repair definitely makes sense. And when the damage is large or there are several of them, it is better not to rush with sealing.

After determining the cause of the repair, the material for the patch should be selected. It must be durable and at the same time elastic. Some experts recommend using condoms or medical rubber gloves for this purpose.

A great option is special patches designed for repairing swimming air mattresses. You can find them in sports stores.

The glue planned for use must have excellent adhesive properties. In this case, the substance must remain elastic after complete drying. This is exactly how products intended for repairing shoes and rubber products behave.

Instructions for sealing the seal

Sealing a rubber seal is a task that does not require special knowledge and skills. However, to ensure that the result does not disappoint, it is better to strictly follow the instructions.

We offer the first repair method - gluing . It is performed according to the following scheme:

- They are preparing a patch . Pieces of the selected material are folded into several layers and glued together. The size of the patch should be 1.5-2 times larger than the defect itself.

- The damaged area and the area around it are degreased . To do this, use alcohol, acetone, white spirit, etc. Wait until the degreaser dries completely.

- Glue is applied to the cuff and patch .

- The lubricated surfaces are pressed against each other either immediately or after a few minutes - this depends on the instructions on the tube of glue.

- The cuff is fixed in its natural position using suitable objects. So the part is left for a day.

After the glue has completely dried, the seal can be reinstalled.

The repaired cuff should be returned to its place using the same method as putting on a new one. Since the rubber is already stretched, you won’t have to put in as much effort as if you were installing a new part.

There is a second method, which is considered more reliable. It combines stitching and gluing.

The method is performed as follows:

- The damage is stitched end-to-end with a thick synthetic thread. In this case, a football seam is used.

- Afterwards, everything is generously impregnated with silicone sealant for rubber and plastic.

Next, as in the previous method, the cuff is left in its natural position for a day, after which it is installed back into the machine body.

After the repair has been completed, you must check the quality of the work. To do this, load the drum with laundry and start the wash on the shortest program. At the end of the cycle, the gluing site is inspected to identify repeated ruptures.

You can change not only the cuff that hermetically seals the hatch of the front washing machine with your own hands. Home craftsmen are quite capable of replacing the washing machine belt. Step-by-step instructions for carrying out this work are described in detail in the article we recommend.

How to replace?

First of all, you should purchase the rubber seal you need. Since cuffs from other machine models may not fit yours, even if they look the same, be sure to tell the seller when purchasing a seal the model of the washing machine on which you are going to install the cuff. Only after making sure that the purchased cuff is exactly the same as your damaged seal, can you begin replacement, which includes the following steps:

- We clean the edge of the tank from contaminants (salts, powder and others). For this task, you will need a warm soapy solution. After removing all the dirt, do not wash off the film formed from the soap solution, as it will help in installing the new cuff.

- Install the rubber seal on the tank. Please note that doing this with a new rubber band will not be too easy. Place the upper part of the seal against the tank (its upper edge) so that the marks coincide, then use two thumbs to tighten the cuff. To do this, your fingers should slide from the center to the sides. In this case, the cuff will not slip off at the bottom, but will fit completely onto the hem.

- We check whether the cuff is installed correctly. The water drainage holes should be positioned strictly at the bottom center, and the tongue, which is found in most elastic bands, should be at the top. In addition, after installing the rubber band, no gaps should form, since leaks are possible due to a loose fit.

- We tighten the inner clamp. You need to act depending on the fastening of the clamp. If its fixation is ensured by a tensioned spring, you need to put the spring part of the clamp on a screwdriver (if you did not remove the front wall, then insert the screwdriver into the locking hole). This way you can freely stretch the spring and put the clamp in its place. If tightening with a screw, simply unscrew the screw, place the clamp in its place, and then tighten the screw to the required torque. It will be even easier to attach a plastic clamp held in place by latches. If your model of machine has a wire clamp, carefully tighten its ends using pliers, and then remove the knot into the existing cuff recess.

- We put the rubber seal on the front wall and tighten the second clamp. We carry out all manipulations with the second clamp in the same way as with the internal one, depending on the features of its fastening.

- Check the tightness of the installed cuff. To do this, you should turn on any short washing program without loading laundry into the machine, and make sure that water does not leak out of the bottom of the cuff.

It also happens that the front panel on the washing machine cannot be removed. This is not very convenient for changing the cuff. There is a way out of this situation, and in the following video they describe in detail and tell how to replace the sealing collar on such washing machines.