4.8 / 5 ( 17 votes)

Atlant refrigerators are popular not only in the native Belarusian market, but also abroad. They work well, are easy to use and are affordable. But, like any other complex equipment, a refrigerator can break down over time.

In our article we will look at the reasons why the Atlant refrigerator most often does not work. We'll tell you how to diagnose the problem yourself.

But for repairs it is better to contact a trusted service. This is a guarantee of safety and reliable operation of the equipment after the fault has been fixed by the technician.

Pipeline blockage: how to fix it?

Thanks to the capillary pipeline, the freon (refrigerant) maintains different pressures. When it enters the pipeline the pressure is equal to the condensate pressure. As it moves, it drops to boiling pressure. And at the exit the agent boils in the evaporator.

But the agent does not travel through the pipe alone, but together with the compressor oil. This is why paraffins appear on the walls of the pipeline. When there are a lot of them, a blockage forms.

Signs of a malfunction in the Atlant refrigerator:

- The motor is running, but the temperature in two chambers is higher than normal.

- The indication is on.

- Or there is an error H on the display.

What to do:

- To eliminate such a malfunction in the Atlant refrigerator chamber, you need to replace the capillary pipeline. The technician will also change the filter along with it. Then it will create a vacuum and fill it with new freon.

- When the blockage is partial, you can try to remove it with a jack.

Compressor failure on Atlant refrigerator

How to repair the compressor in the Atlant refrigerator?

The function of the compressor is to ensure that freon passes through the pipeline properly. The Atlant refrigerator compressor may not work because:

- The winding has broken.

- The winding has shorted out.

- It gets stuck when the motor hums and there is no pressure.

Signs by which you can understand that the Atlant refrigerator compressor has failed:

- It turns on, but then immediately turns off.

- Works with sound, but the agent does not move through the pipe.

- It does not turn on, but there is light in the refrigerator.

- The indicator on the refrigerator is on.

- Or there is an error on the panel.

What to do:

- Replace the motor, filter and refill the refrigerator with freon.

DIY instructions for diagnosing malfunctions of Atlant refrigerators

- 2.1. What to do if the refrigerator does not turn on

- 10.1. Related articles:

Checking the cable

The refrigerator compressor is connected via a cable with connecting parts. The problem may be a faulty cable or contacts.

The compressor has two windings: starting and working. Using a multimeter, connect its tester to the terminals one by one. The values are summed up and compared with the resistance between the two windings.

A working compressor ultimately shows equal values. A slight deviation is allowed within the possible error of the device.

In this case, diagnostics are carried out at a refrigerator temperature of no higher than 20 degrees.

- The first wire is always connected to the working winding terminal.

- The second is to the general exit.

- The third wire is also to the working terminal, after which electric voltage is supplied. A third wire is connected to the output of the starting winding.

Reference! If the compressor starts working, then the problem is not in it, but in the relay. It is necessary to replace the cable that connects the parts to each other.

Electronics malfunction

It is important to know how to determine an electronic malfunction yourself. Most often, the cause is voltage surges, due to which the refrigerator’s protective starting relay may stop working, which leads to breakdown. To check, you need to remove the plastic cover and carefully inspect the contacts. The wires should not show signs of oxidation or rust, which often cause motor malfunction due to voltage fluctuations in the electrical network.

If during inspection it was not possible to detect defects or deviations, the tester rings the parts through the coil contacts, which are located on its input and outer sides:

- If there is zero resistance, we can talk about the serviceability of the part.

- But if the resistance tends to infinity, then the coil and relay have burned out and cannot be used.

They can be repaired if voltage surges do not seriously damage the connecting wires. If the part is completely unsuitable for use, then it is replaced with a new one. In this case, it is important to correct the voltage in the network to the average and acceptable for the operation of the refrigerator. If this is not done, then you can wait for the parts to burn out again.

Control circuit problems

To check the control circuits, it is necessary to carry out diagnostics: short-circuit two wires, having first disconnected them from the relay. This checks the contact between the wire and the power plug.

- If contact appears, then the defrost relay is normal and there is no problem with it.

- If there is no oscillation of the needle, then there are problems with voltage.

If a problem is detected, the unit needs to be checked to diagnose the equipment for damage. The cord may be kinked or severely damaged. In this case, the unit almost completely fails, and the electrical supply does not in any way affect the operation of the equipment.

Inspection of the temperature sensor and thermostat

The following rules should be observed during the process:

- disconnect the wiring and remove it from the equipment with a screwdriver;

- check the defrost regulator;

- check the output with a tester;

- change the sensor if the tester shows a short circuit (this case indicates a clear failure of the part).

If the breakdown is a violation of the defrosting function of the refrigerator, then a special jumper is simply installed. You can do it yourself. To do this, take a metal bug. The metal bug is only suitable for not entirely new refrigerator models.

Attention! It is not advisable to use the bug on a regular basis. This should be a temporary option. The broken element will soon be replaced with a working one.

Compressor failure

Compressor malfunction may include the following:

- Doesn't turn on at all. At the same time, the starting relay clicks, as if initiating a start.

- It works, but doesn't freeze. The unit does not have enough refrigerant or the mechanical part is completely worn out, and the compressor cannot supply normal pressure in the pipes.

- The refrigerator in this case is properly powered from the mains and seems to work, but does not cool the food in the upper compartment and does not freeze the lower part.

- The unit does not cool the chambers, or, on the contrary, it works very actively, which causes ice to appear on the walls. This may indicate a problem with the suction valve, temperature sensor or relay. All these parts are responsible for sending a signal to the start command. A number of refrigerator models (LG, Liebherr, Bosch, Indesit, Samsung, Gorenje, Sharp, Siemens) have an electronic control unit that independently localizes the problem by diagnosing and sending a signal to the launcher.

- A decent layer of ice accumulates on the walls of the refrigerator. A violation is usually associated with a malfunction in the unit’s operating cycle. Also, due to excess refrigerant pressure in the system, the compressor may break down.

It is up to the owners to decide whether to repair it themselves or contact a specialist. If the breakdown is obvious, but there are ways to fix the problem, then this will not entail any extra costs. But if the part is completely faulty, then it is best to replace it at a service center.

Ringing of starting and protective relays

A malfunction of the starting and protective relay may be as follows:

- oxidized or burnt contacts;

- mechanical damage;

- overheating of the posistor element;

- broken relay fastening, incorrect location;

- the spiral is burnt out;

- the core jams.

To check for these faults, the solenoid in the relay induction mechanism is removed.

Then the contacts are checked: if they are oxidized, they can be easily cleaned with sandpaper.

Reference! If the core is broken, it is pulled out and replaced with a working one. The relay must always be in a strictly defined direction, which is indicated by the arrow.

Electric motor problem

A break in the starting winding can lead to heating of the motor. This causes the start protection relay to activate. The electric motor of the refrigerator is completely switched off when the winding fails. The refrigerator may work properly, but not freeze at all.

To check what the problem is in the failure of the electric motor, you need to check whether the condensate is coming out warm or cold. The problem may be due to insufficient freon pumping (read about the features of refilling a refrigerator with freon here). When the space is filled with gas, engine operation returns to normal.

Often the problem may be that the motor/compressor is subject to gradual wear due to prolonged use of the equipment. Excessive load on the motor is a common reason why the electric motor heats up and fails.

Checking the defrost button

To diagnose equipment, you can test the defrost button if your refrigerator model is equipped with one. During normal operation of the defrosting function, diagnostics of the remaining elements of the refrigerator that are powered from the mains will be required.

Atlant refrigerator thermostat malfunction

How to fix the thermostat in the Atlant refrigerator?

If the freezer in the Atlant refrigerator does not work, most likely the problem is the thermostat. It is he who is responsible for cooling.

Signs of a thermostat malfunction in a two-chamber Atlant refrigerator:

- Camera does not work.

- The Atlant refrigerator does not turn off.

- It starts sometimes, but the degree is high, which can be understood by the active light bulb.

What to do:

- Install a new thermostat.

System malfunction full no frost

Malfunctions of the No Frost system in the Atlant refrigerator

The full no frost system consists of a sensor, a heating element, a timer and a fuse. The evaporator is located in the freezer, and the upper chamber is cooled by the fan.

If the equipment works correctly, then at a low temperature the sensor is triggered and turns on the heating element so that the ice begins to melt. Therefore, with the no frost function, manual defrosting is not necessary. If the system breaks down, the evaporator becomes covered with an ice crust and the cold does not enter the chamber.

Signs:

- There is a lot of ice in the freezer.

- The refrigerator compartment of the Atlant refrigerator does not work.

- There is an error H on the display.

If you defrost the refrigerator, it will work for a couple of weeks, but then the same problems will appear again.

What to do:

- Contact the service to have a technician repair the No Frost system.

Features of single and double chamber refrigerators

Despite the operating principle that unites them, there are still differences. In most single-compartment refrigerators, the evaporator is located in the freezer compartment. In the partition between it and the rest of the chamber there are windows with curtains that regulate the flow of cold air. Reliable, efficient and couldn’t be simpler!

A two-chamber refrigerator, which has only one compressor, has an evaporator in each chamber. First, the refrigerant enters the evaporator of the freezer. After the temperature drops, the freon passes into the evaporator of the refrigeration chamber. When the temperature in it reaches the value set by the thermostat, the compressor turns off.

Recently, models with two compressors have become popular, each of which is designed to work with one chamber. This allows you to set your own temperature in each chamber. At first glance, it seems that a refrigeration unit with one compressor is more economical. However, this is not entirely true, since if necessary, with dual-motor models it is possible to turn off one chamber without affecting the operation of the other, which is unacceptable for refrigerators with a single compressor.

Some manufacturers, instead of a second compressor, used valves controlled by electromagnetic coils. They are installed on tubes through which freon enters the evaporators. This allows you to separately set the temperature in the chambers and turn off any of them.

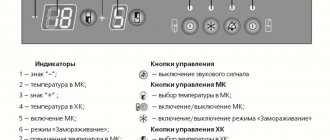

Electrical diagram of the refrigerator Atlant 1709-02, 1700-02.

A1 – display unit B4-01-4.8 display unit M4-01-4.8, B1 – thermostat K-59 L2174, thermostat TAM 133-1M, EL – refrigeration chamber lighting lamp, S1 – switch VM-4.8 , S2-switch, B2-thermostat K-56 L1954, thermostat Tam145-2m-29-2.0-4.8-9-A, R1-freeze heater HX-01, RH1-compressor thermal relay, RA1-start relay compressor, CO1 – compressor electric motor

Freon leak in Atlant refrigerator

Freon leak in the Atlant refrigerator

If your Atlant refrigerator is more than five years old, most likely you will encounter a problem such as a freon leak:

- Drip evaporator . A part made of aluminum eventually deteriorates, cracks, and the agent leaves.

- Freezer heating circuit . It is made of steel. During operation, the metal rusts, especially if there is high humidity, and leakage occurs.

- Connections . Depressurization occurs, and the agent escapes through small cracks.

Features of the Atlant refrigerator

When using Atlant refrigerators

Some moments arise that may be perceived as a malfunction of the mechanisms, but this is not the case. The operation of the refrigerator is accompanied by a number of noises that are functional in nature and not associated with any defect.

To maintain the temperature at the required level in the refrigerator, the compressor periodically turns on and off. The resulting noise is normal. As soon as the refrigerator reaches operating temperature, these noises automatically become quieter.

When the compressor is turned on (off), the temperature sensor-relay is activated, and a click may be heard.

The circulation of refrigerant through the pipes of the refrigeration system is accompanied by gurgling sounds.

In addition, during operation of the refrigerator, sources of additional noise may arise. Increased noise may be caused by improper installation of components (shelves, shelf barriers, etc.) or contact of containers with products placed in the refrigerator. In such situations, the noise level can be reduced by reinstalling components or eliminating the contact of containers with each other.

Sources of noise can also be the elements of the refrigerator (condenser, tubes, wires, elements of the melt water drainage system), if after transportation (moving or improper installation after cleaning) they come into contact with each other. You can eliminate the additional noise level by adjusting the position of the refrigerator elements or installing them correctly.

Leak in drip evaporator

Leak in the drip evaporator of the refrigerator

The drip system works like this: when the motor is operating, frost appears, which melts when the compressor is turned off and there is a plus in the chamber. Melting frost flows through the drain into a container on the motor.

At the same time, the evaporator is often made of aluminum, which means it deteriorates over time. And the agent leaves through small cracks.

Signs:

- If there are two compressors, then the refrigerator may not freeze, but Atlant’s freezer will work well. Although the compressor is working. Maybe ice. And if you don’t turn it off, then after a while the motor will also fail.

- If there is only one compressor, then the Atlant refrigerator stops working. The compressor is running smoothly or is faulty. The condenser does not heat up, there may be ice.

What to do:

- Replace the evaporator.

- Check for leaks.

- Apply a vacuum to release air and remove moisture.

- Refill with agent.

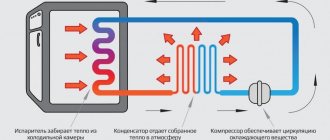

Refrigerator structure and operating principle

In this section we will describe in detail the structure of the refrigerator. What working elements does it consist of and what are they intended for.

Compressor

This is an electric motor equipped with a special mechanism that compresses freon. In the compressor, the pressure of the refrigerant increases so much that it changes from a gaseous state to a liquid state. At the same time, its temperature increases significantly.

Depending on the model, the refrigerator may have one or two compressors. The following types of compressors are used in refrigeration units:

Condenser (external radiator)

The condenser is a tube with a diameter of up to 5 mm. Liquid heated freon passes through it and cools. In refrigerators of large size and performance, the condenser is made in the form of a radiator.

Evaporator

When freon enters the evaporator, it has the opportunity to expand. At the same time, its pressure drops and the refrigerant boils. During the evaporation process, its temperature decreases significantly. As cooled freon passes through the evaporator, it takes heat from the refrigeration chamber.

Different models of refrigerators can have from one to five evaporators. This depends on the number of chambers, compressors, operating conditions and power of the refrigeration unit.

The operation of refrigerators, whether they are simple models or sophisticated ones, is based on one basic principle. Knowing it and the structure of the refrigerator, it is easy to provide the food keeper with optimal operating conditions, which will extend its service life. This knowledge will also come in handy when you need to fix minor, and in some cases, major faults on your own.

Refrigerator ATLANT XM-4008-022.

Leak in freezer heating circuit

Leak in the freezer heating circuit

The tube along the freezer circuit in the Atlant two-chamber refrigerator is needed to allow condensation to escape, otherwise the system will not work. Thanks to the tube, the chamber heats up and condensation does not accumulate. The pipe is made of metal, so over time it will wear out, causing loss of agent.

Signs of a leak:

- Rust.

- High temperature in the freezer and/or refrigerator.

- The engine runs smoothly or does not start.

- Ice.

What to do if the Atlant refrigerator does not turn on due to a leak in the circuit:

- Trim the outline.

- Solder the pipe.

- Change the filter.

- Create a vacuum.

- Refill with freon.

Schemes and principles of operation of a two-chamber single-compressor

A refrigerator compressor consists of an electric motor with a vertically mounted rotor and a piston that compresses the refrigerant. These components are housed in a metal housing made of two halves. They are welded together; replacement of elements is not provided. In case of breakdown, the entire compressor is replaced completely.

The motor is controlled using a relay. It is connected to temperature sensors that analyze the conditions in the cooking chamber and in the freezer.

In modern models, the electrical circuit contains an additional ground loop.

A household single-compressor refrigerator uses isobutane or freon as a refrigerant. The gas is under pressure in the cooling circuit. On the back of the device there is a tube for refilling it if necessary.

The refrigerant in liquid state is pumped by the compressor into the condenser. There it is compressed, and the condenser radiator removes the excess heat that is released. During the compression process, moisture is also released, which is removed by a filter at the bottom of the heat exchanger. Through the capillary channel, the substance enters the evaporator of the freezer. There the refrigerant transitions from liquid to gaseous state. The gas enters the compressor through the tubes.

The fundamental difference between a single-chamber refrigerator with one compressor and a two-chamber Atlant is that the latter has a partition between the working chambers. Each of them has its own evaporator, they are cooled separately.

Compressor relay fault

How to repair the compressor relay of the Atlant refrigerator?

The relay has two important functions: it helps start the capacitor and protects the refrigerator when the voltage increases. The jump may be due to a short circuit. And then the relay breaks the circuit and turns off the motor.

Signs:

- The Atlant two-chamber refrigerator does not turn on or turns on and off.

- The light comes on.

What to do if the cause of the malfunction of the Atlant refrigerator is in the relay:

- Buy a new part.

Electrical diagrams of common Atlant refrigerators.

Having the necessary refrigerator diagram, it is easy to understand the most common malfunctions of Atlant refrigerators

Let’s say right away that the diagrams presented below are typical; most household units Stinol, Indesit, Nord, etc. are built according to them without a no frost system.

Refrigerator diagram Minsk KShD-151, 152, MHM-161, 162

Schematic diagram of a two-chamber refrigerator МХМ-268, МХМ-2706, МХМ-2712

Designations on email schematic diagram:

B — temperature sensor-relay TAM-133-1M-75; S—switch; E - lamp; M - compressor; R - relay RT; K - relay RKT-2; C is a capacitor.

Scheme of operation of the refrigerator МХМ-268:

The products presented in the figures above include one compressor, the operation of which is controlled by a mechanical thermostat TAM-133-1M. From the mains plug (X) through contacts 3, 4 of the thermal relay, the mains voltage is received by the refrigerator compressor circuit, consisting of a start-up protective relay (K), with its contacts attached to the motor-compressor (M). The starting protective unit also includes a thermal relay (T), which turns off the starting winding of the engine after it starts. After cooling to the set temperature, contacts 3-4 of the thermostat open and the refrigerator compressor stops. The device and connection diagram of the refrigerator relay and more information about the operation of the RKT can be found here, and about Atlant refrigeration compressors here.

Electrical diagram of a household refrigerator of the МХМ-1800, МХМ-1802, МХМ-1803, МХМ-1807, МХМ-1809, МХМ-1816 series

Symbols on the diagram:

A1 — display unit B4-01-4.8; B1 — temperature relay sensor TAM-133-1M-46; B2 - temperature relay sensor 145-2M-29; C - capacitor; EL - lamp; K - relay RKT-6; M — compressor electric motor; R1 - freezing heater; R2 - relay RT; S1 - light switch; S2 – “freeze” switch.

Diagram of a two-chamber two-compressor refrigerator MХМ-1841 - МХМ1848 (without clock function)

On the electrical circuit diagram:

A1 - display module; A2 - control module; C1, C2 - capacitor; EL - lamp; K1, K2 - relay RKT-5; M1, M2 - compressors; R1—ХК sensor; R3 — MK sensor; R4, R5 - RT relay; S1 - magnetic switch VM-4.

Electrical diagram of refrigerators МХМ-1801, 1804, 1805, 1806, 1817, 1818, 1833, 1834

On the electrical diagram of the refrigerator:

A2 — display unit B4-47-4.8; B1 — temperature relay sensor TAM-133-1M-47 (ХК); B2 — temperature relay sensor TAM-125-2.3 (MK); C1, C2 - capacitor; EL - lamp; K1, K2 - relay RKT-5; M1, M2 - compressors ХК and МК respectively; R1, R2 - RT relay; S1 - switch WP7.2.4,8; S2 - switch VK-33N.

Damage to the seal in the Atlant refrigerator

How to fix the seal of an Atlant refrigerator?

When the seal is damaged, the door cannot be closed normally and warm air from the room passes into the chamber, which can cause the Atlant refrigerator to break.

Signs:

- The door does not close tightly.

- The Atlant refrigerator motor constantly works and does not turn off.

- The light is active.

- Or error H.

- The refrigerator beeps.

What to do:

- Install a new seal.

Refrigerators with No Frost system

Literally translated, the name of the system means: “without frost.” This is achieved using a built-in fan, which transfers cold from a single evaporator located in the freezer. First, the cold air spreads inside the freezer and then passes through the openings into the refrigerator compartment.

Due to air circulation, uniform temperature distribution in the chambers is achieved. To remove ice, an electric heater located under the evaporator is used, which is turned on by a timer signal several times a day. The resulting water is discharged outside. Otherwise, the device and operating principle are the same as those of conventional models.

Source