If you have to cultivate large areas of soil, it is not always convenient to do this with a shovel or other hand tools. In this case, it is better to use a cultivator, the choice of which depends on several factors and conditions.

First, it’s worth defining the concept of “cultivator”. This is a specialized gardening equipment, the main purpose of which is the treatment (cultivation) of the upper sections of the soil by loosening it. Here there is often confusion regarding the question of what is a cultivator and what is a walk-behind tractor, another popular type of equipment. A walk-behind tractor is a heavy multifunctional agricultural equipment, weighing from 70 kg, equipped with an internal combustion engine and capable of performing a full range of agricultural work: cultivation, hilling, plowing, potato harvesting. When purchasing additional attachments, walk-behind tractors are also capable of removing snow, mowing grass, watering the garden, transporting goods using trailers, and so on. That is, a walk-behind tractor can be a cultivator, but not vice versa.

The advantage of a cultivator compared to walk-behind tractors is maneuverability, lightness (light weight) and fuel economy. In a garden or vegetable garden, this technique is indispensable for digging, loosening and weeding: it has proven itself well when cultivating the soil of greenhouses, flower beds, the ground between trees and rows of vegetables, under bushes.

Cultivator device

A standard cultivator consists of a frame on which the engine, transmission, working shaft with working tools, control handles, one or two transport wheels, and a protective visor are mounted.

The main working tool when working with cultivators are tillers. For most cultivator models, they are made as connections of two, four or six fairly easily removable sections. By selecting their number, they create the processing width required at this stage of work. The rotation of the cultivator cutters leads to cutting the soil into layers, crushing them and mixing them. In this case, the cultivator does not have drive wheels; it moves forward with the help of cutters, which also move, “push” it forward and cause movement.

In addition to the standard tillers described above, cultivators can, if desired, be equipped with a variety of attachments, which significantly expand the possibilities of performing agricultural work on them. Of course, such an additional “attachment” is purchased separately by the owners of the cultivators, so when choosing a cultivator for purchase, it will be useful to compare not only their technical parameters, but also the range of their equipment, their compatibility with various attachment options.

Pros and cons of wide-cut universal cultivators

Wide-cut cultivators have both advantages and disadvantages. Fortunately, there are very few cons.

Minuses:

- high price;

- inability to use cultivators on rocky soils.

pros

- Strong load-bearing beams are made of pipes with a square cross-section of 6 cm. The beams pass through technological holes, increasing the reliability of the equipment.

- The S-shaped racks are staggered, so the cultivator does not become clogged with weeds and debris during operation. This same feature allows you to cultivate heavy soils or areas that are not properly prepared for cultivation.

- The design of S-shaped racks uses strong metal rods with a cross-section of 45x12 mm or 65x12 mm, depending on the presence of a spring.

- The rollers are not fixed rigidly, which allows the load to be redistributed depending on the terrain, because of this the leveling occurs more evenly.

- The depth of tillage can be set extremely accurately, achieving optimal digging of the soil.

engine's type

Engines can be gasoline, diesel, electric. Gasoline engines, in turn, can be two-stroke or four-stroke. Electric motors can be powered either from the mains, that is, they must be constantly connected to an outlet using an electrical cable of the required length, or from a built-in battery.

Electric engines and two-stroke gasoline engines are usually used in light class cultivators. Four-stroke gasoline and diesel engines are installed on medium and heavy class cultivators. The difficulty of operating cultivators with a gasoline engine is the need for constant maintenance. Fuel should be added regularly and oil should be used to lubricate parts. In addition, each model requires certain brands of oil and fuel, so you must strictly follow the instructions. Compared to electric models, gasoline models make too much noise. It is worth remembering about gasoline exhausts, harmful plants, soil and people. Models with a two-stroke engine are cheaper and simpler, but they require more fuel.

Electric cultivators do not have as much power as models with an internal combustion engine, but are great for small areas. Also, according to the observations of some users of electric models, vibration can irritate bees if work is done near the apiary.

Petrol cultivator Crosser CR-K12

Diesel cultivator ZIGZAG DT 902

Electric cultivator FERMER F-105

Types of cultivators according to operating principle

Equipment for loosening the soil can be powered by either gasoline or electricity and a battery. Each type of cultivator has its own characteristics.

See also: What types of trees are best suited for heating a sauna?

Gasoline

Petrol-powered cultivators are the best option for cultivating large plots of land. This technique is distinguished by its high productivity.

There are two types of gasoline-powered cultivators:

- four-stroke – runs on gasoline;

- two-stroke - oil mixed with gasoline is poured into the engine.

A four-stroke motor cultivator is an improved device that during operation consumes less fuel and creates a minimum of vibration and noise.

Characteristics of the petrol cultivator “ELITECH KB 60N”:

- engine – four-stroke, single-cylinder;

- cutter diameter – 33 cm;

- power – 6.5 l/s;

- processing width – up to 65 cm;

- weight – 56 kg;

- fuel tank volume – 3 l.

The cultivator has six cutters and is designed for loosening and hilling soil in personal plots and fluffing up virgin soil. You can add attachments to it for digging up potatoes and adding fertilizer to the soil. The recommended treatment area is 1500 m².

Cultivator for a summer residence, powered by gasoline

Electrical

In small summer cottages, electric cultivators are mainly used. This technique is characterized by its low weight and size. For the drug to work, access to an electrical network is required.

The depth of loosening and engine power of an electric cultivator is significantly less than that of gasoline-powered soil cultivation equipment. The device is easy to use and indispensable when processing small areas of land near the house.

Characteristics of the electric cultivator "HYUNDAI T2000E66":

- power – 2 kW;

- processing width – 55 cm;

- plowing depth – 25 cm;

- cutter diameter – 28 cm;

- weight – 30 kg.

This device operates from a 220V network. Perfect for loosening the soil and weeding areas up to 10 acres.

The cultivator has four cutters for cultivating the soil and one forward gear. The device is equipped with a special fence that prevents cultivated plants from reaching the working tool. The convenient handle is adjustable to the required height.

Rechargeable

Among summer residents, small battery-powered equipment for loosening the soil near the estate is popular. Such cultivators do not require connection to a network and, unlike gasoline-powered machines, are lighter in weight, do not emit smoke, and operate quietly.

Battery cultivators are designed for cultivating soil in greenhouses, around trees, and between rows in garden beds. The disadvantage of the device is the limited time of use. The battery charge lasts from thirty minutes to one hour. After this time, the battery is charged for eight hours.

Characteristics of the Zirka T20XD battery cultivator:

- power – 600 W;

- cultivation width – 45 cm;

- processing depth – 15 cm;

- Battery operating time – 40 minutes;

- weight – 30 kg.

The cultivator is designed for cultivating light top layers of soil. The device has four cutters. It is not capable of processing heavy clay soil, as well as soil that has not been previously cultivated.

Engine power and transmission type

Power is expressed in horsepower, and depending on their quantity, such devices are divided into three types: light (up to 4 hp), medium (4-6 hp) and heavy (more than 6 hp) devices. Typically, the power of a cultivator is directly related to weight. The greater the power of the device, the easier and faster it cultivates the land. Engine displacement – for models with a gasoline unit. The “golden mean” rule applies here. A very weak engine with a small displacement will not be able to cope with an average load. A large and powerful engine will consume a lot of fuel. The amount of fuel consumption ranges from 1-2.5 liters per hour of intensive work.

The transmission transmits rotation from the engine to the working tools - cultivator cutters. The transmission also includes a clutch. This is a device that allows you to turn on and off rotation from the engine to the working body. The following types of transmissions are used in cultivators: gear-worm transmissions, belt-tooth-chain transmissions and some others.

Lightweight cultivator Krones GHA35

Medium-power cultivator MTD T/245

Heavy cultivator Skiper SK 700

How to choose a cultivator

Equipment for processing land plots differs in design, functionality and technical characteristics. There are many different models available at different prices. Knowing the basic parameters of choice, it is easier to find a cultivator that will cope with the tasks.

Power

Ultra-light cultivator

This parameter depends on the weight of the equipment:

- ultra-light, weighing up to 20 kg and power no more than 3 hp. These models are used in small areas. They are convenient to work in greenhouses, flower beds, and flower beds. Ultra-light equipment is maneuverable, so it is suitable for processing hard-to-reach places;

- lightweight, weighing up to 40 kg and power up to 4.5 hp. They also treat small areas, loosen to great depths, hill up, and cut furrows for future plants;

- medium, weighing from 45 to 60 kg and power ranging from 4 to 6 hp. Due to their high power, they can be equipped with attachments: a small plow, a harrow, a hiller;

- heavy, with a mass of more than 60 kg and a power of more than 6 hp. Heavy models have a gearbox, and a large selection of canopies expands the functionality, making the equipment universal. Such machines are used to process large areas: plowing, loosening, transporting loads and much more.

The larger the plot of land, the more powerful the gardening equipment should be.

Plowing width and depth

Cutter

The width and depth of cultivation depends on the power and weight of agricultural machinery. The larger the grip, the faster the land is processed, but at the same time maneuverability decreases:

- for small areas, a working width of 35 cm is sufficient;

- for a large area (from 15 acres to 1 hectare) - from 70 to 105 cm;

- lightweight models are suitable for cultivating soil in small beds;

- a plowing depth of 15–20 cm is enough to loosen and hill up hard soil;

- heavy-duty models with a loosening depth of 30–35 cm are used for work on virgin soils and areas with weeds.

Powerful cultivators are equipped with different cutters, which determine the working width.

Number of speeds

To select speeds, the vehicle must have a gearbox. Models with 2 – 3 forward speeds are used on large flat areas with soft soil, increasing the productivity of work, for example, plowing.

Transmissions with 4-6 speeds make it easier to operate attachments. In addition to forward gears, heavy petrol cultivators are equipped with reverse gears.

Models with reverse gear are more maneuverable and easy to turn and turn around. Electric cultivators do not have a choice of speed.

Maximum width and depth of cultivation

Tilling width is the maximum strip width that the cultivator can cover. A very narrow coverage adds time that is required for high-quality soil cultivation. The width of the processed strip depends on the engine power. Approximately 1 hp required for twenty centimeters of land covered in width. A wide grip is more convenient for processing large areas of land. If weeding between beds is important, then a narrow grip is more convenient.

The tillage depth reflects the distance to which the cultivator cutters penetrate the soil. As a rule, it is directly proportional to the diameter of the cutters. In some cases, the manufacturer separately indicates the cutting depth and cutter diameter. The average value usually does not exceed 25 cm. The tillage depth is set by the adjustable position of the coulter (a strong metal strip that is vertically fixed to the rear of the cultivator). The cutting width is usually adjusted by installing various cutters.

Cultivator with a maximum cultivation width of 1050 mm ZIGZAG GT 903

Cultivator with a maximum cultivation depth of 350 mm Workmaster WT-85

Two main types of farm cultivators

| Continuous cultivators | Inter-row cultivators |

| Solid cultivators are designed for pre-sowing tillage of soil from 4 to 12 cm, leveling plowed soil up to 12 cm, and cultivation of fallows. In one pass of the unit, weeds are destroyed, a mulch layer is created, and the agricultural background is leveled. The depth of the mulch layer reaches 12 cm. The use of continuous cultivators in minimal tillage can significantly reduce soil overheating in summer and reduce moisture evaporation. | Inter-row cultivators are designed for loosening the soil in 70 cm wide rows, hilling and fertilizing crops of corn, sunflower, sorghum, castor beans and other row crops. The use of inter-row cultivators allows you to accumulate and preserve soil moisture, improve the air regime of the soil and the nutritional regime of plants. |

Types of cutters and their speed

The main tool when working with cultivators are tillers. For most cultivator models, they are made as connections of two, four or six fairly easily removable sections. By selecting their number, they create the processing width required at this stage of work. Of course, when work is to be done on heavy, clayey soils, the number of installed sections of soil cutters will need to be reduced. Moreover, it will be important to do this in cases where a cultivator will have to plow up virgin soil or restore agricultural cultivation of a long-abandoned site.

Milling cutters can be either non-separable or collapsible. It is better to choose collapsible knives, since they can be easily replaced if necessary. There are two types of cutter design: “crow’s feet” and with saber-shaped knives.

The last option is the most popular and can be called standard. After all, these types of products are time-tested: their effectiveness is quite high. They have the optimal shape and material. The knives are made from high-quality, high-strength steel.

As for crow's feet products, such products are used for hard soils. They have a solid structure, non-dismountable, due to this their strength is high. Such products are effective in controlling weeds and processing virgin soil. It should be noted that the cutter is a self-sharpening tool. No additional manipulations in this direction are required.

The optimal cutter speed for cultivators is considered to be 150-170 rpm. At this speed of rotation of the cutter, deep cultivation can be done to a depth of up to 15 centimeters. At 200-220 rpm, you can loosen the top layer of soil to a depth of 8-10 centimeters and do pre-sowing cultivation to a depth of 6 centimeters. And increasing the speed to 275-330 ensures effective loosening of row spacing and destruction of the soil crust.

Cultivator with saber blades SunGarden T/35

Cultivator with houndstooth cutters Zigzag GT 134

Working bodies of cultivators

For direct soil cultivation, cultivators can use several different tools that differ in purpose and design. The most common ones include:

- Loosening paws are the main working part of the cultivator. There are up to 7 types of paws, but the most popular are the arrow-shaped paws “flat cutters”, which loosen the top layer of soil and cut off weeds even before they germinate.

- Various types of rollers - depending on the design, rollers can be used for crushing clods, incorporating fertilizers or chopping stubble and crop residues. Most often, rollers are installed behind the paws.

- Spring-roller attachment - consists of several rows of long, thin “needles”. Creates a fine-lumpy soil structure and partially levels it.

- Leveling bar - installed behind all working parts for the purpose of final leveling of the soil after loosening it with paws and discs.

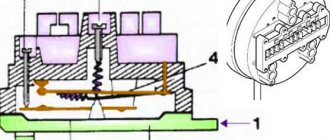

Example in the picture (decoding):

1 - stand; 2 - cheek; 3 - blade; 4 - funnel; 5 - dumper; 6 — tip; 7 - blade; 8 — wing; 9 - slot; 10 - frame; 11 — needle disk; 12 — harrow tooth; 13 - bolt; 14 — bracket; 15 — harrow frame; 16 — bracket; 17, 23 — springs; 18 - cylindrical drum; 19 - tooth; 20 - conical drum; 21 - axis; 22 - holder.

Number of speeds

The number of forward speeds allows you to adjust the speed of the cutter and determine the type of work with the soil as described above. On modern cultivators, it is desirable to have a reverse gear. Light and ultra-light models, of course, do not have reverse gear, but they have a special handle to make it convenient to lift the cultivator and turn it in the right direction. This will be especially useful when working near various obstacles (fences, for example) or in some narrow, limited areas when you constantly need to make an effort to rearrange the cultivator. Heavy class devices weighing more than 60 kg have reverse as standard.

Reverse cultivator FERMER FM-701MS

Hand cultivator video.

Result:

When choosing an assistant, focus primarily on your needs, as well as who will work with the machine. If your family includes pensioners and women, then it is better to choose lightweight, electric models, or even manual ones. If large areas are available for processing, and the farm has strong male hands, you should pay attention to medium and heavy models. To work around the house, caring for indoor flowers, you can use manual mechanisms. With this we say goodbye to you, we wish you a good choice and successful work, see you again!

Which cutters are better for a walk-behind tractor? Milling cutters for walk-behind tractors: their purposes, differences (Salyut and Agro) and video

Farmers know that in order to get a good harvest, a complex of works is necessary, which includes soil cultivation. In household plots, a shovel has always been considered a traditional tool.

Today, many owners of legal acres of land want and are able to efficiently cultivate the soil using special “home” equipment.

Purpose of soil cutters, their role in tillage

These are walk-behind tractors that perform soil cultivation. One of the elements installed on home cultivating assistants is cutters for walk-behind tractors.

They directly affect:

- for high-quality plowing;

- the controllability of the equipment depends on the rototiller;

- influence the transmission;

- and the power unit of the walk-behind tractor.

A cutter for a walk-behind tractor is their main working part. They answer:

- for the depth of loosening of the top layer of soil;

- for creating the structure of cultivated land. Large or finely lumpy version;

- for the fight against weeds.

The difference between soil cutters

They can differ radically from each other. Design and shape may vary. The difference may be in the number of knives and location.

Knives are the main weapon of a rototiller. The material from which they are made directly affects the depth of penetration into the soil.

They can be forged with self-sharpening. Good knives for milling cutters are made by Italian craftsmen. See the video of the walk-behind tractor with cutters at the end of the publication.

Stamped sheets are often used to make knives. In this case, the cutting edge is not clearly defined. Practice shows that their installation is often carried out on inexpensive, budget models of cultivators

Milling cutters for walk-behind tractor Salute

The configuration and equipment of the Salute walk-behind tractor of different models includes a set of cutters with disks for plant protection. Manufacturers of the Salute walk-behind tractor make rototillers from steel blanks or ordinary metal strip.

The cutter knives for Salute are made of spring steel and processed in a special way. The crescent shape allows penetration into the soil with the least resistance. It has been proven in practice that the knives are very reliable.

The three pairs of cutters that come with the kit are bolted on with steel pins. Cutter grip indicators: 350 x 600 x 800 mm.

Milling cutters for Agro walk-behind tractor

The Agro walk-behind tractor includes a number of additional attachments, with which you can better cultivate the soil in a short time: loosen it, remove weeds.

This makes the tool more functional and versatile. The main violin in the “technical orchestra” is the cutter. Characteristics of the rototiller for tillage: the grip width is 610 mm.

The depth of cultivation of the top layer of soil is 80 mm. Penetration into the top layer of the earth, at around 80 mm, is possible only with knives made of high-quality material.

We can conclude that cutters for a walk-behind tractor are a necessary and useful thing. A range of work with additional equipment expands the capabilities of home appliances, increasing the demand for it. It is possible to purchase rototillers separately from walk-behind tractors. This is normal practice, which makes it possible to purchase the necessary additional equipment at the right time.

Do I need to sharpen the cultivator cutters? What is a cultivator and why is it needed?

First you need to understand what a cultivator is, how it works and what it is needed for.

So, this is a type of compact agricultural equipment designed for pre-planting soil preparation. It allows you to plow, loosen and hill up the soil, as well as make furrows and perform harrowing. This unit makes it possible to significantly facilitate agricultural work on a summer cottage or personal plot. The motor cultivator is capable of working where full-size equipment cannot access

Cultivators are divided into groups according to the type of mechanism:

- mechanical manual They are used as additional equipment for more serious equipment. Loosen the soil to a depth of no more than 5 cm and remove only weak weeds located on the very surface;

- electric . Lightweight, maneuverable equipment that is used on limited areas of land. The disadvantage is that it runs on an electrical cord;

- battery . This type of agricultural equipment combines all the advantages of electric analogues with autonomy. They are heavier, but at the same time, mobile and safe;

- gasoline. This technique is distinguished by power, performance and heavy weight. A good option for cultivating large plots of land.

Manual mechanical cultivator

Electric cultivator with cord

Battery unit

Motor cultivator with gasoline engine

Cultivators of any type consist of such basic elements as a frame, control levers, engine, rotor, wheels and cultivation devices (mills).