Chainsaw drive sprocket device

An asterisk or centrifugal mechanism is a part shaped like a star.

It takes on the engine torque and transmits it to the guide and saw chain. This guarantees the rotation of the cutting set and the sawing process itself. It operates automatically, which depends on the amount of engine speed. The clutch drum can be located both outside the chainsaw and on its inside - under a separate cover. It performs a protective function not only in relation to the material from which the sprocket is made, but also for the operator, who may be injured by it during work. In addition to the function of chain rotation, the saw drive star prevents the occurrence of malfunctions of the motor system in cases where the chain jams or stops rotating.

The owner’s desire to equip the headset with a saw chain with a different pitch leads to the need to replace the sprocket with a part with a crown of the corresponding profile. This requirement applies to the entire range of chainsaws made in Europe and China.

The operational reliability of a European-assembled saw, when working under difficult conditions with increased loads, can significantly deteriorate if a Chinese-made sprocket is installed instead of a branded part.

How to remove a sprocket from a chainsaw and replace it with another (instructions with photos and videos)

One of the most loaded components of the mechanism, subject to the fastest wear. The drive sprocket (gear), located on the chain saw’s clutch, transmits rotation to the chain, resting against its links at great speed. Combined with the serious resistance of the material into which the blade “bites,” the gear takes on maximum pressure, which gradually grinds down the metal of the teeth.

As the sprocket it begins to play, causing extremely unpleasant consequences. Fortunately, these items are budget consumables, even for professional brand chainsaws. How to determine the time to replace a sprocket, do it yourself and extend the service life of a new one, we tell and show in this article.

Replacing the drive sprocket on Husqvarna 154, 254, 262 chainsaws

For Husqvarna chainsaw models 154, 254, 262 series

, equipped with

8-tooth

chains with

a 0.325

a Rezer SP 38071

drive sprocket is used .

The part differs from the previous all-metal construction

. This means that there is no such element as a replaceable crown.

On the one hand, such a detail loses

in operational life, on the other hand, it has a more

attractive cost

.

The price is almost two times lower

compared to sprockets with a replaceable crown.

Husqvarna 154, 254, 262

models by clicking on the following link.

Drive sprocket replacement process for Husqvarna 154, 254, 262

has a slightly different algorithm. Let's look at it in more detail.

Remove the side of the chainsaw to gain access to the saw group

.

Using a combination key

loosen

the chain

and remove it together with

the bar

.

Remove the rope starter

from the opposite side.

Use hex wrenches

.

Fix the shaft on the impeller side with a 13mm wrench

.

Using a special key

remove

the clutch

.

Unscrewing should be done clockwise

.

Dismantle

sprocket and needle bearing.

Assembly is carried out in reverse order

.

The clutch should be tightened counterclockwise

.

The force should not be too high

, since the coupling

self-tightens

when rotating.

In fact, the replacement process is not very difficult.

and it is quite possible to produce it

yourself

.

Buy quality drive sprockets

for

Husqvarna 154, 254, 262

in our TUKINGARDEN store.

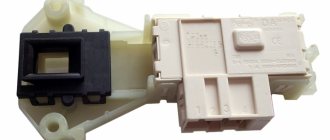

Replacing the clutch drum with sprocket

All modern chainsaws are equipped with a chain brake device and in most models its operation is carried out by means of a belt located on the tire cover and a chain that goes around the clutch drum.

When the chain brake is engaged and the gas trigger is pressed, the clutch disc continues to rotate, and the drum is clamped by the brake band. If you do not turn off the brake in time and continue to press the gas trigger, the tire cover and chains will begin to melt, and the clutch drum may burst.

To replace the clutch drum you must:

- Remove the air filter cover;

- Stop the engine and unscrew the nuts;

- Pull out the clutch disc;

- Stop the engine;

- Install the new disc, press the washer and nut.

Drive sprocket for chainsaw

A chainsaw sprocket or clutch plate serves to transmit rotational motion and power to the saw chain. Structurally, there are three types of drive sprockets;

1. The sprocket is solid. In such a sprocket, the clutch plate is rigidly welded to the drive ring. In case of wear, the entire sprocket is replaced.

2. The sprocket is collapsible. It is a clutch plate with splines onto which the crown drive sprocket fits. The clutch plate wears out very little and a replacement hub is cheap. The collapsible sprocket is very beneficial for large volumes of work and is used mainly by professionals.

3. The sprocket is a replaceable crown. This sprocket is used to replace on collapsible sprockets.

The selection of the drive sprocket is carried out according to the chainsaw model. If you are in doubt about your choice, call us and we will try to suggest the correct spare part.

Design features of drive sprockets

Any manufacturer indicates the tooth pitch in the operating instructions. Considering that a driven sprocket is also installed on the saw bar (designed to create the necessary tension), the pitch here and there should be the same.

Chainsaw drive sprockets can be solid or prefabricated. In the first case, the sprocket includes a hub onto which a ring gear is pressed. This is exactly how the parts in Champion chainsaws are arranged. When replacing, the product should be removed completely, since at home it is almost impossible to maintain the tension value specified at the manufacturer. And purchasing a crown separately is also a problem.

In chainsaws from Stihl or Husqvarna, the replaceable crown is located directly on the drum shaft, and therefore replacing it does not present any difficulties.

Tooth wear is determined by the following criteria:

- There are clearly visible radii at the transition points from the tooth to the cavity.

- The width of the tooth is uneven in height.

- There are metal chips at the top of the tooth.

- There are numerous burrs and marks on the inner surface of the hole in the hub (a consequence of poor lubrication).

- There is a noticeable groove on the sprocket from the saw bar (the chain also needs to be changed).

- The chain jams at the initial moment of start-up.

If at least one of the above factors is present, the drive sprocket must be replaced.

Before starting work (especially if the chainsaw has been running for relatively little time), it is worth checking the fastening of the saw bar. The tensioner screw has come loose or the fastening nuts have come loose - the guide is no longer aligned with the longitudinal line of the saw blade. It begins to contact not with the center, but with the periphery of the teeth of the drive sprocket, provoking their intense wear. After tightening the specified elements, check the operation of the chainsaw: if the play is not eliminated, then the sprocket will have to be changed.

How to change a sprocket on a chainsaw?

To replace a worn element, you will need to buy a part of the same type and with the same dimensions as the standard element. In most cases, the factory chainsaw bearing must also be replaced during repairs.

It is best to initially buy a repair kit, which includes both a bearing and a sprocket. To remove the sprocket from the chainsaw and install a new part in its place, you will also need to prepare tools. Their list includes:

- a universal key, which is supplied with the chainsaw;

- removable key for dismantling the centrifugal clutch. When choosing it, you need to take into account the model of the chainsaw;

- mechanical piston stopper. A metal or plastic tool is suitable for removing the piston.

Replacing the sprocket on the chainsaw tire should be done in the following order:

- First, you will need to remove the saw blade assembly. Using a universal key, you need to unscrew the protective covers;

- Next, you need to remove the standard air filter of the instrument;

- After this, using a universal key, you will need to unscrew the spark plug. In its place, you need to install a mechanical piston stopper - it is necessary to fix the piston in a stationary position;

- Then you will need to install a removable key in the universal key slot to dismantle the clutch mechanism. Using the resulting device, you need to carefully dismantle the standard saw clutch. To do this, the factory assembly should be turned clockwise;

- After removing the coupling, passage to the internal elements is free. This will make it possible to unscrew the sprocket of the household chainsaw;

- The removed drum will need to be carefully inspected. If necessary, the ring or sprocket should be replaced. During replacement, you will need to check the separator. If necessary, you need to replace worn springs and cams of the centrifugal mechanism;

- After replacing all faulty elements, you can begin reassembling the chainsaw. To do this, you first need to unscrew the previously installed piston corkscrew, and also pull out the factory trigger cable. After this, the stopper will need to be screwed back in. This will make it possible to reliably press the centrifugal clutch of the tool onto the engine crankshaft;

- Next, using the universal key, you will need to press the clutch counterclockwise;

- At the end, all previously dismantled parts can be installed back on the chainsaw.

Tool assembly procedure

The chainsaw is assembled in the reverse order. First, the sprocket is installed on the needle bearing, then the clutch drum, the washer and the clutch itself. Screw it counterclockwise, but without unnecessary force. The piston will also need to be fixed, but with left rotation a few millimeters before the maximum top point.

Please note that sometimes the oil drive is equipped with a spring that transmits movement from the sprocket to the pump. If the spring guide does not fall into place, then oil will not be supplied to the chain. Usually the correct position is marked with color and marks; if there are none, you need to slowly rotate the part until a characteristic click is heard.

Next, you need to install a saw bar on the chainsaw. To install the chain, you need to loosen the handbrake by pulling the lever towards you (towards the handle). It is important here that the teeth of the chain fit into the grooves of the sprocket. If you are inattentive, this moment can be missed, which will lead to rapid damage to the chain. Its correct direction is indicated on the body by characteristic pictograms. After installation, it must be tensioned to working condition.

At the end, you need to remove the piston stopper, install the spark plug and air filter in its place. Secure the top housing cover.

Watch the video on how to remove a sprocket from a chainsaw

Types of clutch malfunctions and ways to eliminate them

Here the list of possible breakdowns is not so long, the most common cases are:

Damaged spring , it can be stretched or burst, in both cases the clutch will not work and repairs are necessary. Depending on the brand of chainsaw, you will have to replace the spring or the entire clutch. So, for example, on Stihl saws it is possible to replace the spring, but on Husqvarna and Echo you will have to completely change the clutch.

Clutch drum , on which the chainsaw drive sprocket is located. Wear of the drum and sprocket also impairs the performance of the clutch mechanism; it is determined quite simply; wear inside the drum and on the sprocket is visible to the naked eye. The problem can be eliminated by installing a new clutch drum.

Another type of failure is a faulty bearing inside the clutch drum; its wear is also natural, although not as frequent as compared to the cases described above. On many models of chainsaws, this bearing is replaced, and there is no need to change the entire clutch.

Causes of malfunctions and how to determine the need for replacement

When idling, the spring compresses the cams and they do not touch the drum. As the speed increases, the centrifugal force exceeds the spring stiffness and the cams come into contact with the walls of the drum. The latter begins to rotate.

The teeth of the saw chain mesh with the teeth of the drive sprocket. One of the functions of an automatic centrifugal clutch is to protect the engine when the load on the chain increases beyond the permissible limit. This can occur when the chain gets stuck.

The outer part of the drum is covered by an emergency brake band. When the handle is folded back, the belt is pressed against the drum and slows down its rotation. The effect is the same as when the chain jams.

A feature of all chainsaws is that the drum and clutch cams are attached to the shaft using a nut with a left-hand thread so that the mechanism does not unwind during operation.

Wear on the drive sprocket teeth can occur for several reasons:

- natural wear and tear along the chain teeth;

- accelerated wear as a result of excessive chain tension or lack of lubrication;

- incorrectly selected chain;

- technological defect.

Metal wear can be determined visually by inspecting the sprocket without removing it from the saw. Dents and chips on the surface should not exceed 0.5 mm.

The need for replacement is determined by increased noise when the chain moves, but this is typical only in the presence of deep potholes. It is difficult to notice shallow wear during operation, but the chain will wear out greatly. When the teeth are broken, the chain may move jerkily, which is especially noticeable during operation.

The clutch operates automatically, depending on the number of engine revolutions.

The units are equipped with a centrifugal clutch, which operates automatically, depending on the number of engine revolutions.

When the engine of the unit operates at idle or low speed, the elements of the clutch basket, which have friction linings, have a certain level of freedom in the circular direction. The presence of freedom of movement leads to the fact that, under the action of springs, the elements are attracted to the center of the rotation shaft and do not transmit rotational motion to the sprocket drum.

As the engine speed of the device increases, the centrifugal force exceeds the force of the springs, which leads to displacement of parts with friction linings. Replacing the piston on a Chinese chainsaw. Replacing the piston group of a Chinese chainsaw 4500replacement piston group of chainsaw 4500 cylinder-piston group for a 45 mm chainsaw replacing the piston group on a chainsaw stihl ms180 chainsaw china replacement.

Replacing the sprocket on how to unscrew the clutch on a chainsaw. On a Chinese chainsaw. These elements are pressed against the inner walls of the drum under the influence of centrifugal force. Due to this contact, rotational motion is transmitted to the drum and sprocket, which drives the saw chain of the tool.

More common reasons that force tool repairs associated with replacing the drive sprocket are:

- chain jamming due to defects appearing during operation of the unit;

- the highest wear of the sprocket as a result of long-term operation of the unit.

- professional;

- household.

The main difference between them is the frequency of replacement and the rate of wear: in the models of the “Pro” series, wear occurs faster and repairs occur more often.

The latter consist of a hub with a stationary crown of a certain number of teeth. Their factory pressing does not allow the crown to be removed separately from the hub. This situation is typical for many Chinese chainsaws, for example, from the Champion brand.

The situation with prefabricated sprockets is simpler: the removable crown is quickly unscrewed from the drum axis, so repairs do not cause any particular difficulties. This option is an advantage of most saws of European origin, for example, Shtil or Husqvarna.

Drive gears, according to their design, are divided into:

- Whole. The part includes a hub into which the crown is pressed. You can only remove the part for replacement in its entirety. In the industrial conditions of the manufacturing plant, it is possible to ensure the design values of the interference. Special equipment is used for this. This operation cannot be carried out in a home workshop. Difficulties also arise when trying to buy a crown separately - the manufacturer does not consider it an independent part and does not supply it to stores and service centers.

- Prefabricated. The crown is made as a separate part; it can be removed using a special puller or special tricks with a universal tool.

Solid sprocket

Experts identify the following signs of wear on the drive gear teeth:

- semicircular depressions are visible at the base of the tooth;

- the thickness of the tooth varies with height;

- chipped zones at the top;

- scratches appeared inside the hub hole;

- the chain has worn out the groove on the sprocket;

- When starting, the chainsaw jams.

A chainsaw sprocket with such signs should not be used; it must be removed and replaced.

According to the manufacturer's recommendations, the tool should be inspected before starting work. In this case, be sure to check the condition of the saw bar and whether it is securely fastened. If the screw that regulates the position of the chain roller and its tension is loosened, or the nuts securing the bar to the body are loosened, it deviates from the plane of the chain.

Sprockets with replaceable and stationary crown

After tightening the fasteners and making adjustments, do a test run. If free play remains, the sprocket will have to be removed and replaced.

The Husqvarna 137 chainsaw is an amateur, semi-professional class tool. The model achieved high popularity among consumers due to its good performance, light weight and versatility. These days, the Husqvarna 137 chainsaw is actively used not only by gardeners, but also by utility workers.

There are already several 10-cylinder chainsaws in operation from different manufacturers, capacities, and most importantly for special purposes. Saws are divided into:

- prof (for felling and construction);

- household (garden).

Currently reading: Chainsaw stihl ms 250 technical specifications

Accordingly, their drive gear will be different, as well as the sequence of actions. Discover 253 best selection of husqvarna chainsaw sprockets 142 chainsaw chainsaw replacement. Assembling a husqvarna 142 chainsaw. Husqvarna 140 chainsaw. Replacing a chainsaw sprocket. Husqvarna 340 chainsaw repair, chainsaw replacement sprocket.

In this regard, you need to know how to remove the sprocket from the chainsaw correctly so as not to damage the tool. This part is also called a centrifugal mechanism or clutch disc.

To better understand the entire process, it is necessary to understand what an asterisk is and how it is used.

You may also be interested in the article,

DIY chainsaw chain sharpening

.

The main malfunctions of chainsaws and steps to eliminate them are described here.

And in this article, you can learn how to repair a Parterre 350 chainsaw.

If the part is not replaced in a timely manner, the stability of the tool will be impaired. A worn part provokes excessive vibrations, which, in turn, have a negative effect on the crankshaft bearings.

Tooth wear of up to 0.5 mm is considered normal. However, users often bring the part to a deeper groove of about 1 mm, not realizing that operation causes damage to other parts of the chainsaw. Naturally, subsequently there is a breakdown of the bearings, which need to be replaced.

When the engine of the unit is running at idle or low speed, the elements of the clutch basket, which have friction linings, have a certain level of freedom in the radial direction. The presence of freedom of movement leads to the fact that, under the action of springs, the elements are attracted to the center of the rotation shaft and do not transmit rotational motion to the sprocket drum.

When the engine speed of the device increases, the centrifugal force exceeds the force of the springs, which leads to displacement of elements with friction linings. These elements are pressed against the inner walls of the drum under the action of centrifugal force. Due to this contact, rotational motion is transmitted to the drum and sprocket, which drives the saw chain of the tool.

The main advantage of this type of clutch is that when the saw chain jams, elements with friction linings slip, which protects the internal combustion engine from serious damage.

The main malfunctions of chainsaws and steps to eliminate them are described here.

Features of the Husqvarna 137 chainsaw, which is suitable for all types of work in gardens and households, plantations, small factories and more, is designed with a 2.2 horsepower engine. The fuel tank is designed for 0.4 liters. Recommended tire for Husqvarna 137 chainsaw.

H30, and the length can vary from thirty-four to thirty-eight centimeters. It should be borne in mind that in order to avoid early wear and unforeseen failures, you can not only meet the manufacturer's performance requirements, but also use original spare parts for the Husqvarna 137 chainsaw, which are in an affordable price range.