Error F5 in Atlant cars without a display

If your Atlant does not have a screen, then it will report a problem using the following two lights.

- Atlant SoftControl models. This error is indicated by the blinking of the “Spin” and “Rinse” indicators.

- SMA Atlant OptimaControl. Error F5 is indicated by LEDs “Stop with water” and “Wash”

Decoding the F3 code

Most often, F3 appears on Atlanta 10 or 15 minutes after the start of programs that include washing in hot or warm water. Moreover, when selecting the mode without heating, no failure occurs.

This error indicates problems with water heating - it either does not happen at all or is carried out more slowly than necessary.

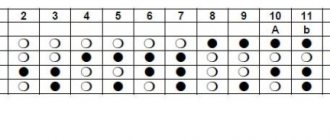

In devices without a display, the washing machine displays the self-diagnosis result in the form of a combination of certain LEDs. Depending on the Atlanta release series, these could be:

- “Water stop” and “Spin” for the line of SoftControl series devices;

- "Rinse" and "Water Hold" for the OptimaControl range.

It is impossible to immediately say what the error is without diagnostics. Moreover, in rare cases, F3 may appear at various stages of the washing machine’s operation, even during rinsing and spinning, at the end of the wash.

Error F5 - when you can fix it yourself

There are many reasons why the Atlant machine does not take in water and shows error F 5. This is not always due to a breakdown. First of all, check whether all conditions for normal operation of the SMA are met. Here is a table with reasons that you can easily eliminate yourself.

| Signs | What is the reason | How to fix |

| SMA Atlant was recently installed. After starting the program, it constantly draws water (you hear the sound of water pouring into the tank), and then stops and displays error F5. | Incorrect installation . The drain hose is probably lowered below the level of the tank, causing the water to flow by gravity into the sewer. Therefore, the machine constantly draws water and then writes an error. | It is necessary to install the machine correctly according to the operating instructions (so that the drain hose is above the level of the tank). If you cannot do this yourself, use a washing machine connection. |

| Incorrect installation of the drain hose. The free part of the drain hose is immersed in water, causing self-draining of water from the tank. | If you discover that the hose has been installed incorrectly, you must remove its free end from the water. | |

| You can’t hear the usual murmur of water when filling, it doesn’t flow into the SMA, and the wash doesn’t start. Almost immediately after the cycle starts, Atlant shows code F5. | There is no water in the water supply. Check if there is a water supply in the house. | If there is no water in your home, contact your utility provider. |

| The water supply to the machine is cut off. Check to see if the water supply valve to the SMA is closed. | If the water supply shut-off valve to the machine is closed, open it. | |

| The inlet hose is pinched. Inspect the inlet hose for kinks and clamps. | Straighten the inlet hose if necessary. | |

| The machine takes a long time to draw water, after which it gives an error. | Weak water pressure. The water supply valve is probably not fully open or there is low pressure in the water supply. | It is necessary to restore normal water supply to the machine. For this:

|

| Atlas takes a long time to fill up with water or doesn’t fill up at all. Then the machine freezes with code F5. | The mesh filter is dirty. To catch impurities in tap water, all washing machines have a special filter mesh in front of the fill valve. Due to its contamination, the pressure of water entering the washing machine decreases, until the supply stops completely. The machine cannot draw water within the allotted time and goes into error. | It is necessary to clean the filter mesh: yourself (according to the instructions for the machine) or by ordering a filter cleaning service from RemBytTech. |

| Error F5 came on while washing or rinsing. | One-time failure of the control unit. The control board probably froze, causing an error. | It is necessary to “reboot” the control module. To do this, unplug the washing machine from the power supply for 10-15 minutes. In case of a one-time failure after turning on the machine, the code will disappear. |

If your situation is not similar to any of the cases described above, unfortunately, you will have to call a specialist.

Finding the cause of the malfunction

If, after starting the program, water is not drawn and the machine shows error F5 on the display, there is a possibility that the fill valve may break. But before disassembling the Atlant washing machine, you need to rule out other possible faults.

What do we have to do:

- Check the filter mesh between the inlet hose and the Atlant washing machine. A filter clogged with debris will not allow water to pass through normally, so remove the element and remove the blockage.

- Turn the water supply valve. When opened incompletely, low pressure is generated, so the valve must be opened at full capacity.

You tried all the methods, but the F5 error did not reset. How then to fix the problem? You need to check the valve itself and its coil on SM Atlant.

Possible faults requiring repair

The technician will be able to accurately determine the reason why Atlant issues the F5 code only after conducting diagnostics. However, so that you can understand the nature of the breakdown and the approximate cost of fixing it, we provide a table of the most common faults that are characterized by error F 5.

| Signs | Breaking | Repair or replacement | Cost (labor only) |

| Atlas does not collect water at all or only at the stage of rinsing clothes. Then the code F5 comes on | Fill valve. More than 2/3 of the reasons for this error in Atlanta are associated with valve failure. This unit, consisting of a housing, a membrane and an electromagnetic coil, opens the water supply to the washing machine. Most often, the coil burns out, causing the valve to fail.

| The faulty valve must be replaced. | from 1600 rub. |

| The machine does not draw water or constantly fills and drains. Error F5 is displayed. | Water level sensor (pressostat) – a unit responsible for measuring the amount of water in the machine. It is possible that:

| The pressure switch needs to be repaired or replaced with a new one. The technician performs diagnostics and:

| from 1700 rub. |

| Atlant does not add water during washing or rinsing, and error F5 appears. | Control block. Most likely, the elements on the board in the water inlet circuit have failed. Also, the reason may be due to the “flat” firmware. | It is necessary to carry out diagnostics and based on its results:

| from 2100 rub. |

| Atlant does not pour water and shows an error code F5. | Damaged wiring or contacts in the circuit section between the water supply valve and the control module. Due to a break in the signal, the valve does not operate at the command of the control unit, and the machine does not fill with water. As a rule, this problem is associated with vibration of the washing machine during operation. In the private sector, wiring is often damaged by mice or rats. | The signal break needs to be repaired. For this:

| from 1600 rub. |

| Leak in the inlet hose . Because of this, the leakage protection system (aquastop) worked and closed the fill valve. | A damaged inlet hose must be replaced with a new one. | from 900 rub. |

*Note! The table shows the price for the work of a specialist without taking into account the cost of spare parts for repairs.

As you can see, there are many reasons for the F5 error to occur. A specialist will help you figure out what exactly is wrong with your SMA. Call RemBytTech:

+7 (495) 215 – 14 – 41

+7 (903) 722 – 17 – 03

Or fill out an online application.

RemBytTech specialists have repaired thousands of Atlant AMAs. Thanks to our experience and professionalism, we provide a guarantee for repairs of up to 2 years. We work conscientiously, we fix it - quickly and right at your home!

Rate this article: 4.9 1 5 14 votes (average 4.9 based on 14 votes)

The procedure for performing repair work

To replace the heating element in the machine, there is no need to have special skills - even a beginner can handle such work. There are no difficulties here, you just need to purchase the original analogue. This should be done after all doubts have disappeared that this is where the problem lies. For repairs you will need a flat-head screwdriver and a nut wrench.

Step by step, all the steps look like this:

- the water supply to the machine is cut off;

- the machine is de-energized, the hoses for supplying and draining water are disconnected;

- To make it convenient to work, the machine should be turned with the back panel towards you;

- the fastening bolts are unscrewed along the entire perimeter;

- All electrical wires are disconnected from the heating element (their connection should be remembered or written down in advance in order to avoid mistakes at the time of connection);

- the functionality of the element is checked using a multimeter;

- After making sure that the heating element has burned out, you need to unscrew the fastening nut and press out the bolt;

- use a screwdriver to pry up the base of the heating element to remove it from the mounting socket;

- the working part is installed, the rubber seals are checked for integrity;

- Now the machine can be assembled and tested for functionality.

Once you have opened access to the heater and determined that it is in working condition, you should not rush to assemble the machine. There is an excellent opportunity to check all wiring and contacts. To do this, take a multimeter and ring each element in turn. It happens that the problem is hidden in the oxide covering the contacts. It just needs to be cleaned.

The last option for checking is the electrical module located at the bottom of the machine, most often near the rear panel. It turns out that by removing the back wall, you can immediately gain access to all problem areas - the heating element, electrical wiring, module. It is easy to get the latter out of the machine; to do this, you just disconnect the chips with the wiring. After this, the module must be tested, and such work can only be performed by an experienced specialist. He can easily identify a burnt triac, which is responsible for the performance of the heating element.