If you repair, let alone sew, clothes yourself, sooner or later you will be faced with the question - Which overlocker to buy, how to choose it correctly among their abundance in stores?

Our website already has a similar article “Which overlocker to buy,” but we decided that additional information would not hurt, the main thing is that it helps you figure out how overlockers differ from each other besides the price, what a knitted overlocker is and which overlocker to choose for your home . At the end of the article, we will try to find out which overlocker can be considered the best, and whether there is such an overlocker at all.

A sewing machine cannot replace an overlocker

It is important to know that a sewing machine cannot overcast fabrics; in any case, it does it completely differently than an overlocker. Therefore, do not trust information that will convince you that this particular model of sewing machine can do everything, including sewing cut edges of fabric. There actually is such a machine and it’s called a carpetlock, and even then, it is rather the closest “relative” of the overlocker, and both the overlocker and the carpetlock have nothing to do with the lockstitch sewing machine, at least not “related”.

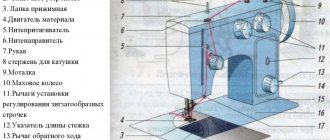

Look at this diagram. This is approximately how the overlock stitch of a three-thread overlocker is formed. With four and five thread overlockers this “pattern” will be even more complex. But you don’t need to know these subtleties; it’s only important to understand that if you want to sew fabrics with high quality, then you need to buy an overlocker for this.

Why a sewing machine cannot replace an overlocker

An overlocker performs cutting, stitching and finishing the edges of knitted fabrics or material that frays quickly. If we talk about the work of a sewing machine, then it sews together the details of the product; some models can embroider and make overlock stitches, but it cannot become a full-fledged replacement for an overlocker, because it only imitates its work.

You can also highlight the fact that overlockers can process fabrics with two, three and five threads, unlike a sewing machine, which only works with 2 threads.

Professional tailors and seamstresses prefer using two devices at the same time.

What is the difference between an overlocker and a sewing machine?

First of all, let's figure out how an overlocker differs from a sewing machine. A sewing machine has two threads, one of which is threaded into the bobbin. The threads, intertwined with each other using a shuttle, form a stitch. At the same time, for the stitching to be beautiful and strong, both threads must be securely pulled together in the stitch. As a result, the seam looks neat and even on both sides. Using a special foot and a zigzag stitch, you can overcast the cut edge on a regular sewing machine. But due to the fact that both threads are pulled together quite strongly in the stitch, such an “overlock” seam cannot withstand much stretching. Simply put, one of the threads may simply burst under load (sudden movement of a person). But with an overlocker this is practically impossible, because the overlock seam is quite strong, stretchable and elastic.

This is achieved due to the fact that the lower thread is not threaded into the bobbin, but directly from the bobbin into the looper. More precisely, two lower threads, since an overlocker has at least two loopers. However, an overlocker can work with two threads (needle thread and looper thread). The second looper is plugged with a special converter or expander (class 51 overlocker).

But three-thread overlockers are already an obsolete sewing technique. Modern overlockers use four threads. And due to this, many combinations are formed that allow you to make different overlock seams. For example, if you remove one needle (or turn it off) from a four-thread overlocker, it will work like a three-thread overlocker. If you put the converter on one of the loopers, it will work on two threads, etc.

Therefore, we can draw a small conclusion. You need to buy a four-thread overlocker (two needles and two loopers, as in the photo). Only such an overlocker can perform several overcast seams and even imitate a flat seam, such as on the hem of a knitted T-shirt.

Disabling one of the needles (right) and the looper (right) using a special plate (converter) will allow you to perform a two-thread narrow overlock stitch, which is indispensable when processing sections of tulle or knitted clothing “rolled” (rolled hem stitch). Hence the name - rolled seam. To choose the right overlocker, pay attention to the availability of this option.

Another advantage of four-thread overlockers is that they are designed for stitching and simultaneously overcasting knitted fabrics.

The main differences between an overlocker and a sewing machine

Shuttle machines use two threads: the upper one is threaded from the main spool, and the lower one is wound onto the bobbin. The stitch is formed by binding, thanks to the shuttle. Using a special overlock foot and the zigzag program, you can quite efficiently process the finished edge (that is, the cut edge) on a regular machine. The design feature of this attachment allows you to sew stitches exactly along the edge of the cut section of fabric. But the quality of such a seam will still be inferior to processing using overlock equipment.

Due to the specifics of its execution, a two-thread seam may not withstand strong tension.

An overlocker uses several threads at once. Today, 4-thread models are quite popular. Also, such devices can be 2-thread (hardly used today), 3-thread or even 5-thread. The lower threads are not threaded into the bobbin, but directly into the looper. This is a metal hook that catches the needle thread during the chain stitch process.

The thread consumption in an overlocker is much higher than in a sewing machine. This is explained not only by the use of several coils at once. The overlock seam itself on such a device is elastic, strong and stretchable due to the increase in the length of each stitch. Therefore, for overlocking equipment it is recommended to use not ordinary spools of thread, but large thread bobbins. Modern overcasting equipment also has a bar with teeth - during operation it slightly stretches the fabric. This option is especially useful when working with knitted material.

Another difference between an overlocker and a regular sewing machine is the stitching function. This means that when overcasting, it trims the edge of the fabric.

Knitted overlocker has a differential conveyor

Before choosing an overlocker, it is advisable to understand the technical details, for example, what is the differential of a knitted overlocker, what is a converter, rolled seam, chain stitch, etc. Then it will be easier for you to follow the suggestions of a store consultant and perhaps refuse to buy an overlocker with functions you don’t need . For example, why do you need an overlocker that has the ability to form a chain stitching seam? If you look at the treatment of burlap on trouser pockets, you will understand what it looks like. And if you don’t find it, then it will be formed like this. The overlocker creates a stitching seam, and an overcast seam is formed next to it. This is only possible by adding a special looper to the overlocker design. This overlocker is very convenient to use in mass tailoring, but it is not at all suitable for home use.

But the presence of a differential in an overlocker is an important and necessary design feature. And its meaning is that when sewing very stretchy fabrics, the edge of the fabric will not stretch under the foot and form “waves”, or, on the contrary, it will deliberately make the edge wavy. For example, if you need to process the bottom edge of a knitted skirt or the flounce of a blouse in this way.

The term “Differential fabric feeding” can be translated into understandable language as the uneven movement of both parts of the conveyor teeth (A and B), as a result of which the fabric under the foot can be gathered or, on the contrary, stretched.

You can choose how the rail should work (stretch the fabric or gather it) using a special switch. It indicates in numbers and graphically the degree of stretching or gathering. As a result, one more conclusion can be drawn. On a modern overlocker there must be differential advance of the fabric. This is especially important to consider when you buy a second-hand overlocker. The fact is that old models of overlockers rarely had this function, since there were no such fabrics.

The difference between an Overlock and a Sewing Machine?

What is the difference between an Overlocker and a Sewing Machine?

Most people who venture into the world of sewing often don't know the difference between an overlocker and a regular sewing machine. The danger of not knowing how to differentiate between the two is that you could end up buying the wrong piece of sewing equipment. Therefore, it is important to educate yourself so as not to make a costly mistake.

If you are a novice sewer and don't know much about the tools used in the sewing craft, you might take a quick look at a sewing machine and a serger and not know that they are two machines designed for completely different purposes. After all, they both have a very similar design. However, there are a few differences and this guide will delve into that to help you make an informed choice about what type of machine to buy.

Differences between a sewing machine and an Overlocker

Before highlighting the differences between a sewing machine and an overlocker, it is necessary to define what each machine does. Essentially, an overlocker is a special type of sewing machine. A typical overlocker is designed to join the edges of one or two pieces of fabric using a cloud/overlock stitch and trim the seam allowance as you sew. Simply put, a serger can sew, fog, and trim excess seam allowance in one pass. Cloudy weather creates locks around the seam to ensure the edges of the fabric don't unravel. Although its function is more specialized, a serger can really speed up the process and create a neat, professional-looking finish.

Some regular sewing machines have an overlock stitch feature that can handle hemming and edging tasks. However, the stitch will lack the stretch and strength that you can only get from a multi-thread overlocker. Moreover, a regular sewing machine cannot sew, fog and trim everything in one step.

However, sewing machines have a wider range of features that you won't find in a serger. For example, these machines typically have more decorative stitch features plus they come with presser feet and attachments for sewing zippers, creating buttonholes, making quilts, and more.

Here's a quick rundown of the differences between an overlocker and a sewing machine:

As mentioned above, a serger ties layers of fabric together and trims away excess seam allowance at the same time. With a regular sewing machine, you'll have to cut your project first and then sew because there's no built-in blade to trim off the excess fabric that sits right in front of the needles.

Unlike a sewing machine, a serger can use three to five cones of thread at a time. Multiple threads are used to create different types of overlock stitches. Basic sewing machines use only one thread, although there are some models with dual needle systems that use two threads.

Another important difference between typical sewing machines and overlockers is speed. The latest units can sew about twice as fast as most home sewing machines. Therefore, a serger can produce professional results in about half the time it would take you to complete the same project with a regular sewing machine.

In terms of structural differences, a serger typically has a telescopic needle bar through which multiple threads pass after exiting the cones. This distinct rod lies horizontally above the neck of the serger and is noticeably missing from a typical sewing machine. Additionally, sewing machines generally have shorter necks than overlockers.

Sewing machines are flexible in that you can turn your fabric and sew it with either the left or right side of the needles. With an overlocker you can only serge on the left side of the needle.

Now that you know the main differences between a sewing machine and a serger, you may be wondering which of the two units to buy. Well, the truth is that overlockers and sewing machines complement each other, and when both are used, you will realize that they make a great team. There will come times when you actually have an overlocker, and situations when a sewing machine is simply irreplaceable. Let's take a look at when you'll need any of these machines.

When to use an Overlocker over a sewing machine

If you work on numerous sewing projects, then it is wise to invest in a serger because of the speed factor. You'll work more efficiently with a serger than you would with a conventional sewing machine for hemming, seam rolling, or edging tasks. To demonstrate how quick the operation can be, think about what goes into hemming pants with a regular sewing machine.

First, you'll have to trim the bottom with a rotary blade or scissors to remove any excess fabric. The next step is to zigzag the bottom to prevent the fabric from unraveling. You would then fold the seam allowance, iron and fold the seam allowance again. Finally, the hem will be sewn using a straight stitch using a twin needle sewing machine.

With an overlocker, the same process can be completed in a few steps. All you have to do is fit the bottom of the trousers, fold once and tighten the hem.

When to use a sewing machine over a serger

A regular sewing machine is essential if you want to insert zippers, make buttonholes, quilt a blanket, topstitch, and create decorative stitches. An overlocker cannot perform any of these functions. However, there are some sewing machines that come with the ability to fog the edges of the fabric. Investing in such machines would be ideal if you cannot afford an overlocker or do not have enough space for an additional sewing unit.

You will find that sewing machines that typically use an additional presser foot that turns them into a serger, or they may have this feature built-in.

It's important to do your research beforehand because different models with this feature vary in design. Keep in mind that while this may be a cheaper alternative, a serger produced by a twin needle sewing machine cannot compare to an overlocker when it comes to stitch quality. Bottom Line

While the cost of purchasing a serger in addition to owning a standard sewing machine can be prohibitive, having both of these sewing machines is well worth the investment, especially if you sew a lot.

Choosing an overlocker, additional characteristics

When we need to choose any equipment, we first of all focus on someone else’s opinion expressed on a forum or a review left in an online store. But most often such statements are too subjective, and sometimes overly emotional. Unsuitable threads or needles can cause the overlocker to work unstably, resulting in negative comments. Modern overlockers are manufactured using new technologies, which practically eliminate all sorts of defects of overlockers of old brands (stitch skips, thread breaks, etc.). The only thing that manufacturers focus on is the price. The lower the price, the fewer technical capabilities the overlocker will have.

But you may not need some of them. For example, turning off the overlock knife. The upper knife moves to the left and rises up. This way, when overcasting the cut edge, there will be no additional trimming of the fabric.

And this lever regulates the length of the stitch, that is, the density of the overlock seam. Perhaps the most inexpensive models will not have this option.

Another lever that not all overlockers have. With its help, you can adjust the width of the overcasting stitch (narrower, wider), which is important when making a rolled seam, but not at all necessary for standard overcasting of fabric.

A good creel is also a necessary thing. It is important that a coil of thread that accidentally falls off the spool does not cling to sharp corners and protruding parts of the overlocker body, otherwise the thread will break. As for the choice of threads, it is best to use threads on a high conical bobbin for an overlocker.

How to thread loopers

An overlocker with automatic threading saves a lot of time. By the way, the thread is threaded pneumatically or mechanically. However, it is much more reliable and efficient when both overlock loopers are clearly visible and threading can be done without difficulty using tweezers. We advise you to pay special attention to this, since you have to thread it often and the more convenient the access to the overlock loopers, the easier it will be to do this and the stronger your nerves will be.

Such a “trifle” as the threading pattern is also important. If you don't use your overlocker often, it's easy to forget how to thread, especially the loopers. It takes time to look for instructions and look at the diagram; it’s another matter when there is a bright and colored sticker glued to one of the covers or the body of the overlock machine, from which you can quickly and easily figure out how to thread the thread. By the way, when buying in a store, try threading the thread into the left looper yourself; perhaps after that you will decide to choose a different brand of overlocker. And in general, no one forbids you to try to sew pieces of fabric of different quality that you took with you in advance. Then you will be able to determine exactly which overlocker to choose.

Well, now you have an idea of how to choose an overlocker, what you need to pay attention to and what functions a modern knitted overlocker must have. All that remains is to find out which overlocker is considered the best and whether such an overlocker exists at all.

Modern four-thread overlock.

Can a sewing machine replace an overlocker?

The overlocker itself comes as an addition to the sewing machine, increasing the functionality of its capabilities. But it is worth noting the fact that it can work well without it. And until recently, this was the case, because overlocking practically did not appear in stores, and only a few professional seamstresses knew about its existence.

A sewing machine is designed to join the edges of fabric. But, albeit slowly, it can process the edges of dense materials. In the case of light fabrics, for example, chiffon, it is better not to use it, as the appearance of defects and stretch marks is inevitable.