Many who are interested in sewing sooner or later ask themselves the question: What is a flat-stitch machine and what is the peculiarity of the so-called flat stitch (flatlock, flatstitch), or in everyday life - a cover stitch?

Most often, a flat seam is associated with some unusual overlock seam. But in fact, this is a completely different type of sewing stitch (photo) and it is formed differently than an overcast stitch, and a special sewing machine is required for this. And the fact that sometimes you can see the flat stitch function in an overlocker advertisement is just an advertising gimmick. Not a single overlocker can make a full-fledged flat seam, but only an imitation that looks like a cover stitch.

In addition to the cover stitch, a flat seam can only be performed by a carpet locker. Moreover, the seams of the carpet can be either overlock or cover-stitched. It’s true that the price of such a universal household machine is equal to the cost of two: an overlocker and a stitcher.

In this article we will look at the features of the formation of a three-needle flat seam on household cover stitching machines. If you are interested in other capabilities of cover stitching machines, see the article Industrial Cover Stitching Machine.

Appearance of a flat seam on factory products

In the top photo you saw a 3-needle version of a flat seam, from the wrong side. But this option is rare; most often a 2-needle flat stitch is used, which you can see on any T-shirt (sleeve hem, hem). Most likely this is due to thread saving. So, for example, processing one T-shirt on a stitching machine will “eat up” at least 3 spools of thread (200 meters each). That is why only large conical bobbins are used for cover stitch machines.

Threads and material for flat seam

The spools of thread used for flat joining should not be small. For example, to process one T-shirt you will need about 3 medium-sized reels (200 meters each). Depending on the capabilities of the sewing equipment, a flatlock on an overlocker can be two or three thread, but the first option is more popular, most likely due to savings.

As for the thickness of the threads, it is best to choose thin lavsan options; they should be smooth, elastic and durable. Such threads will allow you to make a high-quality connection without missing stitches, and it will be easier for the equipment to work. Cotton threads of 40-45 counts, standard for household sewing machines, are not suitable for flatlock. When the seam is stretched, such threads can break, and they also tend to fray during wear. Such a seam will look sloppy.

As for the type of material, any fabric can be used here, although initially this seam was intended specifically for knitwear.

Thin and durable lavsan threads No. 60

Fabrics and threads for cover stitch machines

This version of the coils is the optimal “size” for home use. For comparison, factories use bobbins the size of an inverted bucket.

What is also important to know about threads is that the thinner they are by number, the stronger and more elastic, the “easier” the machine will work, the better the quality of the seam. These machines are very sensitive to the quality of the threads and the slightest thickening on one of them during broaching will lead to the appearance of loops in the stitch. And you should completely forget about thick cotton threads. No 45 threads, 40 threads, threads like LH, LSh, etc. Only smooth and elastic lavsan threads (synthetic) and preferably on conical bobbins.

Otherwise, the machine will malfunction: skips, loops, uneven and constantly changing thread tension in the stitch, and sometimes even thread breaks. By the way, if the fabric suddenly gets “stuck” in the needle plate, never try to pull it out by force. Remove the foot, remove the needle plate and only then decide what to do.

As for fabrics, any will do, but initially the flat-stitch machine was created for sewing modern knitted fabrics.

Threads for cover stitch machines

The number of installed bobbins is one of the most important distinguishing characteristics of sewing machines with loopers. The most common option is machines with four or five threads; they are suitable for processing not only knitwear, but also any other types of fabrics.

The selection of threads for cover stitch machines is an extremely important aspect. This sewing material must be purchased of the proper quality; moreover, the simultaneous use of threads of different thicknesses or compositions is unacceptable. Otherwise, the seam will be defective. Most often, a flat seam on a carpet locker or cover stitch will have skipped stitches, but the settings in the machine may also fail, which is almost impossible to correct on your own. It is better not to experiment with the choice of threads and take all the bobbins from one batch - this will be an additional guarantee of the safety of the equipment.

Adjusting the thread tension of the cover stitcher

Can only an overlocker perform a seam stitch? No, of course, just overcast. And flatlock sewing machines can sew like a regular machine sitting on your desk. The only unique feature is the type of stitch. The stitch will resemble a pigtail from the inside out and it is called a chain stitch (processing the lining of jeans pockets, etc.).

This diagram clearly shows what kind of seams a household flat-stitch machine can make and the recommended tension of the needle and looper threads. The latter option uses 3 needles and a looper.

If for a regular sewing machine the thickness of the threads and their tension are not so important, then for a cover stitcher this is the first condition for its high-quality operation. The threads are braided into such complex “knots” that the slightest change in the tension of any of them will lead to a deterioration in the appearance of the entire stitch.

Start adjusting the tension of each flat stitch thread from the minimum tension values.

Peculiarities

The most characteristic distinguishing feature of the described type of seam is its elasticity. Flat stitches can be produced by different types of machines - cover stitchers, carpet lockers and overlockers. Each of them has its own advantages and disadvantages, which will be discussed further.

The cover stitch is also interesting because of how it fits onto the fabric. To achieve optimal elasticity, during stitching, the machine can tighten or stretch (depending on the settings) the feed material after each next needle step. In addition, thread tension is also specific to these sewing machines: unlike shuttle mechanisms, a flat-stitch sewing machine makes the stitches “relaxed”. Yielding to tension in the finished product, the loops stretch but do not tear, which ensures the integrity of the knitted fabric. The joints of the two parts being ground together are edge to edge, rather than being layered flush on top of each other.

What is a differential rack

The flat seam is inextricably linked with another obscure term - differential. If a flat seam can somehow be imagined, for example, in the form of a flattened flounder. How do you understand what a differential is?

So as not to bore you with technical details, let me explain it to you simply. If you sew knitted fabric tightly on a regular sewing machine, you can stretch it while sewing with your hands, or you can, on the contrary, “drive” it under the foot with a fingernail or an awl. This is how the differential works, that is, a rack with teeth (under the foot). Only in this case, the lath consists of two parts and, depending on the need, these ladle ladles either stretch the fabric during sewing or, on the contrary, compress it.

What is it for? Squeezing under the foot increases the stretchability of the seam and its strength. This quality is important for sports knitted clothing, clothing for active recreation, etc. And stretching of knitted fabric leads to the appearance of a wavy edge (overlock) or a wavy seam (covering). This effect is mainly used as a decorative element for finishing clothes.

This handle (photo) regulates the operation of the differential. N is the normal position, that is, the rack works as one whole. Numbers higher than one means the strip will stretch the fabric; numbers lower than one means it will compress it.

What is a differential conveyor

Making a flat connection is inextricably linked with this part of the sewing equipment: an overlocker must have such a part. This is a special rail with two legs. During work, they either tighten the material or stretch it. Their work is reminiscent of making seams on ordinary household machines, when the master either pushes the material under the presser foot with his hands or stretches it.

This function provides the highest quality connection on knitted and other “stretchy” types of fabric. By compressing the material under the foot, the stitches are stretchable and durable. And if you stretch the fabric, you can achieve a decorative effect when a wavy edge is formed.

The differential rack control is located on the device body. In a neutral position, it works as a single unit, positive numbers are modes of tissue stretching, negative numbers are contraction modes.

What is the difference between a flat-stitch machine and an overlock machine?

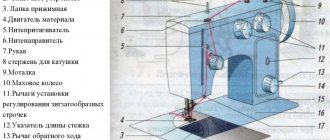

In this photo you see a cover stitching machine. Even externally it is easy to see the difference between it and an overlocker. I didn’t count how many of them there are, but at least ten, try to find them. Some of them have already been mentioned above, some I will name now.

A flat stitch machine does not have knives. Why does she need them if the machine doesn’t sew fabrics?

Here's another one. A flat-stitch machine has only one looper, while an overlocker has two loopers.

This photo shows just the knives and loopers of the overlocker. Please note that in modern models of overlockers the upper knife is placed differently, paired with the lower blade. Very convenient and much safer.

In this video you will learn what a flat-stitch machine is designed for and how it differs from an overlocker. The video is in English, but you can switch the captions to your preferred language.

Flat stitch on overlock

Among the variety of possible stitches, our overlocks can make a flat seam.

Flatlock seams can be 2/3 thread, wide or narrow. The flat stitch can be used in a variety of situations. The key advantage is that it is not very convex. This is a fantastic stitch for hemming seams, which is increasingly being seen on finished garments. This is also a great seam for very fitted items such as sportswear.

Two sides of the seam

Typically our fabrics and sewing projects have an outside and an outside. Reasoning in this context, our flat lock is in fact reversible. The “right” side of the loop looks like rows of small strips of thread or a ladder.

The "wrong" side of this stitch shows our looper thread(s) as they zigzag back and forth across the division of our fabric.

Either of these sides can be used, depending on the project. The outside of the stitching can be used as a blind stitch. And the reverse side has a more decorative appearance and, when using decorative threads, can create really interesting looking and feeling seams.

2/3 - thread seam

Thread count correlates with seam strength, meaning our three-thread flatlock stitch will be stronger than its two-thread counterpart. Keep this in mind when choosing a stitch for your project.

If you are sewing a high-stretch material for active wear that will experience heavy stress and stretch in all directions, choose the stronger three-thread version of the seam. However, when used as a hem for loose clothing or simply as a decorative seam, or for sewing thin fabrics, use a double thread stitch.

Narrow and wide seam

The choice of wide or narrow stitch may depend on the thickness of the fabric being sewn. Or it could just be a visual choice - since this seam is very visible, choose the width that you prefer visually.

Seam setting

Unlike overlock stitching, we have to go beyond the “standard” settings of our overlockers. But don't be afraid - it's very simple. Remember that when we only use one of our needles, it is important to remove the unused needle from the machine.

When a seam is first stitched, it may not seem all that unusual at first. But when the two layers of fabric open and stretch away from each other, the ladders of our stitch open up and the loops lie on the other side.

When sewing a two-thread seam, we do not use an upper looper. To stitch correctly, we need to install a converter. This is a tiny item that is stored in the looper door when the machine is open. Insert the blunt end of the converter into the slot on top of the looper. Then gently pull the pointed end around the back of the looper to thread it through the looper eye.

Sew the seam again and then pull the fabric apart. Here you can see the difference between the two-thread and three-thread versions of this stitch.

Try using interesting threads

You can create some really cool decorative stitch effects when threads of different properties and textures are combined into a flat stitch. These threads will perform best when used in loopers rather than needles.

The textured nylon threads create a very soft, fluffy seam that is great for knits. Heavier cotton or wool threads create full stitches. You can even try metallic threads in the loopers to make your stitching even shinier.

Overlock

This is a type of machine that is usually used for overcasting sections of products, however, there are models that provide a flat-seam function. Initially, overlocks go on sale with a special knife that cuts the fabric after it has been stitched. When switching the equipment to the stitching mode, the knife must be removed. The working presser foot also changes, the level of pressure of which can be adjusted depending on the thickness of the supplied material.

Before you start sewing, you need to set up the machine and adjust the thread tension manually. This is not an easy task and it is better to practice on a rough version of the fabric first. A flat seam is made using an overlocker along the fold of the material. After completing the stitching, it needs to be unrolled, as a result of which the loose loops are pulled out, forming the required wide seam. A characteristic feature of the overlocker is the absence of sleeve overhang. It is believed that an overlocker is a machine for sewing non-elastic fabrics, but this is not entirely correct. Modern models are equipped with a special differential rail, which allows you to successfully work with knitwear.