The devices responsible for ensuring that everything works smoothly are control elements represented by electronic units and sensors. One of the most important parts of any washing unit is the pressure switch.

If the water level sensor is faulty, the control module of the washing machine processes the signal incorrectly or does not receive it at all from this device. In such a situation, the water level in the tank is not controlled, and therefore underfilling or overflowing occurs. All signs of a malfunction of this sensor will be described below.

What is a pressure switch

When wondering what a water level sensor is, you need to understand that any process related to the supply of water to the washing unit must be strictly regulated by a given program. According to the principle of operation, the pressure switches of washing machines Lg, Samsung, Electrolux, Candy, Ariston or any other brands do not differ, but there may be differences in design, appearance and characteristics. This device looks like a small plastic piece, usually round in shape, with electrical wiring connected to it and a tube from the washing tub tank.

The pressure switch in a washing machine is a device that controls the water level in the tank, without which the operation of any unit is simply impossible. The element is small in size, and its replacement does not require major capital investments, but the importance of this part is enormous.

Pressostat adjustment

To adjust the part that controls the water level in the washing machine, there is no need to call repair specialists, because such work can be done independently. You must follow the sequence of actions exactly and work carefully. So, the algorithm for adjusting the pressure switch of a washing machine is as follows:

- the laundry washing unit is disconnected from the electrical network and water pipe;

- Having unscrewed the bolts and disconnected the wiring, remove the pressure switch;

- we find special screws that are used to tighten or loosen the contacts inside the device;

- remove the sealant from their surface.

All of the above actions can be attributed to the preparatory stage, because the main work on adjusting the sensor is still ahead. You will have to use the stripped screws to try to catch the moment of approaching and opening the contact group. In this case, the well-known “poke method” is used, because only a professional washing machine repair specialist can have a special device for performing such work. You will have to act as follows:

- the first screw is turned half a turn, the pressure switch is connected to the machine, the washing machine starts in operating mode;

- If initially the car took in little water, and after adjusting the fluid it became more, you are on the right track. All that remains is to unscrew the screw further in the chosen direction and fill it with sealant;

- if manipulations with the bolt produce the opposite result, it will have to be unscrewed in the opposite direction, making one or one and a half turns.

Related article: Washing machine does not drain water well

Operating principle of the sensor

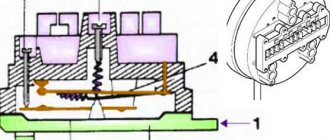

The operating principle of the water level switch of a washing machine is based on the effect of pressure on a special membrane (diaphragm). When water is drawn into the tank of the washing unit, water fills the compression chamber and pressure corresponding to the level of the collected water is injected into the sensor housing through a special tube.

The compression chamber is usually built into the drain pipe. The pipe itself is connected to the tank and the volute from the drain pump using special clamps. There are cameras soldered directly into the tank itself. It happens that these cameras become clogged with slurry and dirt over time!

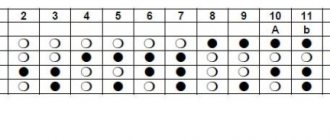

When pressure is applied to the membrane, the contacts close and open, as a result of which a signal about incoming water is sent to the control module. There are several types of pressure switch: pneumatic (mechanical) or with an oscillating circuit (electronic), in this case the mechanical principle will be described. They are also divided into single-chamber and double-chamber.

Double-chamber pressure sensors are specially developed for washing machines with small and large loads. When the load is low, one membrane is activated and water is supplied in a minimum amount. When the drum is heavily loaded, the second membrane is activated, the contacts close and the control processor gives a command to supply the maximum amount of water.

As a rule, the membrane installed inside the sensor is made of rubber or elastic polymer and is designed for repeated on and off cycles. The operating principle of the pressure switch combines the sequential influence of air pressure on the mechanical part, above which the electrical contacts are located, and a direct electrical impulse on the control processor of the washing unit.

Signs of a malfunctioning pressure switch

As with any element of a washing unit, malfunctions can occur in the water level sensor, leading to malfunctions of the entire washing unit. This is expressed in the following signs:

- the washing process begins in the absence of water;

- water is supplied to the tank in too much or too little quantity;

- after the wash is completed, water is not removed from the tank;

- the laundry spinning program is not processed;

- There is a periodic pumping out of dirty water and supply of clean water in the rinsing mode, which is not typical for normal operation;

- malfunctions of the washing machine in all washing programs.

In addition, due to the lack of water in the tank and the heating element being turned on, smoke and a burning smell may appear. Typically, such inclusion ends with the replacement of the heating element. A faulty sensor can also lead to failure of the electric motor due to constant overload on it, since more water is often drawn into the tank than the required level.

Sensor malfunctions

During malfunctions, the owner may wonder how to check the pressure switch of a washing machine? The following phenomena may indicate problems with the sensor:

- Start of washing without water in the drum. In addition, the automatic machine can turn on the heating element without a sufficient degree for washing. This can lead to burnout of the heater, which is not designed for such work.

- The system takes in too much liquid, or does not take in the required amount. A situation may occur with a non-stop supply of water, up to critical breakdowns in the system.

- Waste water is not removed from the tank at the end of work. Also, after the spin program has completed, the loading hatch may be blocked. It should be noted that problems with the spin system are not necessarily caused by a non-working pressure switch.

- The automatic machine does not perform the laundry rinsing algorithm.

Related article: How to connect a washing machine

Such a small part performs a very important job in the machine. Periodically checking its operation will help you avoid major troubles.

Where is the pressure switch located?

In washing machines from most manufacturers, the sensor is installed on a bracket in the upper part of the body on the side wall, however, in each specific case, you can find out where this device is located only by removing the top cover or side trim of the unit. Very rarely, on vertical types of machines, the pressure switch is located at the bottom of the unit.

A distinctive feature that makes it easy to find the sensor is a small-diameter tube connected to it, usually made of rubber or polyvinyl chloride.

Pressostat: what is it and why is it needed?

Many people are interested in what a pressure switch is and what the purpose of this device is. A pressure switch is a small device that helps regulate the water level in the tank, since different washing programs require different amounts. The pressure switch is a small round device to which wires and a tube are connected, connected to a high-pressure reservoir. When liquid is collected in the tank, the required pressure is applied through a rubber tube and the relay opens or closes the contacts, thereby sending a signal to the washing machine about the required water level.

Important! Manufacturers do not recommend changing the standard settings, as this can lead to significant loads not foreseen in the design of the structure.

The pressure switch is indispensable in a washing machine, as it allows you to adjust the water level

In order for the pressure switch to work correctly, it must be checked and adjusted to the required pressure. This will help him give a signal in a timely manner and start the wash. Basically, the sensor is configured by the manufacturer, however, if you wish, you can do it yourself. To do the adjustment yourself, you need to change the position of the adjustment screw located directly on the body.

Among the best sensor models are the following:

- Metalflex HD505;

- T85;

- T85M;

- SPS-L11X.

If the pressure switch breaks down, the device control module would not be able to determine whether the tank is filled with water and how much of it is there. The location of the sensor in a washing machine can be completely different, however, it is generally located at the top of the device. This is a small cylindrical part with wires connected to it and a tube made of plastic leading to a high-pressure reservoir. The pressure vessel can be free-standing or be a specific part of a plastic housing. When water is drawn into the washing machine, pressure equal to it is transmitted. In this case, connection or disconnection of the relay contacts is observed. The washing machine receives a corresponding signal that there is enough liquid in the tank.

Replacing the pressure switch

If checking the water level switch shows that it is faulty, then replacing it in most cases does not cause any particular difficulties. Therefore, you can change this device yourself, without resorting to the help of specialists. Repairing the device itself is not only impractical, but also useless, since the case is non-separable, any attempt to get to the internal parts will lead to a violation of its integrity. Some types of water pressure sensors must be opened, but this is a rather lengthy process and requires some competence in this area.

Replacing the pressure switch in a washing machine begins with disconnecting the vacuum tube and electrical contacts. By loosening or unscrewing the mounting bolts, remove the sensor. Reinstallation of the device is carried out in the reverse order of dismantling. Although the vast majority of sensors are similar in appearance, it must be taken into account that this element is configured for a specific model and brand of washing unit.

When carrying out all types of work, safety measures must be strictly observed. Before starting work, it is imperative to disconnect the plug of the washing unit from the power outlet.

How to check the pressure switch yourself

The water level sensor in the washing machine tank can be checked for functionality at home. To do this, it must be dismantled. Carefully inspect the pressure switch housing and vacuum tube for mechanical damage (cracks, chips, abrasions). Carefully check the tube and inlet fitting for blockages, and if there are any, clean them with a plastic stick or soft wire.

The pressure switch can be checked for functionality by blowing air into its housing using a small hose identical in diameter to the standard one. To do this, attach the hose to the inlet fitting and blow lightly into it several times. In connection with the pressure force, characteristic clicks should be heard inside the housing. The number of clicks depends on how many water levels a particular model of washing unit provides. Their absence indicates a malfunction.

The second way to check the water level sensor is to measure it with a multimeter. This method allows you to be almost one hundred percent sure that the pressure switch is faulty. By connecting the device to the pressure switch, you need to measure the resistance. If the resistance does not change when air is blown into the device body, you can safely send the faulty element for scrap.

In order to avoid undesirable consequences for the entire washing unit as a whole, it is necessary to carefully monitor its operation, and if the slightest malfunction is detected, take the necessary measures. By replacing a relatively inexpensive pressure switch in advance, you can extend the life of the entire washing machine for a long time.

Typical faults

The failure of the water level sensor is most often indicated by malfunctions:

- The washing cycle starts before the washing machine has filled with water. When the washing mode is turned on, the control module turns on the heating element to heat the water. Without water in the tank, the heating element will overheat and burn out.

- There is not enough or too much water for washing. The control module may not close the inlet valve due to a faulty pressure switch. This leads to the machine leaking and flooding the room.

- After spinning, the laundry remains wet. The water from the tank is not completely drained after the washing cycle.

- At the end of the session, the water does not leave the tank and the machine does not open the hatch. The pressure switch does not send a signal to the control module about the presence of water and the module does not turn on the drain pump.

- The washing machine does not work and shows an error code on the display. This is only possible in cars with self-diagnosis. Decipher the error code to find the broken part.

[custom_ads_shortcode3]

Setting the washing machine pressure switch

Along with the serviceability of all elements of the sensor, its precise adjustment is also of utmost importance. It must operate clearly at certain pressure levels, sending the necessary signals to the central control processor. The amount of water supplied to the tank depends on this, which is different at each stage of washing.

Accurate calibration of pressure switches is carried out at the manufacturer's factory using special ohmmeter devices, and under normal conditions no additional adjustment is required. Washing machine repair technicians not only do not recommend, but also categorically deny the possibility of adjusting the pressure sensor at home.

On the adjusting bolt of almost any pressure switch there is a seal, the integrity of which must not be violated. Even if you simply insert a screwdriver and turn the bolt half a turn, and then turn it the same half a turn in the opposite direction, the fine adjustment will be lost. In this case, no one can guarantee the normal operation of the washing unit.

Experiments with adjusting the water level sensor, as a rule, lead to failure of the heating element or the entire unit as a whole. If the cause of malfunctions in the washing machine is indeed the pressure switch, it is replaced entirely, and it is best if this operation is carried out by a service center technician, followed by high-quality diagnostics.

Setting up the pressure switch

To supply the correct volume of water to the washing machine tank, the sensor must be configured correctly. The setting is performed by the manufacturer, but having experience in repairing household appliances, you can adjust the pressure switch yourself. If the washing machine is under warranty, take the device to a service center.

The water level sensor in the washing machine is adjusted using adjusting screws. The moment of closing and opening the contacts is set. It is necessary to adjust the sensor only with the device disconnected from the power supply. There should be no water in the tank of the machine during setup.

The adjustment is made by gradually turning the adjusting screw. It is recommended to turn the screw no more than half a turn at a time. After each turn, close the protective cover of the washing machine and turn on the water supply program.

Adjust until the fluid level in the tank reaches the optimum level. After adjusting the sensor, secure the screw in the socket with a sealing compound. This will prevent spontaneous rotation due to vibration during spinning.

[custom_ads_shortcode1]