A sewing machine is the main tool of a needlewoman. You need to choose it very carefully, having decided on the necessary functions. The appearance should be aesthetic, and the functionality should fully make you feel like a professional. But not only the quality of the device itself affects the service life; proper operation of the device is also important. In order for a sewing machine to serve for a long time, it is necessary to properly maintain it: change parts, clean and lubricate, and adjust mechanisms. This article will tell you how to lubricate a sewing machine, why lubricant is needed at all, and what lubricants are used for this.

Why do you need lubrication?

A sewing machine is a complex device. When creating a stitch, many mechanisms work simultaneously. If you do not clean and lubricate important components on time, the mechanisms will become clogged and fail. This will entail breaking threads, creaking, knocking and general noise. In the worst case scenario, the machine will not work and you will have to replace it.

How to sew a pencil case

Lubricants are needed for:

- Extending service life and improving overall quality of work;

- Easier needle movement;

- Reducing noise during operation;

- Prevent thread breakage and fabric damage;

- Easy and quick adjustment of mechanisms.

Old manual typewriter

Important! Old machines are lubricated every 90 days, while new ones require inspection every 6 months. If the work intensity is low, you can lubricate moving parts once a year.

With constant use, it will immediately become noticeable when new oil is needed.

Old unit Podolsk

What you need for work

To lubricate the machine correctly, you should prepare everything necessary for this. And you may need:

- Machine oil. You can buy it at any hardware store. Even 100 grams of oil will be enough for your head;

- Medical syringe. It is convenient for them to lubricate those parts of the machine that are difficult to get to without disassembling it;

- Brush. A small brush will do a great job of removing dust, dirt and old oil;

You may be interested in: Patterns and sewing of children's shirts for boys

Cleaning kit

- Screwdriver. Some things still have to be unscrewed. On some machines you need to disassemble the body, and on some - certain parts and covers;

- Napkin or cloth. Remains of new and old oil and dust can be safely removed with a napkin;

- Film for surface protection. If the machine has not been cleaned for a long time, there may be a lot of dirt on it, which will end up on the tablecloth or carpet.

Important! This is exactly the set you need to perform high-quality professional cleaning conscientiously.

Sewing machine Veritas

Lubricant for industrial sewing equipment

The latest industrial devices have an automatic lubrication system. You just need to look at the oil level from time to time and fill the reservoir if the mark is below normal.

You might be interested in: Creating a pattern and sewing a transformable dress with your own hands

Some older industrial sewing machines, like household sewing machines, are lubricated using a drip or dry lubrication system. In this case, the main rubbing parts and mechanisms must be processed manually and only by qualified specialists.

Typically, industrial units are treated with mineral or synthetic oils. Among synthetic compounds for sewing mechanisms, silicone ones are in particular demand. This type is used only for certain parts of the device, namely:

- blades and knives;

- motor parts and assemblies;

- plastic and graphite elements.

Treatment should be carried out using a coarse brush and spray.

Tools for cleaning and lubricating Janome machine

Which oil to choose

Oil for such purposes has a special viscosity indicator. If it is too viscous and stringy, then the deep parts will not be lubricated properly, but they bear almost all the load. A composition that is too fluid will also not be useful, since it will not have time to penetrate deeper and will simply drain. This means that the lubricant for the sewing machine should be moderately viscous. Usually this parameter is directly indicated on the box and is recognized upon purchase. When working on a high-quality production machine, lubrication may not be necessary, since such units have an automatic lubrication system.

Regular medium viscosity oil

The best oil will be the one that came with it. If it is not there, you need to choose a better quality lubricant. You can find recommendations for choosing on the website of the manufacturer of this machine. Under no circumstances should you use vegetable oil: this can lead to serious damage and rapid contamination.

Toyota Power Fabriq

What oil to lubricate a sewing machine

When you bought a sewing machine, you probably came with a set of tools with all sorts of screwdrivers and extra presser feet. So in this box or bag you should have a plastic container with oil that is used to lubricate the sewing machine. Don't worry if you don't find the oil in the kit, you can buy it at any hardware store.

Which components need to be lubricated?

It is necessary to determine which operating units of the device need lubrication. This is usually indicated in the instructions for the machine. If it is lost, you can find an electronic version on the Internet on the same official website of the manufacturer. You can do it even simpler: lubricate all the components where there are moving parts. For cleaning and lubricating, you will need a table from which you must remove all valuables in advance so as not to stain them with oil and dirt.

Lubricating the top

How to properly use a sewing machine

In addition to the basic rules for working with fabrics, needles and threads, described in the instructions for each sewing machine model, it is necessary to regularly clean and lubricate the complex mechanism.

- independent – carried out at least once a month during active use;

- professional - it is recommended to do it once every 2-3 years in a repair shop.

Proper storage of the device is also considered an important criterion for the safety of metal components if it is rarely used.

Sequence of disassembling and lubricating the machine

Disassembly of the machine is necessary before lubrication. By looking at it, you can immediately identify elements that can be removed and unscrewed. The general operating procedure is as follows:

- Remove the cover from the needle bar by unscrewing the screw and pulling out the cover;

- Turn the device over and unscrew all the bolts at the bottom;

- Pull back the speed selector knob and remove it;

- Remove the cover from the side without touching the flywheel;

- Unscrew all remaining screws;

- Remove the handle fasteners;

- Lower the presser foot handle down;

- Separate the remains of the plastic housing;

- Remove the shuttle from the holder.

You might be interested in: Features of using fabric shoulder bags

The device is disassembled

No further disassembly steps need to be taken. All elements can be reached with your hands or a syringe. The further procedure for lubricating the components is as follows:

- Place the machine in a position as if it were going to be used for sewing;

- Fill the syringe with lubricant;

- Slowly turn the flywheel counterclockwise;

- Drop oil onto all existing parts and their joints, which will begin translational and rotational movements;

Digging from above

- Under no circumstances should you touch plastic parts and gears that have already been lubricated with a special compound, this may damage them;

- Lubricate the needle bar parts at friction points;

- Remove excess grease with a napkin or rag;

- Check the progress of the nodes by connecting the power;

- Assemble the machine and give it a couple of hours so that the joints of the parts are saturated with oil;

- Run for a couple of minutes with the presser foot raised.

Digging from above

How to lubricate a Janome sewing machine

Janome are popular machines, so the question is relevant. As with any device, they require constant prevention of breakdowns and lubrication. You need to process at least the main components that set the device in motion.

Before work, it is important to read the cleaning and operating instructions and review all explanatory drawings. You need to remove the cover of the device and pour lubricant into the special holes, and also apply it to the rubbing elements.

Janome Sewist 780D

Brother machine lubrication

No less popular brand of cars. It has its own instructions, but if it is lost, it is important to remind you that a couple of drops of oil are enough for processing. They should only be applied to metal surfaces, avoiding smearing plastic.

Important! The brazer especially needs high-quality wiping of excess oil after processing, as well as idle operation to consume the mechanisms.

Removing the shuttle from the Brother

Singer

High-quality Singer machines require lubrication much less frequently, but still require maintenance. You need to start cleaning them from the needle plate. To do this, the screws are unscrewed and cleaning is performed. Next, the shuttle is cleaned: the cap is removed, and the latches are moved apart. The shuttle parts are removed and cleaned of dust. The same is done with the rotation device itself.

Astralux

To service Astralux you need:

- Remove the needle plate by turning the handwheel until the needle is in the highest position;

- Clean the lower fabric feeder. To do this, take out the bobbin cap and clean the conveyor with a brush;

- Clean the mechanisms and lubricate them. Remove the bobbin and cap and fold the two holders to the sides. When this is done, the shuttle will come out freely and the device can be lubricated;

- Reinstall the bobbin and cap by rotating the handwheel.

You might be interested in: Using conventional acrylic paints for painting on fabrics

Astralux needs roller lubrication

Vertical shuttle machines

They especially need lubrication, even imported ones. The steps are the same: remove the bobbin and move the clamps apart, take out the shuttle parts and wipe them thoroughly. Put everything back. In such machines it is important that the needle bar is in the upper position.

Machines with horizontal shuttle

Most of these machines have a lube-free shuttle, but this is a ploy to sell new equipment when the old one breaks due to improper use. Any moving mechanism needs lubrication.

Electric Brother Artwork with horizontal shuttle

Machines with rotating rotary shuttle

This type of shuttle is the most reliable and lasts the longest. Another advantage is its high sewing speed. This is due to its popularity in industrial machines. For long-lasting operation, you need to clean it and add three drops of oil.

General rules

Before studying the detailed instructions, you should pay attention to some general operating rules, following which will extend the service life:

- If the device is not used for a long time, it is better to cover it either with a special case, or at least with a thick cloth. This will protect the mechanisms from dust;

- Disconnection from the network. Is the machine not in use? Then it needs to be de-energized. This is especially true for the most technologically advanced models with modern electronic filling. A power surge can cause serious damage and failures;

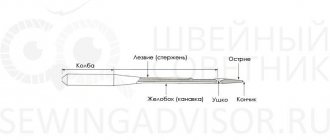

- Regular replacement of needles. In accordance with the operating instructions, the needle is changed every 6 hours if used for home, household sewing and every 4 - for industrial sewing. If such intervals seem too frequent, you need to be guided by sound. When the needle taps too dullly or skips stitches, it’s time to change it; it’s definitely dull;

- Correct needle selection. The needle must match the type of fabric and stitch it easily to avoid increased load on drives and mechanisms;

Children's clothes, knitwear, products based on natural cotton. The best option is standard size 40 cotton threads.

Light items made of chiffon, tulle. The best solution is a 70-80 size reel.

Thick fabric used for tailoring suits is processed with 50-70 threads.

Thin products made from dressed wool, satin, and synthetics look great when processed with threads with a thickness of 40 to 70.

For heavy, dense fabrics (such as tarpaulin), artificial, natural leather, strong threads of 30-40 are used.

- Correct selection of thread. Saving on threads and purchasing low-quality goods is unacceptable. Such savings always have the opposite result; problems appear, in fact, immediately. Poor quality thread can damage the bobbin and ruin the material;

- Buying a quality bobbin. Without a good bobbin, you won't be able to create a smooth stitch. The part must be smooth, without chips at the edges, without other mechanical defects;

- Timely response to incorrect work. You need to constantly “listen” to the sewing machine. If the sound of operation changes, the knock of the needle becomes too dull, the motor begins to hum strainedly, you need to stop the process, carry out an inspection, and try to understand the cause of the malfunction. Operating the device in such conditions can aggravate the damage and provoke the need for expensive repairs.

Caring for a sewing machine with a horizontal hook

You need to purchase a special oil, the main component of which is kerosene, which provides fluidity sufficient to penetrate into all components of the sewing machine. You will also need a small flat-head or Phillips-head screwdriver (depending on the machine model), a brush to collect dust and thread residues, and a soft cloth to collect debris and traces of old used oil.

Some sellers of sewing machines claim that horizontal hooks do not need lubrication, but experienced craftsmen recommend doing it periodically. Any mechanism, even a horizontal shuttle, wears out over time, and lubrication allows you to reduce the load to a minimum and extend the service life.

The most technologically advanced devices, equipped with a rotating rotating shuttle, which are used not only in everyday life, but also in professional sewing production, also require processing.

The operations are as follows:

- Removing the protective window and needle plate;

- Removing the bobbin insert, cleaning the surfaces from various contaminants, including traces of old grease;

- Applying fresh oil to the metal seating element and bearings;

- If you are assembling a bobbin insert, you need to evaluate so that everything is done correctly. Its displacement when the wheel moves is unacceptable. Lastly, the needle plate is installed and secured with the supplied screws.

The needle bar must be cleaned. It can be accessed by removing the cover at the top of the case. It can be fixed either with latches or screws, the exact method is determined by the model.

Sometimes there are assurances that the needle bar does not need to be lubricated, but this is a gross mistake. Its dry running is unacceptable, since there is a high probability of backlash formation, loosening of the needle, and deterioration in the quality of the seam being formed.

Expert opinion

Maxim Malenko

Master of repair of household sewing machines

The part is treated with oil along its entire length; you need to pay attention so that the composition gets onto the clamps and bushings. To understand which connecting rods power the mechanism, you need to turn the wheel. Each connecting rod is thoroughly cleaned and then coated with lubricant.

Caring for a machine with a vertical shuttle

To get the job done, you need to prepare the following:

Lint-free material. A simple piece of cotton fabric will suffice.

Brush with hard bristles. It is not necessary to buy a special brush; an old toothbrush or an unnecessary art brush will do.

Special oil for working with sewing machines.

WD-40. A universal composition, which can be found, for example, in automotive supply stores. The product is presented in the form of an aerosol with a long nozzle tube; it has a fluid consistency, so it easily penetrates into hard-to-reach cavities.

Detailed universal instructions for cleaning and lubricating a sewing machine with a vertical hook are as follows:

- The device is de-energized, the needle is removed from the clamps. This minimizes the likelihood of accidental injury during operation;

- Remove the decorative plug from the screw securing the housing cover. The screw is unscrewed and the screws that secure the bar of the rack and pinion mechanism that moves the fabric are removed. The bar is removed, the area under it is thoroughly cleaned of dirt and thread residues;

- Remove dirt from all connections, remove old grease and apply new one. This is a very painstaking but important process. Lubrication minimizes the coefficient of friction and the device lasts longer. To accurately dose the composition, you should use an oil can; a couple of drops of oil are enough for each compound; excess should be removed with a cloth. By slowly rotating the flywheel, the composition can be evenly distributed over the internal planes of the lubricated mechanisms;

- Removing the shuttle. There is no need for an auxiliary tool at this stage; it is enough to carefully remove the clamps with your hands;

- Roller lubrication. This element must rotate without resistance so that the shuttle movements are clear and powerful. The places where the shafts are secured are also treated with lubricant. Some models of machines have felt pads. There is no need to remove them, they do not complicate processing, but, on the contrary, simplify it, as they absorb excess composition;

- Determining the correct operation of the elements fixing the shuttle mechanism. Parts should move without resistance, softly and smoothly;

- Removing the plate and carriage. Both elements can be pulled out without unnecessary difficulties; they must be thoroughly cleaned of old grease and contaminants and treated with a new compound;

- The highest concentration of contaminants is under the propulsion plate. You can remove particles of material and threads with a toothbrush, and lubricate them with an oil can with a thin spout or a syringe. Processing must be careful, without excess, otherwise there is a high probability of getting dirty and ruining the item when sewing;

- Shuttle processing. Like all previous mechanisms, the shuttle is thoroughly cleaned and lubricated beforehand.

After lubrication, you should not immediately start the device at full power. It is better to work on the machine for about half an hour idle, or with fabrics of minimal density. This will allow the composition to be evenly distributed over all moving elements, which will provide the necessary efficiency of the service procedure.

If you have to deal with old stains that cannot simply be wiped off with a brush, it is recommended to use WD-40. The aerosol softens dust, helps to completely remove it from metal and even plastic elements, and provides additional protection against mechanical stress.

How often should you clean and lubricate?

If the sewing machine is new, then at first you need to lubricate it once every six months. When the device ages, lubrication is carried out every three months. This largely depends on the intensity of the work.

Hook lubrication

If a person uses a machine every day for several hours, it is necessary to constantly listen to it. If suddenly there are extraneous noises, knocking, creaking or rustling, this is a reason to disassemble it and clean it thoroughly, additionally applying a new portion of lubricants. This will prevent breakdowns and sudden failure of the sewing unit.

In addition to oil and a napkin, you will need a screwdriver

In conclusion, we can say that a sewing machine, no matter how high-quality it is, needs repair and maintenance. In order not to repair a broken component of an expensive product, you need to follow simple rules and periodically inspect the device, listen to the sound of its operation, and lubricate it in a timely manner.

Rules for self-lubricating a sewing machine

Parts that are located in easy access areas can be processed independently. But if the machine is still under warranty, do not rush to disassemble it. Carefully read the terms of warranty service and operation. For some mechanisms, you may need to contact an authorized service center.

Why lubricate parts?

Lubrication is required for any mechanisms, no matter what kind of drive they operate on - manual, foot or electric. Lubrication:

- neutralizes friction leading to wear;

- protects against corrosion;

- creates a barrier against dust;

- extends the working life of mechanisms;

- reduces the number of empty revolutions.

Caring for the machine helps to avoid thread twisting, chewing and damage to fabrics.

How often should you lubricate your machine?

The frequency of lubricating the sewing machine depends on the intensity of its use. If you do sewing every day and this is not minor work, but a full load, then you can apply a protective layer even every day before work.

If you sew regularly and a lot, two to four times a week, then monthly prevention is sufficient. If even less often, but regularly, then do the procedure once a quarter.

Machines that are rarely used from time to time are recommended to be lubricated before use. For example, if you were cutting out a dress or getting ready to sew a set of bed linen, you lubricated the sewing machine and prepared it for the load.

Of course, sometimes there is simply no time to do this if you need to quickly make a couple of stitches. But it is important to remember that even when the machine is just standing, the oil dries out and the mechanisms become vulnerable to friction.

All moving metal mechanisms need lubrication. Everything that rotates, spins, moves inside the housing. There is no need to lubricate the external parts, the entire hook, needles, foot.

Manual and automatic lubrication

Lubrication can be manual or automated. In the first case, the responsibility to coat parts and assemblies with oil falls on the user. He must manually apply the product to the desired areas using a special oiler or syringe.

In the second option, oil is simply poured into a designated container, and a smart system directs the substance to the areas of the mechanism. The main thing here is not to forget to add lubricant in time and make sure that it does not run out.

Typically, household sewing machines need to be operated manually. And professional equipment is equipped with automatic supply of lubricants. This is convenient, since lubrication every day is problematic.

To lubricate sewing machines manually, oil is sold in oil cans with long dispensing spouts . The spouts are convenient for grinding parts inside the body. However, you can’t get through everywhere.

For hard-to-reach areas, you can use medical syringes. It is convenient to dose the lubricant with a syringe, because you need to apply a small drop at a time.