Drain pump breakdown - from RUB 1,600*

The pump is designed to pump out water during washing. It consists of a motor and an impeller. Basically, they break down: the pump motor burns out, the impeller is mechanically damaged. In the first case, the sound of the pump is not heard at all, in the second, the pump hums, but the machine does not drain water.

Note! Carefully check the pockets of items before washing. We have more than once encountered a situation where small foreign objects (coins, paper clips, zippers, curtain hooks, etc.) got into the pump and broke its impeller.

SIGNS

The washing machine does not drain the water: you can’t hear the pump working at all, or it is humming, but the water still does not drain from the washing machine. Zanussi cars with a display display error E20 or E21.

HOW TO FIX

Spare parts for the pump are not sold, so the pump needs to be replaced.

*Prices are only for the work of the master, the new pump is paid separately.

Why doesn't the heating element heat the water?

If a puddle is found under or next to the machine, you need to turn off the unit from the electrical network and turn off the water supply using the valve.

Drain the water in the machine through the filter located on the front of the machine in the lower right side and then clean it. After this, you can try to turn on the machine again. If it continues to leak, you need to unplug it again and drain the water.

Trying not to step in a puddle, check the position of the components:

- Hatch cuffs. If it is damaged, it must be removed and replaced.

- Gaskets at the filling hose connection point. A worn gasket must be replaced.

- Drain components – pipe and hose. If there is a violation of the integrity of one of these elements, it must be dismantled and a new one installed.

- The tank of the unit itself. If depressurization is detected, you need to take the car to a service center. In this case, it will not be possible to repair it yourself due to the need for specific equipment.

Be sure to read:

The washing machine does not spin: causes and troubleshooting, how to fix it without repair

If a washing machine (for example, LG FH0B8LD0) does not pump water, and the owner of the equipment cannot determine at first glance what is wrong, it is not necessary to call a technician for diagnosis immediately. You can inspect the device yourself.

- Lack of water in the water supply. It happens that the owner programmed the wash on a timer, but the water was turned off. This is easy to check - just open the tap in the bathroom or kitchen. If there is no water in it, it means that repair work is underway nearby and you just need to wait until it is completed. You will need to stop the program and turn off the device until the water flows. If the things in the machine are slightly damp, then you need to take them out so that an unpleasant odor does not appear. There is some water left in the drum or tank - the drain mode will help.

- Weak pressure - because of this, the washer pumps water very slowly, so it feels like it’s not filling the tank at all. You can understand whether this is the reason in the same way as in the first option - open the tap. If the water flows weakly, then there is a problem with the pressure and you will have to wait.

- The supply valve is not fully open - it must be turned to the maximum “open” position.

- The water supply hose is crushed. This is especially true if the machine is built into a cabinet or rack. If the pressure and tap are in perfect order, you should look for the reason in the equipment itself.

Note: A machine with a “spare” tank will wash even when the water is turned off or its pressure is weak.

- The door is not closed tightly. If the hatch of a unit (for example, Zanussi ZWSE680V) does not close properly, the problem is in the lock. Guide failure is a common consequence of long-term and active use. The problem may be hidden in a broken mechanism that blocks the door. To get things out, you need to unlock the lock through the lid or using a rope. Next is the job of the master. How to check if everything is ok with the lock? When closing the lid it should make a characteristic click. A notification appears on the screen of smart cars that the door is locked.

- The filter is clogged. To fix the problem, you need to turn off the water supply to the washing machine, disconnect the hose and check the fill valve mesh. Before disconnecting, you should place a bowl or bucket under the hose so as not to flood your neighbors. Dirt and rust from the filter are easy to clean. The main weapon is good pressure of running water and a needle for hard-to-reach places. For thorough cleaning, the mesh must be removed with pliers and rinsed under the tap.

- The winding with which the valve is equipped has overheated. In this case, you will need to change it.

- The water sensor is broken. The sensor is triggered by air pressure that passes through the tube. Information about pressure settings is indicated on the equipment body or in the documentation. To check the operation of the part, you need to connect a rubber or silicone tube of the same length and diameter instead of a hose. Then blow into it: if you hear clicks, it means the contact springs are working. Remember: before checking, the washing machine must be turned off, otherwise the heating element will overheat.

- The programmer, the “heart” of the washing machine, is broken. This is decided in the workshop. Of course, there is an option to use a syringe with a liquid designed to clean contacts, but these actions can lead to both removing carbon deposits from the contacts and completely damaging the programmer.

READ MORE: Installation of a flush cistern with a lower water supply

If the wrong mode is selected, the washing machine (even as powerful as the LG FH0B8WD7) will not wring out things. It is only necessary to run an additional spin after the cycle. Or stop the program and select one that involves subsequent spinning of the laundry.

The second natural reason is too low revs. If the user has programmed the equipment to the minimum, the laundry will remain damp, and it will seem that the washer did not spin it.

The problem arises if the equipment does not have a sensor to detect imbalance. When there is too much content in the drum or the item is heavy (the recommended loading weight is exceeded), it simply cannot spin. The solution to this problem is simple - take out half the laundry, distribute the rest more evenly throughout the drum and try again.

This reason is similar to the first, but occurs when the user loads too many clothes with long legs/sleeves. During washing, it gathers into one large lump that cannot be wrung out properly. You will need to drain the water, and then spread the contents of the drum evenly and start the spin cycle again.

Useful: The Indesit IWSB 61051 C ECO EU has an auto option that controls balancing - things are distributed as expected, automatically. Even trousers and sweaters.

Water does not leave the tank at the right time, which blocks the spin cycle. The reason is a clogged drain filter. It is located at the bottom of the washing machine behind the removable panel or lid. The exact location of the component is indicated in the instructions for the specific model.

The part intended for filtration must be checked for the presence of foreign objects and cleaned. To do this, disconnect the washing machine from the network, place a bowl under the filter to collect water and carefully remove it. If the valve is dirty, you will need to clean the tube and/or pipe.

Important: The filtration part most often becomes clogged if the user forgets to check the pockets before loading into the drum, and store receipts, coins and other small items remain in them. They end up in the drain hose and then into the filter.

This is a device responsible for controlling the number of revolutions depending on the selected program and the weight of the loaded laundry. The tachometer fails due to frequent overloads, loose fastenings, faulty contacts and wiring. A loose fastening can be “tightened”; it is better to entrust the solution to the wiring problem to a specialist, but if the problem is directly in the tachometer, then it will have to be changed.

The control panel, which is programmed to perform functions that have separate settings for a specific operating mode, stops sending commands to the drum. This is not the case when you should try to “reanimate” the equipment yourself.

A common problem during long-term use. The malfunction occurs both in the engine hardware and in the “brushes”, which wear out over time. The “brushes” must be replaced, but to do this you will have to disassemble the body of the washer (for example, on the Bosch WAW32640EU, the manufacturer produces components for several years after the equipment is discontinued). If you want to play it safe, you should entrust the matter to a repairman.

If the water in the washing equipment does not heat up, the problem is hidden in a broken heating element or a problem in the wiring. Thus, the wires in most machines (the Indesit BWSA71253WEU is no exception) are located near the body: the wiring frays over time due to vibrations created by the equipment. You will need to solder the damaged sections of the wire, but it is better to replace them with new ones.

- Heating element malfunction. To check the condition of the washing machine element, which heats the water for washing, you need to “ring” the tester. If the heating element is broken, it needs to be changed. It's not difficult to do it yourself. You will need to remove the back “wall” of the machine, for example, Candy CSS4 1372D3/1-S (the unit must be disconnected from the power supply), then loosen the fastenings of the installed part, dismantle it and install a new one. When replacing, you need to be careful not to damage the washer body.

- Scale. Sometimes the heating element begins to work weaker due to scale that has formed. It is enough to take out the part and clean it. To avoid this in the future, it is recommended to use special softeners or install an additional water filter.

- Relay or programmer malfunction. It is better to entrust the repair and replacement of these components to a specialist.

- Broken heating sensor. This element tells the “control” module when to start the heating element. If the sensor is broken, it will have to be replaced.

- The sensor that detects the water level is broken. A blockage in the tube (it is not difficult to clean) or wear and tear leads to breakdown - then you need to replace it.

READ MORE: Don walk-behind tractors features of models 1100 and 1000 900 and K-700 with 7 liter engine power with owner reviews

After the cycle is completed, is there any water left in the washing machine (for example, Gorenje WEI74S3B)? There are 4 reasons for this:

- Program crashes - often caused by a power outage - can be resolved by restarting. First, the program is canceled urgently: the device is disconnected from the outlet (for example, a convenient option with grounding - MOSAIC Legrand 3xSchuko) and turned on again after five minutes. Another way is to change the program to the shortest one. For example, turn on the “rinse-spin” mode or quick wash, which the Samsung WF60F1R0G0WD also has. If it doesn’t help, you need to call a specialist.

- The filter is worn out. To check the condition of the filter, you must first drain the water using the door located in the lower corner of the unit. This procedure should be carried out carefully, having previously prepared a container for draining the water so as not to flood the room. If the filter is clogged, it should be cleaned or replaced.

- The hose is worn out - the part will have to be replaced. If it looks intact, it is worth checking whether the sewer pipe or siphon is clogged. To do this, disconnect the hose, hang it in the sink and turn on the water drain mode. If it flows normally, then the problem is in the sewer itself.

- The pump is not working properly. If you can’t hear it working or, on the contrary, it’s too loud, it means it’s broken. Perhaps it's clogged. To determine the exact cause, you need to take out the pump and see if hair or threads are wrapped around the shaft. If yes, remove them and install the pump again. If the part is clean, but the tester shows that there is no voltage being supplied to it, the element will have to be replaced.

Malfunction of the heating element - from 1800 rubles*

The heating element heats the water for washing. When it fails, the machine washes in cold water, the program reaches heating, and the machine turns off, or the washer overheats the water. The coil in the heating element burns out or it “breaks through” onto the housing. In the second case, the machine can knock out the machine, RCD or overheat the water.

SIGNS

The Zanussi washing machine does not heat the water; models with a screen display error E60, E61 or E69. In rare cases, the machine overheats the water. When overheating, code E62 is displayed.

HOW TO FIX

The heating element needs to be replaced.

*The price is only for the work of the master, payment for a new heating element will be charged additionally.

Zanussi washing machine does not fill with water

In this situation, water is not poured into the tank. Sometimes the machine takes on water, but it happens very slowly. Subsequently, the washing program fails and the process stops completely. This could be due to a faulty heating element or a clogged or faulty inlet valve.

It is quite possible to fix this problem yourself. First, the power plug is removed from the socket, after which the functionality of the heating element is checked. The fact is that if the heating element is damaged, many functions of the washing machine can be blocked. If the element turns out to be faulty, it must be replaced.

If the inlet valve is likely clogged or malfunctioning, you must immediately close the water supply tap to the washing machine. Next, you need to find the connection point between the inlet hose and the tank, disconnect it and check for clogging of the inlet valve screen. If clogged, the mesh must be washed. If the mesh is clean, you should check the inlet hose. To do this, it is lowered into any container, after which the tap opens. Low pressure or complete absence of water indicates problems in the water supply system. If the water pressure is normal, then the problem is in the inlet valve, which should be replaced.

Bearing wear - from RUB 3,800*

The bearings of the washing machine ensure smooth rotation of the drum on the shaft. Over time, the oil seal weakens, water gets into the bearings, they rust and gradually collapse.

SIGNS

The Zanussi machine makes a lot of noise during the spin cycle and may not be spinning. If you remove the back wall of the washing machine (in machines with horizontal loading), you will see rusty stains on the tank from the location of the bearings. If you shake the drum by hand, you will notice how it dangles on the shaft. Sometimes the washing machine stains the laundry with grease from the seal (black spots remain on things) or with rust. In advanced cases, the drum falls down and stops rotating even while washing.

HOW TO FIX

Bearings need to be replaced.

*Rates for replacement of bearings, new oil seal and bearings are paid additionally.

Failure of the control module - from 2300 rubles*

The module, which is also called an electronic controller or board, is a microcircuit with radio elements. It controls the operation of the washing machine. It contains all washing programs. The main reasons for control unit failure are power surges and moisture ingress. As a result, tracks or contacts on the board burn out and/or oxidize, radio elements burn out, and the firmware gets lost.

SIGNS

Signs of module failure are very varied: from the lack of spin to the reluctance of the Zanussi washing machine to turn on. The most common of them are the following. Machine:

- does not turn on;

- the drum does not spin;

- does not drain;

- does not erase;

- does not heat water;

- knocks out the machine gun;

- The programs at SMA Zanussi are going astray.

HOW TO FIX

The technician uses a multimeter to ring the elements and tracks of the microcircuit. Finds faulty ones. Burnt out elements are replaced with new ones, the tracks are soldered. If a firmware failure occurs (due to a power surge), the module memory is soldered off, reprogrammed using special equipment and soldered back in.

If there is significant damage to the control unit, it is completely replaced.

*Control module repair prices are for labor only, components or a new unit are paid separately.

Water does not drain from Zanussi washing machine

The draining procedure is an important final step in the washing program. If water does not want to drain from the Zanussi washing machine system, this indicates serious problems that require quick resolution.

Common causes include a faulty drain pump or a clogged exhaust system. Sometimes, as a result of improper installation, backdraft occurs in the sewer. The water level sensor and electronic control module may be damaged. The drain pump is the main link in the drainage system of washing machines. It is he who ensures the pumping of waste liquid from the tank. Along with the water, various small debris gets inside the pump. During operation, it wraps around the blades and damages the pump. If cleaning does not work, the pump needs to be replaced.

Foreign objects can not only damage the pump, but also clog the outlet pipes of the drain system. The solution to the problem is to remove the blockage and clean out the exhaust pipes.

Backdraft in the sewer is formed as a result of improper installation of the washing machine. For example, if the drain hose is placed too high, the pump starts to work at increased power. Sometimes even this power is not enough and water is not pumped out of the tank.

The level sensor determines the amount of water in the tank. This function is actively used during the draining process. When the water level reaches zero, the pump stops. If the sensor is damaged, it sends incorrect information to the electronic control module. For example, it shows zero liquid level, although the tank is still filled with water and pumping is operating normally. Sometimes the control module itself, which coordinates and controls all processes in the washing machine, including draining waste water, turns out to be faulty.

Abrasion of motor brushes - from 1600 rubles*

The brushes generate an electromagnetic field, under the influence of which a torque is created and the motor shaft rotates. Over time, they wear out, make poor contact with the commutator, and the motor shaft, and as a result, the washing machine drum, stop spinning.

SIGNS

The drum of the Zanussi washing machine does not spin at all or does not gain speed during the spin cycle. Perhaps due to poor contact with the commutator, the brushes spark. Error E50 may appear on the display.

HOW TO FIX

Usually the master changes the brushes when their length becomes less than 1 cm.

*The prices indicated are for replacement of brushes; the parts themselves are paid separately.

The drum does not spin

Such a breakdown usually occurs every 4-5 years. The reason for this malfunction is the limited service life of the drive belt. The main symptom of this problem is that the engine of the Zanussi machine is running, but the drum is stationary.

In order to finally find out why the drum does not rotate, it is necessary to dismantle the rear wall of the Zanussi machine. It happens that the belt simply jumps off the pulley. In this case, you must carefully install it in its place. But if the belt breaks, it is recommended to replace it with a new one.

It is also possible that the drive belt is in place, the motor is running, and the drum of the Zanussi washing machine is stationary. The belt has probably simply stretched and needs to be replaced. After replacing the belt, as a rule, the machine continues to work.

During the inspection, try turning the drum by hand. It should rotate freely. If this does not happen, the bearing has probably failed.

Breakage or stretching of the drive belt - from 1000 rubles*

The belt is only available in Zanussi washing machines with a commutator type motor. It transmits rotation from the motor shaft through a pulley to the drum. When the belt stretches, the machine does not gain speed during the spin cycle due to its slipping. If it breaks, the drum does not rotate at all.

SIGNS

If the belt breaks, the washing machine runs the program: water is poured, heated, drained, but the drum does not spin. If the belt is stretched, then the washing cycle runs normally, but during the spin cycle the drum does not accelerate to the required speed. A stretched belt often falls off.

HOW TO FIX

The belt needs to be replaced, even if it is intact but falls off. Because due to an increase in its length, the tension decreases, and the belt will continue to slip off.

Note! If the new belt continues to fly off the pulley, this may indicate a bad bearing. The drum is loose, so the strap comes off.

*The price list is for work only, a new belt is paid on top of the amount.

DIY Zanussi washing machine repair

According to analytical data from service centers, the device of different Zanussi models has common weaknesses that provoke the majority of repair cases:

- Imperfect design of the locking mechanism.

- The filter is often clogged with dirt, making it difficult to drain waste water and supply clean water. The lower the water quality, the higher the likelihood that the machine will fail.

- The heating element is highly susceptible to scale accumulation, which is why it is recommended to replace this part with another one made of a more practical material.

- Unreliable drive belt. It is recommended to periodically tighten or replace it. This will help increase the service life of the machine.

The advantage of these machines is the presence of a window on the control panel, on which, if a malfunction occurs, its code is displayed. By looking at the instructions or the manufacturer's website, you can determine which module is causing the problem and what you can do to fix it.

Read more ► The washing machine produces electric shock on the body and through the water: how to fix it, what not to do

The washing is completed, but the hatch still cannot be opened

The situation arises due to incorrect operation of the locking device. To open the machine, you will need to unscrew the bottom panel. On the right side near the filter there is a special cable that should be pulled towards you.

Then the machine will open and you can unload the washed items. But in order to be able to do subsequent washes, the equipment will still have to be sent in for repair, since this problem relates to electronic malfunctions.

The opposite situation - after loading laundry, it is not possible to close the hatch - is associated with the fragility of the materials of the hatch clamps.

To check the condition of these parts, disassembling the lock is required. At the open hatch, a couple of screws are unscrewed, the cuff and its holder and lock are pulled out. If damage to the plastic clips is detected, the lock must be replaced. To prevent malfunctions, close the hatch as carefully as possible.

Water does not fill

Several parts may be responsible for this problem.

A sequential check of the status of each of them is required:

- See if the water has been turned off.

- Separate the filling hose from the tank and supply water. If it flows normally into the hose, install it back.

- Remove the top cover and separate the filter and fill valve. If the filter is clogged, it must be cleaned. This procedure should be carried out regularly, even in the absence of malfunctions.

- Check the mesh located at the valve for clogging. If necessary, rinse it.

- Connect the valve to contacts with current of the relevant voltage (marked on the part body). If the valve has opened, it is functioning correctly. Otherwise, the part must be replaced with a new one.

- If the indicated measures do not help, you need to contact a specialist - most likely, the problem is a malfunction of the drain pump or level sensor.

Rumble during spin cycle

Increased noise levels during operation at high speeds can occur due to:

- a small amount of laundry loaded into the machine;

- broken bearing.

Read more ► The washing machine is noisy during the spin cycle: what to do, reasons for the noise when draining water

In the second case, the bearing must be replaced. To do this, pull the tank out of the machine, remove the pulley from the drum and unscrew the bolts located along its edges. Now you need to remove the drum axle shaft from the bearing assembly by gently tapping it with a hammer on a wooden backing.

After removing the bearing, you need to clean the place where it is attached, as well as the axle shaft. Then they install the bearing and coat its ring and semi-axial element with a lubricant. The tank is assembled by lubricating the junction of the halves with sealant.

The drum does not rotate

Sometimes during operation of the machine the drum becomes static. If the engine still runs, the cause is likely either a bad bearing or a misaligned drive belt.

In the first case, the bearing or worn out oil seal is replaced. In the second , removing the back of the case, inspect the condition of the belt. A torn or slipping belt must be replaced with a new one, one that has moved from the pulley must be installed in the correct position.

When the electric motor is faulty and the drum is turned only by hand, the following causes of the problem are possible:

- control unit malfunction;

- worn motor brushes;

- changes in electrical voltage.

In all these cases, it is not recommended to solve the problem yourself. You need to contact the service center.

Breakdown of the hatch locking device - from RUB 1,500*

The lock is designed to lock the door for security purposes so that the hatch cannot be opened during washing. UBLs are thermal and electromagnetic. In thermal cases, a thermal tablet with a conductive coating usually burns out or is destroyed, which normally heats up under the influence of the current passing through it, bends the bimetallic plate, and the door is blocked. Less often, the plate itself loses flexibility and bends worse. Electromagnetic locks break very rarely.

SIGNS

When the UBL fails, the door does not lock and the program does not start. Less often, the hatch does not open after finishing the wash. In models with a display, the malfunction may be accompanied by error E40.

HOW TO FIX

The sunroof locking device needs to be replaced.

*The cost is for labor only, a new lock is paid additionally..

Failure of the water inlet valve - from RUB 1,700*

The valve consists of a membrane and an electromagnetic coil. At a certain moment, the electronic controller sends a signal to the coil, the membrane opens, and water under pressure from the water supply enters the machine. Basically, the coil is burning in the valves. As a result, the membrane does not open and the machine does not draw water. Occasionally, the cause is in the membrane: due to wear, it does not fit tightly, and the machine constantly draws water even when it is turned off (provided that the shut-off valve is open).

SIGNS

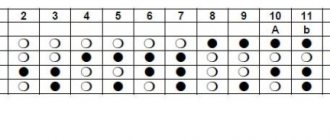

The Zanussi washing machine does not draw water during washing or only during rinsing. The second case is typical for Zanussi cars with double valves. One of its sections (a coil with a membrane) is responsible for collecting water for washing, the second for rinsing. When the second section fails, water is filled as usual during washing, but during rinsing there is no set.

A more rare symptom is unauthorized water intake even when the machine is turned off. In this case, the membrane is to blame. It allows water to pass through, so the machine constantly fills with water.

In Zanussi models with a screen, when the valve breaks down, errors E10 or E11 light up.

HOW TO FIX

They don't sell spare parts for the fill valve, so it needs to be replaced completely.

*The price indicated is for repair work only, a new valve is paid separately.

Damage to the hatch cuff - from RUB 1,800*

The rubber hatch seal prevents water from penetrating between the drum and the body of the machine. When a hole appears in the cuff, the washing machine leaks water during the wash, rinse or spin cycle. Basically, the cuff is damaged by small sharp objects from the pockets of things. Sometimes the seal wears out due to the rotation of the drum.

SIGNS

Zanussi washing machine leaks during washing, rinsing or spinning. There was a hole in the rubber seal of the hatch. The machine may be knocked out if water gets on the contacts of the parts inside the machine.

HOW TO FIX

A damaged seal must be replaced. A temporary solution is to tape the cuff.

*The price is only for replacing the cuff, the new seal is paid separately.