Ink cartridges without a pre-installed print head

With air design

Common and simple in design, cartridges operate by using the pressure difference in two communicating reservoirs. One container is completely filled with ink, and the other has an air column.

The cartridge cover is equipped with a hole for pressure equalization. The ink used for printing is replaced by air as the chamber is released.

The bottom of the “inkwell” is equipped with a transfer valve, the hole is additionally protected by a rubber sealing collar. Installing the cartridge is accompanied by connecting the print head through the valve.

In full-color inkjet printers, the print head has a corresponding number of ink channels equipped with fittings for a strong connection with the cartridges.

With porous filler

There are designs with polymer fillers, used in Canon printers.

The most popular option has 5 cartridges, 2 of them black. One inkwell with black ink has a capacity of 19 ml for printing texts, and the other 9 ml, like the other color inkwells, is used for printing photographs together.

The cartridge body is divided into two unequal compartments. The larger reservoir contains ink-impregnated filler, and the smaller reservoir contains ink. The principle of operation is similar to that of an air cartridge, and the design resembles foam rubber, due to the compartment with filler.

There are options filled with fine-pored foam rubber, without a separate ink chamber. Fine filler cells allow you to hold a significant amount of ink, up to 7 ml. The PG fittings are connected to the cartridge through holes in the housing.

Changing cartridges in printers with a separately installed print unit requires care. It is not recommended to leave the print head without ink for more than 0.5÷1 min.

Refilling Epson cartridges

Epson replacement cartridges are simply a reservoir filled with ink. The head and mechanism that provides printing are located in the printer and cannot be replaced. More precisely, they are subject to it if they fail, but this will have to cost an amount reaching 75% of the cost of a new printer. And what’s most interesting is that the Epson printing unit most often fails precisely because of the use of counterfeit cartridges or home refilling with bad ink, and the warranty in case of such breakdowns is invalid. So if you are the owner of an Epson printer, you better think ten times before you decide to refill! However, the process itself is very simple.

The most important thing is not to remove the cartridge from the printer for more than a minute: otherwise the print head will dry out and you will have to struggle with cleaning it. And this, believe me, will not lead to anything good. The way out of this situation is quite simple and... not very pleasant: you will have to purchase another cartridge - take out the empty one, immediately insert the full one.

The refueling procedure itself, as I already said, is extremely simple, and it is the same for color and black models. The only difference is that in color cartridges you need to refill from 3 to 5 different compartments (according to the number of colors). This is done as follows.

Also interesting: Photo sizes for printing

As soon as you remove the cartridge from the printer, immediately seal the exit hole with a previously prepared piece of tape. Further actions depend on the cartridge model. If the tank has holes (they should be sealed with film) on the lid, then you are in luck, otherwise you will have to drill them yourself. Having sorted out the holes, insert the syringe needle to the bottom of the cartridge and slowly pump in ink. That's all. All that remains is to seal the filling holes (be careful not to accidentally seal the ventilation holes).

Ink cartridges with integrated printhead

With foam filling

Structurally, the cartridge is a container consisting of two blocks - an ink reservoir and a print head. The color cartridge, in turn, is divided into compartments filled with foam rubber and responsible for a specific color of the dye; there can be 3, 4 or 8 of them.

The block with the print head is located at the bottom of the cartridge and is protected from clogging by a fine-mesh filter. From the foam fillers on top, the ink seeps through the filters and enters the print head through channels.

The print head is a plate with nozzles. The design of the PG for Hewlett Packard printers using Thermal Inkjet technology consists of two elements: a chamber-forming strip and film thermistors. An electrical impulse is sent to it through a flexible cable mounted next to the head. Each color has its own set of nozzles, this ensures high color purity in photo printing.

There are holes on the lid of the container through which air escapes and the pressure inside the chambers is stabilized.

Table. Ink tank volumes of original inkjet cartridges

| Hewlett Packard | Black | 9÷42 ml |

| Color | 4÷13 ml per color | |

| Canon | Black | 3÷20 ml |

| Color | 3÷9 ml per color | |

| Epson | Black | 10÷35 ml |

| Color | 5÷10 ml for each color |

With plastic bags

Externally, the consumable item is similar to cartridges with foam filling. But, the principle of operation is the same as that of a Mariotte vessel. Only the role of the second vessel is performed by plastic bags placed inside the body.

The plastic case is equipped with a printing unit, a filter and a lock. Individual structural elements: plastic bags, coil, hole for air intake, platform for air infiltration.

Through the platform, air, in small bubbles, enters the bags. Inside, the bags are equipped with spring plates. The bags ensure a regular supply of ink to the head and prevent it from leaking. The coil keeps the ink from flowing out when there is excess air supply.

Cartridge of all times and peoples HP No. 45

There is another type of cartridge with a print head.

A typical representative is HP51645 (No. 45) for an HP printer.

It contains a sealed container with flexible walls and an elastic spring inside and a print head.

In front of the print head there is also a filter with very small cells that does not allow clots and other “garbage” to pass through.

An elastic spring from the inside expands the flexible walls and maintains a certain vacuum .

The force of gravity is balanced by the reduced pressure, and the ink does not flow out when there is no printing.

Cartridge No. 45 is a very successful development by HP and is still in use today.

It's a pity that printers for working with such cartridges are no longer produced. This record holder has a fairly large capacity - 42 ml and a long print head resource. It lends itself well to refilling.

If you handle it carefully, it can withstand dozens of refills . It is refilled through a hole in the bottom, which is closed with a steel ball and sealed with a round paper sticker.

When reusing this cartridge, the problem with the ink levels not displaying correctly remains. It can be solved in the same way - by manipulating the sealing of individual contacts.

Another advantage of this cartridge is that it has a sealed ink container. Thus, the nozzles do not dry out from the inside , only from the outside. Therefore, it is possible to resuscitate even such copies that, being empty, were removed and lay for several months separately from the printer.

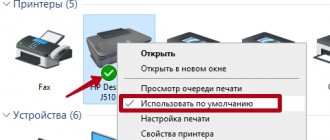

Controlling ink consumption

Currently, it is no longer possible to find cartridges for inkjet printers without microcircuits (chips) that control the consumption of the ink composition. The chip stores data about the type of device, date of manufacture and activation, and the amount of ink used.

On the one hand, such data allows you to keep track of the consumption of the coloring composition, but on the other hand, it complicates the refilling procedure.

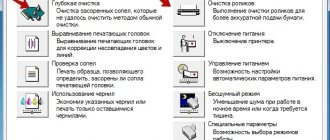

Absorption sponge

The sponge located inside the cartridge container is an absorbent material whose function is to retain the dye. Typically, a sponge with a microporous structure is used as a material of this type.

Thus, the design of the inkjet cartridge is not particularly complex and the number of elements of which it consists is the minimum possible. In turn, this will allow manufacturers of both original and compatible consumables to optimize their cost and make printing more affordable. Despite this, refilling an inkjet cartridge is several times more profitable than buying a new part.

What's not to like about an ink cartridge?

- Long breaks from work.

- Excessive heat from external sources.

- Incompatible ink.

- Blowing through the cartridge to force ink into the nozzles if this is done with excessive force.

- Working in a thermal inkjet printer when one of the cartridges runs out. The nozzles working in conjunction with this cartridge may burn out.

- Cleaning contact pads from oxides with utmost effort and diligence.

- Sealing the print head nozzles with a material with an adhesive base. The adhesive layer may clog the print unit nozzles.

- Pigment ink cartridges do not tolerate low temperatures. Some of the pigment may peel off and precipitate.

Types of Ink Cartridges

An inkjet cartridge is a replaceable printer component that is a container for storing ink and transferring it to the page during the printing process.

Main Differences

- Ink composition: water-based or pigment;

- By type of paint retention: vacuum or with sponge filler;

- By design: with or without built-in print head;

- According to the operating technology: bubble-jet, thermal jet or piezoelectric;

- By the presence of a refill protection system: with and without chips.

Above are the main differences between inkjet cartridges. It is worth noting that all models are replaceable and are considered consumables. From here we can distinguish another category - differences in manufacturing method.

Original – devices manufactured by the official manufacturer of office equipment or companies that are their licensed representatives.

Compatible - devices that are a copy of the original cartridges, manufactured by a third-party company.

Remanufactured are cartridges whose service life has expired. They are completely restored (repaired), which makes it possible to reuse them for printing.

Basic rules for an enjoyable inkjet printer experience

- Always have a spare set of cartridges for your printer. If you receive a message about running out of ink, stop printing and change the consumable within 1 minute.

- A used cartridge intended for refilling should be sealed to prevent drying out. Refill no later than 3 days from the date of removal.

- At least once a week, and preferably twice, print on the printer.

- Cartridges should be removed and installed by holding them by the side surfaces and the cover.

Despite the apparent simplicity of replacing or refilling cartridges, problems often arise. Sometimes due to a misunderstanding of the procedure, and sometimes due to incorrectly translated instructions. Considering the rather high cost of inkjet printer consumables, in such cases you should immediately contact a specialist.

4750

Tags for this article

Expert Reviews Cartridges

Comments

Dirty work: Introduction. Refill HP color ink cartridges

With this short review I would like to begin a series of stories about the “dirty” part of my work, namely the following points:

- Refill HP color ink cartridges

- Refilling HP toner cartridges

- Review of the plotter Wersacamm SP-540V

- Review of the BigPrinter PJ 3216 plotter

Lyrics

As the respected Boomburum recently told us, there is such a wonderful thing in the world as CISS. The thing is certainly useful and necessary not only at home, but also in the work of a small advertising studio, by the standards of Moscow and the region. In my case, CISS is used in three cases:

- Two regular A4 printers (Epson Stylus C87 and Stylus Photo RX600)

- One printer for printing with sublimation ink for subsequent thermal transfer of the image to various surfaces in A3 format (Epson Stylus Photo 1270)

- Two large format printers, also called plotters (Wersacamm SP-540V and BigPrinter PJ 3216)

But this technology also has its disadvantages.

One of them: it is not possible to install CISS on printers from HP, due to the design features of their cartridges, namely, the ink reservoir is combined in one container with the so-called “head”. If you have a strong desire, you can of course find some poor solutions, but experts strictly do not recommend them. As a result, users of HP printers have an original problem - expensive original (from the manufacturer) cartridges plus permanent envy of owners of printers from Epson, who, by the way, in addition to relatively cheap original cartridges, always had extremely cheap Chinese analogues in stock. But since the original point in our country is also the desire to save on “extra and unjustified” expenses, HP printers almost immediately appeared on store shelves along with kits for refilling them.

These sets were from different manufacturers (if you can even call them that :), with different design solutions and, as far as I know, at one time they caused a lot of problems not only for ordinary users, but even for professionals in the field of maintenance and repair of office equipment.

Today, after many years have passed since the first refilling of a cartridge from an HP inkjet printer, I want to present to you the most simple and convenient refilling scheme that has been proven over the years. I can say in advance that the entire process of refueling itself takes less time than searching for tools in the corners for this activity.

Preparation

For refueling we need:

- Three syringes "twenty" (sold at any pharmacy)

- 1 liter ink (the brand of ink can be seen in the photographs, and I have been completely satisfied with them for quite some time, but in general you can use any that will be recommended to you at the nearest computer store)

- Cartridge (you may need several more copies to install it, more on that below)

- Hammer

- Lint-free disposable wipes (not sold everywhere, so regular ones will do)

- Scotch

- Pepyaka 1 (rivet)

- Pepyaka 2 (device for refilling cartridges from set 19... illegible year

It is better to carry out all operations by first laying some moisture-proof material. In my case, this is a backing from a self-adhesive film.

Step 1: Holes

If the cartridge has already been refilled before, this step can be omitted. Otherwise, we need to prepare holes for inserting the syringe. This is done simply, take “penny 1” (in my case it is a rivet, but any sufficiently strong thing similar in diameter can be used. We place the cartridge on the edge of the table and, one by one, carefully, drive all three technological plugs inside the cartridge ( sorry for the out of focus photo):

Professional comment:

In fact, it would be more correct from a technical point of view to pull out the plugs and insert them back after refueling (or burn thin holes next to them and not touch the plugs at all), since they contain a complex air labyrinth to maintain the “correct” pressure in cartridge.

But my experience shows that tape, which usually cannot be glued completely tightly, perfectly fulfills the role of these complex labyrinths.

If you are not satisfied with this decision, I leave this process at your discretion. However, do not forget that the holes still need to be covered with tape as tightly as possible, otherwise you risk flooding your printer with the entire contents of the cartridge. As a result, we get three neat holes:

Step 2: Refueling

Next, fill all three syringes with ink. Two points need to be taken into account: firstly, different cartridges can have different capacities, and secondly, at the moment when the printer begins to signal that ink is running out, only one of the colors is actually running out, the rest can be quite noticeably filled. Based on the weight of the cartridge, you gradually begin to navigate this issue. As a result, I eventually decided to fill the syringes with ink at approximately 75% of the original cartridge volume:

After we have prepared everything directly for the process itself, I would advise you to stock up on several napkins for quickly wiping your hands and excess ink; the process does not always go smoothly. Its essence is this: the cartridge for each color has its own compartment, it contains a certain porous material, extremely similar to good old foam rubber. In order for our refueling to be as painless as possible, we need to insert the syringe needle so that the tip of the needle is almost at the bottom of the reservoir and as close as possible to the place where the heads are located. This way we will avoid possible “air bubbles” in the cartridge, which are quite difficult to get rid of.

So, we place the cartridge on napkins laid in several layers and slowly introduce ink into the reservoirs, but before that, do not forget to check what color the ink is in which compartments. In my particular case, the colors go the other way around in relation to their designation on the sticker (the sticker can be seen in the title picture).

Step 3: Postpartum Treatments

If everything went smoothly, then all the ink will go to its intended destination and only a small puddle will remain under the cartridge. If ink flows like a river from the nozzles or flows out of the technological holes, then there is a reason to either think about an excess amount of ink and supply it too quickly to the reservoirs, or about buying a new cartridge, since this one is most likely no longer suitable for printing. But the first time everything always goes smoothly. After we have made sure that everything went exactly as we expected, I advise you to “blot” the “head” of the cartridge several times from excess ink:

If you don’t have “pepyaki 2”, then don’t worry, you can refuel without it. It consists of a structure consisting of a frame in which the cartridge is mounted, resting its “head” against an elastic band, and a syringe that is connected to a hole in the above-mentioned elastic band. It is used to remove excess air from the bottom of the ink tanks:

But if after “getting wet” you still have marks like in the following photo, then this step can be omitted:

If not all colors appear on the napkin, you can either try again to “reach the tonsils,” that is, apply the ink to the very bottom of the reservoirs, or simply let the cartridge sit (preferably with the upper holes open and its “head” close to the napkin. If you follow the second path, then you should check whether ink has started to come out of the nozzles at least once every 10 minutes, otherwise you risk seeing all the fruits of the work done leak out onto the napkins.

After we still have clear traces of all three colors on the napkin, the technological holes on top of the cartridge are sealed with tape, prudently glued to one of the sides of the cartridge.

Hint:

After you have inserted the cartridge back into the printer, it may be detected by the printer as already used and as a result the printer will refuse to work with it. But in general, this is not scary, since the printer usually remembers only the last two serviceable (that is, it is possible that they are even empty, but working) cartridges. This is where our old used cartridges come in handy

Announcement

Wersacamm SP-540V:

BigPrinter PJ 3216:

PS: Sorry for the photos are not of the highest quality, in the middle of shooting I remembered that I had not set the white balance and had to bring it to mind in CS4. PPS: At first glance, the topic is completely hackneyed and should already be known to all interested parties, but upon closer examination it turns out that original cartridges from HP are still in demand on the shelves, and no one is immune from employment in an organization where the same HP printers are also used. Also, not so long ago the prices for these cartridges increased quite significantly.