Criteria for choosing a mount for an air conditioner

When choosing brackets, the following factors are taken into account:

Features of the building wall. The presence of insulation or a ventilated facade requires extension of the fasteners. Polystyrene foam and other heat-insulating material are not a reliable basis for installing equipment. Metal studs will be required. The fasteners for the air conditioner are selected in accordance with the wall material. Aerated concrete facades have low tensile strength. For installation, special anchors and dowels made of metal or polyamide are used. The surface of the wall should be flat, this will ensure a tight fit of the racks and reduce the level of vibration. The characteristics of the brackets indicate the recommended load. It must match the weight of the installed air conditioner. The maximum load value is 2 times the rated value. A safety margin is necessary to avoid overload when ice freezes in winter. For outdoor units weighing more than 120-150 kg, reinforced brackets are required

The supports are made of metal 3 mm thick. When purchasing, you need to pay attention to whether the hardware is included in the kit. Depending on the model, you will need 4-6 dowels, 4-6 screws with a diameter of 10-12 mm

To secure the external unit, you need 4 galvanized bolts measuring 8 (10) by 50 mm, 4 nuts and 8 washers. The noise level of an operating air conditioner should not exceed levels that are comfortable for people living in the neighboring apartment. To reduce vibration, special rubber washers are installed. Vibration dampers are selected according to the weight of the condenser module of the split system.

Vibration dampers are necessary to reduce noise levels

The dimensions of the slats are selected for climate control equipment of various capacities and dimensions. Most household split systems are mounted on brackets measuring 450x450 mm or 450x500 mm. Hardware is selected according to the load; the weight of external blocks ranges from 36-150 kg. High-power air conditioners require a larger support area for fasteners; products with dimensions of 1000×700 mm, 1200×1000 mm are recommended for them.

The uninterrupted operation and longevity of the air conditioning system depends on compliance with installation rules. The indoor unit is installed on a special plate, fixed clearly along the horizon. The outer part is located on the north or east side (away from sunlight). When choosing mounting sizes, take into account the requirement to install the outdoor module at a distance of 10-15 cm from the wall. The gap is necessary for the free removal of hot air.

Installation instructions

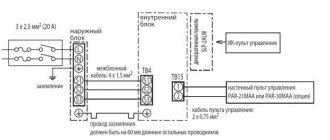

- The brackets are attached to the wall where the air conditioner is installed. The position of the parts is aligned to the building level.

- Markings are made through the perforation.

- The racks are removed. Holes are drilled in the wall using a drill. The dowels get clogged.

- The supporting elements are returned to place and secured with bolts. The installation plane and the strength of the connection are checked.

Mounting requirements

To install the air conditioner, two brackets made of a U-shaped or L-shaped profile are required. The supporting elements consist of a vertical and horizontal post. They have round and oval holes made at the factory. Through them the support is attached to the wall. The perforation has precise geometry. On the vertical post there are a number of holes for anchors that secure the support to the facade of the building. The horizontal bar has a groove for attaching the outdoor unit of the split system.

The bracket holding the external air conditioner module is constantly subjected to static load. It is subject to requirements for strength and corrosion resistance:

- The technical characteristics of the bracket must correspond to the weight and dimensions of the outdoor unit of the air conditioner. Minimum metal thickness 1.5 mm. Smaller posts may sag under load. The length and width of the vertical and horizontal strips have standard values for different models of brackets. Failure to comply with them leads to a decrease in the strength of the support.

- Surface treatment—protecting fasteners from moisture and the negative effects of weather conditions extends their service life. The occurrence of corrosion weakens the metal, and the reliability of the supporting elements is lost. The coating must be resistant to mechanical stress, otherwise scratches will appear during installation. Violation of the integrity of the paint layer leads to the appearance of rust. High-quality anti-corrosion treatment is applied evenly and provides a smooth surface.

- Mounting of the fastening is carried out through the existing holes. Drilling additional slots is not permitted. Destruction of the protective coating of parts leads to rapid corrosion and loss of strength.

- The surface of the racks must be smooth, the edges of the holes must be carefully processed. Notches and protrusions prevent proper installation of the outdoor unit.

Bracket design

The design of the brackets must provide sufficient strength, since air conditioners weighing at least 30 kg are mounted on the brackets. At the same time, the brackets should be lightweight to facilitate installation of the mount at height.

The bracket is made in the form of an independent part or a multi-part structure with a brace, as well as in the form of a significant thickening in the base part. The mechanical principle of operation is the resistance of the material to chipping and shear. For this purpose, steel 2 millimeters thick is used.

The bracket has holes for attaching to the wall, as well as for securing the outdoor unit. There are differences in configuration depending on the manufacturer, but you should choose the brackets of the simplest design.

Application of brackets

Typically, outdoor air conditioner units are installed on the rear or side facades of buildings. At the same time, for a classic household air conditioner, two brackets are enough. But remember, the number of brackets depends on the weight of the equipment, so it is better to double-check the technical specifications of your air conditioner.

Brackets for air conditioners on the facade

The most common types of brackets used when installing air conditioners

Companies involved in the implementation of contracts for the installation of air conditioners use several types of brackets. Among them are the following:

Right angle fasteners made from rectangular metal corners 2-2.5 millimeters thick welded together

Rectangular brackets

Brackets of this type are characterized by ease of manufacture, which is why they are cheaper than their thicker and more durable counterparts. However, this type of fastening is not quite reliable and suitable for long-term use, since it has a rather small margin of safety. When vibrating, it experiences a strong load, which can damage the protective seam. When the anti-corrosion coating begins to wear off, the brackets become vulnerable to the harmful effects of water and other particles that can compromise the integrity of the metal structure.

U-shaped metal fasteners connected to each other. Like the previous sample, they have a right angle of 90 degrees. The thickness of the material is 2-2.5 millimeters and is fastened with special bolts.

U-shaped fasteners connected by bolts

This design is more expensive than conventional rectangular brackets, but it is more reliable. Vibration applies only to the connecting element, while the load on the remaining parts of the structure remains minimal. At the same time, galvanized bolts are not subject to corrosion and oxidation. The coating of the brackets reliably resists the harmful effects of moisture and other atmospheric particles.

U-shaped metal structure with an elongated body, fastened at the bottom with an additional section of channel. The thickness of the metal elements is 2 millimeters.

Reinforced U-shaped structure

In appearance, this design seems to be the most reliable of all presented. Despite the small thickness of the metal elements, the structures can successfully withstand blocks of almost any weight. They do not deform under constant vibration, which guarantees a long service life of the brackets. The coating reliably protects the structure from negative atmospheric influences, preventing deformation, corrosion and oxidation processes in the metal.

Rectangular design of two straight metal corners 2-2.5 millimeters thick

U-shaped structures fastened with a plank

This type of brackets almost completely copies the first sample. The difference between them is that here both corners are fastened together with a connecting metal strip, which significantly strengthens the brackets, allowing them to support blocks of almost any weight. All elements are connected to each other using bolts. The bar lightens the load on the fasteners, and the coating reliably prevents the occurrence of corrosion and oxidation processes due to the negative effects of moisture and precipitation. The connecting strip greatly simplifies the installation of brackets.

Fastening diagram

All of the above samples are suitable for installing almost any outdoor units. The size of air conditioner brackets is traditionally about 40 centimeters in length for the vertical mounting sections.

Types of brackets

Brackets for stable mounting of air conditioners have horizontal elements on which the installed unit is placed and secured against spontaneous displacement, and vertical parts that are pressed tightly against the wall. For ease of fastening, holes are provided.

In most cases, the brackets take the form of L-shaped parts, used in pairs. The differences usually relate to the shape of the profiles used in the manufacture and the presence of additional elements intended to strengthen the structure.

Important! The production of brackets used outdoors uses stainless or ordinary structural steel with anti-corrosion treatment.

Corner brackets

This simplest type of fastening is made by perpendicular welding of corners with a shelf thickness of at least 2 mm. It can withstand moderate loads, but over time, vibration negatively affects the strength of the seam.

In addition, accidental damage to the anti-corrosion coating can lead to a rapid decrease in the strength of the product and a change in its configuration.

Structures made of U-shaped profiles connected by bolts

Such brackets are more reliable due to the presence of additional stiffening ribs and a bolted connection that is resistant to vibration. Fasteners made of galvanized steel do not corrode for a long time and can be replaced with new ones if damage is suspected.

Brackets for outdoor unitBrackets made of U-shaped profile with additional reinforcement

This design is similar to the previous one, but has slightly elongated vertical elements, to which an additional jib is attached at a certain angle. It gives the entire system absolute rigidity and allows it to be loaded with a fairly heavy load.

Brackets made of U-shaped profile, fastened with a horizontal strip

Such devices, in addition to all the positive qualities of the previously described models, also have resistance to horizontal displacement and ease of mounting to the wall. They can be installed under the most expensive and critical equipment.

For information! The presence of elongated holes on the horizontal shelves of the brackets makes them suitable for installation under any brand of air conditioners.

Types of brackets for mounting a split system

As the demand for split systems increases, manufacturers of brackets for mounting air conditioners are obliged to enrich the variety of their products.

The following types of air conditioner brackets are common on the market today:

- Welded L-shaped corners;

- L-shaped corners are connected by a threaded connection;

- universal bracket with horizontal fastening bar.

The latter type is distinguished by the fact that the horizontal bar facilitates the installation process, since it is not necessary to align each bracket individually in the horizontal plane.

Bracket with horizontal bar

There are also different types of brackets for attaching outdoor units of air conditioners. They are certified and have the permissible weight of the external unit. For example:

What is the bracket for?

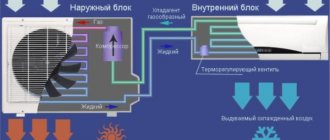

To understand why you need a bracket for an air conditioner, you need to know what your split system consists of. So, all room temperature control devices consist of three components:

- indoor unit containing the evaporator;

- the outdoor unit in which the condenser is located and for which the bracket itself is needed, since this unit is located on the facade of the building;

- a system of pipes through which the refrigerant is transported and combining two units into one split system.

Each of the three components is mounted separately. For example, the indoor unit is installed on a special mounting plate that comes with the device. The freon line system is assembled when installing the air conditioner yourself. To install an outdoor unit, you have to purchase fastenings separately, and for the same model and manufacturer they can be different. It depends on how and where you are going to install the unit. Main factors influencing your choice:

- lightness and at the same time strength, also the brackets must be correctly suited for the correct location and size for a specific model;

- the bracket for the outdoor unit of the air conditioner must support the weight of the device, and it must have some reserve;

- compliance with all standards specified in the installation instructions;

- protection from environmental influences.

Why do air conditioners need brackets?

One of the types of brackets for attaching the outdoor unit of an air conditioner

Since the split system is still the most popular device for cooling air in an apartment, the number of manufacturers and types of equipment is growing rapidly. For conventional, floor-mounted systems, no fastenings are required, but they can take up a lot of space in the room. For this reason, most consumers prefer wall-mounted air conditioners or those that are hung from the ceiling.

Conventional air conditioners consist of the following elements:

- An indoor unit that absorbs all evaporation and supplies cooled air to the room.

- External block. Designed for pumping air into the air conditioner and installed using brackets on the facade of the building.

- Freon line connecting both blocks

The indoor unit has its own mounting plate that comes with the device, so there will be no problems with fixing it to the wall. However, the outdoor unit does not have any fasteners, so a bracket is needed to secure the outdoor unit of the air conditioner.

Basic requirements for brackets for installing the outdoor unit of an air conditioner:

- The bracket must be strong, but not heavy and can withstand the weight of the outdoor unit of the air conditioner. It must also match the diameter of the holes.

- Depending on the weight of the equipment, the brackets must have an appropriate safety margin. The minimum permissible figure is twice the weight of the outdoor unit itself.

- Meet GOST requirements for climate control equipment. The material must withstand any temperature conditions and have an anti-corrosion and anti-oxidation coating.

Outdoor unit mounted on rectangular brackets

Recently, an increasing number of manufacturers have resorted to making brackets from stainless steel, due to the susceptibility of the metal to corrosion from water on their surface.

Production materials and coating

Steel brackets are most resistant to weather conditions

The brackets are made of steel and polyamide. In the first case, graded metal with a thickness of 1.5 mm is used. The coating used is:

- Enamel is an inexpensive option that will provide a neat appearance and protection from moisture for 2-3 years.

- Galvanization – the coating is applied at the factory using the galvanic method.

- Powder polymer paint is a durable option that provides aesthetic appeal and anti-corrosion protection. The coating is resistant to abrasion, mechanical and chemical influences, and sunlight. Common colors: white, gray.

- Manufacturers provide brackets with a quality certificate. Products that have been tested and meet safety standards have such a document. It is better to avoid purchasing uncertified parts.

Polyamide fasteners are recommended when installing air conditioners on frame houses. Plastic is not subject to corrosion; it is installed in regions with a maritime climate. The material dampens vibration well and is resistant to ultraviolet radiation and temperature changes. The production of polyamide structures is carried out in Italy. The disadvantages of the products include the cost, which is 5 times higher than the price of steel angles. This disadvantage hinders the popularity of plastic brackets.