Air fryer device

The convection oven is a device whose main components are:

- a heating element;

- fan;

- Control block.

A more detailed structure of the device is discussed in the following photograph.

The numbers in the photo correspond to the following structural elements:

- cover with fan and electric heater;

- control Panel;

- cover bracket;

- lid lifting mechanism;

- plastic case;

- flask;

- network socket;

- power cord

As a rule, there is a power off and on button on the cover of the device. When the lid is opened, the cooking process stops automatically. If the device is not closed tightly, it will not start working.

Repairing a device at home should begin with diagnostics, that is, with searching for problems. Common malfunctions include the following:

- the device does not turn on at all or suddenly turns off;

- operating modes are not set at all or are set incorrectly;

- The light panel goes out periodically;

- air heating is weak or completely absent;

- The fan does not work (no airflow).

The device does not turn on

If the convection oven does not turn on, and there is no light indication on the light panel, then the first thing to do is to inspect the device for external damage. It is possible that the cause of the malfunction is damage to the case, power cable or plug.

In the event that the cable is damaged, it is enough to simply replace it with a new one or reconnect and insulate the wiring at the break point. The cord may appear intact on the outside, but may not be functional. To determine the integrity of the cable cores, you will need a multimeter (pictured below).

Important! To diagnose, you need to disconnect the power cord from the convection oven and, in the resistance measurement mode set on the multimeter, check the integrity of the wires: touch the opposite ends of each of them with probes. If the wires in the cable are intact, then the device will show that their resistance is almost zero. When there is a break in the core, the multimeter will display infinity.

Next, you need to check the fuse in the same way with a multimeter. If it does not work, it should be replaced.

Air fryers contain a limit microswitch on the lid. It blocks the operation of the device if the lid is not tightly closed. When you press the switch, you should hear a characteristic click, which indicates that it is in good condition. If there is no sound, this may indicate bad contacts or their breakdown. The end switch is replaced by disassembling the cover shell.

To check the limit switch and not disassemble the entire cover, you need to determine which wires are connected to it from the control board: as a rule, only two wires are connected. Next, you need to detach them from the electrical circuit and connect them to a multimeter. When you press the microswitch, the resistance value on the device should change from infinity to 0. If there is no change on the multimeter, then the limit switch does not work and needs to be replaced.

Contact pressure grill. Device, malfunctions, repairs

Although a contact pressure grill is a complex technical device, from the point of view of an ordinary engineer, it is a simple device, the repair of which will not take much time.

So that we can repair the contact grill ourselves, we will try to figure out how it works.

Pressure grills come in both double and single versions. But their general structure is unchanged.

- HEATING INDICATOR

- POWER SWITCH

- THERMOREGULATOR

- BOTTOM DRAWER

- OIL COLLECTION CONTAINER

- BOTTOM PLATE

- SUPPLY WIRE TUBE

- TOP PLATE

- PEN

- POWER SUPPLY CABLE

- SUPPORT LEGS

The internal circuitry of the contact grill is simple. It consists of two heating elements (upper 1. and lower 2. ), a thermostat 3. , a light indicating that the grill is turned on 4. , a button that turns the contact grill on and off 5. , a contact terminal 6.

So. What malfunctions may arise when operating the grill and how to eliminate them.

1. The grill does not turn on.

- Using a tester, we check the input voltage at terminal 6 . It should be 220-240 volts. If there is no voltage, then check the supply wire and, if necessary, replace it. If there is voltage at the contact terminal, check switch 5 . They are usually not expensive and often fail.

2. The grill turns on but does not heat one or two awnings.

- We check whether voltage is supplied to heating element 1 . And 2. If voltage is supplied, but the heating elements do not heat or one heating element does not heat, then it is necessary to replace it.

- If voltage is not supplied to the heating element, then check the thermostat for serviceability.

3. High temperature, the prepared product burns.

- it is necessary to check the functionality of the thermostat. Since the grill is capable of heating up to 250-300 degrees and maintaining the set temperature at the required level. When the thermostat fails, it loses this ability and the heating elements reach their maximum temperature, which leads to the product simply burning.

4. The handle of the upper pressing surface has become loose; the surface does not lock in one position.

- This problem can be solved by adjusting the spring located on the back of the grill.

What you should pay attention to when using a contact grill.

- A contact grill is an industrial equipment that must be operated by a qualified, trained specialist.

- Do not raise or lower the top of the stove with sudden movements or jerks, and do not install it crookedly.

- Before washing or cleaning the contact grill, disconnect it from the power supply and do not pour water on the pressure grill.

- Do not knock on it or place heavy objects on it.

- Do not touch surfaces immediately after turning off the grill. This may cause burns.

- Before using the contact grill, make sure that the power supply line at the location where the grill is installed is working properly.

Note: There is a temperature limiter on the bottom side of the housing, the response temperature is 130C, and the restart temperature is ‹ 40C. If temperatures are higher, a safety button is activated to provide protection. When using again, please press the safety button first.

One more important point. Using the grill is allowed indoors at a constant temperature of at least 15-18 degrees.

No heating or airflow

If all the lights on the device are on, this indicates a proper power supply. But in the case when heating or blowing of the prepared products does not occur, it is recommended to contact a specialized center. With such a malfunction, most likely, there was a break in the wires connecting the parts of the device.

Advice! To fix such a breakdown with your own hands, you need to completely disassemble the convection oven to check the integrity of each wiring and the condition of all electrical connections.

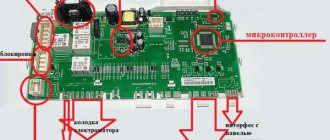

Lack of heating or airflow may also be a consequence of a failure of the control unit. In this case, the following elements do not work:

- timer;

- thermostat;

- mode switch button.

The problem with the control unit most often occurs in cheap, non-original devices without certificates with touch screens. The problem is considered one of the most complex breakdowns, requiring special knowledge in the field of electrical engineering to resolve. In case of malfunctions of this kind, it is better to immediately disconnect the device from the network by removing the plug from the socket.

To repair it yourself, you need to check the integrity of the contacts and ring the board using a tester (multimeter). If there are no signals, then repairs at home will be very difficult for non-professionals. It is better to take the unit to a repair shop.

The control unit has failed

This malfunction is the most difficult. Because of this problem, the air fryer may not only not turn on, but also not switch modes. This problem usually occurs on touch screens. Repairing them will not only be expensive, but also problematic.

You cannot repair this device yourself. If it really doesn't work, then you can call a technician or purchase a new control unit. This breakdown is considered rare and happens if you purchased a Chinese model. If the refrigerator gets very cold, then the control unit may fail.

Checking the heating elements

If the control unit is functioning normally and all internal electrical wiring is intact, and the device heats very little or does not heat up at all, then the heating element is not working. In an air fryer, heating can be carried out using a heating element or a halogen lamp (or its carbon analogue). The latter fails more often, as it has a shorter service life (about 24 months) compared to the heating element (about 10 years).

You can replace a halogen lamp or heating element yourself with parts of the same power. To do this, you will need to disassemble the entire device. In this case, the first thing that needs to be done to replace the heating element is to unscrew the bolts that hold the mesh at the bottom of the device body (a model from the Hotter brand is taken as an example).

Under the mesh there are heating elements and a fan (its blades are visible in the photo below).

The following photo shows the contacts of the heating element.

Important! To check the serviceability of the heating elements, it is necessary to disconnect all contacts. The functionality is checked using a multimeter, just like the power cable: if it breaks, the tester will show an open circuit. Then the heater needs to be replaced.

It is definitely recommended to inspect all wires for breaks or poor contacts at their connections. This is due to the fact that the reason may be precisely in them.

Doesn't heat well

If the convection oven does not heat up or only heats up weakly from below, we can say with confidence that the heating element is not working. The cause of the malfunction may be wear of the heating element at the end of its service life or an open circuit. In the latter case, you can try to repair the damaged area, but according to many reviews on the Internet, it is easier to buy a new part than to spend more than one hour on repairs.

By the way, it should immediately be noted that more often the heating element in the form of a halogen lamp fails, the service life of which is already 2 years compared to the 10 years of a metal heating element. If the lamp under the cover does not heat, you should not replace it with the same one. It would be much more correct to replace the heating element yourself with a metal one. In this case, you will need to dismantle the protective grille, remove the brackets, unscrew the heater and disconnect the wires. After replacement, the parts are assembled in the reverse order. As you can see, you can repair a convection oven with your own hands, which does not gain temperature, without any specific knowledge in electrical engineering!

Determining the performance of the fan motor

There are several signs by which you can determine that the fan is faulty:

- no airflow or very weak air flow;

- the air fryer buzzes when turned on;

- During operation, the device produces an uncharacteristic rumble or grinding noise.

To identify the causes, it is necessary to disassemble the device further. You need to separate the lower part of the fan and the electric motor (they are held together with screws).

Next, you should carefully inspect the engine: you need to inspect the windings and all connecting wires for the presence of burnt areas and for their external integrity.

If grease gets on the shaft and hardens, it can cause problems in the operation of both the electric motor and, accordingly, the fan. In this case, the fan blades will spin very slowly or will not move at all. It is recommended to clean the motor shaft of dirt. Afterwards, lubricate it with special machine or gun oil.

Advice! If you don't have a suitable lubricant, you can even use Vaseline. But it should be taken into account that when heated, it changes its consistency and flows out, so after a short time it will need to be lubricated again.

If the motor winding is externally intact, then to determine the presence of internal breaks in it you will need to use a multimeter. To do this, the device needs to ring the winding output. If the circuit breaks, you will need to buy a new electric motor. In this case, the necessary spare parts for repairs can be purchased on the official websites of the manufacturer or in stores that sell household appliances.

Loud noises during operation of the device may be caused by a faulty bearing on the motor shaft. It is located on the reverse side.

Very often the problem is thickened grease. In this case, by unscrewing 2 screws, you can gain access to the bearing and remove the old lubricant. After this, you need to check the integrity of the bearing. If it is in order, then it needs to be lubricated with oil.

Important! When the bearing has crumbled, is badly worn, or there is a crack in the race, then it needs to be replaced.

Next, you need to reassemble the air fryer in reverse order, returning the lid to its place. To distribute the oil inside the bearing and check that the fan rotates easily, it is recommended to rotate the blades by hand.

How much will it cost to repair an air fryer?

Repair prices start from 300 rubles. And the most expensive repair will cost you 2000 rubles (Replacing the heating element from). According to the GOJA.RU portal, the average cost of repairing an air fryer in 2021 is 1,100 rubles. At the same time, as practice shows, the services of service centers in the city center are somewhat more expensive. Please note that the cost of repairs depends on the air fryer model, age (degree of wear) and the required spare parts for repairs. The exact cost of repairs can be determined only after diagnostics by a service center technician. Urgent repairs tend to cost more. If repairs are needed at home or in the office, pay attention to the presence of a specialist on-site icon.