When the machine is turned off, it fills with water; when idle, a puddle appears on the floor; the powder is not collected during washing. All this indicates a malfunction of the fill valve in the washing machine. Let's figure out how to fix the breakdown yourself.

The instructions are relevant for the following models of washing machines: Ardo / Ardo, Beko / Beko/Veko, Bosch Avantixx, Classixx, Logixx, Maxx, SportLine / Bosch Avantix, Classic/Classic, Logix, Max, Sportline; Brandt / Brandt, Candy Aquamatic, Holiday, CNE, CTS / Candy Aquamatic, Holiday; Daewoo / Daewoo, DEXP / Dexp, Electrolux Time Manager / Electrolux, excuse me, Timemanager, Evgo / Evgo, Gorenje / Gorenje, Haier / Hayer, Hansa / Hansa, Hotpoint Ariston Margherita, RSM, ARSL, ARWM / Hotpoint Ariston Margherita, Indesit IWSB , WISL, WISN, WITL, Innex / Indesit Wisl, Inex; LG / LJ/LV; Miele / Miele, Samsung Diamond, WF, EcoBubble, Bio Compact / Samsung Diamond, Eco Bubble, Bio Compact; Siemens / Siemens, Vestel / Vestel, Whirlpool AWG / Whirlpool, Zanussi Aquacycle, EcoValve / Zanussi Aquacycle, EcoValve; Atlant, Vyatka, Desna, Donbass, Malyutka-2, Saturn, Siberia, Fairy-2, Eureka-3 and other brands with vertical and horizontal loading, automatic and semi-automatic.

Where to start

First you need to make sure that it is the supply valve of the washing machine that has failed. Signs of a breakdown are the entry of water into the tank when the equipment is turned off, or, conversely, its absence when the washing is started.

When doing your own repairs, do not forget to follow safety precautions.

Before disassembling the washing machine, you must:

- disconnect the unit from the power supply - remove the plug from the socket;

- turn off the water at the inlet tap;

- prepare a basin and a rag to clean up spilled water;

- move the machine away from the wall and place it in a free place with access from all sides;

- Put on dry shoes with waterproof soles.

If there is water left in the washing machine, it should be removed through the drain hose next to the filter, or by unscrewing the plug (the compartment is located in front, at the bottom). To do this, use a low basin or other container. Remaining moisture spilled on the floor is wiped off with a rag or rag.

Avoid contact between electricity and water

The water distribution valve is driven by an electromagnet (solenoid) designed to operate from a 220-volt network. Electric shock at 220 V is deadly to humans. A burn appears at the point of contact and death is possible.

Therefore, be careful and be sure to turn off the power to the equipment before starting work by unplugging the plug from the outlet.

Tools

Disassembly and diagnostics of the valve is carried out:

- Phillips and flat-head screwdrivers (we recommend using a screwdriver);

- pliers;

- pliers with sharp jaws;

- multimeter.

All parts can be easily removed without the use of force, especially if there are plastic latches.

Universal instructions for disassembling washing machines: 23 videos for all brands

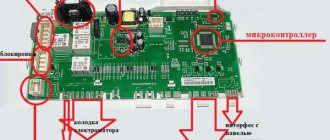

Operating principle and types of washing machine valves

operation algorithm :

- The control module of the washing machine sends a signal to the valve that the washing program is activated.

- An electric current flows to the valve's electromagnetic coil, which creates an electromagnetic field in it.

- The electromagnetic field of the coil opens the valve (the membrane rod is tightened), through which water begins to flow into the detergent cuvette.

- From the cuvette, water and powder enter the washing machine tank.

- When water has been collected in the required amount, the voltage supply to the valve coil is cut off, it closes, and water stops flowing into the tank.

Thus, the solenoid valve can be either open (water is poured in) or closed (water does not enter the unit). The principle of operation is similar to the operation of a conventional faucet, but the device is much more complex.

Classic solenoid valves (aka valves that were previously installed in washing machines) have one coil. The vast majority of modern washing machines have:

- Double-coil - a valve with two sections. The first coil supplies water to the first compartment of the detergent cuvette, the second – to the second, and the third – when both coils are working.

- Three-coil - a valve with three sections. Each compartment of the cuvette has its own coil.

Theory and principle of operation

The shut-off valve on a washing machine performs the same functions as a regular faucet. Only it opens not manually, but with an electric coil at the command of the control unit. When power is applied, water under pressure rushes into the tank or into the powder compartment, depending on the program.

What does the inlet hydraulic valve consist of:

- plastic case;

- solenoid (electromagnetic coil);

- stock;

- spring;

- rubber or polyurethane membrane;

- filter mesh;

- inserts in fittings that reduce pressure;

- seals and fasteners.

When the wash starts, current is applied to the coil and the rod (a metal rod with an elastic band attached) is attracted. The membrane opens, liquid under pressure from the water supply enters the washing machine. When the required quantity is reached, the level sensor (pressostat) signals the control unit and the current is turned off. The spring returns the rod to its original position, closing the water.

Probable malfunctions and their diagnosis

Replacing the filling valve of a washing machine may be necessary when the water supply is disrupted or stopped.

Procedure for diagnosing a malfunction

- Check the filter mesh, clogging of which prevents the normal flow of water.

- Dismantle the part, connect the inlet hose, lower it into the container, apply voltage to the coils one by one. In good condition, when voltage is applied, the valve is open, when disconnected, it is closed. If it stays closed, the coil is probably burned out. There will be no water inlet.

- If water flows in, but after shutting off it continues to flow out, the membrane has become unusable or the rod spring has been completely weakened. Here it is necessary to replace the water supply valve in the washing machine.

You should also check the presence of inserts pressed into the fittings. If they are missing, the compartment overflows and disrupts the proper order of program execution. In such a situation, the solenoid valve should be replaced.

In almost all situations, in the event of pressure disturbances during supply/no flow, the failed unit should be replaced.

Basic faults

Housing, filter mesh, membrane, spring, winding, pipes - all these parts of the intake mechanism fail over time. Let's look at the main types of faults.

The inlet grid is clogged

There is a metal or plastic mesh at the entrance to the valve. It traps large mechanical debris from the pipes without allowing particles to enter the drum. The dirtier the water in the tap, the faster it becomes clogged. Dirt on the filter is visible from the outside; just remove the supply hose. There is no point in disassembling the entire assembly each time for cleaning.

The mesh is removed using pliers, translational and rotational movements. The inlet filter must be cleaned: rinse under running water and blow through with air.

The membrane is clogged

An elastic and elastic rubber membrane moves with each movement of the rod, opening and closing the tube. When clogged, the rubber does not adhere tightly to the walls of the housing and allows water to enter the tank, even in the closed position.

The membrane should be removed from the housing, inspected for integrity, and elasticity checked. If there are cracks or abrasions, the part must be replaced.

The return spring breaks or becomes clogged

Over time, the return spring compresses and may break. If the part is visually in good condition, it should be slightly stretched and put in place during assembly. If there are defects, breaks, or rust, the spring must be replaced with a similar one.

When disassembling, the return spring itself falls out of the housing - just remove the rod. Be careful not to lose the part.

Damaged hull

The plastic shell contains an electromagnetic coil, inside which the rod and membrane move. If there are cracks, water will constantly leak inside the machine and can get onto electrical components. As a result, the “washer” produces an electric shock the moment it touches the body. This is fraught with a short circuit and fire.

The element is dismantled and inspected, checked for leaks. There should be no dents or traces of impacts. If there are visible defects, there is no need to repair the part; it is easier to buy a new unit.

Cracking due to frost

A washing machine installed in a place of seasonal residence, for example, in a country house, freezes in an unheated room in winter.

The remaining water turns into ice. As a result, the body and pipes burst. The membrane and gaskets no longer retain water after defrosting.

At the first sign of water leaks after winter, the inlet valve should be replaced immediately. The machine cannot be turned on until the equipment warms up to a temperature above +15⁰.

Valve hoses

Water, having passed the filling valve, enters the container for detergents and rinse aid through hoses. The integrity of the pipes must be checked first. If there are cracks or tears, water will drip from above onto the engine, pump and other parts located below. In addition to a puddle on the floor, this will lead to a short circuit in the windings of the electric motors with subsequent failure.

How to check the tightness of a hose at home.

- Close one end tightly.

- Place it in a container of water, leaving a free edge on top.

- Fill with air. You just need to blow it in with your mouth.

If bubbles appear in the water, the hose is torn and requires replacement.

Repair or replace the inlet valve of the washing machine

The inlet valve is responsible for the automatic process of drawing water into the washing machine.

This is a special small device that supplies water at the request of the washing programs and when the water reaches the desired level, the process stops. In general, the principle of operation of the valve is similar to that of a faucet familiar to everyone. It also supplies water, although you have to open it manually. On the intake valve, this action is completely automated, which increases the likelihood of its failure. There are different inlets for washing machines. Previously, the operating principle of the valve itself was simply described, but in fact the operating process is a little more complicated. Since it is not enough to simply run water into the machine itself, it also needs to be distributed among different tubes, and at different times during the washing process.

How to check functionality

An electromagnetic coil drives the rod. The performance of the node depends on its condition. You can check it in different ways.

Connect 220 volts

When connecting a 220 V household current to the electrovalve terminals, a magnetic field is formed in the coil, which attracts the metal rod along with the membrane - characteristic single clicks will be heard. When disconnected, everything returns to its place and the water pipe is closed.

Check resistance

The coil is usually soldered to the body, therefore, it is easier to test the contacts with a multimeter. Depending on the design of the bypass valve, the device will show a resistance of 2-4 kOhm on the working coil.

Intake valves are single, double, triple. The coils in each ring separately.

How to check the water supply valve in a washing machine

But, like any other part in a washing machine, the valve can fail. If this happens, your washing machine will stop drawing water. In order to check the valve, you need to perform the following steps:

- The first thing you need to check is whether the valve is clogged ; to do this, unscrew the water supply hose and pull out the mesh filter. Clean it.

- Remove the valve from the washing machine and connect the water supply hose to it, open the water supply tap. The valve must not leak water. Next, you need to alternately apply 220V voltage to each section . Depending on which section you apply current to, the valve should operate and water should flow from the corresponding tube. If one of the washing machine valve coils does not work, it means it is faulty.

- You can also check the functionality of the valve coil using a multimeter; to do this, measure its resistance, if it is in the region of 2-4 kOhm, then the coil is in order, otherwise it is not working.

Be very careful because if water gets on exposed wires, it may cause a short circuit and you may be subject to electric shock. So think about safety.