The service life of vacuum cleaners is on average 5-10 years, and warranty repairs provided by the manufacturer or distribution company are 1-2 years. During this time, equipment rarely fails. Exceptions are manufacturing defects, cheap and low-quality products.

Therefore, if the unit breaks down after the warranty period has expired, you have to contact expensive service centers. Agree, wouldn’t it be nice to learn how to fix some problems yourself? This skill will help when there is no time to wait for a master, and will also save the family budget.

Do you doubt your own abilities? We will help you cope with the problems that arise. In the article, we identified the most common breakdowns of different types of vacuum cleaners, and also provided detailed instructions for eliminating them.

In addition, we have listed the basic rules of operation and prevention, the observance of which will prevent the occurrence of any malfunctions in your device.

Malfunctions in different types of vacuum cleaners

Before you figure out what types of breakdowns most often occur in cleaning devices, you should familiarize yourself with the most popular types of units.

According to the specifics of cleaning, devices for dry and wet cleaning are distinguished. The first type is a more budget option, which is produced by almost all well-known brands - Samsung , Bosch , LG , etc.

Washing vacuum cleaners belong to the premium segment: their cost is much higher, but the functionality of the devices is also high.

With the help of such a unit it is possible to perform not only dry and wet cleaning of floors and furniture, but also to wash windows and use it as an air humidifier

Their design is similar to conventional dry cleaning devices, however, it additionally contains a water container, special nozzles and filters.

Based on the type of construction, the following types are distinguished:

- standard household - floor-standing appliances that move using wheels on the bottom of the case;

- vertical – battery-powered and corded units that provide comfortable cleaning due to their compact size and light weight;

- portable (manual type) – intended for cleaning car interiors, small rooms, cleaning furniture;

- robotic – devices with automatic cleaning programs without user intervention, controlled using a remote control.

Depending on the type of unit, dust particles and debris can be collected in a special fabric or paper bag, in a plastic container or a special container, passing through an aquafilter.

Features of repairing devices with a bag

The principle of operation of a unit with a dust bag is that air masses pass through it, then through an ultra-cleaning filter and the engine compartment. The HEPA filter used in such products not only traps dust microparticles, but also acts as a compressor.

Most often, in these models, filters are the main parts that fail most quickly.

If the device is not properly maintained or the bag and filter elements are not cleaned in a timely manner, the HEPA and fine filters become clogged, which reduces the suction power or leads to engine breakdowns.

Some models have a sensor function for determining the intensity of air intake: if problems are detected, the vacuum cleaner automatically turns off and the filter is cleaned.

If the device does not provide such technology, then you should independently monitor the quality of garbage suction. You should definitely be alerted to the appearance of a hum or overheating of the equipment body - this is a reason to check all the filter elements.

“Diseases” of units with a cyclone filter

The advantage of container models is the absence of the need to frequently replace disposable filters, quick cleaning of the waste container, high quality surface cleaning with additional air cleaning.

The maximum retention of microparticles occurs in the cyclone filter. Therefore, purified air masses, passing through the engine compartment, and then through the HEPA filter, do not clog it. Thus, the filter lasts much longer than in options with bags.

Users note that canister vacuum cleaners do not break down very often. Most often, problems arise with the mesh filter, which is located at the outlet of the cyclone.

During operation of the device, the filter element protects the fan motor from metal and sharp objects that could damage the integrity of the part. Therefore, you should definitely check that it is not clogged with debris before you start cleaning.

Types of breakdowns of models with an aqua filter

The dust collection process is carried out in this way: the incoming air beats the water in the container to small particles, removing it under the front visor.

Dust masses, together with a foggy vortex, continuously pass through the hose and settle to the bottom of the dust collector. Remaining dust particles pass through where moisture is trapped. Next, the purified air without water passes through the engine and cools it.

Having understood the principle of operation of the device, we will now consider the most common failures in its operation.

For a long service life of the vacuum cleaner, you must follow all instructions. It is recommended to fill the container only with purified or distilled water to the indicated mark.

It is also necessary to clean, rinse and dry all used parts. This will allow you to use the device without replacing the HEPA fog filter for 2 years or more.

If you use ordinary water and do not follow the operating instructions for the device, the filter will quickly become clogged. The filter element cannot be cleaned, but only replaced

Another problem is the failure of the fan motor due to burnout of the winding. This can be noticed if the unit begins to overheat, hum, the suction power of debris has decreased, and RCDs and automatic circuit breakers are knocked out. If a problem is detected, you will need to replace the faulty part.

Reasons for disassembling the vacuum cleaner motor

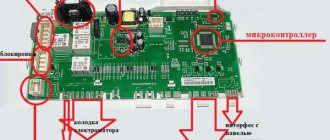

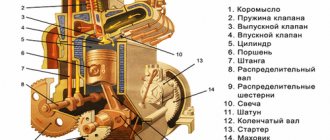

The motor unit of a vacuum cleaner, in turn, consists of 2 fundamental mechanisms:

- Commutator motor;

- Fan.

The fan is attached to the rotation shaft, due to which the suction process takes place. As a rule, the main reason for motor failure is neglect or long-term use.

Manufacturers of household appliances solved the problem with the first option by installing a thermostat that shows the temperature on modern models. The electric motor for the LG vacuum cleaner has this device. When the critical temperature is reached, the thermostat automatically turns off the unit. To continue using the unit, you should leave it for a while until it has cooled down properly.

Another question that owners of household appliances are interested in is “Why do brushes spark?” Like rapid overheating, as well as a strong hum, this problem also applies to a malfunction of the vacuum cleaner. In such cases, the best solution is to replace the motor. But there are situations when the vacuum cleaner engine can still be saved and rehabilitated. These include: rapid loss of suction power. Do not rush to conclusions; perhaps the power drops due to the neglected condition of the filters and brushes. You should always check the equipment first. By the way, repairing an electric motor armature, depending on the level of depreciation, costs 70% of the cost of a complete motor, so it is recommended to purchase a new one.

Although, on the other hand, the design of household vacuum cleaners from different manufacturers is similar, so trying to fix a vacuum cleaner at home is still worth a try.

Repair instructions for various breakdowns

In each of the types of vacuum cleaner discussed above, various elements and components can fail. This depends on the design of the unit and the principle of its operation.

For example, most often users encounter the following problems:

- no traction;

- there is a foreign smell;

- The device does not turn on;

- a short circuit occurs, the plugs are knocked out;

- there is no cord fixation;

- suction power has decreased;

- noise and vibration;

- other.

Next, we will consider in detail what malfunctions most often occur in various types of products, and how to fix them yourself.

If your device has broken down and the warranty period has already expired, do not rush to take it to a service center. Perhaps the breakdown is simple, and you can repair the vacuum cleaner yourself without the help of specialists.

The examples of malfunctions presented below, methods for diagnosing and repairing them will help you independently solve this or that problem with the unit.

Failure #1 - the device does not suck up debris

When such a malfunction is detected, the device produces a characteristic sound in the form of a hum. This indicates that the engine is running, but is not absorbing dust.

You need to pay attention to such elements as a hose and nozzles, a dust collector, filter mechanisms, and make sure that they are intact.

To do this, you should perform a number of actions:

- Check to see if the bag or container is full of trash.

- Separate all parts from the hose - brush, tube. They may contain debris that interferes with the free passage of air flow. If found, clean the accessories under running water or using a long knitting needle.

- If the reason is not in the hose, then the blockage has formed inside the device. Check all filters (exhaust, fine). If possible, read the instructions and rinse the fine filter and dry it. After this, install the part into the vacuum cleaner body and make sure it is working.

- Inspect the garbage receptacle carefully. Fabric bags must be washed or cleaned of fine accumulated dust, which clogs the cells and interferes with the free passage of air.

Other reasons for poor dust suction may be deformed gaskets, seals, or lack of a tight connection between the hose and the product body. A worn o-ring or broken vacuum regulator bushing must be replaced with new parts.

In another case, when air passes well through the tube and brush, but debris remains on the floor, you should check the height of the brush roller.

Try moving the roller a little higher or lower - experiment. Perhaps the roller is simply not adjusted and cannot fully perform its functions

If it is not possible to achieve ideal absorption of debris, then you will need to replace the nozzle.

Failure #2 - the vacuum cleaner emits a burning smell

If during or after cleaning the smell of burnt rubber appears and the engine stops working, then the reason lies in the winding. To do this, you will need to completely disassemble the motor, repair or replace the burnt armature or stator with a new element.

Engine disassembly instructions:

- Unscrew the bolts from the product body.

- Tilt the housing cover, move the coil and wires and remove the motor.

- Unscrew the side bolts and remove the rubber seal.

- Separate the housing into two parts using a screwdriver.

- Remove the motor from the protective housing.

- Bend the flanges and separate the part, releasing the turbine.

- Unscrew the bolt using a socket head, tightly fixing the stator and the rest of the structure.

- Unscrew all connecting elements and remove the brushes.

- Knock out the anchor using a wrench and a hammer.

Check the serviceability of the bearings and, if necessary, treat them with oil.

It is not recommended to replace the winding yourself: after the procedure, dynamic balancing of the armature will be required, which is difficult to perform on your own

After disassembly, replace the failed elements and reassemble the part in the reverse order.

Failure #3 - equipment does not turn on

Have you noticed that when you repeatedly try to turn on the device, there are no signs of its operation? Then you should check the voltage in the outlet to which the device is connected, as well as the integrity of the power cord.

As a rule, the wire breaks where the cord is attached to the plug, resulting in no contact. If you find this problem, then you will need to completely replace the cord with a new one.

For repair you will need:

- Remove the back cover of the device.

- Unscrew the screws securing the diaphragm.

- Carefully remove it without touching the wires.

- Move the block with the gasket to the side.

- Remove the spring and check its serviceability.

- If necessary, replace wiring and damaged elements.

After the repair has been completed, reassemble the unit in the reverse order according to the instructions.

Faulty switches and internal wiring may also cause the breakdown. Another possible reason is the operation of auto-protection against overheating of the device. This technology prevents engine damage due to increased load during operation of the device.

The presence of a thermal switch allows you to prevent overheating of the device in time, and additional options eliminate the cause - for example, they clean the HEPA filter from dust particles.

Many models of washing units have a special relay installed that turns on when overheating of the device is detected.

If you notice that the vacuum cleaner suddenly turns off and its body is hot, then the relay has tripped. The device will turn on automatically after it has completely cooled down.

The reasons for overheating of the product are clogged filters, dust collector, air duct.

The most unpleasant reason for the unit not turning on is a breakdown of the electric motor. Therefore, the first thing to check is the brushes and commutator. Disassembly of the part should be carried out according to the instructions described above.

The collector assembly must be checked for moisture, which could cause a short circuit in the motor winding. If you find a damp environment inside, you will need to dry everything thoroughly.

A short circuit in the commutator compartment is also possible due to graphite dust from the brushes. To eliminate it, you will need to clean the collector with a brush and cloth.

Failure #4 - problems with battery charging

Battery devices also tend to malfunction sooner or later. In addition to mechanical damage, breakdowns of electric brushes and other accessories, users most often note rapid battery discharge, prolonged charging, or loss of dust suction power.

The reason lies in the battery pack. Depending on the frequency of use of the product, the battery must be replaced after 2-3 years. During this time, the element completely uses up its resource, and repeated charging no longer gives any results.

The suction power of the air flow decreases as the battery capacity decreases.

If you notice these malfunctions in the operation of the wireless unit, then it’s time to buy a new battery. The battery can be purchased at a service center or ordered from an online store

Replacement should be carried out carefully: opening the product case, disconnect the broken battery and install a new one in its place.

If you notice problems with the battery within 1-2 years of operation, this is a reason to submit the equipment for warranty repair.

Failure #5 - problem with fixing the power cord

In corded vacuum cleaners, a malfunction of the winding drum often occurs: the cord does not retract when the button is pressed or is constantly wound up while the device is operating.

The cause may be a burst, stretched or slipped spring. To check if this is so, you need to press the button several times from different sides

If a malfunction is detected, repairs should be carried out in the following order:

- Remove the product housing cover.

- Remove the drum and coil spring of the lever with bushing.

- Remove the brake roller and lever.

- Replace deformed elements - coil spring, support, etc.

- Adjust the tension of the cord in the drum.

- Assemble the drum and install it in place.

- Check the functionality of the stopper lever.

- Assemble the vacuum cleaner by attaching the housing cover.

After complete assembly, you should make sure that the auto-winding mechanism is working correctly.

Failure #6 - decreased suction capacity

Reduced traction can be caused by a clogged dust container, dirty filters, engine problems, or a faulty hose. Another reason is corrosion processes in the connecting cord retracting mechanism.

Which, due to long-term operation of the device, can cause periodic malfunctions and also reduce the suction power of dust masses.

You can restore the correct operation of the unit in this way:

- Remove the back cover of the product.

- Sand the contacts using 20-grit sandpaper.

- Treat them with a cloth moistened with alcohol.

- Using the same procedure, clean the slip rings in the drum mechanism.

- Reinstall the cover.

- Check for electrical contact in the winding mechanism.

After these manipulations, you will be able to use the device safely, and its suction capacity will be restored if the problem was hidden in the corrosion of the auto-winding unit.

Failure #7 - malfunction of the dust collector indicator

Jamming of the piston system of the mechanism and deformation of the indicator spring prevent its proper operation.

When the bag is full, the indicator may not work, which may cause the engine to overheat. This is fraught with even greater damage to the unit.

To repair a failed mechanism, you must:

- Remove the front cover.

- Remove the dust bag, filter, grille, ultra-cleaning filter and device handle.

- Unscrew the screw holding the indicator.

- Remove the indicator tube from the housing.

- Remove the rubber bushing and spring from the tube.

- Completely disassemble the entire mechanism in detail.

- Replace the deformed tube, plug, spring, and if there is a blockage, remove it using a sharp object and a brush.

- Assemble the elements one by one into the indicator housing and install it on the device cover.

Based on the results of the completed procedure, make sure that the indicator is working.

Failure #8 - broken brush in the washing unit

A malfunction of the wet cleaning attachment is a consequence of improper use of the device by the user. According to the instructions, the washing vacuum cleaner must be filled with water up to the mark on the tank.

When dry cleaning, the pump will run idle and for this reason its motor will fail. The pump is an integral part of the tank and cannot be repaired, only completely replaced.

The water and detergent spray tubes are located on the outside. When they are clogged, it is quite easy to determine visually: they are transparent.

To clean, you will need to pull the tube from the fitting and the spray mechanism, and then install it back. If a part is damaged, you can use any plastic tube of suitable length and diameter.

Enter the site

RSS Print

Category : Accounting Replies : 16

You can add a topic to your favorites list and subscribe to email notifications.

« First ← Prev. 2 Next → Last (2) »

| Tatiana Gaenkova [email protected] Belarus, Minsk Wrote 17697 messages Write a private message Reputation: 1901 Group: Moderators | #11[65494] December 16, 2009, 16:22 |

Svetlana wrote:

I called the service center and they said that 99% of them were missing precious metals, and I also read the documents for the vacuum cleaner and couldn’t find anything either. I will write it off, but at what expense? The previous accountant attributed 50% of the cost to expenses (teaching)

Svetlana, there is a directory of precious metal contents. You need to look there. Previous The accountant attributed 50% of the cost. on costs, as I understand it, when commissioning as an MBP. You still have 50% of the value left on account 10. The reasons for write-off can be: breakdown due to improper operation (you can write it off to the guilty party, for example), disposal due to unusability (completely worn out, for example). It is necessary to organize a commission and draw up an act. In the report, establish the reason for the write-off (improper operation most likely needs to be confirmed by a conclusion from the repair). If there are precious metals, you cannot write them off. First you need to recycle precious metals. You can read this question in more detail, but I simply don’t have time right now: I’m preparing taxes. You can read the theory of how IBPs are generally written off. I listed for you what I remember. I advise you to write it off as an employee’s salary or “ship it out” (if possible), this is less burdensome than writing it off as expenses. P.S. In my practice, I wrote off the cabinet as an expense (disposal due to unusability). They say it's broken and can't be used again. Drew up an act. But I wouldn’t take that risk with a vacuum cleaner.

I want to draw the moderator's attention to this message because:Notification is being sent...

I’m rarely on the forum, so I can’t advise everyone in private messages. Sorry.| Firefly [email protected] Belarus, Minsk Wrote 447 messages Write a private message Reputation: | #12[65503] December 16, 2009, 16:29 |

Notification is being sent...

An hour of work will teach you more than a day of explanations. There are moments when everything works out, don’t be horrified - it will pass| Tatiana Gaenkova [email protected] Belarus, Minsk Wrote 17697 messages Write a private message Reputation: 1901 Group: Moderators | #13[65524] December 16, 2009, 16:54 |

Notification is being sent...

I’m rarely on the forum, so I can’t advise everyone in private messages. Sorry.| Firefly [email protected] Belarus, Minsk Wrote 447 messages Write a private message Reputation: | #14[65542] December 16, 2009, 5:26 pm |

Notification is being sent...

An hour of work will teach you more than a day of explanations. There are moments when everything works out, don’t be horrified - it will pass| Tatiana Gaenkova [email protected] Belarus, Minsk Wrote 17697 messages Write a private message Reputation: 1901 Group: Moderators | #15[65551] December 16, 2009, 5:33 pm |

Notification is being sent...

I’m rarely on the forum, so I can’t advise everyone in private messages. Sorry.| Firefly [email protected] Belarus, Minsk Wrote 447 messages Write a private message Reputation: | #16[65567] December 16, 2009, 18:06 |

Notification is being sent...

An hour of work will teach you more than a day of explanations. There are moments when everything works out, don’t be horrified - it will pass| Olga [email hidden] Belarus Wrote 1 message Write a private message Reputation: | #17[88344] February 13, 2010, 6:18 pm |

Notification is being sent...

« First ← Prev. 2 Next → Last (2) »

In order to reply to this topic, you must log in or register.

Prevention of vacuum cleaner breakdowns

To increase the service life of equipment, proper care should be taken. Regular fault prevention ensures high-quality and uninterrupted operation of the unit, and also prevents sudden breakdowns or failures during use.

Periodic visual inspection of the device will allow you to identify worn parts and components and replace them in time. Timely replacement of spare parts is necessary in order to avoid more serious damage to other parts.

Preventative engine care

Caring for the electric motor and early diagnosis of faults prevents possible malfunctions in the operation of the equipment.

It is recommended to disassemble the engine once every 1-2 years, lubricate it, change gaskets, rubber seals, clean filters, and also change bearings when they wear out.

The vacuum cleaner should be disassembled in the following order:

- remove the trash container or bag, filter element;

- unscrew the housing cover;

- clean all parts and mechanisms from a layer of dust;

- Unscrew the bolts and disconnect the engine;

- disassemble it into parts, wash, lubricate, check the condition of the winding, brush-commutator assembly, bearings;

- if necessary, replace worn parts;

- Clean the HEPA filter.

Next, you need to reassemble the device in reverse order.

General recommendations for caring for the unit

Since the main function of a vacuum cleaner is to clean the room from dust, it must be regularly emptied of accumulated debris.

To prevent overheating and damage to components and mechanisms of the device, it is recommended:

- After each cleaning, check the cleanliness of the filters and clean them if necessary;

- Empty the dust bag and garbage container in a timely manner;

- store equipment in a dry place, preventing water from getting on the engine and internal parts;

- Avoid contact with sharp objects that could damage important components of the device;

- observe the operating mode of the unit and do not overheat it.

If problems with the device do arise, follow the above basic recommendations for troubleshooting vacuum cleaner problems.

Malfunction ∙ Cause ∙ Remedy

— The vacuum cleaner does not work when turned on or works intermittently

∙ No contact between plug and socket

Strengthen the contacts of the conductive parts of the socket

∙ Break in the connecting cord or poor contact in the reinforced plug

Disassemble the vacuum cleaner, check the connecting cord, determine the location of the break and repair the break or replace the connecting cord. Assemble the vacuum cleaner and turn it on to check its operation.

∙ The switch does not work

Disassemble the vacuum cleaner, remove the switch, and use an ohmmeter or tester to check its operation. Replace faulty switch

∙ Poor contact between the cord winder slip rings and the spring contacts

Disassemble the vacuum cleaner. Remove the cord winding mechanism, inspect the slip rings and spring contacts. If necessary, bend the spring contacts and clean them if they burn. If the spring contact is broken, remove the diaphragm by unscrewing the four screws, release the board and replace the broken contact with a new one.

∙ Poor contact in the wiring diagram

Check the contact connections at the solder points and the conductors for breaks, remove the electric motor from the vacuum cleaner body and check all contact connections with an ohmmeter. In the event of a break, the ohmmeter connected to the outputs of the capacitors will show infinity. It is necessary to find the break point and eliminate the defect

∙ Electric brushes do not fit tightly to the armature commutator (increased sparking, low vacuum)

Disassemble the vacuum cleaner. Remove the electric motor and electric brushes and disconnect them from the wiring harness

∙ Wear or destruction of electric brushes

Replace electric brushes with new ones

∙ Clamping of the conductive cord of the electric brush with a spring

Disassemble the vacuum cleaner, remove the electric motor, remove the electric brushes and free the cord from being pinched by the spring.

∙ Separation of the conductive cord from the electric brush

Replace electric brushes

∙ Burning of brush holders

Disassemble the vacuum cleaner, remove the electric motor and electric brushes, unscrew the screws securing the brush holders, remove them, replace them with new ones

∙ Contamination of the armature commutator (increased sparking under the brushes)

Disassemble the vacuum cleaner, remove the electric motor, crush the cap and clean the armature collector with fine glass sandpaper. After this, use a rag moistened with gasoline or alcohol to thoroughly wipe the grooves between the collector plates and the surface of the collector

∙ Breakage of the armature winding (low vacuum, increased sparking under the brushes)

Disassemble the vacuum cleaner, remove the electric motor, disassemble it and replace the armature

∙ Short circuit of the armature winding (increased sparking, low vacuum, smell)

Replace the motor armature

∙ Open circuit or short circuit in the stator windings

Disassemble the vacuum cleaner, remove the electric motor, disassemble it and replace the stator

∙ Combustion of electric motor windings (smell of smoke)

Disassemble the vacuum cleaner, remove the electric motor and replace it with a new one

∙ Destruction of ball bearings (low vacuum, increased vibration)

Disassemble the vacuum cleaner, remove the electric motor, disassemble it and replace the ball bearings with new ones, having previously filled them with CIATIM-221 lubricant in the amount of 0.5 g for ball bearing 60029 and 0.25 g for ball bearing 60027

— Vacuum cleaner overheating

∙ Excessive contamination of the filter bag (low vacuum, vacuum cleaner does not remove dust well)

Open the locks, take out the filter bag, and clean it of debris. Install bag

∙ Clogged hose (low vacuum, vacuum cleaner does not remove dust well)

Clean the hose by connecting it to the blowout hole of the vacuum cleaner.

∙ Large sparking of electric brushes

Disassemble the vacuum cleaner, remove the electric motor and remove the cap. Check the condition of the collector and, if it burns, clean it. When a ledge is formed on the collector, it is allowed to groove the collector to a diameter of at least 31 mm. After grooving, lay insulation between the plates to a depth of 0.5 mm. The maximum permissible runout of the commutator after grooving is 0.015 mm. If the commutator is in satisfactory condition, it is necessary to wipe the brushes and brush holder

Tips for proper use of the vacuum cleaner

Vacuum cleaners, more often than other household appliances, break down. Reason: the use in the design of commutator motors, characterized by an accelerated rotation speed. If you use a vacuum cleaner that does not have cooling, then pause after the vacuum cleaner has worked for a quarter of an hour. The presence of cooling will allow you to work for more than 15 minutes. This design feature gives you a couple of hours. Strictly adhere to the passport operating mode specified in the specific operating instructions. Engine heating also depends on the degree of dust in the filter.

To keep the device in good condition, you should ensure that the filter is cleaned regularly and stored dry. Avoid washing or getting filters wet, as this is a common cause of vacuum cleaners overheating. Vacuum cleaners require constant care: the grease in the electric motor bearings is changed once every two years, and the serviceability of the graphite brushes is also checked once a year.

How to prevent vacuum cleaner breakdown

To avoid having to repair the vacuum cleaner ahead of time, you should treat it with care, like any household appliance. To extend the life of your vacuum cleaner, you must follow simple rules:

- monitor the cleanliness of filter parts, wash them and change them on time;

- lubricate and replace bearings; if you cannot do it yourself, contact a service center;

- do not drop or hit the vacuum cleaner;

- Ensure that the device is stored correctly.

Do not use the vacuum cleaner if the power cord is damaged, as this may result in electric shock.