When does such a need arise?

The situation when the charger was forgotten at home or left due to lack of space in the bag can always arise. The laptop tends to discharge, and most often this happens at the most inopportune moment. Here a spare battery like a Power Bank could come to the rescue, but it can only be connected using a USB connector . The demand for this function has been obvious for a long time, but much depended on the technical problems of its implementation.

Is it possible or not?

The USB port was designed as a universal connector for connecting any peripheral devices to a computer - keyboard, mouse, printer, scanner, and so on. Large devices in this case were connected to the network separately, and the minimum transmitted current was enough to power the rest.

For example, a current of approximately 0.5 A is transmitted through the USB 2.0 interface. The connectors of the latest standard output up to 0.9 A. But in this case we are talking about supplying power from the computer to the connected device. The possibility of the reverse process appeared only after the development of the USB-C interface, and even then with some restrictions.

How to charge a laptop without charging via USB

So is it possible to charge a laptop via USB? A little less than five years ago, any knowledgeable person would have answered unequivocally - the protocol specifications do not provide for such a possibility. But the situation has changed. The pioneer, as often happens, was Apple. It released a laptop model with a universal port where you can connect peripherals and recharge the device. This is how the new USB type C standard emerged, highly appreciated by users and then picked up by manufacturers.

A little history

At the end of the last century, it was decided to reduce the variety of ports (PS/2, LPT, etc.) and replace them with the USB (Universal Serial Bus) standard. The first generation is designed exclusively for connecting external peripherals. The task of powering them was not a priority; 5V, 0.15A, with a power of 0.75 W was supplied to the connector. This was enough to ensure the operation of the manipulator or keyboard.

In the second generation, at the same voltage, the current was increased to 0.5A, which made it possible to power external hard drives. The new third-generation standard USB 3.1 Type-C could already power mobile devices - the current on it varied from 0.9-1.5A, power up to 15 W. What it brought us:

- Data transfer speed 10 GBps.

- The port is capable of charging devices that require up to 100W.

- The new connector is no different in size from micro-USB.

- Complete symmetry, absence of a key, the position of which, if disturbed, can damage the connector or the connected device.

- Possibility of outputting up to 20V.

- Identical connectors at both ends, i.e., power supply voltages can be transmitted in both directions, depending on need.

- Compatible with all “younger versions” using an adapter.

- The connector is guaranteed to withstand up to 10 thousand connections.

So, we see that before the introduction of the new standard, the ports were used exclusively to power external devices, and not to supply voltage to the computer itself.

Important. It turns out that you cannot charge the device through a regular USB port. It's simply not designed for this.

What laptop can't be powered via USB?

So, the first necessary condition under which you can try to charge a laptop is the presence of a USB-C port. Accordingly, laptops without it are deprived of such an opportunity in principle.

Regulation of power transmission through the connector is carried out by the Power Delivery protocol , which is responsible for the compatibility of the laptop and the connected device in terms of energy. By default, the minimum parameters are used - current up to 2 A at a voltage of only 5 V.

To charge a laptop battery, a higher protocol profile is required, which makes it possible to transmit current up to 3 A at voltages up to 12 V.

Important! You should find out such nuances not by trial and error, but by studying the documentation that comes with the laptop. It should contain specifications for each connector.

Which laptops cannot be charged via USB?

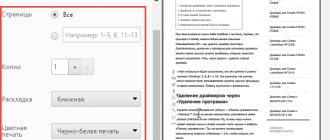

So, the presence of a USB-C port on a laptop does not guarantee the ability to charge it with a low Power Delivery profile. Let's take a closer look at their parameters:

- voltage 5V, current up to 2A, power up to 10 W;

- voltage 5-12V, current up to 1.5-2A, power up to 18 W;

- voltage 5-12V, current up to 1.5-3A, power up to 36 W;

- voltage 12-20V, current up to 3A, power up to 60 W;

- voltage 12-20V, current 4.75-5A, power up to 100 W.

To ensure the laptop battery is charged, at least a third PD profile is required, which is capable of providing the required power and current.

Types of USB ports through which you can charge a laptop

The next pitfall on the way to charging your device is that not every USB-C port is designed to connect a power source . If there are several of them on the laptop case, then it is better to check the technical documentation again. Not all manufacturers conscientiously apply special markings to the body.

Reference. Only a connector that supports the Power Delivery or PD protocol is suitable for this purpose.

As a rule, a suitable connector should have a standard USB marking in the form of an icon with an arrow placed in an irregular frame. To make the designation even clearer, an image of a battery or electrical plug can be placed next to the connector. Devices from ASUS and Lenovo, for example, can boast of this.

Type-C port

The first specification for this connector was published by USB developers in 2014. It supports the 3.1 standard and, to the delight of many users, is made symmetrical . In previous versions of the port, connecting devices was only possible with a certain position of the plug.

In addition, the new interface is smaller in size, which reduces the thickness of the laptop body. In the future, Type-C ports should replace all the variety of different connector options that required adapters and corresponding wires.

Now you can find several port options:

- The first is a 2.0 standard connector, which provides equipment connection and data transfer at speeds of up to 480 Mb/s.

- Connectors working with the 3.1 standard can transmit 5 or 10 Gb/s. They are distinguished by the additional SS marking.

- DisplayPort is also made according to the same specification, with which the laptop can be connected to a TV or monitor. This connector is marked with a pictogram in the form of a stylized letter D.

Possible consequences of non-standard charging

Charging standards. Time passes, one connector is replaced by another, but the standards for the electrical characteristics of chargers remain unchanged. But the rules have been broken - now, to charge a high-capacity battery or accelerated charging, increased voltage and current are supplied.

Important. Not all devices are designed for increased performance. But no matter how much the charger gives out, the device will take exactly as much energy as it needs. This process is controlled by the controller.

With “fast” charging standards, everything happens in a similar way. In USB Power Delivery, the maximum voltage is 20V, which should simply burn out the connector of a gadget not prepared for this. However, these technologies require mutual verification of compatibility - both on the part of the charger and the device being charged. They exchange information, an instant check occurs, and charging begins. If the technologies do not match, then charging with minimal parameters is provided.

Connecting charging via a regular USB port

If you use the “native” power supply and certified cable that comes with the device, no problems will arise. The protection provided by the protocol rules will simply work, the port will turn off and simply will not accept external power that is not intended for it.

Important. Owners of older models will not be able to charge a laptop via a USB port under any circumstances. All they have to do is carry a spare battery with them or not go far from the outlet.

The decision, as always, is yours. Good luck!

Subscribe to our Social networks

Hi all! And so, in the last entry on the gearbox, I had a problem due to which the gearbox assembly stopped, or, to be more precise, it rolled back almost to the very beginning ((((But, I called on my mobile phone, the necessary spare part arrived!

an old broken one and a new filter, supposedly. In fact, if it didn’t hold the magnet with its paws, then it wouldn’t be fucking needed.

I also ordered a retaining ring for the 3rd gear, because I didn’t like how my old one fit into place...

I bought it for retaining rings and off we go! The previous entry showed how to assemble it at the beginning (the only thing before that was that I fixed my mistake and installed a magnet and a filter mesh before installing the drive shaft). When assembling I used the diagram:

from the Christmas tree In principle, everything is visible there as what is installed, with the exception of the synchronous clutch for 1-2 gears (this was in the past BZ).

I installed the rear gear. Immediately while the output shaft was not standing, I put on the second part of the housing in order to match the technical holes for the rear gear retainer bolts!

ok, let's collect further

stuck the output shaft together with the 4th gear gear

installed the retaining ring of the secondary shaft Oh, YES! The new circlip for the 3rd gear did not fit, it turned out to be narrow (as I wrote there are 5 sizes), and the 3rd gear gear moved up and down, so I installed the old circlip, it holds and okay, maybe I was finding fault with it...

Well, now I somehow need to put it all together as it was... I found a picture on D2 I conjured a spell, reconciled it, and assembled it the second time))) I installed the full size, set everything to neutral Full size, something like this Full size, before that I also put the rod in reverse gear We look at the full size, check that everything is in place, twist the shafts (raising the secondary one because it doesn’t fit a little with the drive one). But it doesn’t converge because there is a plate in front of the secondary shaft bearing, which lifts the secondary shaft when you twist it by putting the second part of the housing on it. We wash the full size, install new oil seals. Checked everything again, coated the gearbox with sealant, having previously degreased it, and put on the second part of the housing! Don’t forget to use a screwdriver to catch the plate on the secondary shaft so that later there are no problems with tightening it! I inserted the screwdriver (where it doesn’t interfere with the shafts) and held it until tightening at least 2 bolts of the plates... Naturally, the gearbox housing won’t fly in easily , since there is a bearing on the secondary shaft that is pressed into the housing, so I started tapping through a wooden mandrel, and then... I’m a fool! I tightened the gearbox housing bolts and began to tighten them evenly little by little, and the housing sat down)))) The full size immediately caught the bolts of the secondary shaft plate, I suffered for about 10-15 minutes, but luckily it was successful. By the way, the plate is placed with a slot in the direction of the drive shaft. I took the full size and immediately tightened the reverse gear retainer bolt (after I pulled the gearbox housings together). By the way, I took the full size sealant like this And put all the bolts (except for the gearbox housing) on thread sealant. Full size tax... what next and then I was tormented to insert the gear shift mechanism... It seems that all the forks are in neutral, but then one fell a little, then the other, I suffered and suffered, and as they say - “if you suffer for a long time, something will work out!”)))) In about 10 minutes, I stuck it in, screwed on the clamp, and installed the spring, tightened the nut. Full size, what's next? I put the fifth gear on the drive shaft, a retaining ring, and threw on the Full size synchronous coupling without the fork, tightened the bolt of the secondary shaft from above, and turned on the 5th speed Well, accordingly, I turned on the rear gear in parallel, I don’t remember exactly how, but with the lever towards the reverse gear for sure. And all this is natural to tighten the secondary shaft bolt! I left the old bolt, although they write that it is disposable, I don’t know why? I installed it with red thread sealant. Well, then turn off all the speeds, leave neutral, and it’s time to assemble the fifth gear as normal with a fork! Full size something like this Don't forget about the correct installation, tightening, or how to say... in general, about tightening the 5th gear fork! Here is a link, this is written about and shown in photos No. 3-4. Well, I also decided to check, in general, to turn on the 5th: Full size rod to the left and up (counterclockwise), if on, then it’s normal, but you don’t need to overtighten the plug either! So, further... We wash the full size, dry it Again, sealant, and hop: Full size clutch fork seal is new, release valve too Naturally Full size, also bought a new SVAG Full size and the final touch is the cover))) Which is also disposable and reusable)))) Oh yes, what a finale ? What about the speed sensor? what about reverse? The speed sensor turned on all the lights, began to screw in the reverse sensor, and...: Full size, why is it so tender((((Okay, then I was able to unscrew the thread with a screwdriver and a hammer! Oh well, I thought, I’ll buy it for what it’s worth... AHA, 820r for some primitive sensor! Damn it ((((on AvtoVAZ it costs 100r))) SO, well, that’s it, finally the gearbox is ready for installation!

After reading this post and the accompanying discussion, I decided to try to clarify what USB Power Delivery is and how it actually works. Unfortunately, I got the impression that most of the discussion participants take 100 watts over USB too literally, and do not fully understand what is behind this at the level of circuitry and protocols. So, briefly – the main points:

- USB PD defines 5 standard power supply profiles - up to [email protected] A, up to [email protected] A, up to [email protected] A, up to [email protected] A and up to [email protected] A

- Cables and ports for Power Delivery are certified and have additional pins in the connector

- The cable type and its compliance with the profile are determined automatically through additional pins and determination of the USB connector type (micro, standard, A, B, etc.)

- Regular USB cables (not Power Delivery) are certified only according to the first profile up to [email protected]

- When connecting, roles are distributed between who gives current (Source / Source) and who consumes (Sink / Receiver)

- The Source and Receiver exchange messages using a special protocol that runs parallel to traditional USB

- The protocol uses the VBus/GND pair as a physical medium. That is why Power Delivery does not depend on the main USB protocol and is backward compatible with USB 2.0 and 3.0

- Using messages, the source and receiver can change roles at any time, change the current and/or voltage, go into hibernation or wake up, etc.

- Optionally, devices can support PD control via traditional USB requests, descriptors, etc.

Below the cut are the details.

About male dogs About cables

USB Power Delivery works with six types of connectors: Accordingly, the following types of connections are allowed in pairs. Separately, it is worth noting that the specification directly prohibits distortions with several connectors on one side of the connecting cable, which is quite logical, given currents of up to 100 watts. On the other hand, the use of adapters and adapters is not prohibited, provided that they comply with the power supply profile and do not short-circuit the cable shield to its ground.

About ports

After USB PD certification, ports are marked as follows: This logo informs about the USB version (2.0 or 3.0 SuperSpeed), as well as the power profiles that the port supports. The value “I” means the consumed profile necessary for the full functioning of the device, and the value “O” indicates which profile the port can provide. Examples of port markings:

- The first port supports USB2. It can provide power using Profile 1 ( [email protected] ) and uses Profile 3 ( [email protected] or [email protected] ) for full functionality. For example, a port for a tablet or netbook.

- The second port supports USB2. It can provide power using Profile 2 ( [email protected] or [email protected] ) and uses Profile 4 ( [email protected] or [email protected] or [email protected] ) for full functionality. For example, a port for a laptop or laptop.

- The third port supports USB3. It only provides power according to Profile 1 ( [email protected] ). It itself is not powered via VBus. For example, the port of a desktop, monitor, TV, etc.

- The fourth port supports USB3. As in the first example, it can provide power according to Profile 1 ( [email protected] ) and itself requires power according to Profile 3 for full functioning ( [email protected] or [email protected] ).

Come up with an example yourself