General rules for replacing the start relay in refrigerators

The start-up relay, despite its small size, is important for the operation of the unit. It performs the following functions:

- starts the motor-compressor engine;

- organizes stable operation of the refrigeration unit, blocking the effects of power failures;

- protects against temperature changes.

The starting protection mechanism combines two types of relays: thermal and starting. They are located in one building. A similar design is used in domestic and imported household appliances.

Problems in it are expressed through extraneous noise (knocks, humming, rattling), problems with starting the motor-compressor (does not turn on at all, starts and immediately dies down, takes too long to get into operating mode) and frequent activation of the protective part of the start-protection relay. These symptoms are caused by faults both internally and externally. The reasons explaining the latter include unreliable fastening or incorrect installation of the part inside the electrical circuit.

An accurate diagnosis can be determined only by disassembling the element completely. It is quite difficult to do this without the appropriate experience and special knowledge. One awkward movement can damage the unit forever.

The check begins by removing the cover. The first thing that catches your eye is the contacts. Particular attention should be paid to the nest from which they come. If traces of burning or oxidation are noticeable, then there is no point in further disassembling the part. It should simply be removed and replaced with a new one. If there are no problems with the contacts, the technician must inspect the rod and coil with the core.

If there are no obvious problems, all removed parts are cleaned with an alcohol wipe (from dirt) and sandpaper (from corrosion). The most common reasons include:

- problems with one of the relays (thermal or starting);

- violations of the regulation system;

- contact divergence;

- problems with the motor-compressor itself.

All of the above can be solved by replacing the relay. Before carrying out diagnostics, you should prepare the necessary tools. In particular, a flathead screwdriver and a tester. This is a device that checks the functionality of the spare part. It will help find the cause if a visual inspection does not produce results. You will also need a wiring diagram for your refrigerator. Without it, it will be difficult for a non-professional to understand.

A new or repaired start-up relay is installed as follows:

- Install a new mechanism in place of the old one.

- Screw the screws that attach the element to the compressor frame (mount the bracket).

- Fix the external contacts using the previously marked wires.

- Install the block and return the wire clamp to its original position.

Refrigerator malfunctions

Refrigerators are reliable devices that rarely cause problems for their owners. But the device is complex, the breakdown can be trivial or require expensive repairs. Major refrigerator malfunctions are repaired in service centers or by specialists at home.

Typical refrigerator malfunctions

You can be wary and start troubleshooting the cold generator for several reasons. In the refrigerator or one of its chambers:

- the specified temperature regime is not maintained;

- ice formation has increased or puddles of water appear;

- The compressor operates noisily, with knocking and rattling;

- the compressor does not turn off, or starts and stops after an instant;

- there is no lighting or the lighting is constantly on;

- The mode does not change when the thermostat is installed in a different position;

- The compressor does not turn on, there is no alarm.

Each of these signs, when diagnosed, can give several causes of malfunctions. Some of them can be eliminated on their own, while others require the intervention of a specialist.

Typical refrigerator malfunctions have long been known, diagnostics have been developed, and tables for troubleshooting exist. They are in the Operation Manual, in the “Troubleshooting” section.

How to determine if a refrigerator is faulty yourself

First of all, you need to check the instructions to see if the refrigerator is installed correctly and ensure timely cleaning of the cabinets from the ice coat.

Typical refrigerator malfunctions include the most frequent equipment breakdowns, subject to the operating conditions of the device. Most often, failure of the thermostat unit is diagnosed. It is connected to a manual temperature controller, uses sensors to determine the temperature in the chamber and gives the command to start and stop the compressor.

The consequence of incorrect operation of the thermostat can be rare starts of the compressor, causing thawing, turning on the motor for a short time and operation without stopping. A failure in device settings is difficult to eliminate; it is easier and cheaper to replace it. Other types of malfunctions of household refrigerators cause similar symptoms.

Diagnostics of the cooling system can reveal a lack of freon due to depressurization or its complete leak. In this case, the compressor does not pump in cold, even when working without stopping. In this case, the motor itself may overheat and fail.

If the light in the chamber is constantly on, the door is skewed and the contact to open the network does not work. Problems will immediately arise here - depressurization of the refrigerator due to the door not closing tightly. The destruction of the sealing rubber leads to an increase in temperature in the chamber. These easily removable reasons in the set lead to frequent malfunctions of other components due to increased load.

The lack of light inside the refrigerator may be due to a burnt-out light bulb or a broken power button. If the refrigerator does not turn on, the indicators do not light up - the reason is a damaged power cord or a de-energized line. Electrical circuit malfunction is one of the causes of equipment failure.

Malfunctions of household refrigerators

Household refrigerators differ from industrial ones in dimensions. Refrigerant leaks in them occur unnoticed. There are no duplicate control devices provided.

If the device has an electronic control circuit, an error will appear on the display; the malfunction has already been diagnosed. In other cases, only visual inspection can prevent costly repairs in time. Often it is not possible to identify a complex breakdown on your own.

For clarity, let’s look at when the refrigerator does not turn on, but the light is on. What are the causes of the malfunction? There is a light in the chamber, the refrigerator clicks, sometimes the motor will turn on for a second and stop again.

- The starting relay makes clicking noises; the windings in the motor have short-circuited and will require replacement.

- A thermostat malfunction is diagnosed in the same way - it does not give a command to turn on the electromechanically controlled compressor.

- On models with an electronic control type, this is a signal to check the air sensor - the sensor needs to be replaced.

- The electronics will not give a start command if the door is not closed tightly.

Even if there is no light, you need to make sure that the light bulb has not burned out due to a power surge. Electronic control requires a stable network voltage of at least 195 V. By the way, the Gorenje refrigerator operates in the range of 200-240 V, accepting other parameters as a malfunction.

The refrigerator malfunctions for a reason - it hums, but does not start, also requires diagnostics. Only a master can find the exact cause of the failure from the expected ones:

- The protective relay-regulator requires replacement;

- low voltage in the network;

- the compressor is jammed;

- short circuit in the motor starting winding;

- The starting capacitor or defrosting device is faulty.

If the engine is humming and the compressor is running, and the chambers are warm, the breakdown should be looked for in the evaporator. In order to correctly diagnose, the technician needs to know what preceded the emergency stop.

Signs of a refrigerator malfunction

If the refrigerator is new, when the parts are running in, it operates with increased noise. When running in, the parameters should be standard. Particular attention should be paid to ensuring external conditions and the correct installation level.

The temperature in the refrigeration chamber is increased - a leak may occur. You can eliminate this reason yourself. Try sandwiching a strip of paper 5 cm wide and 0.8 mm thick between the door and the camera. If it is not pinched, the door needs to be sealed.

Rapid formation of a fur coat on the evaporator indicates a faulty heater. The fur coat on the interchamber partition is also a thermoelement, but different.

A whistling sound in the compressor or a knocking sound in the engine when starting up signal a mechanical problem. Such noise on an old device indicates that the refrigerator will soon fail - the motor-compressor will need to be replaced.

If the refrigerator is electrocuted, this is a serious reason to stop the unit and call a technician. Let a specialist measure the insulation with a megger and search for wires with damaged insulation.

Refrigerator evaporator malfunctions

An evaporator is a device in which liquid freon turns into a gaseous state, taking heat from the chamber. Evaporators are rolled-welded with a metal thickness of 1.5 cm; a labyrinth of passages is laid inside the sheet. The joints of the refrigerant inlet and outlet are connected by welding with copper pipes and insulated.

Evaporator malfunctions can occur for several reasons:

- sensor failure after a short circuit or power surge;

- mechanical damage to tubes, depressurization of connections accompanied by freon leakage;

- blockage in the capillary tube;

- corrosion.

Evaporator repair is work that is carried out at a service center. By welding a thin aluminum sheet, you can find a gas leak under special conditions.

Conclusion

Careful handling of the appliance and compliance with the maintenance instructions will extend the trouble-free operation of the refrigerator. We invite you to watch a video about the main reason for refrigerator failure.

Refrigerator malfunctions

crio.pro

Types of start-up protection relays

Despite the variety of external designs, modern refrigerators use two main types of start-up relays:

- Current. They are triggered when a certain amount of current flow is reached. A normally operating motor consumes a given current. When the motor overheats, the current consumption increases sharply, the device trips and breaks the circuit, turning off the engine. After the motor cools down, the device resumes its operation.

- Current-thermal. They are triggered both when the current value is reached and when the set temperature is reached. As long as the motor draws normal current, the helix through which it passes is subject to slight heating and has no effect on the bimetallic strip. The higher the current passing, the more the coil heats up. It heats the sensitive plate, which changes its shape so much that this leads to the opening of the contacts through which the electric motor is powered.

In current-thermal devices, an increase in temperature leads to a change in the shape of the bimetallic plate. It is welded from two plates, the metals of which have different coefficients of thermal expansion. When heated, the bimetallic plate bends and opens the contact group, turning off the electric motor. After the engine has cooled, the plate returns to its original shape and closes the contact groups, starting the engine again. In addition to the thermal protection circuit, the engine is also turned on and off by a thermostat.

The plate is heated in various ways:

- direct – heating is carried out by flowing current;

- indirect - a separate spiral heater is used.

The starting protection device also performs the function of starting the electric motor. To do this, a large starting current is supplied to the motor winding for a short time, and after the rotor moves away and begins to rotate, the current decreases to operating values.

Externally, the device looks like a small box attached to the compressor casing.

Devices may have:

- Two contacts - phase 220 volts and Ground. Used on synchronous electric motors.

- Three contacts: start winding, run winding and ground. Such designs are used on asynchronous electric motors.

Contacts are distinguished by the color of the cables passing to them.

Induction relays of the DXR type are mounted on the frame of the refrigerator and are designed to control motor-compressors of the DXM type. To increase the speed of operation and shutdown of the motor, a strong permanent magnet is placed near the plate. When the plate, bent under the influence of heat, falls into the zone of attraction of the magnet, it attracts it, accelerating the operation. The attraction of the magnet also gives additional time for the overheated motor to cool down. The cooled plate overcomes the attraction of the magnet and closes the contacts.

Relays of the RTP type have a lower operating current and smaller dimensions. It does not require fixing to the frame and is mounted directly on the wires.

You can check the serviceability of the start-up relay with an ohmmeter, multimeter or other available measuring device. A working device has zero resistance between the contacts. If the resistance is infinite, the device is faulty and needs to be replaced.

The start-up protection device operates in a single electrical circuit with the thermostat.

The refrigerator user manual indicates which appliances can be used for each specific model. This allows you to select a suitable replacement device if the exact same ones that failed are no longer available.

Start protection relay device

Let's look at the relay design using the Tablet as an example. The part we are interested in is located near the compressor motor. Its color is black, as it absorbs heat better than all other shades. Next, you need to note two phases (one for 220 V, and the other for grounding) and, accordingly, two inputs/outputs. Some refrigerator models have three phases (the third is considered the ground phase). There is also a motor winding and a direct starting winding.

Connecting the refrigerator start relay is not difficult. The main thing is to have certain skills, an electrical diagram and instructions for the refrigerator. To make work easier for craftsmen and ordinary users, the wires are already painted. You just need to remember their location when removing the old relay, and when installing a new one, return them to their place. Next, all that remains is to connect a working device.

But even wires, each decorated in its own color, will not prevent a malfunction. Regardless of the operation, all movements must be careful and smooth. With one sharp jerk it is possible to completely damage the refrigerator. Before you start working, you should check all contacts. The easiest way to do this is to remove some paint from the body, but this should only be done as a last resort.

Tips and practical recommendations for disassembling the refrigerator

During disassembly, you should adhere to all necessary safety precautions. The instructions for each refrigerator contain a list of them, so before disassembling it is best to carefully read them in order to avoid possible negative consequences. The advantages of disassembling a refrigerator are that there is no need for a full-fledged working set of tools - a few screwdrivers will be enough, and if you don’t have any, ordinary knives with different lengths of metal tips will do.

Location of different types of relays

Before connecting the relay, you should decide where it is located. After all, there are many varieties, therefore, there are also designs. The first thing that catches your eye is the dimensions, followed by the mounting method (without attaching to the frame, on a wire) and current indicators, for example, the DXM relay operates at lower parameters than the DXR.

If there is a need to directly connect a refrigerator without a relay, then these nuances will not be useful. The selection of a suitable part should be carried out taking into account the brand of the refrigerator, the type of motor-compressor, technical parameters and the required design. It is desirable that the latter be the same as that of the previous relay.

The starting relay of the Antant refrigerator is connected to the motor-compressor casing. To position the device correctly, you must follow the arrow shown on the cover. Example in the photo.

How does the start relay work?

Despite the large number of patented products from various manufacturers, the operation schemes of refrigerators and the operating principles of starting relays are almost the same. Having understood the principle of their operation, you can independently find and fix the problem.

Electrical diagram of the device

The relay circuitry has two inputs from the power supply and three outputs to the compressor. One input (conditionally zero) passes directly.

The other input (conditionally – phase) inside the device is split into two:

- the first passes directly to the working winding;

- the second passes through the disconnecting contacts to the starting winding.

If the relay does not have a seat, then when connecting to the compressor you must not make a mistake with the order of connecting the contacts. Methods common on the Internet for determining winding types by measuring resistance are not correct in general, since some motors have the same resistance of the starting and running windings.

Therefore, it is necessary to find documentation or disassemble the refrigerator compressor to understand the location of the feed-through contacts.

This can also be done if there are symbolic identifiers near the outputs:

- “S” – starting winding;

- “R” – working winding;

- “C” – general output.

The relays differ in the way they are mounted on the frame of the refrigerator or on the compressor. They also have their own current characteristics, so when replacing it is necessary to select a completely identical device, or better yet, the same model.

Closing the contacts in the start relay

An electromagnetic starting relay works by closing a contact to pass current through the starting winding. The main operating element of the device is a solenoid coil connected in series with the main winding of the motor.

At the moment the compressor starts, with the rotor static, a large starting current passes through the solenoid. As a result, a magnetic field is created that moves the core (armature) with a conductive strip installed on it, which closes the contact of the starting winding. The rotor begins to accelerate.

As the rotor speed increases, the amount of current passing through the coil decreases, as a result of which the magnetic field voltage decreases. Under the action of a compensating spring or gravity, the core returns to its original position and the contact opens.

The compressor motor continues to operate in the mode of maintaining rotor rotation, passing current through the working winding. The next time the relay will work only after the rotor stops.

PTC resistor in the start relay

Relays produced for modern refrigerators often use a posistor - a type of thermal resistor. For this device, there is a temperature range below which it passes current with little resistance, and above which the resistance increases sharply and the circuit opens.

In a starting relay, a posistor is integrated into the circuit leading to the starting winding. At room temperature, the resistance of this element is insignificant, so when the compressor starts operating, current flows unhindered.

Due to the presence of resistance, the posistor gradually heats up and when a certain temperature is reached, the circuit opens. It cools down only after the current supply to the compressor is stopped and starts skipping again when the engine is turned on again.

Defrosting the refrigerator in 8 steps

Adjust the temperature of the refrigerator to 0 degrees, then unplug it and open the door wide open.

- How to defrost a refrigerator with two compressors? The principle is still the same, the only difference is that its chambers can be defrosted one by one or at the same time.

Remove all food from the chamber. It’s good if you planned the defrosting of the refrigerator in advance and were able to organize supplies so that there are no perishable or frozen foods left among them. And if not? The following tips will help you preserve food while defrosting the refrigerator:

Also remove all containers, shelves and bars from the cells. By the way, we advise you not to take food out of the refrigerator directly in containers, as the plastic may crack due to their weight.

If your refrigerator does not have a container for collecting melt liquid, place towels or several layers of newspaper sheets under it, and a drip tray on the bottom shelf. Typically, this measure is required for older models of refrigerators; with modern equipment, the water is drained into a special sump (most often it is located at the back of the refrigerator).

Now all that remains is to wait for the refrigerator to defrost. The natural process of melting the ice coat can take from 3 to 10 hours, depending on the thickness of the ice.

- The best way to defrost your refrigerator is the traditional way - just leave it overnight.

But if you wish, you can speed up the process with simple steps. First, let the refrigerator just sit for half an hour, then choose one of the following methods for faster defrosting and start practicing.

When figuring out how to defrost a freezer, you should take into account its characteristics. In individual devices, it is advisable to carry out the cleaning procedure every month to prevent the formation of ice that interferes with the movement of containers. Others have a special system that makes it unnecessary to defrost the freezer frequently. Using the correct algorithm of actions, you can quickly remove ice.

Current type protection relay

An asynchronous motor is a complex electrical device that is prone to breakdowns. If a short circuit occurs, the circuit breaker installed in the distribution panel will trip.

If the fan, which cools the winding and mechanical moving elements, fails, the built-in thermal protection of the compressor will react.

However, a situation may arise when the motor begins to consume 2-5 times more rated current for a long time (more than 1 second). Most often this occurs when there is an unplanned load on the shaft resulting from a jammed motor.

The current increases, but does not reach the short circuit values, so the machine selected for the load will not work. There is also no reason for the thermal protection to turn off, since the temperature will not change in such a short period of time.

The only way to quickly respond to the situation and avoid melting of the working winding is to trigger the current protection, which can be installed in different places:

- inside the compressor;

- in a separate current protection relay;

- inside the start relay.

A device that combines the functions of turning on the starting winding and current protection of the motor is called a starting protection relay. Most refrigerator compressors are equipped with just such a mechanism.

The action of current protection is based on three principles:

- as the current increases, the resistance increases, which leads to heating of the conductive material;

- under the influence of temperature, the metal expands;

- The thermal coefficient of expansion differs for different metals.

Therefore, a bimetallic plate is used, which is welded from metal sheets with different expansion coefficients. Such a plate bends when heated. One end of it is fixed, and the other, deviating, opens the contact.

The plate is designed for a temperature response when a current of a certain strength passes. Therefore, when replacing the start-up relay, it is necessary to check its compatibility with the installed compressor model.

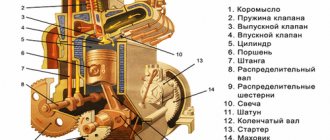

Unit details

The basis of the device is an electrical circuit, without which operation is simply impossible. Before disassembling the refrigerator, you should study the details:

- motor and compressor, they consist of a starting winding and a working winding;

- button responsible for defrosting mode;

- thermal regulator;

- thermal protective relay consisting of two contacts;

- a relay that includes a coil and contacts.

When the contacts on the defrost button and the thermal regulator are closed, current is supplied to the electric motor through the starting and protective relay. During the switching process, the voltage in the working winding increases greatly, passing through the coil and switching the contacts on the starting relay. Next, the current is conducted into the contacts of the starting winding, the value of which gradually decreases.

After the voltage in the coil decreases, the relay contacts are released, and the starting winding stops conducting current. If the voltage in the network fluctuates, the equipment overheats, thermal protection is triggered, eliminating fire and overheating.

Frequent start relay malfunctions

Given the small number of relay elements, you can sequentially test them for functionality. To do this you will need a flathead screwdriver and a multimeter.

Problems with operation

From a design point of view, a relay with a coil is a device with normally open contacts, and a posistor version is a device with normally closed contacts. Although in both cases there are possible options when, at start, there will be no current supply to the starting winding or, conversely, its shutdown will not work.

If the compressor is operational, but does not turn on following a command sent from the refrigerator control unit, this indicates a lack of voltage on the stator starting winding.

The reason for this may be:

- electrical circuit break;

- contact strip problem;

- posistor overheating;

- the electrical protection system is triggered and does not return to its normal position.

If the refrigerator turns on for 5-20 seconds and then turns off, then most often this is a consequence of the relay’s protective mechanism triggering.

The reasons may be the following:

- the protective mechanism is working properly, but the operation occurs due to problems in the working winding of the motor;

- the protective mechanism is working, but the relay does not open the contacts in the starting winding circuit;

- The protective mechanism is faulty, false operation occurs when the temperature is slightly overheated.

Since there may be several reasons for the malfunction, it is necessary to carry out a complete diagnosis of the start-up protection relay of the refrigerator.

Problems with electrical circuit contacts

A faulty start-up relay can be detected using a multimeter.

To do this, you need to ring three sections of the electrical circuit:

- If there is a break in the area from the input to the output to the working winding, then it is necessary to check the location of the contact opening with the protective mechanism. It is possible that it worked and did not return to its original state or that the opening contacts were oxidized.

- If there is no contact in the area from the input to the output to the starting winding, then in addition to a banal break in the conductor, two options are possible: opening the circuit by a protective mechanism or lack of contact through the bar.

- A break in the straight (zero) section means mechanical damage to the chain - it is the easiest to find and fix.

If the relay operation is based on the use of an induction coil, then it is necessary to forcibly raise the bar - otherwise there will be no contact.

The posistor is not working correctly

To make sure that the posistor is working properly, you need to check it in a cold and heated state.

First of all, you need to wait until the posistor has cooled down (2-3 minutes in a non-working state is enough) and ring it with a multimeter. If there is no current or a high resistance is detected, the posistor is faulty and needs to be replaced.

To check the disconnection ability, you need to connect a consumer of electricity, for example, a hundred-watt incandescent lamp, to the posistor. To do this, you need an electrical plug with two terminals that are connected to the input of the device. The wires from the lamp are connected to the connectors leading to zero and the starting winding.

When the plug is plugged into the socket, the light will light up. Since the rating of the passing current in the experiment is significantly less than when starting the compressor, the posistor will heat up for a long time - for a hundred-watt lamp the response time will be 20-40 seconds.

If the light goes out after a while, then the device is working properly. If the consumer is not de-energized, this means that the posistor is not working. Repairing it at home is impossible, it is inexpensive, so you need to purchase an element with similar parameters.

Problems with the contact strip

There are two types of contact strip problems:

- no current passes when the contacts are closed;

- The bar sticks and won't go down.

The first problem may arise due to oxidation of contacts. In this case, you need to clean them with sandpaper. Also, the reason may be the curvature of the position of the bar, then it is necessary to install it horizontally.

A more difficult problem is the junction of the bar and the pin, which is affected by the magnetic field of the solenoid. The solution to the problem here is individual and depends on the type of malfunction.

Sticking of the strip is expressed in the fact that it does not come off along with the core. To do this, you need to clean the contacts to remove the adhesive and make them smooth.

Abnormal operation of current protection

If, when ringing, a lack of contact is detected from the input to both windings, then most likely the break occurred in the protection zone.

In most cases, this is either a contact failure that opens the bimetallic plate, or damage in the area of the heating coil.

If the damage cannot be corrected otherwise, you will have to purchase a new relay.

Frequent breakdowns and DIY repairs

The most common malfunctions often occur due to trivial reasons, and with proper diagnosis, equipment can be repaired quickly and with a minimum of effort. Do-it-yourself repair of the Know Frost refrigerator is accessible to everyone; highly specialized technical knowledge is not needed.

View » Malfunctions of two-chamber refrigerators Indesit No Frost and do-it-yourself methods for eliminating them

Leaking

If a puddle has formed near the refrigerator, the temperature regime has been disturbed, or the refrigerant circuit has become depressurized, first inspect the thermal insulation layer and the door seal for mechanical damage. If found, the seal must be repaired or replaced and the seal restored.

Another likely source of the problem is a faulty compartment drain due to a blockage. Also check if the drainage tube has become disconnected: this happens if the equipment has been rearranged.

Freezes and frost appears

Most often, the reason is simple: it’s time to defrost the refrigerator. But, if defrosting occurs regularly, and frost still forms, check the tightness of the door and the freezer: perhaps the seal is worn out or does not fit tightly. Sometimes the door does not close completely because the compartment is full or something is in the way. A sheet of paper, which normally should not penetrate under the door, will help you examine the tightness at home.

It happens that the thermostat is set to too high a cooling level, then manual adjustment will be required. Sometimes the sensor or compressor itself fails and needs to be replaced.

Turns on, but does not freeze or cool

Such a breakdown is most often caused by a malfunction of the thermostat or compressor. In both cases, parts must be replaced. There are also software failures in the control system of “smart” modern refrigerators. You could also accidentally start defrosting, after which you need to turn on the refrigerator again.

Sometimes the reason is that the entire cooling system is clogged, in particular the loop tube in which the refrigerant circulates, or there is a freon leak. Carefully examine the external and internal circuits; you can fix the leak yourself.

Please note that the refrigerator does not freeze well and is a result of overloading with food. There should be no heating devices located nearby that heat the walls and prevent proper cooling.

Doesn't turn on

The reason is a violation of the integrity of the electrical circuit. Examine the cord and plug, and check the voltage at the outlet. If everything is in order, most likely the electric motor has failed and needs to be replaced.

Some models equipped with control units do not turn on due to software errors. It is extremely difficult to identify such problems on your own, and you will have to contact a service center to fix them.

Long-term operation without shutdown

Normally, the refrigerator operating time does not exceed 20 minutes.

Cyclic switching on and off is a design feature of the equipment that prevents rapid wear of parts. The engine start is controlled by a thermostat. If the device does not turn off, the temperature inside the compartment has not reached a sufficiently low temperature, which occurs if the door is depressurized. Inspect the seal for damage, wear, or peeling. And if the door is in order, the thermostat itself or the compressor may have failed, then replacement will be required.

Another common cause of the problem is a refrigerant leak, which needs to be found and fixed as quickly as possible.

Sometimes the refrigerator operates without stopping in the enhanced freezing mode selected by the user. However, you cannot leave the equipment in this condition for a long time: this will lead to wear of parts, overheating and burnout of the winding in the engine, or breakdown of the compressor.

In modern models, continuous operation can also be a consequence of a software failure in the control system.

Increased noise level

Often a rattling noise occurs because the refrigerator is positioned unstable. The instructions require that the equipment be mounted on a hard, flat surface, but this requirement is not always met.

Another possible reason is a breakdown or obstruction of the compressor due to a layer of ice. Due to improper installation, it happens that the tubes and the compressor casing come into contact and rattle when the engine is turned on. Sometimes noise is caused by a fan that is loosely screwed on or in contact with other parts.

To resolve the problem, make sure that the requirements of the installation instructions are met: check the reliability of the fastening and the correct location of the structural elements.

No lighting when the door is open

The first thing to do in this case is to check the light bulb: it could simply burn out. It happens that the lighting does not turn on because the sensor does not receive a signal to open the door. Sometimes, for some reason, the integrity of the electrical circuit is broken and no current is supplied to the lighting equipment.

There is water inside or under the bottom

If a puddle has formed inside the case or under the refrigerator, in most cases it is condensation caused by a violation of the temperature regime. For example, in your absence the power was turned off or still hot food was put in the refrigerator. The room may be too warm, which increases evaporation inside the chamber.

Abundant condensation also occurs when the door is not closed tightly or is depressurized if the seal is damaged and peeled off.

To fix the problem, check the leaks and return the room temperature to normal.

The red light is on

The indicator indicates a breakdown of the thermostat or compressor. Parts that have become unusable will have to be replaced. On some models, a red indicator light warns of a freon leak. When diagnosing, check the operating instructions, which provide a complete explanation of the indicator readings.

Video: refrigerator compressor start relay

Refrigerator compressor start relay.

Watch this video on YouTube

Do you want to understand better than others?

- Replacing the starting relay of an LG refrigerator with your own hands - To replace the starting relay, you must perform the following sequence of actions: To avoid injury, before starting work, you need to disconnect the refrigerator from the electrical network,...

- Replacing the start relay of a Bosch refrigerator with your own hands - To replace the start protection relay, you must perform the following sequence of actions: To avoid injury, before starting work, you need to disconnect the refrigerator from the electrical network,...

- Replacing the start relay of a Samsung refrigerator with your own hands - Start relays rarely fail. Most often these are old single-chamber refrigerators with induction start relays. As a rule, you can only check the serviceability of the relay...

- Replacing the starting relay of the Biryusa refrigerator with your own hands - The device of the starting relay P1 for the Biryusa refrigerator 22, 3, 6, 18 When inspecting this device, the first thing you pay attention to is the contacts of the starting type winding, which belongs to...

- Do-it-yourself replacement of the start relay of a Stinol refrigerator - Diagnosis of faults in the start relay of Stinol refrigerators Despite the fact that the manufacturer is doing everything possible for the long-term operation of Stinol refrigerators, with…