Level calibration

When the flask is secured with screws, calibration is quite simple:

place the rack against the wall and position the bottle strictly in the center. Mark and draw a line from below.

turn the level over to the other side and combine it with one of the ends of the segment. Again, make sure that the bubble is in the center. Draw a second line.

Now all that remains is to divide the resulting angle in half and draw a third line (bisector) between the two

apply the rod to this line and adjust the flask with screws until the bubble is centered

The correct vertical is plumb. Moreover, the plumb line must be made of non-ferrous metal.

Steel can be affected by magnetic fields if the cord is long enough. In addition, magnetized sawdust often sticks to the plumb line itself, and this is again an unnecessary error and deviation.

If the bulb is glued in, you can try to adjust it by gently tapping it with a screwdriver attached to the edges of the bulb.

You need to hit the elevated part. True, good accuracy is difficult to achieve in this way.

Either way, you have little to lose. After all, your level is already shamelessly lying. If this method helps, you need to glue the joints of the flask with superglue.

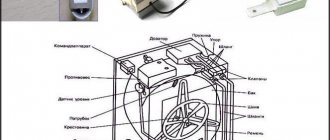

Types of levels

To correctly adjust the level, you must first decide what it will be.

Manufacturers today offer:

- A hydraulic level (water) is the usual type, which consists of 2 individual flasks connected using a hose. Its length is 5−25 m, and a scale is applied to the flasks for ease of use. There is no need to adjust this level; it is used only for the horizontal plane. The price of the equipment is low; this type of mechanism is designed to install other types of equipment.

- Bubble device - makes it possible to carry out precise work. In appearance, it is a ruler of various lengths, which contains 3 flasks filled with liquid (most often alcohol). A tool is used for vertical and horizontal measurements, but it must be installed before starting work.

- Magnetic - is special equipment with magnetic inserts; it guarantees a high level of convenience when working with iron surfaces.

- Pipe - has a light weight and small size. Perfect for measuring pipes, profiles and similar materials.

- Laser is a clear, special equipment with small dimensions. The range of its beam, with the support of which the measurement is carried out, is 100 m. The device system can be different, most often it is inserted on a tripod, but there are also magnetic types. The modifications themselves are presented in a wide variety; it is possible to choose directly the type you need.

- The electronic laser mechanism is digital special equipment; special instructions are used to configure it. The price of the equipment is higher, but the quality is excellent.

Frame

When choosing a level, first of all you should pay attention to its body. It must have thick walls (minimum 1.5-2mm thick) or be cast

If there are inserts at the ends, it is difficult to determine the thickness of the metal “by eye”. Therefore, focus more on weight. Thin-walled ones are very light and can literally be pressed through with your fingers.

Even T-rails do not always have greater rigidity compared to a rectangular profile. Here a lot depends on class=”aligncenter” width=”720″ height=”322″[/img]

A defect in the form of bending of the profile may appear if you carry it not in a separate case, but in a simple bag with the rest of the tool.

It would be very good if there were shockproof rubberized inserts along the edges. It's rubber, not plastic. When dropped, the plastic simply breaks off.

For home needs, the most optimal length of the building level is 60cm.

Sometimes it is very useful if the level has magnetic inserts.

And if there are also holes for the size of the 220V socket block, then this greatly facilitates the electrician’s work.

Of course, you can have several tools of different lengths. One is small for installing a block of sockets, the other is larger for large switchboards, boxes and cable channels.

What is a building level and how to work with it

We have almost come close to the second tool, which is called the building level. This is the ideal ruler with water bubbles.

Let's lean our level (ruler with bubbles) against the heads of the self-tapping screws, which we previously screwed plumb into the wall:

By reading my blog, you are probably making repairs.

this page to your bookmarks .

This is where all the useful home improvement stores are located. If you are going to plaster the walls yourself, then you will definitely need a building level! Buy or borrow from friends a level 2 meters long. Notice the bubble that is at the top of the ruler. Let's take a closer look at it:

The bubble should be clearly in the middle of the boundaries. If so, then your level is in excellent condition. By the way, this is how the level is checked. However, it would be nice to immediately check it in 2 dimensions: vertical and horizontal. You can read about this in detail in the article: How to check the building level. If you plumb the heads of the screws and carefully lean a level against them, and the bubble is clearly in the middle, then everything is in order, then you can continue to work with this level.

| If the bubble is located far from the borders on the left or right, then quickly change this level to another, if purchased in a store. There is nothing worse than starting to do precision work with a broken level. It will be very disappointing that you will spend a lot of effort and time, do what is called everything step by step, and at the same time get a crooked result! In the catalog on the left you can find suitable levels, plumb lines and other measuring instruments. |

Read also: Schematic designation of sockets and switches

Well, if your level doesn’t lie, then you always have a vertical in your hands. Now, to check whether something is vertical, simply lean the plane of the level against the plane of the object being examined and watch the bubble. If the bubble is in the middle, then the object is standing upright!

I told all this for the purpose that further, in the following articles, we will begin to place beacons using a level and plumb line, which means you should have an idea of how this is done!

I highly recommend that you practice on your curved and untreated wall and try to set one vertical, and at the same time check your level. The very next article will be devoted to attaching the plaster mesh to the wall, and after that we will install the first beacon. It will be less convenient to place it on a grid, so practice placing the vertical simply on a bare and crooked wall.

I wonder if any of the experienced craftsmen can do without a plumb line?

Bubble, electronic, laser or water levels can be called a must-have tool for a builder. With their help, they check the correct installation of equipment or finishing elements, and the angle of inclination of the pipes. Such a convenient tool can also be used at home. For example, it will be needed to hang shelves evenly. But what to do if the device produces incorrect data? The most difficult situation is when the laser level has gone wrong; the device is expensive and quite delicate. In some cases, adjustment can be done independently.

How to use a laser level at home, advice from experts

Laser levels have long been popular among professional builders. Thanks to the gradually decreasing prices for these useful devices, home craftsmen have also begun to use them. However, it is difficult for a builder without experience to master this rather complex tool. We will help you understand the variety of models and the rules of use and adjustment.

- Alignment of walls,

- Production of floor screed,

- Wallpapering,

- Laying tiles,

- Installation of door frames and window frames.

All this can be done using bubble and laser levels, but with a laser device this work is performed faster and more accurately. The laser-drawn line can be of any length, does not require a stepladder or an assistant for marking, and instantly reaches ceilings of any height. Once you turn on the power, coordinate lines will instantly appear throughout the entire area of the room.

Most laser levels can draw multiple intersecting lines at once, with the angle selected by the user.

Types of laser levels

By installation method:

Of course, you have to pay for convenience. Therefore, the auto-tuning level is more expensive.

According to the principle of beam formation:

In addition to the highest level of accuracy and convenience compared to mechanical devices, laser levels allow you to perform work that is inaccessible to mechanical devices.

According to the method of placement at the work site:

How to check a laser level for accuracy

The laser level should be checked every 2-3 months of use. You can entrust this procedure to a service center by paying a certain amount of money. However, when used at home, you can easily evaluate the accuracy of the device yourself.

To do this, you need a free room with a flat floor and a distance between the walls of about 20 meters.

We place the tool near the first wall, align it horizontally and make a mark on the wall

We turn it 180 degrees, make a mark on the opposite wall

Then, without changing the height of the tripod, we move it to the opposite wall and install it opposite the mark

Rotate it 180 degrees. The marks on the first wall must match. If not, you need to make adjustments according to the instructions for setting up the device.

We check the vertical alignment in a similar way.

The measurement error increases with the distance from the device to the measurement surface. Discrepancies of 1-2 mm at a distance of 10 m can grow to 1-2 cm at a distance of 100 m. If you do not work with such areas of premises, there is no need to spend money on a professional device.

Preparing the laser level for use

Before using the device, the following preparations should be made:

- Check the charging of the batteries or batteries in the device. It will be a shame if they run out of charge at a crucial moment,

- Remove all foreign objects in the path of the laser beam. A stepladder installed at a distance of 1 meter from the level will provide a shadow up to 2 meters wide on the opposite wall,

- The surface on which the device will be installed must be level,

- Take care to protect your eyesight and warn your colleagues at the construction site about laser measurements,

- If the level line covers the entire perimeter, the device should be located in the center of the room.

What to look for when purchasing?

Craftsmen prefer metal or aluminum levels with rubber handles. The cross-section of the strip can be rectangular, I-beam, or cross-shaped. The tire walls should be thick, the ideal body is cast. A rectangular section is stronger than an I-beam.

A good sign will be the weight of the instrument - it is believed that a moderately heavy level provides greater accuracy of readings than a light one. Sometimes one of the sides of the body is marked in the form of a ruler , which allows the tire to work as a construction meter, expanding the possibilities of use.

When inspecting the level when purchasing, pay attention to the integrity of the ampoules .

A new device must be checked before purchase for accuracy of readings . The glued bulb is not adjustable, such a tool cannot be corrected. To check, the body is applied with the working side to a horizontal surface and the location of the bubble is remembered. When you rotate the tool 180 degrees, the position of the bubble should remain the same. Do the same by checking the vertical sight.

Large tool stores are often equipped with

a special inspection stand . Indicators of a quality bubble level:

- measuring marks are applied inside the flask and will not be erased during operation;

- the tire metal is additionally processed to increase strength or powder coated;

- shock-resistant housing, such a device will not suffer damage if accidentally dropped;

- Magnetic fastening system holds the level on metal surfaces, allowing you to work hands-free;

- rubber plugs at the edges;

- adjusting bolts on the edge of the “eye”.

For home use , a medium-priced device with a body length of 40-60 centimeters is sufficient. To measure horizontally and vertically, two “eyes” are enough. As a rule, even professional builders rarely use a flask located at an angle of 45 degrees.

A device with one working surface is not suitable for use on the ceiling. In an upside-down position, the values are displayed incorrectly; in such cases, use a tool with two working sides.

Read also: How to check a thermistor with a multimeter

A professional tool is always double-sided and has a higher cost. The manufacturer indicates the measurement error for each side on the bar. The housing is selected according to size for specific tasks and work. Usually masters have several levels of different lengths.

Solving problems with daylight and sunlight

Sooner or later, every user of a laser level needs to mark the street; this can be any construction on a personal plot, in the landscape design of a plot of land or during the construction of a garage.

And at hour “X” you turn on the device on the street in the daytime, and are disappointed to discover that the beam is completely invisible even at 5 meters, and it doesn’t matter at all whether they are expensive or cheap laser levels. Yes, alas, solar daylight is the most destructive for a laser of this class, but there are several ways out of this situation, see them below.. In this case, a laser beam receiver will undoubtedly help you! Most laser levels have a key that switches the device to a special pulsating mode, in which the lines begin to burn an order of magnitude dimmer

It is this function that allows you to work with a laser level outdoors in any degree of illumination.

In this case, a laser beam receiver will certainly help you! Most laser levels have a button that switches the device to a special pulsating mode, in which the lines begin to burn an order of magnitude dimmer. It is this function that allows you to work with a laser level outdoors in any degree of illumination.

A laser radiation receiver is a separate, small device; they come in different sizes, designs, with or without an LCD display. Laser radiation receivers are practically not supplied complete with laser levels and are purchased separately.

Receivers are included with almost every rotating laser level; these are levels designed to work over long distances up to 1000 meters! The laser radiation receiver has a special built-in photocell that detects the laser beam and shows its location with a visual and audio signal, at a time when the beam is not visible to the human eye. The range of operation with the receiver for each laser level (having this function) is different, but the minimum starts from 30 meters! See technical specifications in device reviews.

But there are other ways

in addition to the detector itself, which will allow you to work outdoors during the day with a laser level. Not all methods can be called a full-fledged alternative to the receiver, but there is one really very similar and affordable option. Let's look at each method in more detail.

1. Method

This is to use some object with a reflective surface, a simple metal ruler is best. If you turn it at a certain angle, the laser line will be clearly visible.

2. Second option

Suitable only for those whose devices have additional laser points, for example, like an inexpensive Chinese level (the point of this particular model is pictured in the photo). The fact is that the beam concentration at a point is much greater than in a line, so the laser point is clearly visible during the day on the street at a distance of up to 15 meters in one direction.

3. Method

Suitable for everyone, with any model of level. As you probably already guessed, this is marking in the dark, and the darker it is, the farther the laser beam will be visible.

Therefore, if you are thinking about or are planning to purchase a laser level, I recommend that before purchasing, you immediately determine for yourself whether you will need to do any work outdoors in daylight, and based on this, consider a level with or without the function of “working with a receiver.”

4.

The most interesting method

for determining the location of a laser beam over long distances. Moreover, marking can be done at a much greater distance than with a receiver, if your level has such a mode.

Yes, it should be noted that this method works with absolutely every laser plane builder, no matter whether it has a receiver mode or not!

So, to mark on the street, for example at 100 meters, we need a simple cell phone with a front camera, which almost everyone has today.

Next, to detect the laser line, turn on the front camera of the phone and begin scanning the area where the line supposedly passes. When the laser beam hits the front camera accurately, a bright dot will be visible on the phone screen, which will fade when the phone is slightly moved up or down.

At the moment when the glow of the dot on the screen is the brightest, we make a mark exactly opposite the camera’s eye.

This way you get markings with minimal error, with the same operating principle as a laser receiver.

For a better understanding of the method, we recommend watching the following videos:

Preparing the laser level for use

Before directly turning on the LED that creates the laser beam, the device must be prepared for operation. Preparation consists of installing the device on a tripod or simply on a flat surface. Many models are designed so that their working position can only be adjusted on a tripod - it contains bubble levels for initial alignment and all the rotary levers for fixing the beam in the desired position. Rotary instruments are equipped with additional types of mounting to the wall or ceiling. This is due to the fact that their use often requires installation in a suspended state, for example, when installing a large suspended ceiling.

Before turning on the laser level, it must be installed on a stationary tripod.

The main task during installation is to give a stable position to the laser level. Its vibrations or falls during operation are unacceptable, so the tripod is positioned at the desired level with the maximum leg opening, then the mounting location is leveled, and only after that the level itself is secured.

Construction laser levels are usually powered by replaceable batteries or rechargeable batteries

Instruments with a pendulum leveling device are designed so that the pendulum locking mechanism is only released when the power is turned on. For additional control of the vertical position, many models provide a sound signal that stops as soon as the device is in the desired state.

Electronic equalization also occurs after power-up. It is necessary to give the sensors a certain time to self-align. The level's support consists of 3 legs, by adjusting the length of which servomotors bring the instrument to a horizontal position. The laser beam turns on only after the hum of the motors stops. The same thing happens with a rotating level mounted on a wall or ceiling, only instead of the horizontal position of the supporting legs, the vertical axis of rotation of the LED is adjusted.

What do the divisions on the flasks mean?

Most of the divisions at the construction level are quite understandable to a novice user. On various models there is a familiar ruler for measuring distances or marking segments. Some manufacturers offer offset blocks for marking holes according to a template.

The most questions are raised by divisions at the construction level, seen on cylinders with bubbles inside. Let's look at what these marks are below.

- Marking marks needed to determine the accuracy of the horizon. When the device is placed on a flat surface, the air in the corresponding flask will be placed strictly between the marks, the edges of the bubble will come close to them.

- Error marks. They are located behind the horizon accuracy marks, closer to the edges of the bulb. Present in products of the middle and expensive categories. Each of them comes with instructions that indicate the division price. When the bubble is displaced to such marks, the slope of the surface can be determined in millimeters per linear meter.

Important! In levels with rotary flasks, on which the risks of determining the error are marked, it is proposed to measure angular deviations. All data necessary for calculations is given in the operating instructions for a particular device.

What should you know to conduct a quality level accuracy check?

Basic functions of a household laser level.

If we take into account a laser level that has manual leveling based on a bubble level, then there is a possibility of inaccurate measurements and inspections. To check the horizontal plane, you will need the laser level itself, mounted on a special tripod with a height adjuster lever

To check the accuracy, the device is installed near the walls on which marks need to be applied.

The level works in two planes. One is horizontal and is designated by the letter X, and the second (vertical) is designated by Y. Instrument manufacturers often mark these letters on top of the body of the measuring devices. If there are no markings and you need to check the device for the first time, you should mark the letters on the case yourself.

The horizontal plane must pass at the top of the level; it is designated by the letters X and Y, respectively. These two axes are marked accordingly on the top of the device cover. Each beam must have a verified axis. It is calibrated if necessary using the instructions or contacted by a measuring instrument service center.

Electronic level

The electronic level is an improved version of the bubble level. It has three familiar flasks for checking the horizon vertically, horizontally, and at an angle of 45 degrees. In addition, the device has a digital display on which the rotation angle values are displayed according to the readings of the position sensors.

A rough check when purchasing in a store is done in the same way as in the case of a bubble level. That is, place the device on a flat surface and rotate it 180 degrees. If the readings on the display do not change, then everything is in order. But this rarely happens.

Read also: Pinout of socket for truck trailer

Calibration of the electronic level is mandatory by the manufacturer. According to the recommendations, it is done:

- before starting critical measurements;

- before first use;

- after the device falls onto a hard surface;

- after exposure to shocks or vibrations during transportation;

- after a temperature change, transition from a cold zone to a warm one.

The calibration procedure is described in detail in the instrument's operating instructions. In general, one of the display buttons is called CAL. To calibrate the level, you need:

- place it on a flat surface;

- squeeze for 10 seconds;

- press the calibration button, the display shows 0;

- wait another 10 seconds and press the button again;

- after one appears on the display, rotate the level 180 degrees;

- wait 10 seconds;

- press the calibration button and remove the device from the surface.

Important! For the calibration to be correct, it is necessary to select a guaranteed horizontal plane. In a construction site, this could be a sheet of foam floating in a trough filled with water. Other surfaces may not be horizontal, in which case calibration will cause the electronic level to read incorrectly.

Checking the inclination of the entire plane of the laser level relative to the horizon

For those who have just started using a laser level or are just planning to purchase one, we recommend that you familiarize yourself with the general errors found in laser levels.

We install the laser level exactly in the middle between two walls located approximately 5 meters from each other. Turn on the laser level and mark the point indicated by the laser cross on the wall. We rotate the laser plane builder 180 degrees and mark a point on the opposite wall, placing the point at the intersection of the vertical and horizontal planes.

Next, we move the laser level to one of the walls and install it at a distance of 0.6 - 0.7 meters from the wall, and make the same marks on the walls by analogy as described above.

We measure the distance between points a1 and a2, also between currents b1 and b2. We subtract the resulting distance from the other (a1 and a2) - (b1 and b2), compare the resulting value with the declared accuracy, if the resulting value does not exceed the stated accuracy in the instructions, then your laser level shows the horizontal plane correctly.

Example: When checking the accuracy of a laser plane plotter, the distance between the points was: (a1 and a2) = 4 mm, and (b1 and b2) = 6 mm. Thus, the resulting error of the laser level is: (b1 and b2) – (a1 and a2) = 6 – 4 = 2 mm. We compare the resulting error with the error declared by the manufacturer.

This applies to laser levels that do not have a 360 degree horizon.

To check the horizontal plane of levels with cone prisms, such as Hilda 3D, or levels with cylindrical prisms, but also having a horizon of 360 degrees, such as ADA 6D Servoliner, the easiest way is to pass all sides of the horizontal plane through a point at a distance of 5 - 10 meters. Here you should also remember how the error is calculated correctly.

How to make a columnar foundation with your own hands quickly and easily

Casting concrete columnar structures will require lengthy and rather dirty work with mixing cement mortar, installing and strengthening columnar formwork, leveling and cleaning working surfaces. You can take a simpler route and buy ready-made blocks with a length of 40 cm and a cross-section of 20x20 cm. A foam concrete block of the structural grade D1200 or heavy expanded clay concrete grades are best suited.

For heavier versions of the house, granite blocks can be made. To do this, blocks are cast on a manual machine for pressing cinder blocks filled with heavy rock. Such a block will be able to withstand a load of 300-400 kg, which corresponds to the weight of the walls of a timber house. If you have experience working with your own hands with laying stone on cement mortar, then you can build 6-8 columnar supports in half a work shift.

In addition to standard rectangular blocks, massive hollow blocks in the form of a truncated pyramid with a reinforcing frame are cast on the machine. A pin or threaded rod is placed in the upper base of the pyramidal columnar support, which allows you to tie the installed pillars with a wooden beam or steel profile. It is enough to compact and fill the horizontal platform in order to install a finished foundation field of columnar supports along stretched cords.

Adjustment, configuration, repair of building level. How to adjust it?

There are levels in which adjustment is possible. The sensitive element (flask with liquid) is fixed with a bolt at such levels. If the bolt is loosened, you can rotate the sensitive element, thereby adjusting the level. Setup is usually done in one of two ways. Either we simply move the flask by hand (this adjustment is less precise), or there is an adjusting bolt, by turning which we adjust the position of the flask (more precise adjustment is possible). Not all hydraulic levels are suitable for adjustment. There are those in which the bulb is glued in. If such a tool is faulty, it must be thrown away.

Adjusting the level is not a problem if you have a strictly horizontal surface. But a vicious circle arises. To repair a building level, you need a horizontal surface, and to find a horizontal surface, you need a working level. Let's get a horizontal surface using a broken spirit level.

Cut a stack of small pieces of paper, such as newspaper. Let's find a stable (immobile) approximately horizontal surface. Let's put our faulty level on it. Place several pieces of paper under one end of the level so that it shows horizontality. Let's remember how much paper we put in this (first) time. Let's turn the level horizontally so that its right end is now on the left, and its left end is on the right. If the level is working, then it will continue to show horizontality, since a working level shows the horizon, and there is only one horizon, from right to left, and from left to right. If the level needs to be adjusted, then as a result of turning it over, the air bubble in the flask will shift, the level will show that it is no longer horizontal.

Let's place a few more pieces of paper under one of the ends of the level so that it again begins to show horizontality. You may have to place the paper under the same end as last time, perhaps under a different one. At the same time, we count each piece placed. Now we will remove exactly half of the pieces of paper placed in the second stage. If there were an odd number of them, then we round them up. Congratulations, we got the true horizon.

But the level shows a deviation. Loosen the fixing screw, turn the flask so that it shows horizontal, and tighten the fixing screw. The setup has been completed successfully.

Adjusting the vertical flask is done in exactly the same way. But to perform it you need an assistant, since it is performed on an approximately vertical wall. But on such a wall, pieces of paper and a level will not hold on their own. An assistant will have to hold them.

From a mathematical point of view, the proposed method is not entirely accurate, but for construction purposes the error is acceptable.

(read more...) :: (to the beginning of the article)

| 1 | 2 | 3 |

:: Search

Unfortunately, errors are periodically found in articles; they are corrected, articles are supplemented, developed, and new ones are prepared. Subscribe to the news to stay informed.

If something is unclear, be sure to ask!Ask a question. Discussion of the article.

More articles

DIY built-in closet. Instructions. Scheme. Drawing…. Built-in wardrobe - we design and install. How to do it yourself, with your own hands...

Examples of adhesives. Poxypol, liquid nails, universal superglue. Armir... Typical gluing errors. The right technology. Additional techniques - arm...

LED lighting lamps 220 volts. Features, impact on vision... Use of LED lighting lamps in everyday life. Properties, features. Review….

Knitting. Royal crown. Drawings. Pattern patterns... How to knit the following patterns: Royal crown. Detailed instructions with explanations...

Insulation to keep it warm... Insulation, typical mistakes, how to do it right...

How to install a coal boiler? Choosing a location, location?... Tips for choosing a location, installing a coal boiler, connecting a chimney...

Barrel steel, iron, metal. For sale. We buy, we buy, p... Iron barrel - choice, protection against rust, corrosion. How to buy and extend the term...

Knitting. Air diamonds. Drawings. Pattern patterns... How to knit the following patterns: Air diamonds. Detailed instructions with explanations...

How to setup?

Adjustment of the instrument is possible only with adjusting screws located at the edges of the flask. The readings of a glued bulb cannot be corrected.

For horizontal calibration you will need:

- thin screwdriver;

- wall or any vertical surface;

- pencil.

By placing the device against the wall, changing the position of the body brings the bubble to the central position. Draw a line with a pencil. Then the instrument is turned over and the bubble is again placed in the center between the marks. Draw a second line. The angle between non-coinciding marks is divided in half. This line will be the control line.

Use a thin screwdriver to adjust the position of the flask by turning the screws. The position of the body coincides with the control line, after which the test is repeated. This time both lines should match.

The correct display of the vertical is checked using a plumb line. The bubble of the calibrated instrument will come to the central position when the working side coincides with the suspended cord.